build a homemade diy tft lcd driver breakout board pcb factory

Along 3 years I have been trying several leg mechanism, at first I decided to do a simple desing with tibial motor where placed on femur joint.This design had several problems, like it wasn"t very robust and the most importat is that having the motor (with big mass) that far from the rotating axis, caused that in some movements it generate unwanted dynamics to the robot body, making controlability worse.New version have both motors of femur/tibial limb at coxa frame, this ends with a very simple setup and at the same time, the heaviest masses of the mechanism are centered to the rotating axis of coxa limb, so even though the leg do fast movements, inertias won"t be strong enough to affect the hole robot mass, achieving more agility.Inverse Kinematics of the mechanismAfter building it I notice that this mechanism was very special for another reason, at the domain the leg normally moves, it acts as a diferential mecanism, this means that torque is almost all the time shared between both motor of the longer limbs. That was an improvent since with the old mechanism tibial motor had to hold most of the weight and it was more forced than the one for femur.To visualize this, for the same movement, we can see how tibial motor must travel more arc of angel that the one on the new version.In order to solve this mechanism, just some trigonometry is needed. Combining both cosine and sine laws, we can obtain desired angle (the one between femur and tibia) with respect to the angle the motor must achieve.Observing these equations, with can notice that this angle (the one between femur and tibia) depends on both servos angles, which means both motors are contributing to the movement of the tibia.Calibration of servosAnother useful thing to do if we want to control servo precisely is to print a calibration tool for our set up. As shown in the image below, in order to know where real angles are located, angle protactor is placer just in the origin of the rotating joint, and choosing 2 know angles we can match PWM signal to the real angles we want to manipulate simply doing a lineal relation between angles and PWM pulse length.Then a simple program in the serial console can be wrtten to let the user move the motor to the desired angle. This way the calibration process is only about placing motor at certain position and everything is done and we won"t need to manually introduce random values that can be a very tedious task.With this I have achieved very good calibrations on motors, which cause the robot to be very simetrial making the hole system more predictable. Also the calibration procedure now is very easy to do, as all calculations are done automatically. Check Section 1 for the example code for calibration.More about this can be seen in the video below, where all the building process is shown as well as the new leg in action.SECTION 1:In the example code below, you can see how calibration protocol works, it is just a function called calibrationSecuence() which do all the work until calibration is finished. So you only need to call it one time to enter calibration loop, for example by sending a "c" character thought the serial console.Also some useful function are used, like moving motor directly with analogWrite functions which all the calculations involved, this is a good point since no interrupts are used.This code also have the feature to calibrate the potentiometer coming from each motor.#define MAX_PULSE 2500 #define MIN_PULSE 560 /*---------------SERVO PIN DEFINITION------------------------*/ int m1 = 6;//FR int m2 = 5; int m3 = 4; int m4 = 28;//FL int m5 = 29; int m6 = 36; int m7 = 3;//BR int m8 = 2; int m9 = 1; int m10 = 7;//BL int m11 = 24; int m12 = 25; int m13 = 0;//BODY /*----------------- CALIBRATION PARAMETERS OF EACH SERVO -----------------*/ double lowLim[13] = {50, 30, 30, 50, 30, 30, 50, 30, 30, 50, 30, 30, 70}; double highLim[13] = {130, 150, 150, 130, 150, 150, 130, 150, 150, 130, 150, 150, 110}; double a[13] = { -1.08333, -1.06667, -1.07778, //FR -1.03333, 0.97778, 1.01111, //FL 1.03333, 1.05556, 1.07778, //BR 1.07500, -1.07778, -1.00000, //BL 1.06250 }; double b[13] = {179.0, 192.0, 194.5, //FR 193.0, 5.5, -7.5, //FL 7.0, -17.0, -16.0, //BR -13.5, 191.5, 157.0, //BL -0.875 }; double ae[13] = {0.20292, 0.20317, 0.19904 , 0.21256, -0.22492, -0.21321, -0.21047, -0.20355, -0.20095, -0.20265, 0.19904, 0.20337, -0.20226 }; double be[13] = { -18.59717, -5.70512, -2.51697, -5.75856, 197.29411, 202.72169, 185.96931, 204.11902, 199.38663, 197.89534, -5.33768, -32.23424, 187.48058 }; /*--------Corresponding angles you want to meassure at in your system-----------*/ double x1[13] = {120, 135, 90, 60, 135 , 90, 120, 135, 90, 60, 135, 90, 110}; //this will be the first angle you will meassure double x2[13] = {60, 90, 135, 120, 90, 135, 60, 90, 135, 120, 90, 135, 70};//this will be the second angle you will meassure for calibration /*--------You can define a motor tag for each servo--------*/ String motorTag[13] = {"FR coxa", "FR femur", "FR tibia", "FL coxa", "FL femur", "FL tibia", "BR coxa", "BR femur", "BR tibia", "BL coxa", "BL femur", "BL tibia", "Body angle" }; double ang1[13] = {0, 0, 0, 0, 0, 0, 0, 0, 0, 0, 0, 0, 0}; double ang2[13] = {0, 0, 0, 0, 0, 0, 0, 0, 0, 0, 0, 0, 0}; float xi[500]; float yi[500]; float fineAngle; float fineL; float fineH; int motorPin; int motor = 0; float calibrationAngle; float res = 1.0; float ares = 0.5; float bres = 1.0; float cres = 4.0; float rawAngle; float orawAngle; char cm; char answer; bool interp = false; bool question = true; bool swing = false; int i; double eang; int freq = 100; // PWM frecuency can be choosen here. void connectServos() { analogWriteFrequency(m1, freq); //FR coxa digitalWrite(m1, LOW); pinMode(m1, OUTPUT); analogWriteFrequency(m2, freq); //femur digitalWrite(m2, LOW); pinMode(m2, OUTPUT); analogWriteFrequency(m3, freq); //tibia digitalWrite(m3, LOW); pinMode(m3, OUTPUT); analogWriteFrequency(m4, freq); //FL coxa digitalWrite(m4, LOW); pinMode(m4, OUTPUT); analogWriteFrequency(m5, freq); //femur digitalWrite(m5, LOW); pinMode(m5, OUTPUT); analogWriteFrequency(m6, freq); //tibia digitalWrite(m6, LOW); pinMode(m6, OUTPUT); analogWriteFrequency(m7, freq); //FR coxa digitalWrite(m7, LOW); pinMode(m7, OUTPUT); analogWriteFrequency(m8, freq); //femur digitalWrite(m8, LOW); pinMode(m8, OUTPUT); analogWriteFrequency(m9, freq); //tibia digitalWrite(m9, LOW); pinMode(m9, OUTPUT); analogWriteFrequency(m10, freq); //FR coxa digitalWrite(m10, LOW); pinMode(m10, OUTPUT); analogWriteFrequency(m11, freq); //femur digitalWrite(m11, LOW); pinMode(m11, OUTPUT); analogWriteFrequency(m12, freq); //tibia digitalWrite(m12, LOW); pinMode(m12, OUTPUT); analogWriteFrequency(m13, freq); //body digitalWrite(m13, LOW); pinMode(m13, OUTPUT); } void servoWrite(int pin , double angle) { float T = 1000000.0f / freq; float usec = float(MAX_PULSE - MIN_PULSE) * (angle / 180.0) + (float)MIN_PULSE; uint32_t duty = int(usec / T * 4096.0f); analogWrite(pin , duty); } double checkLimits(double angle , double lowLim , double highLim) { if ( angle >= highLim ) { angle = highLim; } if ( angle <= lowLim ) { angle = lowLim; } return angle; } int motorInfo(int i) { enc1 , enc2 , enc3 , enc4 , enc5 , enc6 , enc7 , enc8 , enc9 , enc10 , enc11 , enc12 , enc13 = readEncoders(); if (i == 0) { rawAngle = enc1; motorPin = m1; } else if (i == 1) { rawAngle = enc2; motorPin = m2; } else if (i == 2) { rawAngle = enc3; motorPin = m3; } else if (i == 3) { rawAngle = enc4; motorPin = m4; } else if (i == 4) { rawAngle = enc5; motorPin = m5; } else if (i == 5) { rawAngle = enc6; motorPin = m6; } else if (i == 6) { rawAngle = enc7; motorPin = m7; } else if (i == 7) { rawAngle = enc8; motorPin = m8; } else if (i == 8) { rawAngle = enc9; motorPin = m9; } else if (i == 9) { rawAngle = enc10; motorPin = m10; } else if (i == 10) { rawAngle = enc11; motorPin = m11; } else if (i == 11) { rawAngle = enc12; motorPin = m12; } else if (i == 12) { rawAngle = enc13; motorPin = m13; } return rawAngle , motorPin; } void moveServos(double angleBody , struct vector anglesServoFR , struct vector anglesServoFL , struct vector anglesServoBR , struct vector anglesServoBL) { //FR anglesServoFR.tetta = checkLimits(anglesServoFR.tetta , lowLim[0] , highLim[0]); fineAngle = a[0] * anglesServoFR.tetta + b[0]; servoWrite(m1 , fineAngle); anglesServoFR.alpha = checkLimits(anglesServoFR.alpha , lowLim[1] , highLim[1]); fineAngle = a[1] * anglesServoFR.alpha + b[1]; servoWrite(m2 , fineAngle); anglesServoFR.gamma = checkLimits(anglesServoFR.gamma , lowLim[2] , highLim[2]); fineAngle = a[2] * anglesServoFR.gamma + b[2]; servoWrite(m3 , fineAngle); //FL anglesServoFL.tetta = checkLimits(anglesServoFL.tetta , lowLim[3] , highLim[3]); fineAngle = a[3] * anglesServoFL.tetta + b[3]; servoWrite(m4 , fineAngle); anglesServoFL.alpha = checkLimits(anglesServoFL.alpha , lowLim[4] , highLim[4]); fineAngle = a[4] * anglesServoFL.alpha + b[4]; servoWrite(m5 , fineAngle); anglesServoFL.gamma = checkLimits(anglesServoFL.gamma , lowLim[5] , highLim[5]); fineAngle = a[5] * anglesServoFL.gamma + b[5]; servoWrite(m6 , fineAngle); //BR anglesServoBR.tetta = checkLimits(anglesServoBR.tetta , lowLim[6] , highLim[6]); fineAngle = a[6] * anglesServoBR.tetta + b[6]; servoWrite(m7 , fineAngle); anglesServoBR.alpha = checkLimits(anglesServoBR.alpha , lowLim[7] , highLim[7]); fineAngle = a[7] * anglesServoBR.alpha + b[7]; servoWrite(m8 , fineAngle); anglesServoBR.gamma = checkLimits(anglesServoBR.gamma , lowLim[8] , highLim[8]); fineAngle = a[8] * anglesServoBR.gamma + b[8]; servoWrite(m9 , fineAngle); //BL anglesServoBL.tetta = checkLimits(anglesServoBL.tetta , lowLim[9] , highLim[9]); fineAngle = a[9] * anglesServoBL.tetta + b[9]; servoWrite(m10 , fineAngle); anglesServoBL.alpha = checkLimits(anglesServoBL.alpha , lowLim[10] , highLim[10]); fineAngle = a[10] * anglesServoBL.alpha + b[10]; servoWrite(m11 , fineAngle); anglesServoBL.gamma = checkLimits(anglesServoBL.gamma , lowLim[11] , highLim[11]); fineAngle = a[11] * anglesServoBL.gamma + b[11]; servoWrite(m12 , fineAngle); //BODY angleBody = checkLimits(angleBody , lowLim[12] , highLim[12]); fineAngle = a[12] * angleBody + b[12]; servoWrite(m13 , fineAngle); } double readEncoderAngles() { enc1 , enc2 , enc3 , enc4 , enc5 , enc6 , enc7 , enc8 , enc9 , enc10 , enc11 , enc12 , enc13 = readEncoders(); eang1 = ae[0] * enc1 + be[0]; eang2 = ae[1] * enc2 + be[1]; eang3 = ae[2] * enc3 + be[2]; eang4 = ae[3] * enc4 + be[3]; eang5 = ae[4] * enc5 + be[4]; eang6 = ae[5] * enc6 + be[5]; eang7 = ae[6] * enc7 + be[6]; eang8 = ae[7] * enc8 + be[7]; eang9 = ae[8] * enc9 + be[8]; eang10 = ae[9] * enc10 + be[9]; eang11 = ae[10] * enc11 + be[10]; eang12 = ae[11] * enc12 + be[11]; eang13 = ae[12] * enc13 + be[12]; return eang1 , eang2 , eang3 , eang4 , eang5 , eang6 , eang7 , eang8 , eang9 , eang10 , eang11 , eang12 , eang13; } void calibrationSecuence( ) { //set servos at their middle position at firstt for (int i = 0; i <= 12; i++) { rawAngle , motorPin = motorInfo(i); servoWrite(motorPin , 90); } // sensorOffset0 = calibrateContacts(); Serial.println(" "); Serial.println("_________________________________SERVO CALIBRATION ROUTINE_________________________________"); Serial.println("___________________________________________________________________________________________"); Serial.println("(*) Don"t send several caracter at the same time."); delay(500); Serial.println(" "); Serial.println("Keyboard: "x"-> EXIT CALIBRATION. "c"-> ENTER CALIBRATION."); Serial.println(" "i"-> PRINT INFORMATION. "); Serial.println(" "); Serial.println(" "n"-> CHANGE MOTOR (+). "b" -> CHANGE MOTOR (-)."); Serial.println(" "m"-> START CALIBRATION."); Serial.println(" "q"-> STOP CALIBRATION."); Serial.println(" "); Serial.println(" "r"-> CHANGE RESOLUTION."); Serial.println(" "p"-> ADD ANGLE. "o"-> SUBTRACT ANGLE. "); Serial.println(" "s"-> SAVE ANGLE."); delay(500); Serial.println(" "); Serial.println("---------------------------------------------------------------------------------------------------"); Serial.print("SELECTED MOTOR: "); Serial.print(motorTag[motor]); Serial.print(". SELECTED RESOLUTION: "); Serial.println(res); while (CAL == true) { if (Serial.available() > 0) { cm = Serial.read(); if (cm == "x") { Serial.println("Closing CALIBRATION program..."); CAL = false; secuence = false; startDisplay(PAGE); angleBody = 90; anglesIKFR.tetta = 0.0; anglesIKFR.alpha = -45.0; anglesIKFR.gamma = 90.0; anglesIKFL.tetta = 0.0; anglesIKFL.alpha = -45.0; anglesIKFL.gamma = 90.0; anglesIKBR.tetta = 0.0; anglesIKBR.alpha = 45.0; anglesIKBR.gamma = -90.0; anglesIKBL.tetta = 0.0; anglesIKBL.alpha = 45.0; anglesIKBL.gamma = -90.0; } else if (cm == "i") { // + Serial.println(" "); Serial.println("---------------------------------------------------------------------------------------------------"); Serial.println("---------------------------------------------------------------------------------------------------"); Serial.println("(*) Don"t send several caracter at the same time."); delay(500); Serial.println(" "); Serial.println("Keyboard: "x"-> EXIT CALIBRATION. "c"-> ENTER CALIBRATION."); Serial.println(" "i"-> PRINT INFORMATION. "); Serial.println(" "); Serial.println(" "n"-> CHANGE MOTOR (+). "b" -> CHANGE MOTOR (-)."); Serial.println(" "m"-> START CALIBRATION."); Serial.println(" "q"-> STOP CALIBRATION."); Serial.println(" "); Serial.println(" "r"-> CHANGE RESOLUTION."); Serial.println(" "p"-> ADD ANGLE. "o"-> SUBTRACT ANGLE. "s"-> SAVE ANGLE."); Serial.println(" "); delay(500); Serial.println(" "); Serial.println("---------------------------------------------------------------------------------------------------"); Serial.println(" "); Serial.print("SELECTED MOTOR: "); Serial.print(motorTag[motor]); Serial.print(". SELECTED RESOLUTION: "); Serial.println(res); Serial.println("Actual parameters of the motor: "); Serial.print("High limit: "); Serial.print(highLim[motor]); Serial.print(" Low limit: "); Serial.print(lowLim[motor]); Serial.print(" Angle 1: "); Serial.print(ang1[motor]); Serial.print(" Angle 2: "); Serial.println(ang2[motor]); Serial.println("---------------------------------------------------------------------------------------------------"); } else if (cm == "m") { // + secuence = true; } else if (cm == "s") { // + } else if (cm == "n") { // + motor++; if (motor >= 13) { motor = 0; } Serial.print("SELECTED MOTOR: "); Serial.println(motorTag[motor]); } else if (cm == "b") { // + motor--; if (motor < 0) { motor = 13 - 1; } Serial.print("SELECTED MOTOR: "); Serial.println(motorTag[motor]); } else if (cm == "r") { // + if (res == ares) { res = bres; } else if (res == bres) { res = cres; } else if (res == cres) { res = ares; } Serial.print("SELECTED RESOLUTION: "); Serial.println(res); } } if (secuence == true) { Serial.print("Starting secuence for motor: "); Serial.println(motorTag[motor]); for (int i = 0; i <= 30; i++) { delay(20); Serial.print("."); } Serial.println("."); while (question == true) { unsigned long currentMicros = micros(); if (currentMicros - previousMicros >= 100000) { previousMicros = currentMicros; if (Serial.available() > 0) { answer = Serial.read(); if (answer == "y") { question = false; interp = true; secuence = true; } else if (answer == "n") { question = false; interp = false; secuence = true; } else { Serial.println("Please, select Yes(y) or No(n)."); } } } } answer = "t"; question = true; if (interp == false) { Serial.println("___"); Serial.println(" | Place motor at 1ts position and save angle"); Serial.println(" | This position can be the higher one"); rawAngle , motorPin = motorInfo(motor); calibrationAngle = 90; //start calibration at aproximate middle position of the servo. while (secuence == true) { /* find first calibration angle */ if (Serial.available() > 0) { cm = Serial.read(); if (cm == "p") { // + Serial.print(" | +"); Serial.print(res); Serial.print(" : "); calibrationAngle = calibrationAngle + res; servoWrite(motorPin , calibrationAngle); Serial.println(calibrationAngle); } else if (cm == "o") { // - Serial.print(" | -"); Serial.print(res); Serial.print(" : "); calibrationAngle = calibrationAngle - res; servoWrite(motorPin , calibrationAngle); Serial.println(calibrationAngle); } else if (cm == "r") { // + if (res == ares) { res = bres; } else if (res == bres) { res = cres; } else if (res == cres) { res = ares; } Serial.print("SELECTED RESOLUTION: "); Serial.println(res); } else if (cm == "q") { // quit secuence secuence = false; Serial.println(" | Calibration interrupted!!"); } else if (cm == "s") { // save angle ang1[motor] = calibrationAngle; secuence = false; Serial.print(" | Angle saved at "); Serial.println(calibrationAngle); } } } if (cm == "q") { Serial.println(" |"); } else { secuence = true; Serial.println("___"); Serial.println(" | Place motor at 2nd position and save angle"); Serial.println(" | This position can be the lower one"); } while (secuence == true) { /* find second calibration angle */ if (Serial.available() > 0) { cm = Serial.read(); if (cm == "p") { // + Serial.print(" | +"); Serial.print(res); Serial.print(" : "); calibrationAngle = calibrationAngle + res; servoWrite(motorPin , calibrationAngle); Serial.println(calibrationAngle); } else if (cm == "o") { // - Serial.print(" | -"); Serial.print(res); Serial.print(" : "); calibrationAngle = calibrationAngle - res; servoWrite(motorPin , calibrationAngle); Serial.println(calibrationAngle); } else if (cm == "r") { // + if (res == ares) { res = bres; } else if (res == bres) { res = cres; } else if (res == cres) { res = ares; } Serial.print("SELECTED RESOLUTION: "); Serial.println(res); } else if (cm == "q") { // quit secuence secuence = false; Serial.println(" | Calibration interrupted!!"); } else if (cm == "s") { // save angle ang2[motor] = calibrationAngle; secuence = false; Serial.print(" | Angle saved at "); Serial.println(calibrationAngle); } } } /*--------------------start calibration calculations------------------*/ if (cm == "q") { Serial.println("___|"); Serial.println("Calibration finished unespected."); Serial.println(" Select another motor."); Serial.print("SELECTED MOTOR: "); Serial.print(motorTag[motor]); Serial.print(". SELECTED RESOLUTION: "); Serial.println(res); } else { Serial.println("___"); Serial.println(" |___"); Serial.print( " | | Interpolating for motor: "); Serial.println(motorTag[motor]); secuence = true; //real angle is calculated interpolating both angles to a linear relation. a[motor] = (ang2[motor] - ang1[motor]) / (x2[motor] - x1[motor]); b[motor] = ang1[motor] - x1[motor] * (ang2[motor] - ang1[motor]) / (x2[motor] - x1[motor]); Serial.println(" | |"); } interp = true; } /*---------------------------make swing movement to interpolate motor encoder-----*/ if (interp == true and secuence == true) { delay(200); double x; int k = 0; int stp = 180; swing = true; i = 0; orawAngle , motorPin = motorInfo(motor); previousMicros = 0; while (swing == true) { // FIRST unsigned long currentMicros = micros(); if (currentMicros - previousMicros >= 10000) { // save the last time you blinked the LED previousMicros = currentMicros; x = x2[motor]; calibrationAngle = a[motor] * x + b[motor]; servoWrite(motorPin , calibrationAngle); rawAngle , motorPin = motorInfo(motor); if ((i % 3) == 0) { yi[k+1] = x; xi[k] = rawAngle; Serial.print(" | | Real ang: "); Serial.print(x); Serial.print(" -> Servo ang: "); Serial.print(calibrationAngle); Serial.print(" Enc: "); Serial.println(rawAngle); k++; } if (i >= stp) { swing = false; } i++; } } swing = true; i = 0; while (swing == true) { // moving unsigned long currentMicros = micros(); if (currentMicros - previousMicros >= 10000) { // save the last time you blinked the LED previousMicros = currentMicros; x = x2[motor] + float(i) * (x1[motor] - x2[motor]) / stp; calibrationAngle = a[motor] * x + b[motor]; servoWrite(motorPin , calibrationAngle); rawAngle , motorPin = motorInfo(motor); if ((i % 6) == 0) { yi[k+1] = x; xi[k] = rawAngle; Serial.print(" | | Real ang: "); Serial.print(x); Serial.print(" -> Servo ang: "); Serial.print(calibrationAngle); Serial.print(" Enc: "); Serial.println(rawAngle); k++; } if (i >= stp) { swing = false; } i++; } } swing = true; i = 0; while (swing == true) { // SECOND unsigned long currentMicros = micros(); if (currentMicros - previousMicros >= 10000) { // save the last time you blinked the LED previousMicros = currentMicros; x = x1[motor]; calibrationAngle = a[motor] * x + b[motor]; servoWrite(motorPin , calibrationAngle); rawAngle , motorPin = motorInfo(motor); if ((i % 3) == 0) { yi[k+1] = x; xi[k] = rawAngle; Serial.print(" | | Real ang: "); Serial.print(x); Serial.print(" -> Servo ang: "); Serial.print(calibrationAngle); Serial.print(" Enc: "); Serial.println(rawAngle); k++; } if (i >= stp) { swing = false; } i++; } } swing = true; i = 0; while (swing == true) { // moving unsigned long currentMicros = micros(); if (currentMicros - previousMicros >= 10000) { // save the last time you blinked the LED previousMicros = currentMicros; x = x1[motor] + float(i) * (x2[motor] - x1[motor]) / stp; calibrationAngle = a[motor] * x + b[motor]; servoWrite(motorPin , calibrationAngle); rawAngle , motorPin = motorInfo(motor); if ((i % 6) == 0) { yi[k+1] = x; xi[k] = rawAngle; Serial.print(" | | Real ang: "); Serial.print(x); Serial.print(" -> Servo ang: "); Serial.print(calibrationAngle); Serial.print(" Enc: "); Serial.println(rawAngle); k++; } if (i >= stp) { swing = false; } i++; } } swing = true; i = 0; while (swing == true) { // FIRST unsigned long currentMicros = micros(); if (currentMicros - previousMicros >= 10000) { // save the last time you blinked the LED previousMicros = currentMicros; x = x2[motor]; calibrationAngle = a[motor] * x + b[motor]; servoWrite(motorPin , calibrationAngle); rawAngle , motorPin = motorInfo(motor); if ((i % 3) == 0) { yi[k+1] = x; xi[k] = rawAngle; Serial.print(" | | Real ang: "); Serial.print(x); Serial.print(" -> Servo ang: "); Serial.print(calibrationAngle); Serial.print(" Enc: "); Serial.println(rawAngle); k++; } if (i >= stp) { swing = false; } i++; } } swing = true; i = 0; while (swing == true) { // moving unsigned long currentMicros = micros(); if (currentMicros - previousMicros >= 10000) { // save the last time you blinked the LED previousMicros = currentMicros; x = x2[motor] + float(i) * (x1[motor] - x2[motor]) / stp; calibrationAngle = a[motor] * x + b[motor]; servoWrite(motorPin , calibrationAngle); rawAngle , motorPin = motorInfo(motor); if ((i % 6) == 0) { yi[k+1] = x; xi[k] = rawAngle; Serial.print(" | | Real ang: "); Serial.print(x); Serial.print(" -> Servo ang: "); Serial.print(calibrationAngle); Serial.print(" Enc: "); Serial.println(rawAngle); k++; } if (i >= stp) { swing = false; } i++; } } swing = true; i = 0; while (swing == true) { // SECOND unsigned long currentMicros = micros(); if (currentMicros - previousMicros >= 10000) { // save the last time you blinked the LED previousMicros = currentMicros; x = x1[motor]; calibrationAngle = a[motor] * x + b[motor]; servoWrite(motorPin , calibrationAngle); rawAngle , motorPin = motorInfo(motor); if ((i % 3) == 0) { yi[k+1] = x; xi[k] = rawAngle; Serial.print(" | | Real ang: "); Serial.print(x); Serial.print(" -> Servo ang: "); Serial.print(calibrationAngle); Serial.print(" Enc: "); Serial.println(rawAngle); k++; } if (i >= stp) { swing = false; } i++; } } Serial.println(" | | Interpolation finished!"); /*-------Calculate linear interpolation of the encoder from 60 meassures done in swing------*/ double sx = 0; double sy = 0; double sx2 = 0; double sy2 = 0; double sxy = 0; double xmean = 0; double ymean = 0; int n = 300; for (int i = 0 ; i < n ; i++) { sx += xi[i+10]; sy += yi[i+10]; sx2 += xi[i+10] * xi[i+10]; sy2 += yi[i+10] * yi[i+10]; sxy += xi[i+10] * yi[i+10]; } ae[motor] = (n * sxy - sx * sy) / (n * sx2 - sx * sx); //sxy / sx2; // be[motor] = (sy - ae[motor] * sx) / n; //ymean - ae[motor] * xmean; Serial.println(" | | Moving back to ZERO position."); // turn the motor back to middle position swing = true; i = 0; while (swing == true) { unsigned long currentMicros = micros(); if (currentMicros - previousMicros >= 10000) { // save the last time you blinked the LED previousMicros = currentMicros; x = x1[motor] + float(i) * (90 - x1[motor]) / 60; calibrationAngle = a[motor] * x + b[motor]; servoWrite(motorPin , calibrationAngle); rawAngle , motorPin = motorInfo(motor); eang = ae[motor] * rawAngle + be[motor]; if ((i % 4) == 0) { Serial.print(" | | Servo ang: "); Serial.print(calibrationAngle); Serial.print(" -> Real ang: "); Serial.print(x); Serial.print(" -> Encoder ang: "); Serial.println(eang); } if (i >= 60) { swing = false; } i++; } } Serial.println("___|___|"); Serial.println(" | "); Serial.println("___"); Serial.println(" | Calibration finished satisfactory. Results data:"); Serial.print(" | HIGH lim: "); Serial.print(highLim[motor]); Serial.print(" LOW lim: "); Serial.println(lowLim[motor]); Serial.print(" | angle 1: "); Serial.print(ang1[motor]); Serial.print(" angle 2 "); Serial.println(ang2[motor]); Serial.print(" | Regression Motor a: "); Serial.print(a[motor], 5); Serial.print(" b: "); Serial.println(b[motor], 5); Serial.print(" | Regression Encoder a: "); Serial.print(ae[motor], 5); Serial.print(" b: "); Serial.println(be[motor], 5); Serial.println(" |"); Serial.println(" | ______________________________________________________________"); Serial.println(" | | |"); Serial.println(" | | This code won"t be able to save the updated parameters |"); Serial.println(" | | once the robot is shutted down. |"); Serial.println(" | | |"); Serial.println(" | | Please, write down the results |"); Serial.println(" | | and save them in the definition of each variable. |"); Serial.println(" | |_____________________________________________________________|"); Serial.println(" |"); Serial.println("___|"); Serial.println(" Select another motor."); Serial.print("SELECTED MOTOR: "); Serial.print(motorTag[motor]); Serial.print(". SELECTED RESOLUTION: "); Serial.println(res); } interp = false; secuence = false; } } SAFE = false; Serial.println("Calibration killed"); } // END OF CALIBRATION

I found the TFT screen and Uno on Banggood.com about a month ago and over the weekend I was messing with the pair and found the tftbmp draw code in the demo.. I extended it with the ability to read any bmp file on the SD card.. so all you do is put your bitmaps on the SD and plug it in.. Having to add/edit/recompile/reload the Uno everytime is BS... Here is my code:

If you’ve been hanging around microcontrollers and electronics for a while, you’re surely familiar with the concept of the breakout board. Instead of straining to connect wires and components to ever-shrinking ICs and MCUs, a breakout board makes it easier to interface with the device by essentially making it bigger. The Arduino itself, arguably, is a breakout board of sorts. It takes the ATmega chip, adds the hardware necessary to get it talking to a computer over USB, and brings all the GPIO pins out with easy to manage header pins.

But what if you wanted an even bigger breakout board for the ATmega? Something that really had some leg room. Well, say no more, as [Nick Poole] has you covered with his insane RedBoard Pro Micro-ATX. Combining an ATmega32u4 microcontroller with standard desktop PC hardware is just as ridiculous as you’d hope, but surprisingly does offer a couple tangible benefits.

The RedBoard is a fully compliant micro-ATX board, and will fit in pretty much any PC case you may have laying around in the junk pile. Everything from the stand-off placement to the alignment of the expansion card slots have been designed so it can drop right into the case of your choice.

That’s right, expansion slots. It’s not using PCI, but it does have a variation of the standard Arduino “shield” concept using 28 pin edge connectors. There’s a rear I/O panel with a USB port and ISP header, and you can even add water cooling if you really want (the board supports standard LGA 1151 socket cooling accessories).

While blowing an Arduino up to ATX size isn’t exactly practical, the RedBoard is not without legitimate advantages. Specifically, the vast amount of free space on the PCB allowed [Nick] to add 2Mbits of storage. There was even some consideration to making removable banks of “RAM” with EEPROM chips, but you’ve got to draw the line somewhere. The RedBoard also supports standard ATX power supplies, which will give you plenty of juice for add-on hardware that may be populating the expansion slots.

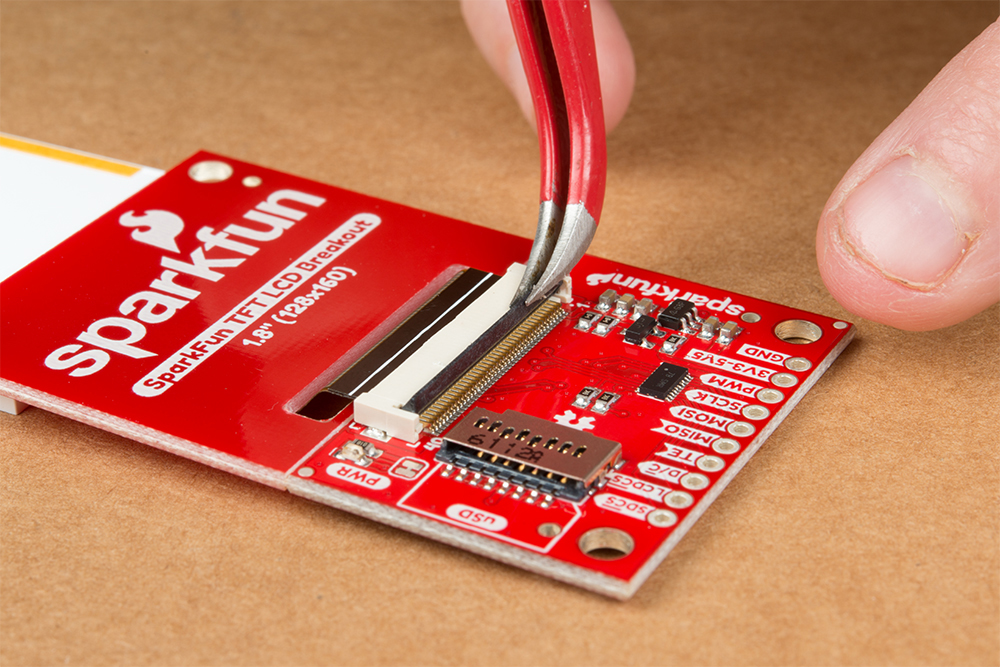

This breakout board is designed to work in conjunction with our TFT displays to give you a faster, more flexible development process. This development tool will jumpstart your workflow by providing an all-in-one solution to run your hardware application and act as an intermediate PCB. With a compact design that allows for easy placement in your application, breakout boards make it easier than ever to connect with any MCU and see your design in action. This particular breakout board has a 40-pin FFC connector, 2.54mm pitch, and is breadboard friendly. It has a configurable LED driver with PWM, a power LED indicator, and open-source hardware.

Adjust the length, position, and pinout of your cables or add additional connectors. Get a cable solution that’s precisely designed to make your connections streamlined and secure.

Choose from a wide selection of interface options or talk to our experts to select the best one for your project. We can incorporate HDMI, USB, SPI, VGA and more into your display to achieve your design goals.

The 1.8″ display has 128×160 color pixels. Unlike the low cost “Nokia 6110″ and similar LCD displays, which are CSTN type and thus have poor color and slow refresh, this display is a true TFT! The TFT driver (ST7735R) can display full 18-bit color (262,144 shades!). And the LCD will always come with the same driver chip so there’s no worries that your code will not work from one to the other.

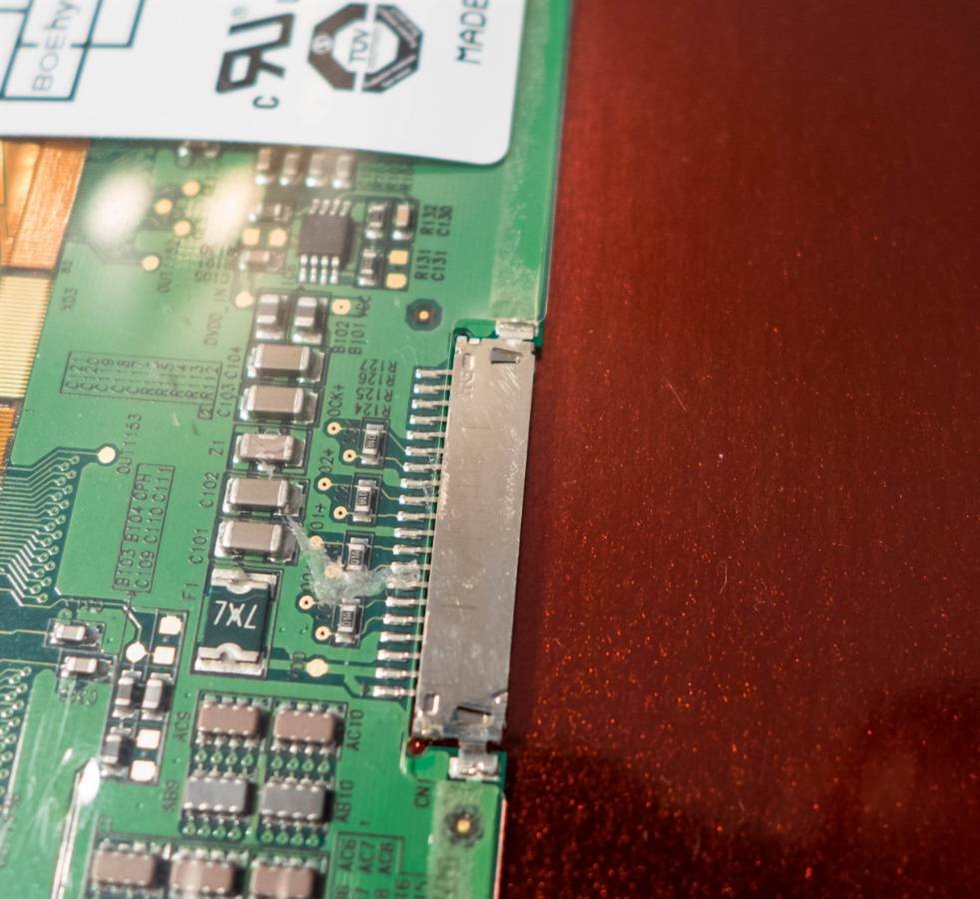

The breakout has the TFT display soldered on (it uses a delicate flex-circuit connector) as well as a ultra-low-dropout 3.3V regulator and a 3/5V level shifter so you can use it with 3.3V or 5V power and logic. There is a microSD card holder on the back so you can easily load full color bitmaps from a FAT16/FAT32 formatted microSD card.

The Adafruit 1.8” TFT LCD Breakout Board also features an EYESPI connector for a simpler connection to the LCD. EYESPI is a single 18-pin FPC used as a quick way to connect displays.

This website is using a security service to protect itself from online attacks. The action you just performed triggered the security solution. There are several actions that could trigger this block including submitting a certain word or phrase, a SQL command or malformed data.

This website is using a security service to protect itself from online attacks. The action you just performed triggered the security solution. There are several actions that could trigger this block including submitting a certain word or phrase, a SQL command or malformed data.

This website is using a security service to protect itself from online attacks. The action you just performed triggered the security solution. There are several actions that could trigger this block including submitting a certain word or phrase, a SQL command or malformed data.

This website is using a security service to protect itself from online attacks. The action you just performed triggered the security solution. There are several actions that could trigger this block including submitting a certain word or phrase, a SQL command or malformed data.

I"d been thinking about designing a project based on the Raspberry Pi RP2040, and to get more familiar with it I decided to try building a minimal RP2040-based computer on a prototyping board.

The RP2040 is a dual-core Arm Cortex-M0+ running at up to 133MHz, with 264 Kbytes of on-chip RAM, and support for up to 16 Mbytes of off-chip flash memory via a QSPI bus. It was designed in Cambridge, UK, by the team behind the Raspberry Pi boards, and is fabricated by TSMC using their 40nm process

My initial idea was to mount the RP2040 on a breakout board, bringing all the contacts to two rows of 28-way headers, and then mount all the other components on the prototyping board as I did with my earlier projects such as Minimal ATSAMD21 Computer and Minimal ATmega4809 on a Breadboard. However the only QFN56 breakout boards I could find arrange the pins in a square, making them unsuitable for a prototyping board.

I therefore started designing my own breakout board in Eagle. I soon realised that I could reduce the number of header pins by interconnecting the supply lines, and including the decoupling capacitors on the board. The hardware design datasheet

The board grew from a simple breakout board to something similar to the Raspberry Pi Pico, so you might wonder why I bothered to design it rather than just buy a Pico. The answer is that I wanted the experience of building my own board, and I wanted a board on which I could easily try out different components, such as different flash chips.

Unlike many other processors the RP2040 doesn"t include flash on chip, but includes a QSPI flash interface to make it easy to interface an external flash chip. I used the recommended part, the Winbond W25Q128JVS, which provides 16Mbytes, the largest amount of flash that the RP2040 will support. You can use any compatible flash chip up to 16Mbytes; see the hardware design datasheet for information about choosing a different flash chip.

Most of the passive components are 0402 size. This is smaller than I usually use so I was a bit apprehensive about working with them, but it wasn"t too difficult. I was also amazed at how cheap these components are; I got a pack of 50 100nF capacitors for 15 pence

For the other components I avoided the smallest package sizes, and chose the versions that are most widely available. The flash memory chip is SOIC, the 3.3V regulator is SOT23-5, and the crystal is 5x3.2mm.

There"s a good discussion in the RP2040 hardware design datasheet of how to calculate the crystal capacitors from the crystal"s load capacitance. The crystal I chose specifies a load capacitance of 12pF, and using their calculation the crystal capacitors should be 14pF; the values I used, 12pF, are close enough to this (it"s a coincidence that this is the same as the load capacitance).

None of the component values are particularly critical, and most of them could be ±10%, apart from the crystal capacitors which should probably be ±5%. The parts in the following parts list are just suggestions.

Unlike on the Raspberry Pi Pico, the pin legends are on the top of the board. The numbers correspond to the pin number in the I/O port, which is the same as the Arduino pin number. They are all in sequence, apart from 28 and 29 which are swapped as that"s the only way I could manage the PCB layout. The USB connections are in the same order as on a USB breakout board, so you can plug one onto a prototyping board alongside the appropriate pins.

All the main components are on the top of the board, apart from the decoupling components which are on the bottom of the board to make the PCB layout simpler. The tracks and spacings are 7mil, so you should be able to get it fabricated with the cheapest PCB option.

The RP2040 is only available in one package size, QFN56, and I think it"s safe to say that this makes the board impossible to solder with a conventional soldering iron. You"ll either need a hot air gun, or a reflow oven. I used a Youyue 858D+ hot air gun set to 275°C. You"ll also need a magnifying glass for examining the board.

Inevitably there may be some solder bridges between some of the package pins, and I used a conventional soldering iron with a fine tip to remove these. I avoid using solder braid as I find that this scratches the PCB; instead I stripped a short section of insulation from a fine stranded cable, dipped it in flux, and then used this to soak up the excess solder on each solder bridge.

As this was the first time I"d worked with 0402 components I found it a bit of a challenge. When picking them up with the tweezers it"s easy to accidentally flick them across the room, and they also tend to blow away if you get the hot air gun too close! I recommend ordering a few spares in case this happens.

With a continuity tester check between adjacent RP2040 pins to ensure that you haven"t missed any solder bridges. I used my Continuity Tester. Most of the pins come to header pins, making this relatively easy.

The next step is to fit headers to the Minimal RP2040 Board, fit it on a prototyping board with a USB connection and an LED, and try running the Blink example program.

I recommend Earle Philhower’s Raspberry PiRP2040 Boards core which supports a wide range of RP2040 boards, supports more Serial, SPI, and I2C ports, and gives significantly better performance than the Arduino RP2040 core. For instructions on how to install it see: https://github.com/earlephilhower/arduino-pico.

Set Flash Size to the appropriate option for the SPI Flash chip you"ve used. If like me you used a 128Mbit chip choose the 16MB option, and choose the one with FS to allocate space for use by LittleFS.

After I published my $1 MCU write-up, several readers suggested I look at application processors — the MMU-endowed chips necessary to run real operating systems like Linux. Massive shifts over the last few years have seen internet-connected devices become more featureful (and hopefully, more secure), and I’m finding myself putting Linux into more and more places.

Among beginner engineers, application processors supplicate reverence: one minor PCB bug and your $10,000 prototype becomes a paperweight. There’s an occult consortium of engineering pros who drop these chips into designs with utter confidence, while the uninitiated cower for their Raspberry Pis and overpriced industrial SOMs.

This article is targeted at embedded engineers who are familiar with microcontrollers but not with microprocessors or Linux, so I wanted to put together something with a quick primer on why you’d want to run embedded Linux, a broad overview of what’s involved in designing around application processors, and then a dive into some specific parts you should check out — and others you should avoid — for entry-level embedded Linux systems.

Just like my microcontroller article, the parts I picked range from the well-worn horses that have pulled along products for the better part of this decade, to fresh-faced ICs with intriguing capabilities that you can keep up your sleeve.

If my mantra for the microcontroller article was that you should pick the right part for the job and not be afraid to learn new software ecosystems, my argument for this post is even simpler: once you’re booted into Linux on basically any of these parts, they become identical development environments.

That makes chips running embedded Linux almost a commodity product: as long as your processor checks off the right boxes, your application code won’t know if it’s running on an ST or a Microchip part — even if one of those is a brand-new dual-core Cortex-A7 and the other is an old ARM9. Your I2C drivers, your GPIO calls — even your V4L-based image processing code — will all work seamlessly.

At least, that’s the sales pitch. Getting a part booted is an entirely different ordeal altogether — that’s what we’ll be focused on. Except for some minor benchmarking at the end, once we get to a shell prompt, we’ll consider the job completed.

As a departure from my microcontroller review, this time I’m focusing heavily on hardware design: unlike the microcontrollers I reviewed, these chips vary considerably in PCB design difficulty — a discussion I would be in error to omit. To this end, I designed a dev board from scratch for each application processor reviewed. Well, actually, many dev boards for each processor: roughly 25 different designs in total. This allowed me to try out different DDR layout and power management strategies — as well as fix some bugs along the way.

I intentionally designed these boards from scratch rather than starting with someone else’s CAD files. This helped me discover little “gotchas” that each CPU has, as well as optimize the design for cost and hand-assembly. Each of these boards was designed across one or two days’ worth of time and used JLC’s low-cost 4-layer PCB manufacturing service.

These boards won’t win any awards for power consumption or EMC: to keep things easy, I often cheated by combining power rails together that would typically be powered (and sequenced!) separately. Also, I limited the on-board peripherals to the bare minimum required to boot, so there are no audio CODECs, little I2C sensors, or Ethernet PHYs on these boards.

As a result, the boards I built for this review are akin to the notes from your high school history class or a recording you made of yourself practicing a piece of music to study later. So while I’ll post pictures of the boards and screenshots of layouts to illustrate specific points, these aren’t intended to serve as reference designs or anything; the whole point of the review is to get you to a spot where you’ll want to go off and design your own little Linux boards. Teach a person to fish, you know?

Coming from microcontrollers, the first thing you’ll notice is that Linux doesn’t usually run on Cortex-M, 8051, AVR, or other popular microcontroller architectures. Instead, we use application processors — popular ones are the Arm Cortex-A, ARM926EJ-S, and several MIPS iterations.

The biggest difference between these application processors and a microcontroller is quite simple: microprocessors have a memory management unit (MMU), and microcontrollers don’t. Yes, you can run Linux without an MMU, but you usually shouldn’t: Cortex-M7 parts that can barely hit 500 MHz routinely go for double or quadruple the price of faster Cortex-A7s. They’re power-hungry: microcontrollers are built on larger processes than application processors to reduce their leakage current. And without an MMU and generally-low clock speeds, they’re downright slow.

Other than the MMU, the lines between MCUs and MPUs are getting blurred. Modern application processors often feature a similar peripheral complement as microcontrollers, and high-end Cortex-M7 microcontrollers often have similar clock speeds as entry-level application processors.

When your microcontroller project outgrows its super loop and the random ISRs you’ve sprinkled throughout your code with care, there are many bare-metal tasking kernels to turn to — FreeRTOS, ThreadX (now Azure RTOS), RT-Thread, μC/OS, etc. By an academic definition, these are operating systems. However, compared to Linux, it’s more useful to think of these as a framework you use to write your bare-metal application inside. They provide the core components of an operating system: threads (and obviously a scheduler), semaphores, message-passing, and events. Some of these also have networking, filesystems, and other libraries.

Comparing bare-metal RTOSs to Linux simply comes down to the fundamental difference betweenthese and Linux: memory management and protection. This one technical difference makes Linux running on an application processor behave quite differently from your microcontroller running an RTOS.((Before the RTOS snobs attack with pitchforks, yes, there are large-scale, well-tested RTOSes that are usually run on application processors with memory management units. Look at RTEMS as an example. They don’t have some of the limitations discussed below, and have many advantages over Linux for safety-critical real-time applications.))

Small microcontroller applications can usually get by with static allocations for everything, but as your application grows, you’ll find yourself calling malloc() more and more, and that’s when weird bugs will start creeping up in your application. With complex, long-running systems, you’ll notice things working 95% of the time — only to crash at random (and usually inopportune) times. These bugs evade the most javertian developers, and in my experience, they almost always stem from memory allocation issues: usually either memory leaks (that can be fixed with appropriate free() calls), or more serious problems like memory fragmentation (when the allocator runs out of appropriately-sized free blocks).

Because Linux-capable application processors have a memory management unit, *alloc() calls execute swiftly and reliably. Physical memory is only reserved (faulted in) when you actually access a memory location. Memory fragmentation is much less an issue since Linux frees and reorganizes pages behind the scenes. Plus, switching to Linux provides easier-to-use diagnostic tools (like valgrind) to catch bugs in your application code in the first place. And finally, because applications run in virtual memory, if your app does have memory bugs in it, Linux will kill it — leaving the rest of your system running. ((As a last-ditch kludge, it’s not uncommon to call your app in a superloop shell script to automatically restart it if it crashes without having to restart the entire system.))

Running something like lwIP under FreeRTOS on a bare-metal microcontroller is acceptable for a lot of simple applications, but application-level network services like HTTP can burden you to implement in a reliable fashion. Stuff that seems simple to a desktop programmer — like a WebSockets server that can accept multiple simultaneous connections — can be tricky to implement in bare-metal network stacks. Because C doesn’t have good programming constructs for asynchronous calls or exceptions, code tends to contain either a lot of weird state machines or tons of nested branches. It’s horrible to debug problems that occur. In Linux, you get a first-class network stack, plus tons of rock-solid userspace libraries that sit on top of that stack and provide application-level network connectivity. Plus, you can use a variety of high-level programming languages that are easier to handle the asynchronous nature of networking.

Somewhat related is the rest of the standards-based communication / interface frameworks built into the kernel. I2S, parallel camera interfaces, RGB LCDs, SDIO, and basically all those other scary high-bandwidth interfaces seem to come together much faster when you’re in Linux. But the big one is USB host capabilities. On Linux, USB devices just work. If your touchscreen drivers are glitching out and you have a client demo to show off in a half-hour, just plug in a USB mouse until you can fix it (I’ve been there before). Product requirements change and now you need audio? Grab a $20 USB dongle until you can respin the board with a proper audio codec. On many boards without Ethernet, I just use a USB-to-Ethernet adapter to allow remote file transfer and GDB debugging. Don’t forget that, at the end of the day, an embedded Linux system is shockingly similar to your computer.

When thinking about embedded device security, there are usually two things we’re talking about: device security (making sure the device can only boot from verified firmware), and network security (authentication, intrusion prevention, data integrity checks, etc).

Device security is all about chain of trust: we need a bootloader to read in an encrypted image, decrypt and verify it, before finally executing it. The bootloader and keys need to be in ROM so that they cannot be modified. Because the image is encrypted, nefarious third-parties won’t be able to install the firmware on cloned hardware. And since the ROM authenticates the image before executing, people won’t be able to run custom firmware on the hardware.

Network security is about limiting software vulnerabilities and creating a trusted execution environment (TEE) where cryptographic operations can safely take place. The classic example is using client certificates to authenticate our client device to a server. If we perform the cryptographic hashing operation in a secure environment, even an attacker who has gained total control over our normal execution environment would be unable to read our private key.

In the world of microcontrollers, unless you’re using one of the newer Cortex-M23/M33 cores, your chip probably has a mishmash of security features that include hardware cryptographic support, (notoriously insecure) flash read-out protection, execute-only memory, write protection, TRNG, and maybe a memory protection unit. While vendors might have an app note or simple example, it’s usually up to you to get all of these features enabled and working properly, and it’s challenging to establish a good chain of trust, and nearly impossible to perform cryptographic operations in a context that’s not accessible by the rest of the system.

Secure boot isn’t available on every application processor reviewed here, it’s much more common. While there are still vulnerabilities that get disclosed from time to time, my non-expert opinion is that the implementations seem much more robust than on Cortex-M parts: boot configuration data and keys are stored in one-time-programmable memory that is not accessible from non-privileged code. Network security is also more mature and easier to implement using Linux network stack and cryptography support, and OP-TEE provides a ready-to-roll secure environment for many parts reviewed here.

Imagine that you needed to persist some configuration data across reboot cycles. Sure, you can use structs and low-level flash programming code, but if this data needs to be appended to or changed in an arbitrary fashion, your code would start to get ridiculous. That’s why filesystems (and databases) exist. Yes, there are embedded libraries for filesystems, but these are way clunkier and more fragile than the capabilities you can get in Linux with nothing other than ticking a box in menuconfig. And databases? I’m not sure I’ve ever seen an honest attempt to run one on a microcontroller, while there’s a limitless number available on Linux.

In a bare-metal environment, you are limited to a single application image. As you build out the application, you’ll notice things get kind of clunky if your system has to do a few totally different things simultaneously. If you’re developing for Linux, you can break this functionality into separate processes, where you can develop, debug, and deploy separately as separate binary images.

The classic example is the separation between the main app and the updater. Here, the main app runs your device’s primary functionality, while a separate background service can run every day to phone home and grab the latest version of the main application binary. These apps do not have to interact at all, and they perform completely different tasks, so it makes sense to split them up into separate processes.

Bare-metal MCU development is primarily done in C and C++. Yes, there are interesting projects to run Python, Javascript, C#/.NET, and other languages on bare metal, but they’re usually focused on implementing the core language only; they don’t provide a runtime that is the same as a PC. And even their language implementation is often incompatible. That means your code (and the libraries you use) have to be written specifically for these micro-implementations. As a result, just because you can run MicroPython on an ESP32 doesn’t mean you can drop Flask on it and build up a web application server. By switching to embedded Linux, you can use the same programming languages and software libraries you’d use on your PC.

Classic bare-metal systems don’t impose any sort of application separation from the hardware. You can throw a random I2C_SendReceive() function in anywhere you’d like.

In Linux, there is a hard separation between userspace calls and the underlying hardware driver code. One key advantage of this is how easy it is to move from one hardware platform to another; it’s not uncommon to only have to change a couple of lines of code to specify the new device names when porting your code.

Yes, you can poke GPIO pins, perform I2C transactions, and fire off SPI messages from userspace in Linux, and there are some good reasons to use these tools during diagnosing and debugging. Plus, if you’re implementing a custom I2C peripheral device on a microcontroller, and there’s very little configuration to be done, it may seem silly to write a kernel driver whose only job is to expose a character device that basically passes on whatever data directly to the I2C device you’ve built.

But if you’re interfacing with off-the-shelf displays, accelerometers, IMUs, light sensors, pressure sensors, temperature sensors, ADCs, DACs, and basically anything else you’d toss on an I2C or SPI bus, Linux already has built-in support for this hardware that you can flip on when building your kernel and configure in your DTS file.

When you combine all these challenges together, you can see that building out bare-metal C code is challenging (and thus expensive). If you want to be able to staff your shop with lesser-experienced developers who come from web-programming code schools or otherwise have only basic computer science backgrounds, you’ll need an architecture that’s easier to develop on.

This is especially true when the majority of the project is hardware-agnostic application code, and only a minor part of the project is low-level hardware interfacing.

Sleep-mode power consumption. First, the good news: active mode power consumption of application processors is quite good when compared to microcontrollers. These parts tend to be built on smaller process nodes, so you get more megahertz for your ampere than the larger processes used for Cortex-M devices. Unfortunately, embedded Linux devices have a battery life that’s measured in hours or days, not months or years.

Modern low-power microcontrollers have a sleep-mode current consumption in the order of 1 μA — and that figure includes SRAM retention and usually even a low-power RTC oscillator running. Low-duty-cycle applications (like a sensor that logs a data point every hour) can run off a watch battery for a decade.

Application processors, however, can use 300 times as much power while asleep (that leaky 40 nm process has to catch up with us eventually!), but even thatpales in comparison to the SDRAM, which can eat through 10 mA (yes mA, not μA) or more in self-refresh mode. Sure, you can suspend-to-flash (hibernate), but that’s only an option if you don’t need responsive wake-up.

Even companies like Apple can’t get around these fundamental limitations: compare the 18-hour battery life of the Apple Watch (which uses an application processor) to the 10-day life of the Pebble (which uses an STM32 microcontroller with a battery half the size of the Apple Watch).

Boot time. Embedded Linux systems can take several seconds to boot up, which is orders of magnitude longer than a microcontroller’s start-up time. Alright, to be fair, this is a bit of an apples-to-oranges comparison: if you were to start initializing tons of external peripherals, mount a filesystem, and initialize a large application in an RTOS on a microcontroller, it could take several seconds to boot up as well. While boot time is a culmination of tons of different components that can all be tweaked and tuned, the fundamental limit is caused by application processors’ inability to execute code from external flash memory; they must copy it into RAM first ((unless you’re running an XIP kernel)).

Responsiveness. By default, Linux’s scheduler and resource system are full of unbounded latencies that under weird and improbable scenarios may take a long time to resolve (or may actually never resolve). Have you ever seen your mouse lock up for 3 seconds randomly? There you go. If you’re building a ventilator with Linux, think carefully about that. To combat this, there’s been a PREEMPT_RT patch for some time that turns Linux into a real-time operating system with a scheduler that can basically preempt anything to make sure a hard-real-time task gets a chance to run.

Also, when many people think they need a hard-real-time kernel, they really just want their code to be low-jitter. Coming from Microcontrollerland, it feels like a 1000 MHz processor should be able to bit-bang something like a 50 kHz square wave consistently, but you would be wrong

Ms.Josey

Ms.Josey

Ms.Josey

Ms.Josey