bistable lcd displays pricelist

High contrast and wide viewing angle: The monochromatic bistable LCD’s contrast ratio is as high as 25:1, viewing angle about 80 degree in all directions.

Bistable Liquid Crystal materials require protection from UV light. A UV blocking material with a minimum 98% cut of at 380nm and lower spectral components is required.

The finished product design should incorporate a transparent cover such as acrylic, polycarbonate etc. to protect the viewing area of the display. Place the protective cover as close to the display bistable module as possible. The protective cover should be sufficient thickness to resist bending.

The power used for screen refreshing is pretty high. So, it will not worthwhile for an application if the screen has to be refreshed more than 20 to 50 times depending on the battery used. Bistable display technology has been used for shelf label and E-reader. Bi-stable LCDs requires the use of a voltage booster. Designing into some environments needs to be cautious, examples: explosive gas. Bistable LCDs are limited to one color of character and one color of background.

Bistable LCDs are reflective and do not require a backlight. This can be a disadvantage in areas with dark ambient light. If the lighting has to be used, it can only use front light instead of backlight. It can be expensive and lose its key advantage of low power.

Bistable LCD Display offers the perfect display in a world of imperfect LCD technology. Think about this; perhaps in a perfect world automobiles would require no gas; air conditioners in Arizona would require no power; and food crops would require no rain or water. We do not live in a perfect world but there is a LCD display technology that can display an image that requires zero power. Is it possible?

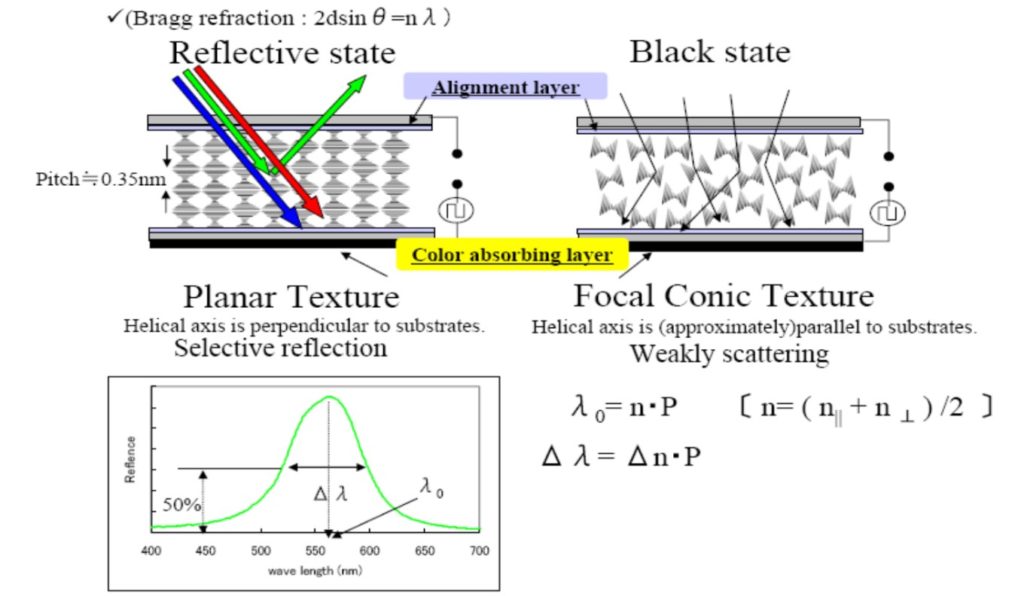

Well, yes and no... the Bistable LCD Display, also called cholesteric liquid crystal (ChLCD), e-paper, and even zero power, do offer a great power savings. They do not require any power to display the image, but there is a need for power to change the image. This unique bi-stable property means that an image placed on the display will remain indefinitely without the need for refreshing as is necessary in an active matrix display such as a TFT LCD Displays or a passive matrix display such as a monochrome character LCDs.

At this time all Bistable LCD displays are custom built to the customer’s specification. This requires a one-time tooling fee and an MOQ (minimum order quantity).

Zero power displays are reflective and do not require a backlight. This can be a disadvantage in areas with dark ambient light, but the plus side is they are very readable in direct sunlight. This is a great advantage over many other display technologies that have to compete with sun light, making the other displays difficult to read.

Some of the bistable LCD display is equipped with on-board RAM memory to store the image. They can be manufactured as a Chip on Glass (COG), Chip on Flex (COF) and Chip on Board (COB).

The largest possible glass size at this time is 18 inches. The product designer can build the custom bistable display to a size that meets their design requirements.

New Vision Display acquired the ZBD LCD technology – including patents, know-how, employees and facility – on September 20th, 2019. ZBD LCDs are a low-power, reflective, bistable LCD technology that offers paper-like reflectivity, wide viewing angles, wide storage/operating temperatures, and long-term stability at a low cost. ZBDs use standard LCD material with a robust and proven supply chain. Because of their unique advantages, ZBDs are an excellent display solution for battery-operated devices, outdoor environments, and bright lighting conditions. Call us to discuss if ZBD LCDs are the right choice for your project!

From laptop computers to mobile phones and digital cinema, Liquid Crystal Displays (LCDs) form integral parts in an increasing array of consumer electronics and communication devices. Ernst Lueder"s unique combination of theory andpractice presents all the information required for the development and manufacture of energy efficient, enhanced performance Liquid Crystal Displays.

* Methods for designing improved Thin Film Transistors (TFTs), active matrix LCDs, Liquid Crystal on Silicon (LCOS) devices and light valves for projectors.

* Guidance in the use of printing processes and the design of transmissive and reflective LCDs with increased viewing angles, lower voltage levels and plastic substrates.

Practising electrical engineers, physicits, chemists and display specialists will find this a valuable resource. Researchers will appreciate the practical guidance in the design of improved LCDs, whist students are provided with a useful overview of the field.

The Society for Information Display (SID) is an international society which has the aim of encouraging the development of all aspects of the field of information display. Complementary to the aims of the society the Wiley-SID series is intended to explain the latest developments in information display technology at a professional level. The broad scope of the series addresses all facets of information displays from technical aspects through systems and prototypes to standards and ergonomics.

Adding bistability (image memory) to a display has remained an attractive feature for several reasons. In the 80s and 90s, it was seen as a way to allow displays with a large line count to be realized without the need for an active matrix backplane. More recently, bistability is used in many applications where images are updated infrequently and battery life is important.

Many diverse approaches have been investigated to achieve such operation including, bistable LC (nematic, Cholesteric, Smectic A and ferroelectric), electrophoretic, electrowetting, electrochromic and phase change displays. Only a few examples of these have ever “crossed the chasm” and successfully made it into mass production. One example is the ZBD LCD technology – invented in the 1990s and widely deployed in electronic shelf labels.

The ZBD LCD technology uses standard nematic liquid crystal materials within a passive matrix display. However, one surface is no longer a rubbed polyimide layer but instead is a microscopic diffraction grating. This interacts mechanically with the long-range order in the LC material and allows two different optical states to be obtained without any holding voltage.

In summary, a microscopic surface grating of optimum dimensions and chemistry provides two stable pretilt angles (typically 90° and 5°) to a neighboring nematic LC. Of course, this is not enough to create a bistable display since we still need a method to switch between the two states. Once again the grating-induced distortion of the nematic provides the answer.

While standard passive matrix STN displays struggle to address more than 256 lines, the threshold behavior in the ZBD LCD allows addressing of many thousands of lines. Indeed, the practical upper limit of display complexity is constrained by electrode resistivity and driver cost rather than the display technology itself.

The biggest challenge in manufacturing the ZBD LCD has been the realization of a cost-effective method of patterning the high-resolution diffraction grating onto the LCD mother-glass. Direct photolithographic methods proved too slow and too expensive. Therefore a replication process was established in which a high-cost photoresist master grating is copied into nickel (similar to CD/DVD nickel stamper tooling) then the nickel pattern is copied into film (similar to hologram fabrication) which is then cheap enough to be used as a consumable surface for the final UV cured replication step onto the LCD glass surface. The replication process speed matches other processes on an STN production line.

Following the grating replication step, this mother-glass is assembled opposite a standard rubbed polymer surface. This step and all downstream processes use equipment and materials that are common with STN. In the most common ZBD LCD configuration, the grating is placed opposite a rubbed polymer surface such that the low tilt grating state induces a 90° TN arrangement while the high tilt state leads to a HAN (hybrid aligned nematic) arrangement. Usually, front and rear polarizers are arranged so that the TN state is white and the HAN state is black. Unlike a continuously addressed TN display, the bistable TN state in the ZBD LCD has a very low tilt angle throughout the cell and so has much wider optical viewing properties.

Reflective LCDs have traditionally suffered from a ‘metallic-like’ reflection which means that they only show high reflectivity when the display is oriented close to the specular condition with respect to the user and the light source. In recent years, novel light shaping diffusers have become available which have been used in conjunction with the ZBD LCD configuration to deliver a truly paperlike reflectivity similar to electrophoretic displays.

Recent advances in the ZBD LCD technology have also increased the operating temperature range which now extends from -10°C to +90°C. A stored image remains on the display from -40°C to +110°C. Furthermore, these displays can be tested to automotive specifications (e.g. 500 hours at 85°C). These properties together allow a wide variety of portable, outdoor and rugged applications that cannot be served by other technologies.

Ms.Josey

Ms.Josey

Ms.Josey

Ms.Josey