repair lines on lcd screen supplier

Laser machine, the purpose of repair is further hope to be able to correct the defective part, make originally filtered to throw away waste products, to patch the acceptable products. At the current acceptable product standards, the first is absolutely no color line defect; Second, at present many products have highlight the "no spot guarantees", therefore cannot have a pixel is always shine bright spot, but it can be a way to accept a few dark spots. So the object of laser repairing, mainly on color line defect and bright spot.

Welding: in a second metal overlapping across, use the appropriate energy and wavelength of laser, melt the metal parts and welding together, connecting the two electrode which was not connected (and to realize disconnection by cut off ) to realize repairing.

LCD screen laser repair machine (hereinafter referred to as laser machine), in the LCD screen maintenance industry is at high-end technology of repairing, is the most high-end technology. In the LCD screen repair area except COF losing welding, TAB burnt (the fault with can be repaired by bonding machine) other such as bright line, half line, point, line, coarse, multi-line can use laser machine to repair. Laser machine in the LCD screen repair process has high efficiency, high repair rate, low cost (the same fault in the laser machine does not need to replace parts, not only save cost but also improve repair rate not influenced by lack accessories) etc, and widely used by large production factory, brand after-sales and maintenance of the company as a main screen equipment.

Shenzhen Wanbo Hi-tech Co Ltd is specializing in manufacturing TAB COF bonding machine, ACF bonding machine, LCD screen laser repair machine, LCD tv repair machine, lcd display lines laser repair machine etc. We have R&D team based in Shenzhen. Our goal is to build perfect world.

Try using lcd tv screen repair machine found on Alibaba.com to make many types of production jobs faster and easier. Each model can be filled with different types of liquid and quickly dispensed into containers. Use lcd tv screen repair machine to fill paint cans with speed and precision. Other compatible fluids include resin or glue, making such devices suitable for manufacturing all kinds of helpful products.

All lcd tv screen repair machine are built to be easy to operate, reducing labor and training times needed. Some versions can pour food-grade liquids such as beer or milk into bottles for future sealing. Most units work automatically so workers can program them and stay back as they work on their own. When installed on a factory floor, they offer greater efficiency to help save time and costs.

Shop for lcd tv screen repair machine at Alibaba.com to find many helpful suppliers with a wide range of options that can be ordered. Choose just the right size to fit the intended workspace. Pick a wattage level that promises good speed and power without using too much electricity and driving up costs. Certain designs can dispense products in the form of powder or granules into nearby containers. Use these to package particular powdered food and pharmaceutical ingredients.

Search for lcd tv screen repair machine on Alibaba.com and enjoy lower costs when working with various liquids or powders. Whether for use in food manufacturing or building materials, there are plenty of options to browse. Find a satisfactory brand that will improve efficiency for better overall quality in each final product.

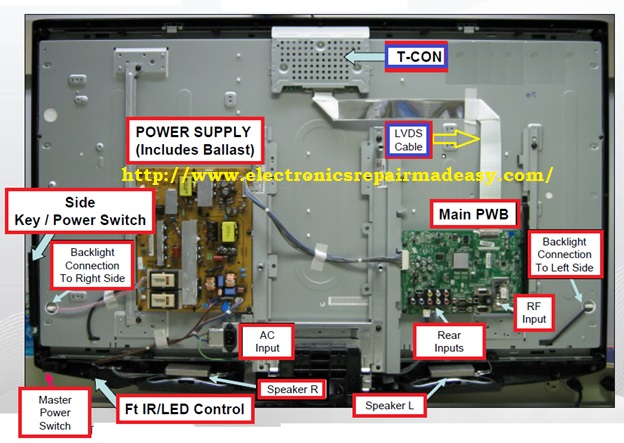

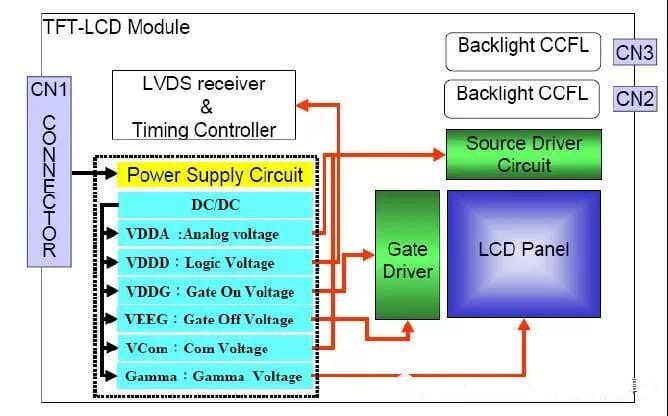

Vin: PWB input voltage (12V)VDD: ASIC, source IC, gate IC driving power (3.3v)VGH: TFT component switching voltage (~30V)VGL: TFT component turn-off voltage (~ -6v)VAA: step control voltage (~17V)VCOM: liquid crystal reversal reference voltage (~7V)

3. #If all the above is OK, measure the LVDS voltage value. Under normal conditions, the LVDS signal’s RX+/ RX-voltage value is about 1.2v, and RX+/ RX-difference value is about 200mV. At the same time, the resistance of the LVDS signal to ground and the resistance between the LVDS signal pairs can be measured (100 ohms). If there is an exception to these values, try replacing the ASIC.

1. #Confirm whether the COF on side X is hot compared with the normal temperature, whether there is fracture or wear crack, and whether the COF is burnt.

2. #Confirm whether the VAA is normal (normally about 17V). If abnormal, disconnect the RP32 to confirm whether it is caused by DC/DC loop or X-side COF: disconnect RP32, if the VAA is normal, the COF is bad, CO must be changed; COF can be Disconnect one by one to determine which NG disconnects RP32, VAA NG, try to change UP1; at the same time, confirm whether the continuity of the surrounding triode is OK.

4. #Determine whether the gate IC is OK. There is a signal test point on the back of COG-IC, and the green paint can be scraped for measurement confirmation; If there is a gate IC problem, which IC fault can be confirmed. The confirmation of gate IC fault is only for analysis when you are interested, and this method is not recommended.

3. #Confirm whether the RSDS value is correct, normal RSDS is about 1.2v, and the signal difference is about 200mV; At the same time, we can confirm the resistance between RSDS signal (normal 100 or 50 ohms) and RSDS resistance to ground. If the voltage is NG, check if the ASIC and X-COF are hot.

1. #Adjust the VR knob to see whether it can be adjusted and whether the screen performance changes. At the same time, confirm the VCOM value (about 7v), if NG, replace the VR knob.

2. #Confirm VGH/VGL voltage (about 30V VGH and -6v VGL), and confirm whether it is DC/DC loop NG or COF IC NG; The corresponding resistance of disconnected VGH and VGL can determine whether it is a DC/DC problem or a COF-IC problem. If it is DC/DC NG, try to replace UP1 or confirm whether the corresponding transistor is OK.

3. #Confirm whether the gate IC is OK. There is a signal test point on the back of COG IC, which can scrape the green paint for measurement confirmation; Or cut COF halfway from G3. If there is a gate-ic problem, which IC fault can be confirmed.

2. #Confirm whether there is 12V input, if not, confirm whether the connector is OK, and confirm the resistance value of 12V voltage to earth; If conn. NG, change conn.; If 12V is short-circuited to the ground, disconnect FP1 to determine the short-circuiting circuit.

3. #Confirm whether FP1 is open; if open, replaces fuse. If the 12V accessory of this model has a reverse diode, confirm the continuity of the diode and check whether it is burnt.

B. Confirm VAA resistance to ground at VAA test point of R plate (A short circuit usually occurs), disconnect the corresponding capacitance of the following 3 COF, and confirm VAA resistance to the ground again. If OK, replace the capacitor, if NG, replace COF. If VAA is still NG, confirm DC/DC loop as all models.

6. #Disconnect RP32 to confirm VAA, if NG, try to change the PWM IC (in general, it will be good), if still NG, try to change the gamma-ic or corresponding to the VAA several large capacitances (in general, it is rare, this situation is generally accompanied by VAA to the ground short circuit).

3. #Shaking module, if vertical lines disappear or reappear, then it can be judged that the possible cause is COF pin broken, and the crease should be found under the OM microscope.

4. #Press the LCD glass side of the panel, if the vertical lines disappear or reappear, it can be judged that the cause of poor contact, OM checking should be able to find the poor contact.

5. #If there is no display change in pressing, confirm whether ITO is damaged under the OM microscope, or pin signal waveform corresponding to needle COF.

Depending on the backlight structure, there will be different results. The failure of the performance may be a point-off, or it may be a backlight with a dark band.

3. #Disassemble the backlight, confirm whether there is a short circuit with broken skin on the lamp strip, whether the plug of the lamp strip is fully integrated with the socket, whether the pin is aslant/off, whether the connector is off, and whether the LED bead is black and injured.

4. #The fault of the product is basically caused by the above reasons. If the appearance is fault-free, the lamp bar can be crossed to confirm whether the phenomenon follows the lamp bar, or the voltage of the lamp bar and the conduction condition between the lamp beads can be measured.

The above is the full text of LCD screen failure repair guide, we hope it is helpful to you. If you need to buy LCD and find a reliable LCD supplier, we suggest you to read our other great blog – How to find a reliable LCD supplier.

Founded in 2014, VISLCD is a professional LCD supplier. We provide LCD modules, touch LCD and customized LCD in various sizes with stable quality and competitive price. Welcome to contact us for any LCD demand, thank you.

Vertical lines appearing on LCD screen is very common. Whether the screen belongs to a laptop computer or desktop PC, mobile phone, or even a television, the fault is usually due to the ribbon cable and its connections.

A faulty ribbon cable can cause all sorts of havoc manifesting in bright vertical lines. Sometimes they can be coloured lines such as blue, green, grey, black, and red. The lines can appear thick or thin and on just one-half of the screen. Sometimes the fault will manifest as two vertical white lines. You can even get horizontal lines as well.

If you have lines appearing on the LCD screen, then the first simple thing to check is the seating of the ribbon cable that connects the display panel to the motherboard. Most of the time, the fault is with the poor connection made by the ribbon cable.

One of the most common problems with ribbon cables is oxidation of the contacts. It can happen either on the ribbon cable contacts or on the socket contacts. Manufacturers often use a mix of gold and copper for the electrical contacts, however, if they have not used enough gold, then oxidation occurs over time. This results in a working television or laptop screen suddenly exhibiting lines.

The solution is of course very simple, one needs to clean the contacts with a high quality electrical contact cleaner. It is best to clean the socket and the ribbon cable contacts, which will solve the fault.

One of the most common faults with laptops is that the ribbon cable connecting to the LCD panel cracks. It typically fails near the hinge area due to flexing in that region, and over time, some of the tracks on the plastic cable breaks. I have seen these types of faults on many laptops. It does not matter whether it is a Lenovo, IBM, Acer, Samsung, Toshiba, or even a MacBook Pro!

It is also possible to have a dislodged cable, which typically occurs on mishandled laptops. The plastic clip that holds the ribbon cable is very small and delicate and if the laptop receives an impact, the ribbon cable can dislodge.

This type of fault can also occur on LCD televisions; however, it tends to be on new units, where the box has received an impact during transit from the factory.

In this situation, the repair can be easy, as the cable will simply require reseating. However, there is still the labour time to consider as it can take the best part of the day to gain access to the ribbon cable.

If the laptop has a socket that provides a VGA output, then the first thing to do is to hook up another good monitor to it to see if the picture is good. If the picture on another monitor is good, then you can be sure that the video chipset and the motherboard electronics are operating properly, and it is a connection issue.

I used this same method of troubleshooting to repair an LCD television recently. Modern televisions have a video out socket, and if you feed the signal from that to another monitor, you can check for the quality of the video display. If the external monitor does not show lines, then you know for sure that it is a connection issue. Hence, this method of troubleshooting works for some of the modern televisions as well.

When half of the vertical interlace is missing showing a picture that is broken up vertically, the display appears with vertical lines. This is usually due to a cracked ribbon cable.

Generally, for laptops a replacement cable is always required due to it breaking near the hinge. I had this Dell laptop and replacing the LCD ribbon cable solved the problem. I managed to buy a replacement from Dell for a modest price £6.00. The laptop was just outside the warranty period; however, they still shipped out the cable free of charge. This is the reason why people buy Dell. In my experience Dell tend to stand by their customers and products, and their prices for replacement parts are realistic and down to earth.

Replacing a laptop ribbon cable is simple, and the top-half of the laptop, and keyboard needs removing to gain access to the socket on the motherboard side. As you can see, it flexes near the hinge area and breaks where the ribbon cable wraps around the hinge.

If the picture responds to input but displays a messy image, such as jumbled multicolored squares, the AV (audio visual) board may be damaged. This is usually a rectangular circuit board located near the audio and visual cables. Replace obviously damaged parts using a soldering iron, or order a replacement board and carefully install it to the same screws and ribbon cables.

The main control buttons may be faulty. Clean them with a metal cleaner, or jostle to attach a loose connection. If necessary, locate the circuit board they are attached to and re-solder any broken connections.

Check input cables for damage, or try other cables of the same type. If necessary, inspect the circuit board they are attached to and re-solder damaged connections.

This website is using a security service to protect itself from online attacks. The action you just performed triggered the security solution. There are several actions that could trigger this block including submitting a certain word or phrase, a SQL command or malformed data.

Thank you but unfortunately, none of these fix the issue. I"ve disconnected and reconnected the display about 15 times, have cleaned both sets of pins, and have verified that no pins are broken on each of the connectors. I did replace the battery of this phone but have not touched the motherboard other than using a spudger to remove the display, battery, and force sensors (I don"t know a better word for them); taking off the midframe I see no visible damage to the motherboard under a magnifying glass. I have contacted ifixit and have stated the replacement process. Thank you for your suggestions.

I had the same problem when removing and installing an iPhone 6 plus battery. After connecting all four flex cables to the mother board the phone either would not boot up or there were vertical lines on the display. Basics, basics, basics……unplug battery connector. Unplug all four flex cable connectors. Re-attach all four flex cable connectors, then connect battery flex cable. After installing both metal shields and closing the phone it booted up properly and worked just like new. Viola!

Most of the LCD users face Diagonal, Jagged & both /vertical horizontal lines on LCD, usually these lines demonstrate panel damage. Sometime single line ( horizontally / vertica...

Samsung UA32J400ARLive Repair Training for Lines on Display. For New Batch dates & Attain Training Call - 9220079945Visit: https://www.osciallateinstitute.co...

Whether you stepped on it, leaned on it, dropped it, closed it on your keys, or subjected it to extreme temperatures, one thing’s for sure: right now you can barely see anything on your laptop screen!

Some other issues people may have with their screens are vertical lines or bars; these may be white, a bright color, or solid black, as below, and commonly result from a failure of tiny electrical connections within the screen’s body.

In all these situations, the screen itself has been ruined – the glass cannot be repaired, and humans are incapable of fixing the tiny connections that have broken.

But all is not lost!Replacements for PC laptop LCDs are usually fairly inexpensive – around $150-200 in most cases. We can find the perfect matching part for your screen and install it in short order (our primary vendor is in Apex and can usually get screens to us the next day), and all will be as good as new!

We also can replace Apple MacBook displays! We source entire display assemblies from a vendor in Virginia which means you can get your Mac screen replaced in as little as 24 hours! Try getting service that fast anywhere else!

ELSIN provides warranty and post-warranty repairs of LCD screens for service organizations, LCD panel makers, manufacturers and distributors of monitors, laptops, TVs and individual customers.

The advantageous location of ELSIN in the center of Europe in Pilsen city in Czech Republic enables fast service to customers across Europe and especially in the regions of the Czech Republic and Slovakia.

As the only company in the Czech Republic we carry out repairs of LCD panels including replacement of polarization film and repair of defective lines / blocks for sizes of 10 ” – 65 ” with a capacity of over 2000 pieces per month.

Industrial repair utilizes all facets of AGDisplays’ capabilities. We repair most aspects of LCD technologies so that our customers do not have to replace whole units for minor repairs. AGDisplays are experts in LCD panels and LCD technology. At our 84,000 square foot facility, AGDisplays performs both low-volume and high-volume production levels; we maintain high tech, state of the art equipment to perform precise procedures. With our high level of expertise, our teams provide technical skills and lend our creative problem-solving abilities to give our customers LCD displays that meet the demanding needs of your industries.

With over 40+ years of experience, we train our individuals through a specific curriculum in which we evaluate regularly. Our team is ready to deliver high-performance display repairs to our customers. Trained personnel are evaluated prior to employment and during employment on a regular basis to determine their workmanship quality exceeds the standards set by AGDisplays. We also provide repair warranty services for panels that are no longer under OEM warranty.

AGDisplays is focused on refurbishing and repairing your LCDs; we specialize in providing cost-effective alternatives to LCD replacements. We may use recycled LCD parts, which are always 100% tested. Using refurbished parts gives the customer the ability to keep cost low. Using AGDisplays’ repair/refurbish service guarantees your products are using quality and inspected components.

AGDisplays most often uses brand new, quality LCD components when repairing and refurbishing your display product. Our company values quality components, that’s why strictly maintain our databases, and follow supply chain processes. We have an International Procurement Office in China that are constantly verifying vendors with whom we maintain current business practices.

Our LCD experts prepare custom display layouts including unit dimensions and segment content to redesign your panel for optimal functionality. Inspections on deliverables are evaluated to ensure AGDisplays is only working with quality materials. During manufacturing, various product inspections take place such as performance measures. For quality assurance measures, we perform a full diagnostic analysis for each repaired unit that can include the following:

Our quality resources become available to you at an affordable price. We have a direct relationship with LCD distributors, providing our customers with the same resources.

LCD repolarization is the process in which a person or company will remove an existing polarized film from an LCD stack up. Polarizing films are used in an LCD stack up to increase readability and clarity created on the LCD. The films polarize light to create a defined direction. LCDs may use various types and combinations of films; not all of these films are considered polarizing films. In the LCD Industry typical laminations can consist of optical polarizer laminations to the LCD glass surface or perhaps an anti-reflective film laminated to the top polarizer. AGDisplays employs three different types of polarizers: reflective, transflective or transmissive. An LCD stack configuration is determined by the lighting conditions your LCD will operate in.

Reflective polarizers are applied to the bottom layer of the LCD glass and reflect 100% of the ambient light that enters through the top layer of the glass. Transmissive polarizers allow the light from a backlight source to pass through the bottom and top layers, towards the user. In this instance, the backlight must be on for the display to be readable. Benefits of this polarizer are increased display brightness, reduced driving current and extended half-life of the backlight. Transflective polarizers allow display readability with the LCD backlight on or off. This polarizer reflects some ambient light passing through the front glass; at the same time, it uses the backlight source to pass through the glass.

The AGDisplays experts perform LCD repolarization in one of the multiple Class 1000 clean rooms that are located in our facility. Using a clean room is important because it minimizes the risk of contamination find its way into the LCD as an AGDisplays technician is performing a repolarization on an LCD display.

Depending on the type of polarization used in the particular LCD build, the film may also increase display contrast and readability, create sharper and clearer image quality, provide deeper colors, increase viewing angles and more.

LCDs can be repolarized to return your scratched display to original form, and additional lamination services such as anti-reflective and anti-microbial properties, EMI protection, and LCD protection. With our lamination enhancements, you can be assured that your LCD is protected from surface scratches, acid-etching, and other particle contaminants. Replacing a polarized film will not repair damage to a broken LCD. AGDisplays can replace damaged LCD screens that cannot be repaired by repolarization.

An ESD Flooring system is used to discharge electrical static charge. The discharge of the electrical static helps reduce or eliminate the possibility of damaging sensitive electronic components during the manufacturing process. Even the smallest ESD discharge may have an adverse effect on electronic components. Using a ESD flooring system limits component failure as part of AGDisplays’ quality control processes.

An ESD-control floor coating has conductive particles within it which allows the coating to be electrically active; this allows electrical current to travel through it—permitting the electrical charge to travel from one point to another. This flooring works together with ESD protection devices like footwear, garments, and grounding straps, to minimize body voltage generation (BVG) and to control grounded discharge.

Cleanrooms are used across any industry where small contamination particles would negatively affect product manufacturing processes. A cleanroom is a controlled environment that is designed to keep a low level of air pollutants such as dust, airborne microbes, chemical vapors and more. Other parameters that are controlled include temperature, humidity and pressure. An air filter, called the High Efficiency Particulate Air (HEPA) filter, is designed to trap particles that are 0.3 micron and larger from getting into the controlled environment. In other more stringent requirements, clean rooms may use an Ultra Low Particulate Air (ULPA) filter. Employees who work in cleanrooms train in contamination control theory. Employees enter and exit cleanrooms through airlocks and/or gowning rooms. Employees are required to wear gowns made of material designed to trap contaminants that are naturally generated by the skin and body.

TV repair costs between $60 and $350 with most spending $207 on average for LCD, LED, plasma, and 4K TVs; costs are higher if repairing older DLP, projection, and HD TVs. TV problems like display issues, powering-on problems, or sound issues can be fixed. Pickup and delivery fees may apply.

The cost to repair a TV will include the price of parts and labor costs, plus other associated costs. Additional charges include a trip fee for a technician to come to your home, a fee to transport your TV to and from a repair shop, and the diagnostic fee to determine what needs to be replaced.

The cost to repair a TV screen can be significantly more than the cost of purchasing a new TV. For this reason, replacing or repairing a broken TV screen is not considered feasible.

For example, the price of a new Samsung 40-inch LED TV is about $400, yet the cost of a replacement display panel for this model is about $380. This price is only for the replacement part and does not cover diagnostic costs, labor costs, or travel or shipping fees.

Broken TV screen repair is not a service offered by most TV or electronics repair companies. For example, BestBuy"s 90-day warranty, does not list broken TV screen repair as one of the problems they service.

Unless you are trying to fix a TV from the ’80s or earlier, cracked TV screen repair is not feasible; the entire display panel must be replaced instead. The cost of a replacement TV display panel is more than the cost of buying a new TV, and that’s before labor and other service costs.

The cost of TV screen replacement is generally the same as or more than the cost of buying a new TV. Therefore, replacing a broken or malfunctioning TV screen is not considered a viable option. If the TV is under the manufacturer’s warranty, the manufacturer may replace the entire unit.

TV manufacturers do keep replacement TV screen panels on hand to support products under warranty in case the screen malfunctions, due to manufacturer defect.

If you still want to replace a damaged or malfunctioning TV screen, your best option is to find a used replacement panel or a broken TV of the same model on which the screen is still functional. You might find one on eBay, and you can hire a technician to change out the panel.

The cost of a used replacement TV panel ranges from $50 to $350 or more, excluding shipping, depending on the brand and size. Note that the chances of finding exactly the part you need in excellent condition are slim, and the cost excludes the cost of installation by a repair shop.

Whether your TV is LCD, LED, plasma screen, or 4K (Ultra HD), the cost to fix common problems ranges from $60 to $350, depending on the repair type and the brand of TV being repaired.

These repair problems could have more than one possible source, so a technician should take time to narrow down the exact problem. TVs are repaired by replacing faulty components.

TV motherboard replacement costs between $200 and $350, including parts and labor, or about $275 on average. Motherboard replacement parts range from $35 to $199and labor costs from $60 to $125.

A TV inverter repair costs $104 to $171, including parts and labor, with an average cost of $138 for a TV with one inverter board or $178 for two. Parts range from $7 to $74, and the average labor cost for TV inverter repair is $97 per hour.

The function of an inverter board in a TV is to power the backlight of the screen. The inverter board requires a few hundred volts of power. If the inverter board goes bad, this would cause the TV to power on and have sound but no picture.

When an inverter component goes bad, it is usually replaced rather than repaired. In some cases, the capacitors on a converter board fail, and a technician can fix it by replacing the capacitors rather than replacing the entire inverter component. However, if an entire inverter board replacement is not available for the model of TV being repaired, replacing the capacitors may be the only option for TV inverter repair.

A flat-screen TV bulb replacement costs between $60 to $115, with most homeowners spending $84 for parts and labor. The price for replacement bulbs ranges from $18.50 to $80.

If an older model LCD TV or projection TV powers on and has sound but no picture, this may be due to lamp burnout, which is both common and expected. In this case, replacing the bulb will fix the problem. An experienced technician should be able to replace the bulb quickly and easily.

TV backlight repair costs $100 to $122, including replacement parts and labor, at a repair shop. In-house repair costs are more due to trip fees. The price of backlight replacement parts averages around $2.50for each LED and between $20 and $25 for each CCFL strip.

If the CCFL strips for your TV are no longer available, a technician can convert the backlight from CCFL to LED using the same number of backlighting strips. Each strip of LEDs costs between $12 and $30.

A new inverter may be needed to power the LEDs, costing between $7 and $74before labor, or an average of $40. In some cases, a repair shop can convert a CCFL backlight to LED without installing a new inverter.

Backlight failure in a TV may also be due to failure of the power inverter that supplies power to the backlight. In rare cases, both the inverter and the lighting components fail.

Repairing a TV power supply board costs $23 to $234 for parts alone. Completely replacing the power supply board costs $250 for parts and labor. If one capacitor has failed, the cost for replacement capacitors is low. However, it’s more cost-effective for the technician to replace the entire board rather than spend time trying to diagnose and replace faulty capacitors one by one.

The cost to fix an HDMI port on a TV is $93 to $302. In some cases, the input circuit board that the HDMI port connects to may be damaged and need to be replaced. The cost for replacing this input circuit board, including labor, ranges from $200 to $350.

TV capacitor repair costs $60 to $129, including parts and labor. The cost for the replacement part ranges from $0.06 to $14, with the labor portion ranging from $60 to $125 per hour. TV capacitors protect the circuit from getting too much power, filter signals, and facilitate changing channels.

It is not possible to fix a TV capacitor when it fails; it needs replacing. If your TV stops working while you are using it and you notice a smell similar to ammonia or bleach, this is a sign that a capacitor has blown. However, some capacitors do not make any noticeable smell when they blow.

Flat screen replacement glass is not available. The only option for flat-screen TV glass repair is to try optical glass glue, which costs $1.70 for a 5-ml. tube. This may be an option for TV glass repair if the crack is only a few inches or less. TV panels are built as one unit at the factory, with the glass adhered to the display panel.

In-home CRT repair ranges from $199 to $249. The cost of repairing a CRT picture tube ranges from $199 for a TV that is 27 inches or smaller to $249 for a TV that is 28 inches or larger.

A TV fuse repair costs between $61 and $136, with most spending $99 on average. The cost of the replacement fuse itself is $1.50 to $11, while labor ranges from $60 to $125 per hour. Additional fees may apply.

LCD flat-panel repair is not considered cost-effective. If the glass is cracked or the display is physically damaged, it is cheaper to replace the entire TV than to repair or replace the display panel.

Estimating TV repairs costs by brand is not something TV repair shops offer, however, there are general prices by type. When looking for specific repair costs for your TV, you’ll find them in the common repairs price list above. Pricing applies to brands such as Samsung, LG, Sanyo, TCL, Insignia, HiSense, Sony, Toshiba, Pioneer, and Vizio.

More popular TVs are usually less expensive to repair because repair shops order replacement parts for them in bulk, which allows them to buy those parts at a lower cost.

The cost of flat-screen TV repair ranges from $42 to $359. You cannot fix a broken screen, but the price of a new flat-panel TV starts from around $249 for a 1080-mp (non-4K) LED TV from LG to as much as $14,999 for an 85-inch 8K LED TV from Samsung. A TV referred to as a “flat TV” or “flat-screen” TV might be any of the following:

LCD TV repair typically costs $60 to $85 for diagnostics testing, and $200 to $300 to perform repairs. LCD TVs use backlighting, which may fail. Newer LCD TVs use LED strips for backlighting. Older ones might use CCFL. If CCFL backlighting fails, a technician can replace it with LED backlighting.

An LED TV is just an LCD TV that uses LED backlighting, which all newer models do (older models use CCFL backlighting). The cost to replace one LED backlighting strip ranges from $100 to $122, including parts and labor.

The cost to replace the motherboard, inverter, or LED"s in a 4K TV ranges from $100 to $275 or more depending on the brand and model. The cost for screen repair for a 4K TV is irrelevant because it cannot be fixed or replaced at a cost that is lower than the cost of a new 4K TV.

Digital light processing (DLP) TVs are also known as projection TVs. DLP big screens have not been made since 2012, and DLP TV repair is usually not worth the cost except for a lamp burnout, in which the bulb can be replaced. The cost to replace bulbs ranges from $60 to $115.

TV repair shops charge an average $60 to $125 per hour, or a flat rate of $50 to $250, which includes the diagnostic fee. Additional costs after that depend on the repairs needed and the brand and type of TV. However, most stores will have a minimum charge of about $90.

Best Buy TV repair is provided through the Geek Squad TV & home theater service. Geek Squad TV repair starts at a base cost of $100 for a diagnostic fee. TV repair is covered under Best Buy’s protection plan, which costs $280 per year when you purchase a TV from Best Buy at the time of purchase, or within the return period printed on your receipt.

The brand and model of your TV will dictate the final repair cost, with more expensive brands and larger TVs costing more to repair. Consider the remaining lifespan of the TV before paying for repairs. You can now buy bigger TVs with more features and better displays for a TV that won’t need repairs for a while and probably comes with a warranty.

The cost of labor to fix a TV ranges from $60 to $125 per hour, or a flat rate of $90 to $299. If the work is performed in your home, the cost ranges from $25 to $125 per hour plus the trip fee. Most TV repairs take 1 to 3 hours if the repair specialist has the parts already.

If you live in a remote area, you may need to ship your TV to a repair facility, costing $99 to $175. Be sure to choose a delivery service that allows you to track the shipment and confirm delivery. When sending your TV into a service center for repair, you will be contacted regarding the associated costs and asked to process payment before the repair is completed, which usually takes two weeks including the shipping time.

Many TV repair shops charge a diagnostic fee that ranges from $20 to $60, depending on whether it is done in your home or the repair shop. Some shops charge a flat fee that ranges from $50 to $250that covers both the diagnostic cost and labor cost. In many cases, the initial diagnostic fee will be applied to the repair cost if you have the shop do the repair.

The more expensive a TV is, the more sense it makes to purchase an additional warranty to defray the potential for costly repairs. Best Buy offers an $89 five-year extended warranty for entry-level TVs. On larger TVs such as the 85-inch Samsung QLED 8K TV, which costs $14,998, the five-year warranty from Geek Squad costs an additional $1,699—11.33% of the cost of the TV.

With modern TVs, repair entails component replacement or replacement of capacitors, for which high levels of certification are not necessary. Generally, TV repair shops will let you know if their employees have certification.

First, check that the connecting cable is securely in the socket on both ends. If that doesn’t work, try substituting another data cable if you have one, or test it with a replacement cable.

Satellite dish repair is either covered by your satellite service company or the cost for a technician to fix it ranges from $80 to $150. Repairs may also be billed at an hourly rate of $50 to $65.

The cost of mounting a TV ranges from $149 to $199, with most people paying around $174 for the labor. The mounting hardware costs between $20 and $500 depending on the brand of mounting hardware and the size of your TV.

There are various ways you might be able to save money on TV repair. These include transporting your TV to a repair shop, using a shop that charges in 15- or 30-minute increments, diagnosing the problem yourself, using salvaged parts, and doing the repair work on your own.

You can also consider the cost of TV repair when purchasing a new TV. More popular TV models are less expensive to repair because repair shops buy parts for the most common TVs in bulk and are therefore able to get them at lower prices.

Plug - If the TV is not powering on and no status LEDs are lighting up, start by plugging the TV into a different outlet. If the TV is too challenging to move, you can run an extension cord from another nearby outlet.

Circuit breaker - Check the circuit breaker for the power outlet that the TV plugs into. You can check the breakers by opening the door to your breaker panel and looking for circuit breakers that are in the OFF position.

Remote control - If the TV is not powering on with the remote control, you should try replacing the batteries. For remote controls with a status LED light, there could be enough power to light the LED but not enough power to send a signal to your TV.

Inverter is bad -It is possible that the inverter, which powers the backlights, has gone bad and needs to be replaced. It’s also possible that one or more capacitors on the inverter have gone bad, in which case a technician may be able to replace capacitors more cheaply than replacing the entire inverter.

Lamp burnout -In a projection TV or older LCD TV, no picture may be caused by lamp burnout. In this case, a technician can replace the bulb quickly and easily.

If the picture is displaying but there are problems such as vertical lines, a double picture, or a white display, this could indicate a faulty motherboard or mainboard.

Plug headphones into the headphone jack. If sound comes from the headphones plugged into the headphone jack, this indicates a problem with the TV speakers.

The primary way to save money on TV repair would be to perform the work yourself. This may require you to purchase and get familiar with various tools such as soldering tools, and methods for replacing a capacitor or some other component.

The right parts - It can be complicated to determine which component of a TV is failing and causing the TV not to work correctly. If you buy a replacement part and perform the repair yourself, the TV may still not work, either because you replaced the wrong part, the part was old and not working properly to begin with, or you did not perform the work correctly. Buying multiple replacement parts can become costly.

Lack of experience – you might cause more damage to the TV due to your lack of knowledge and experience, and you might also end up causing a fire with your soldering iron or being electrocuted.

The cost of repairing a TV could be as much as $500 if multiple repairs are needed. Consumer Reports recommends not to spend more than 50% of the cost of a new TV repairing the old one.

If you have a newer TV that cost thousands of dollars, having it repaired would most likely be cost-effective. If the TV only cost a few hundred dollars to begin with, replacing the TV is more likely to be the best option.

Not included in these prices from Best Buy are 1080P screens, which range from $249 to $279 for 43-inch TVs from brands like Samsung, Sony, and LG. On the upper end, Sony and Samsung both have 95-inch 8K LED TVs for $69,999.

In most cases, a flat-screen TV can be fixed. The exception is a physically damaged display panel or screen. Most other issues including failing speakers, backlights, or power supply. Burned out fuses and damaged input ports can also be repaired.

If the screen is not physically damaged but is not showing a picture or is displaying “snow’” or vertical or horizontal lines, a technician can repair the TV by replacing failed components. If the screen is physically damaged, it cannot be repaired.

You cannot replace a broken flat-screen display. New TVs costs anywhere from $249 for a 1080P (non 4K) LED TV from LG to as much as $14,999 for an 85” 8K LED TV from Samsung.

If you live in a remote area, you may need to ship your TV to a repair facility, costing $99 to $175. Be sure to choose a delivery service that allows you to track the shipment and confirm delivery.

Ms.Josey

Ms.Josey

Ms.Josey

Ms.Josey