ips lcd screen burn manufacturer

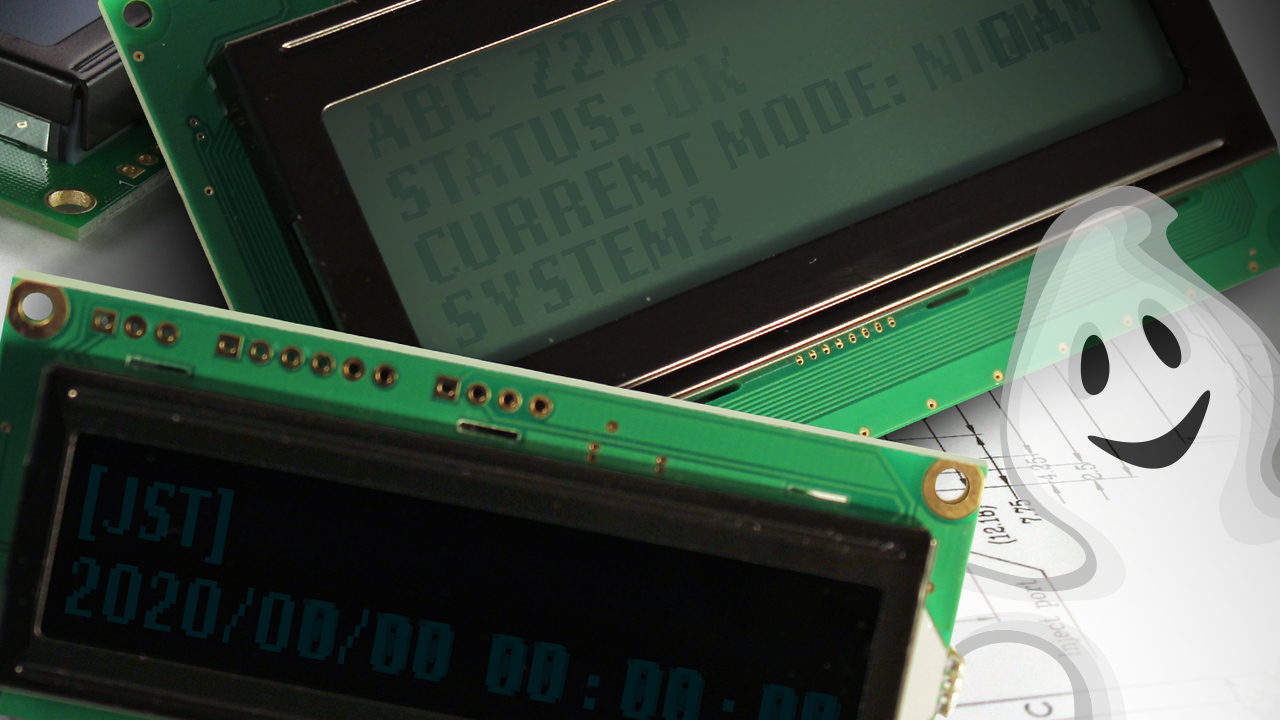

Image burn-in, also referenced as screen burn-in or ghost image, is a permanent discoloration of sections on an electronic display caused by increasing, non-uniform use of the screen.

The term burn-in dates back to when old monitors using phosphor compounds that emit light to produce images lost their luminance due to severe usage in specific display areas.

Chances are you"ve encountered image burn-in and image retention before, but you didn"t know which one you were seeing. They both have the same visual effects, so it"s easy to mistake them for each other, but there"s one key difference:

Most of the time, these guides explain how image retention works and how you can speed up its recovery process. We want to clear up any confusion you might have about image burn-in and image retention on LCD and OLED displays.

Image retention, also known as ghosting or image persistence, is the temporary effect of images remaining visible on LCDs or OLEDs for a short period, usually a few seconds.

If the images fade away after a short time, you are dealing with temporary image retention. If the images stay permanently, you are dealing with image burn-in.

Image retention doesn"t require any intervention from the user to make it go away – it"ll do that by itself. Retention will often occur before burn-in does on newer display technology like our

using a screen saver, cycling various graphics on the screen to exercise the pixels, and powering off the display whenever possible will help clear the image retention on your display.

These are the same tricks you"ll see advertised as a "cure" for image burn-in, but don"t be fooled. There"s no fix for burn-in, only ways to prolong it from happening.

Before you assume your screen has burn-in damage, try these tips and wait to see if it"s just image retention. Image retention is a harmless and common occurrence on many screens.

Image burn-in is caused by screen pixels that stay activated in a static position for long periods of time.Think of a TV in a lobby or waiting area that"s always playing the same news channel. The news channel footer and logo get burned into the screen permanently, even when you change the channel.

When LCD or OLED pixels stay activated in a static position, they"ll eventually become "stuck" in that position. When this happens, you"ll notice a faded, stubborn image that persists on the screen.

When pixels fail to activate or deactivate entirely, it results in faded images that won"t clear from the screen. This is common in applications using character LCDs where the alphanumeric characters are updated less frequently.

Remember: There"s no way to remove or reduce burn-in after it occurs. If a stubborn image persists for extended periods or after restarting your display, you"re likely dealing with image burn-in.

Even the most advanced displays will experience burn-in at some point, but there are some simple actions you can take to extend your screen"s lifespan before burn-in occurs. With the proper practices, you can get years of outstanding performance from your display without any burn-in effects.

A screensaver is a good alternative if you can"t turn your display off. For displays that don"t need to be ON at all times, it"s helpful to let the screen rest when not in use.

Get those pixels moving! The longer a pixel stays activated in a static position, the closer it gets to being burned in. You can exercise your screen"s pixels with scrolling text, moving images, or changing colors.

For an OLED display, decreasing the contrast will lower the brightness and reduce the rate of image burn. More illumination (brightness) requires more current, which reduces OLED pixel lifespans.

For a LCD display, lowering the contrast will put less stress on the liquid crystals and will help to reduce the rate of pixels becoming weak, or sticking.

Remember that image burn-in is not reversible and can not be fixed once it happens. Whether it is a scrolling effect, rotating pixels, using a screensaver, or turning off the screen when not in use, it"s essential to establish image burn-in preventive measures to help extend the lifespan of your display.

On August 31, 2017, we started a long-term 20/7 burn-in test on 3 TVs (OLED vs VA vs IPS). Our goal was to see how their performance changed over time, especially with static images like network logos, black bars in movies, or video games with a fixed interface.

Permanent image retention is a more serious issue, but it requires looking at the TV"s performance over months or years. We tested three TVs side-by-side, the OLED LG B6, the VA Samsung KU6300, and the IPS LG UJ6300 in a two-year-long test.

This test ended in 2019, as we feel that we now have a good understanding of what types of content are likely to cause burn-in. However, we still haven"t addressed the issue of longevity in general, and we don"t know if newer OLED panels are still as likely to experience burn-in. To that end, we"ve decided to start a new accelerated longevity test to better understand how long new TVs should last and what are the most common points of failure. Although burn-in isn"t the main goal of this test, we"re hoping to better understand how newer OLED panels compare to the older generation of OLEDs. It"s generally accepted that burn-in isn"t as much of an issue as it used to be, but it"s unclear just how much better the newer OLED TVs are. With new panels, new heatsinks, and even brand-new panel types like QD-OLED, there are a lot of unknowns.

The 20/7 burn-in test ran for about two years, from August 31, 2017, until November 15, 2019. The goal of this test was to see whether burn-in could happen for the three most popular TV types (VA LCD, IPS LCD, and OLED). These are the results of our experiment:

Long periods of static content will cause burn-in on OLED TVs. The red sub-pixel appears to degrade the fastest, followed by green and blue. The effect is cumulative, as even cycled logos do burn-in (but over a longer period). We investigated this further in our Real Life OLED Burn-in Test.

Black letterbox bars were displayed for almost 5,000 hours (equivalent to 208 days of continuous letterboxing). Some letterboxing is starting to become noticeable on full-screen slides, but not in normal content. As a result, we don"t expect letterbox bars to cause any issues for people. It"s due to the uneven aging of the screen. The black portions of the screen haven"t aged as much as the rest, so those dark areas appear brighter in regular content.

:max_bytes(150000):strip_icc()/Emerson-McDonalds_CNN_Burn-In-5692ad0d3df78cafda81df58-5c619daec9e77c0001d92fc1.jpg)

Have you ever left your TV or monitor on for days, stuck on the same image? You return to your screen, only to find an image burned into the display. No matter what you do, it won"t go away. It is a permanent image burn.

Why do monitors and TVs get image burn? Why can"t manufacturers prevent LCDs and plasma screens from a burnt image imprint? Moreover, what can you do to fix an image burn?

In some cases, you can minimize the image burn effect. In others, you can remove the image burn completely, so long as it hasn"t been burning too long.

Before flat-screens and crystal displays, most TVs and monitors featured CRT (Cathode Ray Tube) technology. In CRTs, individual pixels comprise a red, blue, and green phosphor component. Depending on the intensity of each phosphor component, the pixel appears to the human eye as a unique color.

When a particular still image remains for too long, the intensity of each phosphor component diminishes at an uneven rate. The result is a ghost image on the screen, which is known as image burning.

This is a very simplified version of how a plasma screen works. However, the main thing to understand is that plasma screens use phosphor material (like CRTs) to turn those photons into images.

LCD and LED do not work in the same way as CRTs, either. LCD and LED screens use backlit liquid crystals to display colors. Although manufacturers market screens using LED and LCD, an LED screen is still a type of LCD. The white backlight filters through the liquid crystals, which extract particular colors per pixel.

LCD and LED displays don"t suffer from the same type of image burn as CRTs and plasma screens. They"re not completely clear, though. LCD and LED screens suffer from image persistence. Read on to find out more about image persistence.

Before you can fix screen burn-in, take a second to understand why these images burn in the first place. LCDs and LEDs don"t suffer from burn-in as seriously as plasma screens. But static images can leave an imprint on both display types if left alone for too long. So, why does image burn happen?

First, let"s tackle plasma screen burn-in. Remember why CRTs experience image burn? When a still image remains on the screen for too long, the phosphor components in each pixel wear out at different rates. The uneven burn rates leave behind a ghost image, forever etched into the screen.

Plasma screens also suffer from phosphor deterioration. Plasma burning occurs when pixels on the screen are damaged through long exposure. The phosphor loses its intensity and only shows the light it was fed repeatedly. In this case, the still image, which causes the burn.

LCD and LED screens can also experience image burn, though the image burn process can take longer to develop into a permanent issue. In addition, LCD and LED screens suffer from another issue, known as image retention (also known as image persistence or an LCD shadow).

Image retention is a temporary issue that you are more likely to notice before it becomes a permanent issue. However, proper image burn can still affect LCD, LED, and OLED screens.

Image retention is a different issue from image burn (although it is a precursor to image burn). For example, you"re using an image of a steam train as a reference point for a drawing. You have the steam train image on your screen for a few hours before you decide to play a video game instead.

When you load up the video game on the screen, you can still see the faint outline of the steam train on the screen. The steam train image will remain for a short while, but the movement and color changes of the video game (or film, TV show, or other media type) should erase the retained image.

The other thing to consider is that LED and OLED image burn-in, when it happens, is irreversible. That"s because of how LED and OLED screens work. Individual pixels within an LED display decay when they emit light.

Under normal use, an LED, OLED, or QLED screen won"t suffer image burn. However, if you leave your screen on a single channel for hours every day, then burn-in can become an issue, as it would with almost any screen.

Issues arise when a screen shows a single news channel 24 hours a day, every day, causing channel logos to burn-in, along with the outline of the scrolling news ticker and so on. News channels are a well-known source of television burn-in, no matter the screen type.

Image burn-in fixes exist for LCD and plasma screens. How effective an image burn-in fix is depends on the screen damage. Depending on the length and severity of the image burn, some displays may have permanent damage.

The best fix for screen burn is to prevent it in the first place. Okay, that isn"t super useful if your screen is already experiencing image burn. However, you should always try not to leave your screen on a still image for too long. The time it takes for an image to burn-in varies from screen to screen, between manufacturers, sizes, and panel type.

Another prevention method is to reduce screen contrast as much as you can. Unfortunately, most screens aren"t calibrated correctly, often pushing the contrast and brightness settings too high.

Lower contrast means the lighting across your screen is more even. This means less strain on specific areas of the screen, which helps protect against image burning.

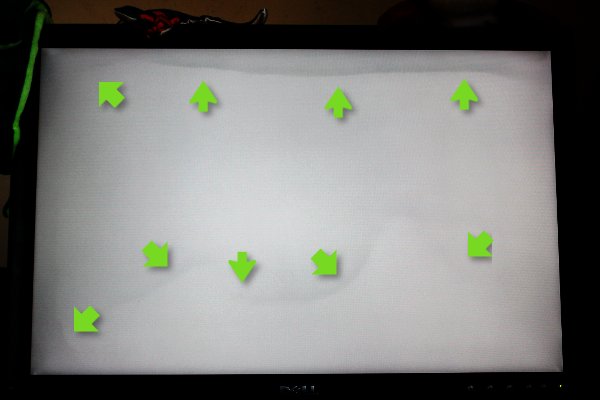

If your plasma or LCD screen already has image burn-in, you can try turning on white static for 12 to 24 hours. The constant moving of white-and-black across your screen in random patterns can help remove the ghost image from your screen.

Unfortunately, this won"t work for extreme cases. Some TVs will have a built-in pattern swiping option that basically accomplishes the same thing (filling your screen with random patterns).

Pixel-shift constantly slightly adjusts the image on your screen, which varies the pixel usage to counteract image burn. You might have to enable a pixel or screen shift option in your screen settings. Pixel-shift is a handy feature for LED and OLED screens that cannot recover from image burn and should help counteract an LCD shadow.

Other modern screens feature built-in screen refresh functions that the manufacturer will advise using to remove image retention and image burn issues.

The best tool for fixing ghost images is JScreenFix. The original program helps fix monitors with dead pixels, but the same company also released an "advanced" version of the tool, known as JScreenFix Deluxe.

While the Deluxe version uses advanced algorithms to repair burned screens and prolong plasma and LCD longevity, the official site is no longer up and running, and there is no way to download the full version officially.

Another option is to set a completely white desktop background and leaving to run for a few hours. The solid color might reset the image burn. A solid color background is more likely to help with image persistence than image burn, but it is still worth trying.

If you have television burn-in, you can attach a laptop to your TV using an HDMI cable, extend your desktop to the television, and share the white screensaver. Hopefully, that will shift your television burn-in.

The team over at ScreenBurnFixer offers a few different ways you can attempt to fix screen burn on your TV or monitor. As with any other screen burn-in fixes, their chance of working depends on the scale of the issue.

You can head to the ScreenBurnFixer Video page and find a video that matches your screen type, then let the video play for as long as possible (we"re talking multiple hours, not a quick half an hour blast). Alternatively, head to the Chart page and find your device or a device that matches your specifications.

There are several ways you can attempt to fix screen burn-in. The results will vary between the screen type and the level of burn-in. A screen with extensive image burn may not clear entirely, although you might see an improvement.

Some screen degradation over time is understandable. However, if you follow the steps in this guide, you"ll protect your screen from image burn before it becomes a permanent issue.

:max_bytes(150000):strip_icc()/screenburnin01-5bdc37e9c9e77c00269c4545.jpg)

If you spend long enough debating the merits of LCD vs. OLED display technologies, eventually, someone will touch upon the subject of the dreaded OLED screen burn in. The point made is that OLED displays will inevitably suffer from horrible-looking artifacts over time, while LCD and new technologies like Mini-LED won’t. But like most of these debates, you’ll probably hear as many overblown anecdotes as you will actual facts about the issue.

You may never have experienced it for yourself, but many consumers are wary about the possibility of burn in when pondering their next smartphone purchase. Particularly as expensive flagship smartphones have universally adopted OLED display technology. Apple, Google, and other manufacturers acknowledge that burn in can be a problem in rare cases. OLED technology has made its way to much more affordable price points in recent years, putting the issue on the radar for even more consumers.

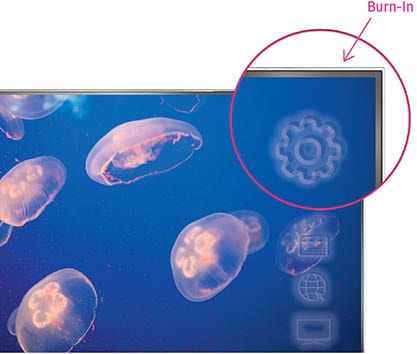

The word “burn in” is a little misleading, as no actual burning or heat problems are involved. Instead, this term describes a display suffering from permanent discoloration across any part of the panel. This may take the form of a text or image outline, fading of colors, or other noticeable patches and patterns on display. The display still works as expected, but a somewhat noticeable ghost image or discoloration persists when the screen is on. To be considered screen burn in, these artifacts have to be permanent and are a defect caused on the display hardware side. Rather than a graphical glitch that may be caused by software, temporary image retention, or a problem with the display driver circuitry.

The term dates back to old CRT monitors, where phosphor compounds that emit light to produce images lost their luminance with time. LCD panels can exhibit similar problems, but these are much rarer due to the nature of LCD’s backlight and color matrix design.

Although not as bad or noticeable as old CRT issues, today’s OLED smartphone displays can eventually suffer from a similar problem. That being said, it’s pretty difficult and rare to notice unless you know what you’re looking for, and it takes hundreds, if not thousands, of hours of screen-on time before any such errors appear. In smartphones, pattern burn in is typically associated with always-on displays, navigation buttons, and the notification bar. The example below demonstrates a textbook case:

Although most smartphones now support gesture navigation controls in the place of the old button design. So this type of burn-in is much less of a problem than it used to be.

The cause of all screen burn in is the varying lifecycle of a display’s light-producing components. As these parts age, their brightness changes, and therefore the panel’s color reproduction gradually shifts with time. Although this can be mitigated somewhat with clever software, all displays experience some color shift as they age. But with burn in, some parts of the screen age faster than others. This can gradually shift the perceivable colors of the screen in one area more than in another, leaving what looks like a ghost image behind.

With modern smartphone and smartwatch technology, screen burn in can manifest due to the different life spans between the red, green, and blue LED subpixels used in OLED panels. As we mentioned before, areas of the display that seldom change, are bright white, or are often black and switched off, such as navigation buttons or the notification bar, are the most likely areas to notice this issue. You may also notice the effect in darkened status bars designed to hide display notches.

So, if one part of the panel spends a lot of time displaying a blue or white image, the blue pixels in this area will degrade faster than in other areas. That’s essentially what burn in is. However, display manufacturers do account for this in their panel designs.

If OLED screens have a problem with burn in, why do we continue using them? Burn in is a true downside to OLED displays, but there are plenty of reasons consumers and manufacturers like them. For starters, image quality is much better than in LCDs. OLED panels can reproduce more vibrant colors, more contrast, wider viewing angles, and faster refresh rates. Colors tend to be much more saturated, and blacks are much darker.

Additionally, burn in problems are only common after prolonged periods of use. As you may already know, smartphone manufacturers don’t expect you to keep a smartphone for more than 2-3 years. Recent statistics show that consumers currently keep their phones for an average of 2.75 years.

At this stage, manufacturers are very aware of the potential issues and have already taken some intelligent steps to help avoid burn in. For starters, Samsung has been using its pentile subpixel arrangement in its AMOLED displays since the Galaxy S3. By making the blue subpixel larger, it requires less current to drive in order to provide the necessary light. Driving the LED with less current increases its lifespan, so it takes longer for any noticeable color shift to occur.

This doesn’t directly address the issue of different parts of the screen aging at different rates, but it does mean that it will take significantly longer to notice than with older or cheaper OLED panels. More expensive and modern OLED panels are built with longer-lasting LEDs and well-designed layouts, meaning flagship smartphone displays age slower. These days, it’s cheaper phones packing cheaper displays that are marginally more likely to see issues after heavy use.

There are software solutions too. Android Wear product manufacturers can enable the OS’s “burn protection” option. This mode periodically shifts the screen’s contents by a few pixels, so they spend equal time displaying different colors. Smartphones equipped with Always-On display technology employ a similar tactic. Google also suggests a selection of design guidelines tailored to avoid screen burn-in problems when designing OLED watches. The move towards gesture rather than on-screen navigation controls is also helping to alleviate one of the more noticeable burn in areas.

If your screen is already burnt in, there’s not much that can be done to undo the damage. Some apps on the Play Store claim to reverse the problem. These will end up “burning” the rest of the screen to match the colors, which isn’t a real solution.

Try to make it so that the screen isn’t displaying the same thing all the time, in the same areas of the screen. For example, if you have a widget that almost always looks the same, chances are it will eventually burn into the image. Move things around now and then, and try to keep the view of your phone dynamic.

All that said, screen burn in isn’t something that should concern many users if they’re looking to buy a new OLED smartphone. Modern panels have much longer lifespans than early OLED smartphones, and even then, burn in was rare. Just don’t leave a static image on the screen 24/7 with the brightness set at max.

The bottom line is that you should be looking at several years’ worth of use out of a modern smartphone display before any screen burn in will be noticeable. But it doesn’t hurt to be aware of what can happen to aging handsets and how to maximize their lifespan.

Originally posted byAlways and never are problematic. Sure it"s possible, it depends on the details of what your phone screen is doing and why. If it"s a major defect/failure, which is always possible, then obviously it would be permanent. And no amount of

You"re going to have to decide for yourself whether your phone screen is temporarily defective, or permanently defective. I"d typically lean toward the latter. Since it"s been a few months already I don"t think you"re likely to wake up tomorrow and find it operating like new...

q/a should have caught it or it passed their min dead pixel req, (15 years ago many 720p lcd displays had a 5-10 dead/stuck pixel clause in their warranty that they would not cover)

Originally posted byAre you sure it"s screen burn and not a fault? I had a 10.1" Samsung tablet replaced after almost a year of ownership because a fine vertical line appeared on the screen. I"m confident it wasn"t screen burn.

OLED vs. IPS LCD is a topic that comes up whenever consumers upgrade to a newer TV or a smartphone. Should you buy a TV that uses an IPS LCD display or should you pick up a TV with an OLED screen? Well, the answer isn’t so straightforward because they both have their advantages and disadvantages. In this article, we will explain how these screen technologies work and which one you should opt for while buying a TV.

IPS LCD (In-Plane Switching Liquid Crystal Display) and OLED (Organic Light-Emitting Diode) are the two most commonly used screen technologies. Older technologies, such as TN (Twisted Nematic) and PLS (Plane-to-Line Switching) displays, have almost disappeared (except in the world of PC monitors and budget laptops) because IPS LCD and OLED are clearly better in almost all aspects. Other technologies such as Mini-LED, MicroLED, and QNED technologies are extremely new and they won’t become mainstream for a few years.

So, when you are finally deciding which TV to buy, the real battle is between OLED and IPS LCD. So where do these stand? Which is better for you? Which one should you pick for your new home theatre? Read on for more information on the OLED vs IPS LCD battle.

IPS LCD displays are perhaps the most common display type days, especially in TVs and laptops. Laptops, entry-level and mid-range smartphones, and most TVs use LCD displays. So, how do IPS displays work? IPS displays use an array of LCD pixels that shift colour as required. However, they don’t emit light on their own. That’s the reason they need a backlight made up of LEDs (Light-Emitting Diodes). The backlight can be arranged in various layouts: towards the edges, spread across the whole display, or separated into different sections.

IPS screens display the black colour by changing the alignment of LCDs so that pixels block the transmission of light, but some light still gets through. That’s the reason IPS LCD displays can’t display true deep black colour. Instead, they display dark grey and there is some ‘backlight bleed’.

In a nutshell, OLED displays don’t use separate backlight sources. Instead, every pixel can reproduce its own light (also known as self-emissive displays). So, there’s no need for an additional backlight and each pixel can be turned on or off as needed. Since there is no need for a separate backlight plane, OLED displays are much thinner than LCD displays. They also offer a much better contrast ratio and viewing angles. However, the organic material used in OLED pixels tends to “burn” over the years that results in ghosting. Moreover, they can’t be as bright as LCD, Mini-LED, or Micro-LED displays.

We have given you a brief overview of IPS and OLED technologies. But which one is better? And which of these will be right for you? Here’s a list of pros and cons to help you in your purchase decision, where it is for smartphones or TVs.

OLEDs have a quicker response time: OLEDs individually-lit pixels can switch on/off or change colour faster. This makes for lower ghosting during fast-and-frenetic action scenes or while playing games. Ghosting refers to when the image on the screen seems to be following itself around or is blurry at the edges.

IPS LCD TVs offer higher brightness: IPS LCD TVs use a powerful backlight which also lets them get much brighter than their OLED counterparts. This can make for better HDR and even offer a better viewing experience if your TV room gets a lot of sunlight.

IPS TVs suffer from backlight bleed and blooming: This is less of an issue with high-end IPS TVs, but some cheaper models may suffer from glow (bright, greyish areas near the corners of the screen) or backlight bleed (patches or leaks of light, usually around the edges).

OLED TVs can suffer burn-in: OLED displays are at risk of burn-in, a condition in which a static image left on for too long can get permanently ‘burned’ onto the display and may appear like a ghostly dark patch.

IPS TVs are much cheaper: OLED is a relatively newer technology and is more expensive to manufacture. Currently, very few companies make OLED display panels. LG Display makes most of the OLED panels found on OLED TVs, while Samsung Display, CSOT, LG Display, and BOE make OLED screens for smartphones and smaller products. Most manufacturers also tend to restrict OLED tech to their largest, most feature-packed range, fueling the perception of OLED being expensive.

Follow Onsitego on Facebook, Instagram, Twitter, and YouTube to get the latest news, reviews, maintenance tips, and videos about your favourite gadgets and appliances.

LCDs, regardless of variant, work by altering the alignment of polarizing crystals between polarized filters. Unless the crystals are overdriven to the point of electrolysis, they should have nearly infinite lifespan. The backlight is more likely to become a limiting factor.

Ever notice a partial discoloration of text or image across the screen of your monitor? This can be annoying, especially when the monitor is an industrial display used to help your business.

These unpleasant discolorations are known as screen burn-in. In this blog post, we will discuss how to prevent and recover from LCD monitor screen burn-in.

LCD display burn-in, also known as ghost image or image sticking, is the retention of the previous image on the screen even after you’ve swiped the screen. LCD burn-in happens on an LCD screen when pixels cannot return to their relaxed condition after a static image shows on the screen for an extended period.

LCD monitor screen burn-in is the permanent version of image retention. Screen burn-in occurs when an image is shown on a screen for so long that it may still be seen after the screen is off. LCD burn-in happens when some sub-pixels have remained so brilliant for a very long time that they are unable to go back to their initial state. They always produce a “ghost” image because they are inherently “stuck” in a non-neutral state.

When pixels stay in the same place for an excessively long time before switching to another position for a brief period, this can lead to LCD monitor burn-in. In addition, when an image is displayed on a screen excessively, the liquid crystal material in the LCD panel becomes polarized. As a result, it develops into a permanent discoloration known as LCD display burn-in.

Image persistence on LCD screens is avoidable and can be corrected. There are several ways to prevent or repair screen burn-in in LCD monitors, which include the following:

Screen burn-in isn’t as common on modern display technologies as it was in the past, but few screens are immune to its ability to ruin a perfectly good display. If you run into this irritating problem, here are some tips and tricks that might help fix it.

Screen burn-in is a noticeable discoloration or ghosting of a previous image on a digital display. It’s caused by the regular use of certain pixels more than others, leaving them to display colors slightly differently. The end result is a noticeable and often permanent impression on the display.

Time, screen brightness, and other factors can cause burn-in, but the circumstances are different for each display technology, as different screens and their pixels operate differently at the hardware level. For LCD panels, like those used in many TVs and computer monitors, burn-in can develop because pixels eventually become unable to return to their unlit state and retain a colored profile.

Colloquially “burn-in” is used as a catchall term for any kind of ghosted image on a screen. The most common form of such “burn-in” though, is technically known as image retention. While that might seem like a case of pedantic semantics, it’s an important distinction to make. Screen burn-in refers to permanent degradation of a display which is almost impossible to fix; image retention is typically fixable.

As described above, screen burn-in on a technical level is hard to fix. However, the much more common image retention is not. Here’s how to sort out your image retention problems on whatever device you have.

Enable Pixel-Shift. Many modern TVs have a built-in pixel-shift, or screen shift, which constantly moves the image slightly to vary pixel usage. If not enabled automatically, you should be able to turn it on in the settings menu. Other settings offer “Refresh” functions that can be manually run to try and clean out any image retention problems.

Use a White Screensaver. Try setting your screensaver to a pure white image and leaving it to run for a few hours. That may not remove image retention entirely, but it should dampen how noticeable it is.

Try JScreenFix. Some have also found success using JScreenFix. Although designed to fix stuck pixels rather than burn-in, it may help clear up any issues you’re experiencing.

Try a burn-in fixer. There are a number of great burn-in fixer apps on the Google Play Store and Apple App Store. Some, like OLED tools, will try to fix image retention and check for more permanent burn-in.

Replace the screen. If none of the above works, your best bet is to either replace the screen yourself or talk to your mobile carrier about a replacement device. Manufacturers like Apple have extended the warranties on certain devices that are prone to image retention and burn-in, so if your device is fairly new, you should still be covered by the warranty.

To prevent screen burn-in on a TV, reduce the brightness to the 45-50 range, use the sleep timer and screen savers, and turn the TV off when not in use. If you have an OLED TV, turn on pixel shift and play a color-changing video that"s designed to help lower the risk of burn-in.

On Androids and iPhones, reduce the brightness to 50 percent or lower, use a screen-timeout length of about 30 seconds, and turn off your phone when not in use. You can also operate in dark mode, use swipes and taps instead of button navigation, and download a screen-burn fixer app.

On a smartphone, screen burn presents as a discolored display with pink or gray tones. On monitors and TVs, it looks like a "ghosting" of previous images remaining on the screen. Screen burn happens so gradually that you may not notice it until using a white background.

Display technologies are advancing every day. All the major tech giants like Apple, Samsung, One Plus use one among these technologies for building the displays of their Apple phones or Galaxy Notes. Each has its advantages and disadvantages. So which one is better? Is it the AMOLED favored mostly by Samsung? Or is it the IPS LCD favored by Apple for their iPhones? Let us take a detailed look at the features of AMOLED vs IPS display technologies.

Compared to the LCD and LED displays, the diodes in the OLED display produce light individually meaning they do not need a backlight like their predecessors. OLEDs use lesser electricity and are thinner compared to LEDs. They are also bendable and may even be curved. However, they are much more expensive than LED displays. Hence in the earlier days, it was majorly used for displays for

AMOLEDs have deep black lights. The blacks are darker than LEDs and LCDs because parts of the screen can be switched off altogether. AMOLEDs are also thinner and lighter than LCDs. This feature especially stands out in a dark theater room where OLED displays give a higher contrast ratio compared to LCDs making for an excellent visual experience. This feature of OLED which can work with no backlight makes it better than LCDs whether or not they have an LED backlight.

One of the disadvantages the AMOLED had over LCD was the blurriness caused in sunlight which is a result of its lowered peak-brightness values. This issue was corrected in the advanced Super AMOLEDs. In the Super AMOLEDs, the size of gaps between the various layers of the screen namely the cathode layer, anode layer, organic active layer, TFT layer is made narrower than before.

Another problem associated with the AMOLEDs is that the organic materials used in the emissive layer and the conductive layer suffer degradation. This happens comparatively in a short amount of time. As a result, various display problems arise including image persistence, burn-in, etc which are essentially screen burn type problems and color shifts where some colors fade quicker than others. Burn-in is essentially the pixel quality becoming trash after a while because of the degradation of the organic molecules.

Most flagship models of major companies like Samsung, Apple, and One Plus use either super AMOLED or IPS panel premium LCDs. So what exactly is an IPS display? and how does it feature against like the likes of super AMOLEDs?

First, let us understand the basics of a standard LCD. Simply put, when you apply current to some crystals, they may or may not let through the light which comes from a backlight that covers the whole display. In addition to this, there are polarization and color filters present in LCDs which finally give the primary colors Red, Blue, and Green.

Before we get into detailed explanations, you have to keep in mind that for the final end-product that ends up on the market, the quality of the display does not solely depend on whether it is IPS or AMOLED. The companies usually put their tweaks on top of the existing technology before making them available in the market. AMOLEDs are a newer technology than IPS LCD and improve on it in some areas while still lagging in others.

The IPS LCD stands for In-Plane Switching Liquid Crystal Displays. It emerged onto the scene as an improvement on the existing and vulnerable Thin Film Transistor LCD technology commonly referred to as the TFT. Samsung was the leading manufacturer to employ Super AMOLEDs. The IPS display is mainly being used in Apple iPhones. Apple beginning with the iPhone X is switching to AMOLED displays with contrast ratios of 1000000 to 1

As said before, an IPS display is an improved version of the regular TFT LCDs. Here, the difference comes in the way the anode and the cathode are arranged. They are planted as strip electrodes on one of the two glass substrates.

The IPS display scores big time when it comes to offering better viewing angles compared to the other LCD technologies like Twisted Nematic LCD (TN) and Vertical Alignment LCD (VA). The IPS display can be viewed without any color degradation or blurriness at flimsy shallow angles compared to TN and VA displays.

The consistency of colors and clarity of pictures at wider viewing angles is the major advantage of an LCD. IPS displays have higher resolution. They also can display a wide range of colors. These features also make the IPS displays costlier than TN and VA LCDs. Normally IPS monitors allow up to 178 degrees of viewing angles. These displays almost guarantee absolute color accuracy.

For other LCD models, the color and the brightness of an image vary when viewed from different angles. Compared with them, IPS displays are more suited for someone working as a visual/graphic artist. As a regular television, all LCD models are mostly considered equally good. This is because the viewers would mostly be sitting right in front of the screen where these differences between the models do not matter.

IPS displays are capable of displaying a wider spectrum of colors. Considering no monitors can display the entire color spectrum visible to the human eye, IPS LCD panels are the closest things to a perfect display monitor far better than TN and VA LCDs

Image retention is a problem often associated with LCDs. This happens because of the crystal which gets into a particular position for the light to go through stays in that same spot without falling back into its original position. This leads to some parts of the image being left on the screen. This is, however, a temporary problem. The crystal will eventually twist back into the position when the current is applied to it again. When it comes to color accuracy, the previous generation of LCDs was no match for the AMOLED. They had the highest color accuracy among mobile phones. But recent versions of the LCDs have fared much better versus their counterparts.

Large-sized IPS monitors are not affordable for the average customer. They should be avoided since they offer nothing impressive over other LCDs considering the price range. However, if you are a visual artist or a photographer, IPS displays provide the best color accuracy in the market. It would be more beneficial to you compared to an ordinary TN display unit.

AMOLEDs and IPS LCDs are two sides of the same coin in a sense. They both got their advantages and disadvantages. Their disadvantages are mostly overshadowed by the many tweaks installed by the parent companies to ensure customer satisfaction. From high power consumption to ugly blacks, the flaws are minimized in every newer version.

Apart from the fact that it doesn"t feel like a "real" IPS panel (at certain angles part of the screen is dimmer), the screen somehow has a weird burn-in issue. After about 15-20 minutes of viewing a static image (like a PDF for example) and then switching to a dark image, I can already read bigger text on the area where the PDF was. In fact, while I was writing this I can already see the outline of this text box if I switch to a dark window (which is 100% opaque).

EDIT: I was on YouTube few minutes ago for maybe 15 minutes and I was able to take a picture of the burn-in afterwards. If you know the YouTube logo, you will easily recognize it and this was just a short time I had it on the screen while watching a video.

Screen burn-in, image burn-in, or ghost image, is a permanent discoloration of areas on an electronic display such as a cathode ray tube (CRT) in an old computer monitor or television set. It is caused by cumulative non-uniform use of the screen.

One way to combat screen burn-in was the use of screensavers, which would move an image around to ensure that no one area of the screen remained illuminated for too long.

With phosphor-based electronic displays (for example CRT-type computer monitors, oscilloscope screens or plasma displays), non-uniform use of specific areas, such as prolonged display of non-moving images (text or graphics), repetitive contents in gaming graphics, or certain broadcasts with tickers and flags, can create a permanent ghost-like image of these objects or otherwise degrade image quality. This is because the phosphor compounds which emit light to produce images lose their luminance with use. This wear results in uneven light output over time, and in severe cases can create a ghost image of previous content. Even if ghost images are not recognizable, the effects of screen burn are an immediate and continual degradation of image quality.

The length of time required for noticeable screen burn to develop varies due to many factors, ranging from the quality of the phosphors employed, to the degree of non-uniformity of sub-pixel use. It can take as little as a few weeks for noticeable ghosting to set in, especially if the screen displays a certain image (example: a menu bar at the top or bottom of the screen) constantly and displays it continually over time. In the rare case when horizontal or vertical deflection circuits fail, all output energy is concentrated to a vertical or horizontal line on the display which causes almost instant screen burn.

Screen burn on an amber CRT computer monitor. Note that there are two separate burned-in images: one of a spreadsheet program, and another of an ASCII-art welcome screen.

Phosphor burn-in is particularly prevalent with monochromatic CRT screens, such as the amber or green monochrome monitors common on older computer systems and dumb terminal stations. This is partly because those screens displayed mostly non-moving images, and at one intensity: fully on. Yellow screens are more susceptible than either green or white screens because the yellow phosphor is less efficient and thus requires a higher beam current. Color screens, by contrast, use three separate phosphors (red, green, and blue), mixed in varying intensities to achieve specific colors, and in typical usage patterns such as "traditional" TV viewing (non-gaming, non-converged TV usage, non-Internet browsing, broadcasts without tickers or flags, no prolonged or permanent letterboxing) are used for operations where colors and on-screen object placement approach uniformity.

Modern CRT displays are less susceptible than older CRTs prior to the 1960s because they have a layer of aluminum behind the phosphor which offers some protection. The aluminum layer was provided to reflect more light from the phosphor towards the viewer. As a bonus, the aluminum layer also prevented ion burn of the phosphor and the ion trap, common to older monochrome televisions, was no longer required.

A nearly two-year-old LCD television showing extreme burn-in of CNN"s circa 2008 digital on-screen graphic; this television is in a McDonald"s restaurant where CNN is permanently turned on and displayed throughout the business day.

In the case of LCDs, the physics of burn-in are different than plasma and OLED, which develop burn-in from luminance degradation of the light-emitting pixels. For LCDs, burn-in develops in some cases because pixels permanently lose their ability to return to their relaxed state after a continued static use profile. In most typical usage profiles, this image persistence in LCD is only transient.

Both plasma-type and LCD-type displays exhibit a similar phenomenon called transient image persistence, which is similar to screen burn but is not permanent. In the case of plasma-type displays, transient image persistence is caused by charge build-up in the pixel cells (not cumulative luminance degradation as with burn-in), which can be seen sometimes when a bright image that was set against a dark background is replaced by a dark background only; this image retention is usually released once a typical-brightness image is displayed and does not inhibit the display"s typical viewing image quality.

Screensavers derive their name from their original purpose, which was an active method of attempting to stave off screen burn. By ensuring that no pixel or group of pixels was left displaying a static image for extended periods of time, phosphor luminosity was preserved. Modern screensavers can turn off the screen when not in use.

In many cases, the use of a screensaver is impractical. Most plasma-type display manufacturers include methods for reducing the rate of burn-in by moving the image slightly,Android Wear watches with OLED displays can request that Android Wear enable "burn protection techniques" that periodically shift the contents of the screen by a few pixels.

Other examples: Apple"s iPhone X and Samsung"s Galaxy series both mitigate or delay the onset of burn-in by shifting the pixels every minute or so for the battery, Wi-Fi, location, and service bars. Also, parallax scrolling may be enabled for the home screen to give icons a 3D-like effect, a setting Apple refers to as "perspective zoom". AG Neovo patented Anti-burn-in technology is also using pixel shifting to activate the pixels to move by the designed time interval to prevent burn in effect on LCD monitors.

Google requests that when these techniques are enabled, watch face developers do not use large blocks of pixels so that different pixels are burned in with each shift, reducing the overall wear of the pixels.

Some screensavers move around, such as those on DVD players or those on some television sets that move around paused video after a long period of inactivity.

Depending on the type of screen, it is sometimes possible to remedy screen burn-in through the use of remedial software and remedial devices. In the case of OLED screens on Android phones, burn-in reduction apps can display an inverted image of the navigation and status bars (which are constantly displayed and therefore the most likely elements to be burned in) to burn in opposite pattern, resulting in a screen whose sub-pixels have more even luminosity and therefore less visible burn-in artifacts.

The most prevalent burn-in image on early televisions was said to be that of the RCA Indian-head test pattern, which would often follow the formal television station sign-off. This was due to the viewer leaving the television set on at the end of the day, which was not recommended by the television manufacturers.

Glass substrate with ITO electrodes. The shapes of these electrodes will determine the shapes that will appear when the LCD is switched ON. Vertical ridges etched on the surface are smooth.

A liquid-crystal display (LCD) is a flat-panel display or other electronically modulated optical device that uses the light-modulating properties of liquid crystals combined with polarizers. Liquid crystals do not emit light directlybacklight or reflector to produce images in color or monochrome.seven-segment displays, as in a digital clock, are all good examples of devices with these displays. They use the same basic technology, except that arbitrary images are made from a matrix of small pixels, while other displays have larger elements. LCDs can either be normally on (positive) or off (negative), depending on the polarizer arrangement. For example, a character positive LCD with a backlight will have black lettering on a background that is the color of the backlight, and a character negative LCD will have a black background with the letters being of the same color as the backlight. Optical filters are added to white on blue LCDs to give them their characteristic appearance.

LCDs are used in a wide range of applications, including LCD televisions, computer monitors, instrument panels, aircraft cockpit displays, and indoor and outdoor signage. Small LCD screens are common in LCD projectors and portable consumer devices such as digital cameras, watches, calculators, and mobile telephones, including smartphones. LCD screens have replaced heavy, bulky and less energy-efficient cathode-ray tube (CRT) displays in nearly all applications. The phosphors used in CRTs make them vulnerable to image burn-in when a static image is displayed on a screen for a long time, e.g., the table frame for an airline flight schedule on an indoor sign. LCDs do not have this weakness, but are still susceptible to image persistence.

Each pixel of an LCD typically consists of a layer of molecules aligned between two transparent electrodes, often made of Indium-Tin oxide (ITO) and two polarizing filters (parallel and perpendicular polarizers), the axes of transmission of which are (in most of the cases) perpendicular to each other. Without the liquid crystal between the polarizing filters, light passing through the first filter would be blocked by the second (crossed) polarizer. Before an electric field is applied, the orientation of the liquid-crystal molecules is determined by the alignment at the surfaces of electrodes. In a twisted nematic (TN) device, the surface alignment directions at the two electrodes are perpendicular to each other, and so the molecules arrange themselves in a helical structure, or twist. This induces the rotation of the polarization of the incident light, and the device appears gray. If the applied voltage is large enough, the liquid crystal molecules in the center of the layer are almost completely untwisted and the polarization of the incident light is not rotated as it passes through the liquid crystal layer. This light will then be mainly polarized perpendicular to the second filter, and thus be blocked and the pixel will appear black. By controlling the voltage applied across the liquid crystal layer in each pixel, light can be allowed to pass through in varying amounts thus constituting different levels of gray.

The chemical formula of the liquid crystals used in LCDs may vary. Formulas may be patented.Sharp Corporation. The patent that covered that specific mixture expired.

Most color LCD systems use the same technique, with color filters used to generate red, green, and blue subpixels. The LCD color filters are made with a photolithography process on large glass sheets that are later glued with other glass sheets containing a TFT array, spacers and liquid crystal, creating several color LCDs that are then cut from one another and laminated with polarizer sheets. Red, green, blue and black photoresists (resists) are used. All resists contain a finely ground powdered pigment, with particles being just 40 nanometers across. The black resist is the first to be applied; this will create a black grid (known in the industry as a black matrix) that will separate red, green and blue subpixels from one another, increasing contrast ratios and preventing light from leaking from one subpixel onto other surrounding subpixels.Super-twisted nematic LCD, where the variable twist between tighter-spaced plates causes a varying double refraction birefringence, thus changing the hue.

LCD in a Texas Instruments calculator with top polarizer removed from device and placed on top, such that the top and bottom polarizers are perpendicular. As a result, the colors are inverted.

The optical effect of a TN device in the voltage-on state is far less dependent on variations in the device thickness than that in the voltage-off state. Because of this, TN displays with low information content and no backlighting are usually operated between crossed polarizers such that they appear bright with no voltage (the eye is much more sensitive to variations in the dark state than the bright state). As most of 2010-era LCDs are used in television sets, monitors and smartphones, they have high-resolution matrix arrays of pixels to display arbitrary images using backlighting with a dark background. When no image is displayed, different arrangements are used. For this purpose, TN LCDs are operated between parallel polarizers, whereas IPS LCDs feature crossed polarizers. In many applications IPS LCDs have replaced TN LCDs, particularly in smartphones. Both the liquid crystal material and the alignment layer material contain ionic compounds. If an electric field of one particular polarity is applied for a long period of time, this ionic material is attracted to the surfaces and degrades the device performance. This is avoided either by applying an alternating current or by reversing the polarity of the electric field as the device is addressed (the response of the liquid crystal layer is identical, regardless of the polarity of the applied field).

Displays for a small number of individual digits or fixed symbols (as in digital watches and pocket calculators) can be implemented with independent electrodes for each segment.alphanumeric or variable graphics displays are usually implemented with pixels arranged as a matrix consisting of electrically connected rows on one side of the LC layer and columns on the other side, which makes it possible to address each pixel at the intersections. The general method of matrix addressing consists of sequentially addressing one side of the matrix, for example by selecting the rows one-by-one and applying the picture information on the other side at the columns row-by-row. For details on the various matrix addressing schemes see passive-matrix and active-matrix addressed LCDs.

LCDs are manufactured in cleanrooms borrowing techniques from semiconductor manufacturing and using large sheets of glass whose size has increased over time. Several displays are manufactured at the same time, and then cut from the sheet of glass, also known as the mother glass or LCD glass substrate. The increase in size allows more displays or larger displays to be made, just like with increasing wafer sizes in semiconductor manufacturing. The glass sizes are as follows:

Until Gen 8, manufacturers would not agree on a single mother glass size and as a result, different manufacturers would use slightly different glass sizes for the same generation. Some manufacturers have adopted Gen 8.6 mother glass sheets which are only slightly larger than Gen 8.5, allowing for more 50 and 58 inch LCDs to be made per mother glass, specially 58 inch LCDs, in which case 6 can be produced on a Gen 8.6 mother glass vs only 3 on a Gen 8.5 mother glass, significantly reducing waste.AGC Inc., Corning Inc., and Nippon Electric Glass.

In 1922, Georges Friedel described the structure and properties of liquid crystals and classified them in three types (nematics, smectics and cholesterics). In 1927, Vsevolod Frederiks devised the electrically switched light valve, called the Fréedericksz transition, the essential effect of all LCD technology. In 1936, the Marconi Wireless Telegraph company patented the first practical application of the technology, "The Liquid Crystal Light Valve". In 1962, the first major English language publication Molecular Structure and Properties of Liquid Crystals was published by Dr. George W. Gray.RCA found that liquid crystals had some interesting electro-optic characteristics and he realized an electro-optical effect by generating stripe-patterns in a thin layer of liquid crystal material by the application of a voltage. This effect is based on an electro-hydrodynamic instability forming what are now called "Williams domains" inside the liquid crystal.

In the late 1960s, pioneering work on liquid crystals was undertaken by the UK"s Royal Radar Establishment at Malvern, England. The team at RRE supported ongoing work by George William Gray and his team at the University of Hull who ultimately discovered the cyanobiphenyl liquid crystals, which had correct stability and temperature properties for application in LCDs.

The idea of a TFT-based liquid-crystal display (LCD) was conceived by Bernard Lechner of RCA Laboratories in 1968.dynamic scattering mode (DSM) LCD that used standard discrete MOSFETs.

On December 4, 1970, the twisted nematic field effect (TN) in liquid crystals was filed for patent by Hoffmann-LaRoche in Switzerland, (Swiss patent No. 532 261) with Wolfgang Helfrich and Martin Schadt (then working for the Central Research Laboratories) listed as inventors.Brown, Boveri & Cie, its joint venture partner at that time, which produced TN displays for wristwatches and other applications during the 1970s for the international markets including the Japanese electronics industry, which soon produced the first digital quartz wristwatches with TN-LCDs and numerous other products. James Fergason, while working with Sardari Arora and Alfred Saupe at Kent State University Liquid Crystal Institute, filed an identical patent in the United States on April 22, 1971.ILIXCO (now LXD Incorporated), produced LCDs based on the TN-effect, which soon superseded the poor-quality DSM types due to improvements of lower operating voltages and lower power consumption. Tetsuro Hama and Izuhiko Nishimura of Seiko received a US patent dated February 1971, for an electronic wristwatch incorporating a TN-LCD.

In 1972, the concept of the active-matrix thin-film transistor (TFT) liquid-crystal display panel was prototyped in the United States by T. Peter Brody"s team at Westinghouse, in Pittsburgh, Pennsylvania.Westinghouse Research Laboratories demonstrated the first thin-film-transistor liquid-crystal display (TFT LCD).high-resolution and high-quality electronic visual display devices use TFT-based active matrix displays.active-matrix liquid-crystal display (AM LCD) in 1974, and then Brody coined the term "active matrix" in 1975.

In 1972 North American Rockwell Microelectronics Corp introduced the use of DSM LCDs for calculators for marketing by Lloyds Electronics Inc, though these required an internal light source for illumination.Sharp Corporation followed with DSM LCDs for pocket-sized calculators in 1973Seiko and its first 6-digit TN-LCD quartz wristwatch, and Casio"s "Casiotron". Color LCDs based on Guest-Host interaction were invented by a team at RCA in 1968.TFT LCDs similar to the prototypes developed by a Westinghouse team in 1972 were patented in 1976 by a team at Sharp consisting of Fumiaki Funada, Masataka Matsuura, and Tomio Wada,

In 1983, researchers at Brown, Boveri & Cie (BBC) Research Center, Switzerland, invented the passive matrix-addressed LCDs. H. Amstutz et al. were listed as inventors in the corresponding patent applications filed in Switzerland on July 7, 1983, and October 28, 1983. Patents were granted in Switzerland CH 665491, Europe EP 0131216,

The first color LCD televisions were developed as handheld televisions in Japan. In 1980, Hattori Seiko"s R&D group began development on color LCD pocket televisions.Seiko Epson released the first LCD television, the Epson TV Watch, a wristwatch equipped with a small active-matrix LCD television.dot matrix TN-LCD in 1983.Citizen Watch,TFT LCD.computer monitors and LCD televisions.3LCD projection technology in the 1980s, and licensed it for use in projectors in 1988.compact, full-color LCD projector.

In 1990, under different titles, inventors conceived electro optical effects as alternatives to twisted nematic field effect LCDs (TN- and STN- LCDs). One approach was to use interdigital electrodes on one glass substrate only to produce an electric field essentially parallel to the glass substrates.Germany by Guenter Baur et al. and patented in various countries.Hitachi work out various practical details of the IPS technology to interconnect the thin-film transistor array as a matrix and to avoid undesirable stray fields in between pixels.

Hitachi also improved the viewing angle dependence further by optimizing the shape of the electrodes (Super IPS). NEC and Hitachi become early manufacturers of active-matrix addressed LCDs based on the IPS technology. This is a milestone for implementing large-screen LCDs having acceptable visual performance for flat-panel computer monitors and television screens. In 1996, Samsung developed the optical patterning technique that enables multi-domain LCD. Multi-domain and In Plane Switching subsequently remain the dominant LCD designs through 2006.South Korea and Taiwan,

In 2007 the image quality of LCD televisions surpassed the image quality of cathode-ray-tube-based (CRT) TVs.LCD TVs were projected to account 50% of the 200 million TVs to be shipped globally in 2006, according to Displaybank.Toshiba announced 2560 × 1600 pixels on a 6.1-inch (155 mm) LCD panel, suitable for use in a tablet computer,

In 2016, Panasonic developed IPS LCDs with a contrast ratio of 1,000,000:1, rivaling OLEDs. This technology was later put into mass production as dual layer, dual panel or LMCL (Light Modulating Cell Layer) LCDs. The technology uses 2 liquid crystal layers instead of one, and may be used along with a mini-LED backlight and quantum dot sheets.

Since LCDs produce no light of their own, they require external light to produce a visible image.backlight. Active-matrix LCDs are almost always backlit.Transflective LCDs combine the features of a backlit transmissive display and a reflective display.

CCFL: The LCD panel is lit either by two cold cathode fluorescent lamps placed at opposite edges of the display or an array of parallel CCFLs beh

Ms.Josey

Ms.Josey

Ms.Josey

Ms.Josey