tft lcd construction for sale

We are changing our TFT part numbers to have them better describe the parts being ordered. The change should be complete for all TFT modules shipping within the next six months.

This graphic display module is a 2.4" diagonal, full color TFT. Suitable for embedded applications, it is low-power, uses a white LED backlight, and has an integrated touch panel which has its connection brought out to the main TAB connector for the display.

The connector on the CFAF240320K-024T-TS is a flex tail mated with a "COG" (chip on glass) display construction. This style of connector is designed to be soldered directly to corresponding pads on your PCB by using a hot-bar soldering machine. High volume contract manufacturers will be familiar with this type of construction and its assembly methods. There are hot-bar soldering machines made that are designed for prototype, rework or repair work of TAB connections.

Leveraging 50 years of presence in avionic cockpit lighting we provide the ultimate display solutions. Cevians has rapidly become the fastest-growing privately owned company offering fully customized TFT-LCDs. Our highly vertically integrated technological foundation, from material science, thin-film coatings, optical designs, electronics and electro-mechanical designs to system engineering, makes Cevians’ capabilities and product offerings truly unique and the natural partner for Tier 1 OEMs.

Understanding the diverse industry ecosystem, we offer the level of product that integrates perfectly in each customer’s base model, from supplying custom TFT-LCD to LCD modules, display head assemblies (DHA), and fully ruggedized display systems. This flexible strategy allows our customers to efficiently use their resources for core competencies.

LCD is the abbreviation for liquid crystal display. An LCD basically consists of two glass plates with a special liquid between them. The special attribute of this liquid is that it rotates or “twists” the plane of polarized light. This effect is influenced by the creation of an electrical field. The glass plates are thus each coated with a very thin metallic film. To obtain polarized light, you apply a polarization foil, the polarizer, to the bottom glass plate. Another foil must be applied to the bottom glass plate, but this time with a plane of polarization twisted by 90°. This is referred to as the analyzer.

In the idle state, the liquid twists the plane of polarization of the incoming light by 90° so that it can pass the analyzer unhindered. The LCD is thus transparent. If a specific voltage is applied to the metallic film coating, the crystals rotate in the liquid. This twists the plane of polarization of the light by another 90°, for example: The analyzer prevents the light getting through, and the LCD thus becomes opaque.TN, STN, FSTN, blue mode, yellow-green mode

However, the different colors occur only in displays that are either not lit or that are lit with white light. If there is any color in the lighting (e.g. yellow-green LED lighting), it overrides the color of the display. A blue-mode LCD with yellow-green LED lighting will always appear yellow-green.Static or multiplex driving method

Every LCD has a preferred angle of view at which the contrast of the display is at its optimum. Most displays are produced for the 6°° angle of view, which is also known as the bottom view (BV). This angle corresponds to that of a pocket calculator that is lying flat on a desktop.

LCDs without lighting are hard to imagine these days. However, since there are basically four different types of lighting, the type selected depends very much on the application. Here is a brief overview to clarify the situation:LED

Standard LCDs have a temperature range of 0 to +50°C. High-temperature displays are designed for operation in the range from -20 to +70°C. In this case, however, additional supply voltage is generally required. Since the contrast of any LCD is dependent on the temperature, a special temperature-compensation circuit is needed in order to use the entire temperature range, and this is particularly true for high-temperature displays (-20 to +70°C). Manual adjustment is possible but rather impractical for the user.

However, the storage temperature of a display should never be exceeded under any circumstances. An excessively high temperature can destroy the display very quickly. Direct exposure to the sun, for example, can destroy an LCD: This is because an LCD becomes darker (in positive mode) as it gets hotter. As it gets darker, it absorbs more light and converts it to heat. As a result, the display becomes even hotter and darker... In this way, temperatures of over 100°C can quickly be reached.Dot-matrix, graphics and 7-segment displays

The first LCDs were 7-segment displays, and they are still found today in simple pocket calculators and digital watches. 7 segments allow all of the digits from 0 to 9 to be displayed.

The semiconductor industry now offers a very large range of LCD drivers. We generally distinguish between pure display drivers without intelligence of their own, controllers with a display memory and possibly a character set, and micro-controllers with integrated LC drivers.

Many ask themselves, "What is the difference between an LCD display and a TFT-display?" or "What is the difference between a TFT and an OLED display?". Here are these 3 sometimes extremely different display technologies briefly explained. LCD vs. TFT vs. OLED (comparison).

- The LCD (Liquid Crystal Display) is a passive display technology. The operation and the structure are described above. Passive means that an LCD can only darken or let out light. So it always depends on ambient light or a backlight. This can be an advantage because the power consumption of a LCD display is very, very low. Sometimes even less than the accumulated power consumption of an E-paper display, which in static operation requires absolutely no energy to maintain the content. To change the contents, however, a relatively large amount of power is required for an E-paper display.

LCDs can also be reflective, so they reflect incident light and are therefore legible even at maximum brightness (sunlight, surgical lighting). Compared to TFT and also OLED, they have an unbeatable advantage in terms of readability and power consumption :; the "formula" is: Sunlight = LCD.

- A TFT-display (of Thin-Film Transistor) is usually a color display (RGB). From the construction and the technology it corresponds to the LCD. It is also passive, so it needs a backlight. This is in any case necessary except for a few, very expensive constructions. However, a TFT needs much more light than the monochrome relatives, because the additional structures on the glass as well as the additional color filters "swallow" light. So TFTs are not particularly energy-efficient, but can display in color and at the same time the resolution is much higher.

- OLED displays (by Organic-Light-Emitting-Diode) are as the name implies active displays - every pixel or sign generates light. This achieves an extremely wide viewing angle and high contrast values. The power consumption is dependent on the display content. Here OLEDs to TFTs and LCDs differ significantly, which have a nearly constant power consumption even with different display contents. Unfortunately, the efficiency of converting the electric current into light energy is still very poor. This means that the power consumption of OLEDs with normal content is sometimes higher than that of a TFT with the same size. Colored OLEDs are increasingly used in consumer devices, but for the industry, due to their availability and lifetime, currently only monochrome displays are suitable (usually in yellow color).

In the reaction time, the OLEDs beat each TFT and LCD by worlds. Trise and Tfall are about 10μs, which would correspond to a theoretical refresh rate of 50,000 Hz. Possibly an advantage in very special applications.

Finally the question "What is better, LCD, OLED or TFT?" Due to the physical differences you can not answer that blanket. Depending on the application, there are pros and cons to each individual technology. In addition to the above differences, there are many more details in the design and construction that need to be individually illuminated for each device. Write us an e-mail or call us: we have specialists with some 20- and 30-year experience. We are happy to compare different displays together with you.AACS and IPS technology

Distributor of component LCDs for equipment which provide high-contrast ratio, color saturation, luminance and performance enhancements such as advanced wide viewing (AWV) for true color fidelity, super-high brightness (SHB) and wide temperature range. Focus on industrial, instrumentation, hand-helds, medical and other low-to-medium volume markets. High-bright LED backlights for outdoor use. LVDS interfaces decrease EMI. Factory installed touch screen solutions. 3.5" to 12.1" QVGA, HVGA, VGA, WVGA, SVGA, XGA, WXGA. Also distributes other related products including LED drivers, lamps, indicators, LED assemblies, segment displays, LED mounts, LEDs, and light pipes. Distributor of electronic components, hardware and fasteners and provides design/value engineering support, fulfillment strategies, procurement services and transactional models to meet specific needs and priorities.

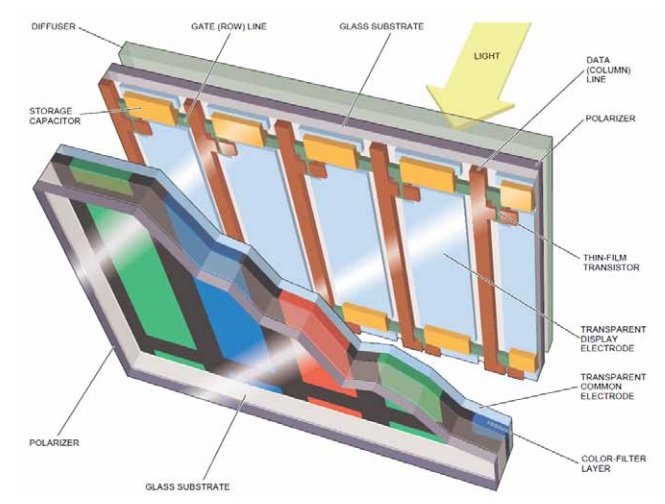

A liquid crystal display (LCD) has liquid crystal material sandwiched between two sheets of glass. Without any voltage applied between transparent electrodes, liquid crystal molecules are aligned in parallel with the glass surface. When voltage is applied, they change their direction and they turn vertical to the glass surface. They vary in optical characteristics, depending on their orientation. Therefore, the quantity of light transmission can be controlled by combining the motion of liquid crystal molecules and the direction of polarization of two polarizing plates attached to the both outer sides of the glass sheets. LCDs utilize these characteristics to display images.

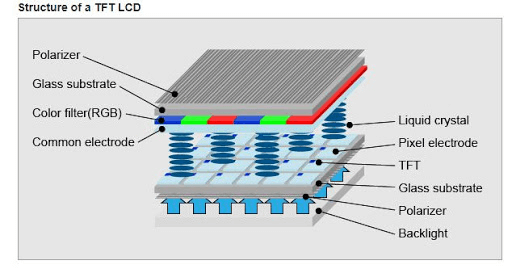

An LCD consists of many pixels. A pixel consists of three sub-pixels (Red/Green/Blue, RGB). In the case of Full-HD resolution, which is widely used for smartphones, there are more than six million (1,080 x 1,920 x 3 = 6,220,800) sub-pixels. To activate these millions of sub-pixels a TFT is required in each sub-pixel. TFT is an abbreviation for "Thin Film Transistor". A TFT is a kind of semiconductor device. It serves as a control valve to provide an appropriate voltage onto liquid crystals for individual sub-pixels. A TFT LCD has a liquid crystal layer between a glass substrate formed with TFTs and transparent pixel electrodes and another glass substrate with a color filter (RGB) and transparent counter electrodes. In addition, polarizers are placed on the outer side of each glass substrate and a backlight source on the back side. A change in voltage applied to liquid crystals changes the transmittance of the panel including the two polarizing plates, and thus changes the quantity of light that passes from the backlight to the front surface of the display. This principle allows the TFT LCD to produce full-color images.

March 23, 2015 – Plymouth, MI - Kyocera today introduced two small-form-factor TFT LCD displays that offer high performance and robust design for industrial markets. Available now, both products are designed to perform in harsh environment and extreme temperature applications including outdoor control panels, construction and agricultural equipment, avionics, and other devices that require reliable performance in the most punishing environments.

The new 4.2-inch TFT LCD panel (T-57152GD042H-LW-AAN) features a 480 x 272 resolution, brightness of 700cd/m², and contrast ratio of 1200:1. Featuring Kyocera"s Advanced Wide Viewing (AWV) technology, this panel offers a wide viewing angle of 160 degrees in both vertical and horizontal directions. It features a standard 18-bit digital RGB interface, along with a wide operating temperature range of -30°C to +85°C and anti-glare surface treatment. The design is based on automotive specifications, with a storage temperature range of -40°C to 95°C, making it ideal for even the most extreme outdoor applications.

The new 5-inch TFT LCD panel (T-55923GD050J-LW-ABN) is a portrait mode display that features a 480 x 640 resolution. Its optical characteristics include 800cd/m2 brightness, a 500:1 contrast ratio and a viewing angle of 140 degrees horizontally and 110 degrees vertically. It features a standard 24-bit digital RGB interface and a wide operating temperature range of -30°C to +80°C, giving another option for devices that must perform reliably in harsh operating environments.

"Kyocera brings almost 40 years of experience in LCD technology innovation, helping to make the company a preferred supplier of displays for industrial applications as well as automotive and medical equipment," said Cynthia Ferrell, Vice President of Kyocera Industrial Ceramics Corporation"s Display Division. "We continue our commitment to developing environmentally friendly products, and all of Kyocera"s TFT LCDs are RoHS compliant to reduce potentially hazardous substances."

Kyocera expanded its global LCD business in 2012 with the acquisition of Japan-based Optrex Corporation (now Kyocera Display Corporation) - a manufacturing, sales, marketing and R&D enterprise with nearly four decades of LCD innovations. Kyocera Industrial Ceramics Corporation, Display Division, is the sales, marketing and value-added assembly arm for these products in the Americas, with LCD sales offices in Plymouth, MI; Atlanta, GA; Vancouver, WA; and San Diego, CA. LCD warehouse, distribution center and value-added assembly services are located in Plymouth, MI, with company headquarters in Hendersonville, NC.

Kyocera Corporation, the parent and global headquarters of the Kyocera Group, was founded in 1959 as a producer of fine (or "advanced") ceramics. By integrating these engineered materials with other technologies, Kyocera has become a leading supplier of LCDs, industrial ceramics, electronic components, semiconductor packages, cutting tools, solar power generating systems, printers, copiers and telecommunications equipment. During the year ended March 31, 2014, the company"s net sales totaled 1.45 trillion yen (approx. US$14.1 billion). The company appears on the latest "Top 100 Global Innovators" list by Thomson Reuters, and is ranked #531 on Forbes magazine"s current "Global 2000" listing of the world"s largest publicly traded companies.

Our company specializes in developing solutions that arerenowned across the globe and meet expectations of the most demanding customers. Orient Display can boast incredibly fast order processing - usually it takes us only 4-5 weeks to produce LCD panels and we do our best to deliver your custom display modules, touch screens or TFT and IPS LCD displays within 5-8 weeks. Thanks to being in the business for such a noteworthy period of time, experts working at our display store have gained valuable experience in the automotive, appliances, industrial, marine, medical and consumer electronics industries. We’ve been able to create top-notch, specialized factories that allow us to manufacture quality custom display solutions at attractive prices. Our products comply with standards such as ISO 9001, ISO 14001, QC 080000, ISO/TS 16949 and PPM Process Control. All of this makes us the finest display manufacturer in the market.

TFT LCD display is the general category that includes TFT display panels, MCU TFT displays, Arduino TFT displays, Raspberry Pi TFT displays, HDMI TFT displays, IPS TFT displays, VGA TFT displays, and embedded TFT displays.

TFT LCD panel means TFT LCD glass with LCD controller or LCD driver and backlight, with or without touch panel. Orient Display provides broad range products with the most competitive TFT LCD Panel Price by working with the most renowned TFT panel glass manufacturers, like AUO, Innolux, BOE, LG, Sharp etc.

Orient Display offers a range of small to mid to large size TFT LCDs. Our standard products for TFT screens start at 1” in diagonal size and up to 7 inches and to 32 inches. Orient Display TFT displays meet the needs for applications such as automotive, white goods, smart homes, telecommunications industrial, medical, and consumer devices.

Orient Display not only provides many standard small size OLEDs, TN or IPS Arduino TFT displays, but also custom made solutions with larger size displays or even with capacitive touch panels.

If you have any questions about Orient Display TFT LCD displays or if you can’t find a suitable product on our website. Please feel free to contact our engineers for details.

Welcome to buy TFT display online for your development. STONE offers a series of TFT (thin-film transistor) LCD modules, including 3.5 “, 4.3 “, 5 “, 7 “, 8 “, 10.1 “, 12 “and 15” TFT displays.Stone displays include a variety of technology upgrades, such as resistive touch screens, capacitive touch screens, high-resolution displays, and IPS displays. These LCD screens can display rich colors, clear pictures, and bright images. STONE TFT LCD can play music, it can play videos. STONE HMI displays are suitable for a variety of products in industrial, medical, and consumer applications. You can use any MCU for control, such a

Taiwan-based makers shipped a total of 61.37 million large-size (9-inch and above) TFT-LCD panels during the fourth quarter of 2016, decreasing 1.5% on quarter but increasing 2% on...

China Star Optoelectronics Technology (CSOT) in late November 2016 started construction of an 11G LCD factory with monthly production capacity of 140,000 glass substrates in Shenzhen,...

Sakai Display Product"s (Sharp"s subsidiary) 10G using 2,880mm by 3,130mm glass substrates) TFT-LCD factory in Japan is currently one of the highest generation plants but four 10.5G...

AU Optronics"s (AUO) newly unveiled 6G LTPS LCD factory in Kunshan, eastern China, has obtained LEED (Leadership in Energy and Environmental Design) Platinum Certification from the...

AU Optronics (AUO) on November 16 kicked off volume production at a 6G LTPS (low-temperature poly-Si) TFT-LCD factory in Kunshan, eastern China, according to the company.

Taiwan-based makers shipped 62.29 million large-size (9-inch and above) TFT-LCD panels in the third quarter of 2016, increasing 6.7% on quarter and 6.2% on year, and accounting for...

Taiwan-based TFT-LCD panel makers shipped 309.749 million small- to medium-size panels in the third quarter of 2016, increasing 15.0% on quarter and 0.8% on year, according to Digitimes...

AU Optronics (AUO) will inaugurate a 6G LTPS TFT-LCD factory in Kunshan, eastern China, on November 16 and start production later in the fourth quarter. AUO expects production capacity...

Global production capacity for large-size TFT-LCD panels in 2016 is estimated at 208 million square meters, increasing 6.6% on year, and the capacity will increase 3.9% to 216 million...

Global shipments of large-size (9-inch and above) TFT-LCD panels will slightly increase from 673.37 million units in 2016 to 684.60 million units in 2021, equivalent to an annual...

As Samsung Display, LG Display and Japan Display have shut down mostly 5G to 6G TFT-LCD lines to gradually expand AMOLED production capacity since the beginning of 2015, global shipments...

Taiwan-based TFT-LCD panel makers generated total production value of NT$164.135 billion (US$5.13 billion) in the second quarter of 2016, increasing 1.90% on quarter but decreasing...

Taiwan-based TFT-LCD panel makers AU Optronics (AUO), Innolux and Chunghwa Picture Tubes (CPT), at the Touch Taiwan 2016 taking place in Taipei during August 24-26, showed that they...

HONG KONG, July 20 (Reuters) - Hong Kong LCD maker Truly International Holdingsexpects its new production line to lift revenue growth this year and to make significant contributions to profit starting from 2008.

Truly’s US$200 million thin-film transistor-liquid crystal display (TFT-LCD) panel line in southern China’s Guangdong province has an annual production capacity of up to 24 million units of small to medium-sized displays.

Wong expects the firm to sell 5 million TFT-LCD units in the second half of this year and up to 20 million units in 2008. This will boost its revenue growth by a further 5 percent to 8 percent in 2007 and by more than 10 percent in 2008, he said.

Truly’s TFT panel line is not designed to compete with the world’s large TFT producers but to form the front and integral part of a vertical integration chain for its finished TFT module products.

Global LCD makers such as South Korea"s Samsung Electronics, LG.Philips LCD, Taiwan"s AU Optronics Corp.and Chi Mei Optoelectronics Corp.focus on large-sized panels for TVs and PC monitors.

The company generates more than two-third of its revenues by selling LCD products to mainland handset manufacturers including Lenovo Group, Ningbo Bird Co. Ltd., Huawei Technologies [HWT.UL] and ZTE Corp..

Each year, cell phone manufacture’s release new phones and each year, the size of the phone’s display grows.Current cell phone designs contain a 4.3” OLED and are set to increase to a 5.3” display. You would think that everyone would want a larger display. So why buck the trend and choose a smaller LCD module?

When I purchased my latest cell phone, I choose one that had a very small 1.8 inch color TFT (Thin Film Transistor) display. In fact, the sales people tried to ‘up-sell’ me to the latest, largest AMOLED (active-matrix organic light-emitting diode), but I held out for the smaller color TFT display. Why? The same reason that many Focus Display’s customers choose a 1.8 inch TFT...

Many of the OEMs (Original Equipment Manufacturers) that incorporate our small LCD displays are building portable, battery powered products that requires a color display that conserves battery life. The 1.8 “ color module is a perfect fit for medical diagnostic equipment, baby monitors, portable printers and handheld test equipment just to mention a few. All of these products require low power.

Small color TFT’s are not the lowest power consuming display, there are monochrome graphics and segmented displays, their small size draws much less power than the larger displays.

Ms.Josey

Ms.Josey

Ms.Josey

Ms.Josey