esp32 with camera and tft display ov7670 fifo manufacturer

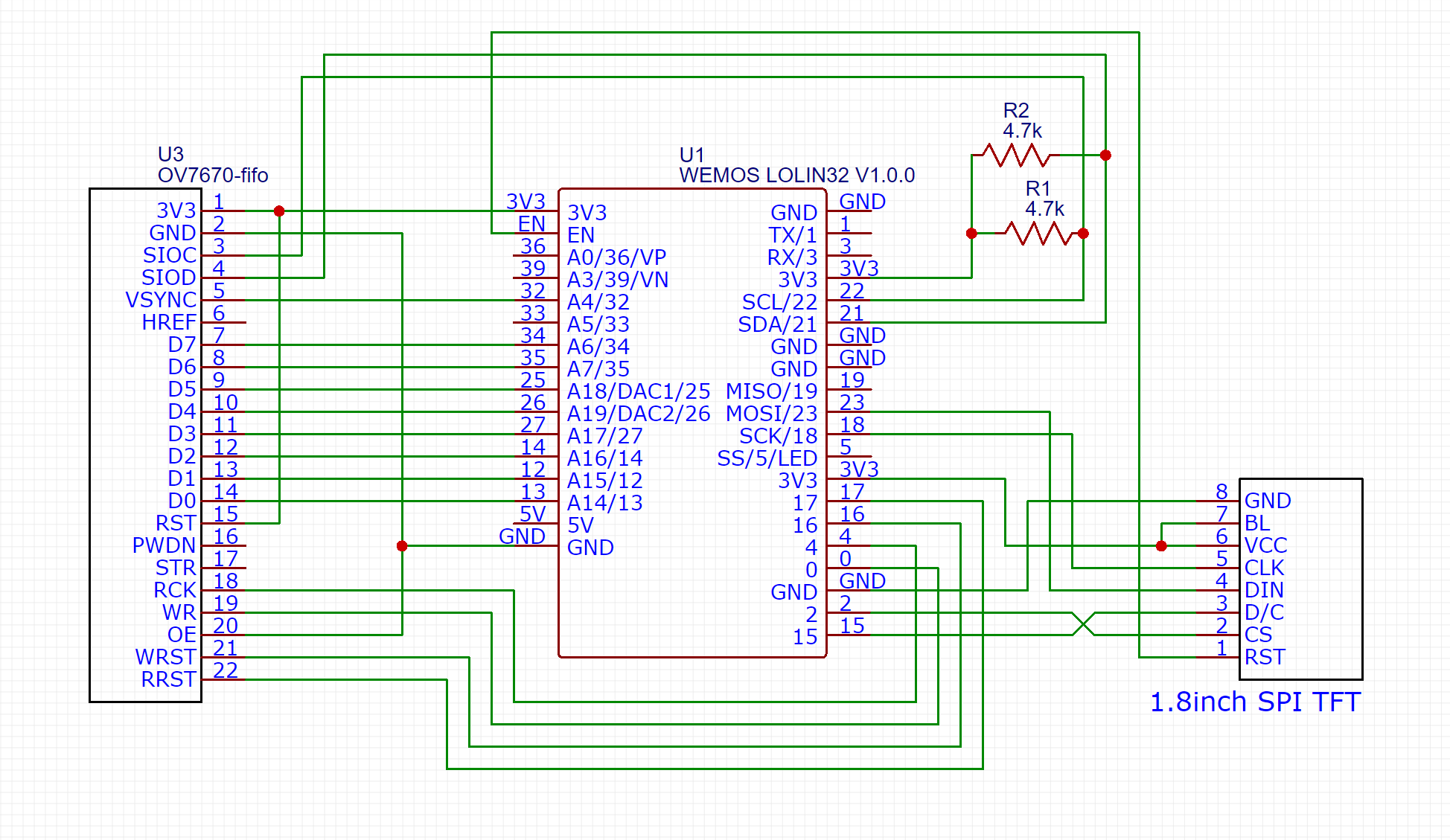

The parts used here are the LOLIN32 microcontroller. Any ESP32 board can be used. The code is currently independent of the actual processor, so you can use also different platforms.

The camera is the cheap OV7670 with FIFO (AL422b). The camera supports up to VGA resolution but the FIFO can only store 3MBit. This is just sufficient for QQVGA or section of higher resolutions.

The “real-time” output is done on the 1.8″ SPI TFT display. Due to the single data line, the update rate is really limited. To be able to run the display on 3.3V the jumper on the back side must be closed.

The pin connections of the devices can also be found in the code. The definitions can be changed except for MOSI and SCK for the SPI interface which is native on these pins on the ESP32. Using other microcontrollers, the corresponding native SPI pins have to be used.

There are some limitations configuring the pins of the ESP32. Pins 34, 35, 36(VP), 39(VN) are read-only. Those can’t be used for I2C, the clock (XCLK) or TFT signals. Pins 0, 2 and 5 are used as boot signals. Those should not be used as inputs to avoid problems while programming. Pin 5 is also attached to the LED on the LOLIN32 board. Pins 6-11 (if available) are a no go since those are wired to the SPI flash memory connected to the ESP32.

[{"id":"9ecc75dd.22e2e8","type":"mqtt in","z":"5a254896.947618","name":"","topic":"home/camera1","qos":"1","broker":"171132c7.ece67d","x":168.8333282470703,"y":222.0666732788086,"wires":[["784e5a67.89db04"]]},{"id":"6bd0fd9c.4f3c14","type":"ui_template","z":"5a254896.947618","group":"d960fd60.7c918","name":"","order":0,"width":"6","height":"5","format":"","storeOutMessages":true,"fwdInMessages":true,"templateScope":"local","x":612.83349609375,"y":222.0667266845703,"wires":[[]]},{"id":"784e5a67.89db04","type":"function","z":"5a254896.947618","name":"camera iframe","func":"msg.template = \"<iframe frameborder="0" width="100%" height="100%" src="http://\" + msg.payload + \""></iframe>\";\nreturn msg;","outputs":1,"noerr":0,"x":408.83337783813477,"y":222.20002460479736,"wires":[["6bd0fd9c.4f3c14"]]},{"id":"171132c7.ece67d","type":"mqtt-broker","z":"","broker":"localhost","port":"1883","clientid":"","usetls":false,"compatmode":true,"keepalive":"60","cleansession":true,"willTopic":"","willQos":"0","willPayload":"","birthTopic":"","birthQos":"0","birthPayload":""},{"id":"d960fd60.7c918","type":"ui_group","z":"","name":"Camera","tab":"e694697d.4bec28","order":1,"disp":false,"width":"6"},{"id":"e694697d.4bec28","type":"ui_tab","z":"","name":"Camera","icon":"dashboard","order":5}]

I CAN WALK AGAIN! yaaay.. Back in the lab making videos.This video is the first of a miniseries showing how to interface a camera to a microcontroller (ESP32...

Seguir una dieta «low carb» es una de las estrategias más frecuentes empleadas en la pérdida de peso. Pero, ¿es necesario? Cuando se clasifican alimentos

Alluvodna strankaRaspberry PiEnclosures Boxes CasesLCD TFT OLED Display for RPiAccessories Cables Power SuppliesmicroSD Memory Card & AdapterRaspberry PI Single-board ComputerCamera for Raspberry PiShield & Board for Raspberry PiWiFi for Raspberry PiKeyboard & Touchpad for Raspberry PiRaspberry Pi Kit Pack bundleRELAY BOARDGSM/GPRS/3G/4G/LTE/WiMax/5G/GSM BOARDS FOR RASPBERRY PIRaspberry Pi 400 (Pi400 RPI400)Raspberry Pi Compute ModuleRaspberry Pi PicoRaspberry Pi Zeromicro:bitmicro:bit KITArduinoBREAKOUT BOARDS, Accessories & CablesArduino KitOriginal ARDUINO BoardsOriginal ARDUINO ShieldsARDUINO BoardsARDUINO ShieldsARDUINO Box EnclosuresESP32 ESP8266Development Tools8051 Development ToolsMicrochip AtmelBREAKOUT BOARDS & SHIELDSARM Development ToolsCypress PSoC DevelopmentProgrammersData LoggersSTMICROELECTRONICSWeb ServerAndroid MINI PC / Development Kit.NET Micro FrameworkFPGA ALTERA Intel Xilinx Lattice Microchip CPLD ASICSingle board Linux computerJTAG ToolsMAXQ2000System On ModulesFREESCALEParallax Basic Stamp PropellerBeagleBoard BeagleBoneCubieboard Cubietruckx86 Vortex86Banana PiODROIDFTDI Chip’s FT90x, ..OLIMEXOnion (Omega2)Základné doskyAI - Deep Learning - Neural NetworkJetson (NVIDIA)SparkFun MicroModBIOMETRIC MEDICAL E-Health Sensor EEG EKGEnclosures Boxes CasesWearable electronic / E-TextilesPrototyping SADY STAVEBNICECompilers & SoftwareSingle Board ComputerMotor DriverElectronic Components / Battery / Memory cardM5StackMeasuring instrumentsDigital OscilloscopesSpectrum AnalyzersWaveform GeneratorsDigital MultimetersPower SuppliersUniversal CountersLogic AnalyzersLCR MeterPower MeterHandheld Digital MultimeterNon-invasive AC Current SensorData loggerData AcquisitionImaging IR ThermometerDC ELECTRONIC LOADS - Elektronická záťažLCD TFT OLED e-paper0.9 - 5" LCD display5 - 8" LCD display8 - 16" LCD displaye-Paper / E-INKOLED / AMOLEDCOG, VFD, Character/Monochrome LCDDisplay AccessoriesIoT (THE INTERNET OF THINGS)SONOFFComplete Robots3D Printer, Bluetooth Printer, Thermal PrinterGaming System ArcadeVyberame / WE LOVE TRENDUnipiNUMATO

"Upper layer" main development board contains ESP32-PICO-D4 SiP, battery connector & charger circuit with LiPo charge status LEDs, Reset & pull-up IO0 buttons, and a green LED on GPIO4.

Clone of the SparkFun ESP32 Thing board. Compact ESP32 based development board with battery connector, and the typical development board component accoutrements.

Version 2.0 of this board (1) corrected polarity labeling on bottom silk-screened battery symbol and (2) changed the LiPo battery connecter direction.

Development board/module with ESP-WROOM-32 module, USB-to-UART, Reset & Boot (IO0) buttons, Li-ion battery connector & charger, two Grove connectors, LED on IO2, and three indicator LEDs.

The ESP32-LyraTD-MSC Audio-Mic HDK (hardware development kit) combines the ESP32-LyraTD-MSC ("audio-mic development board") with a secondary "top" board.

The ESP32 touch sensor development kit, ESP32-Sense Kit, is used for evaluating and developing ESP32 touch sensor system. ESP32-Sense Kit consists of one motherboard and multiple daughterboards. The motherboard contains a display unit, a main control unit and a debug unit. The daughterboards have touch electrodes in different combinations or shapes, such as linear slider, wheel slider, matrix buttons and spring buttons, depending on the application scenarios. Users can design and add their own daughterboards for special usage cases.

Features an xBee socket with switchable VCC voltage (3.3 V or 5 V), so 2G (SIM800) and 3G (SIM5360) xBee modules will work on it to provide cellular network access.

ESP-WROOM-32 based development board with SH1106 OLED display (128×64 pixels), RJ-45 Ethernet connector, CAN-bus connector, Micro USB connector, USB-to-UART bridge, LiPo battery connector and charging circuit.

Board with MEMS Microphone (ICS-43434) and class-D amplifier embedded 1-channel DAC (Maxim MAX98357A); intended for Amazon Alexa experimentation and development.

ESP32 development board with ePaper display, TI PCM5102A DAC, ICS43434 MEMS Microphone, CP2102N USB-to-UART bridge, microSD card slot, and LiPo charger.

Circular board with ESP-WROOM-32 module, Ethernet (LAN8720A), stereo audio CODEC (WM8978), microphone, 3.5 mm audio receptacle, USB-to-UART bridge (CP2104), Micro USB connector, and SD card slot.

Has column-similar/redundant dual-row connections along the longest sides for easier stand-alone use without a breadboard (but still could be used with a breadboard).

2× Ethernet (optional), 1× Serial Port RS-232/485, OLED 0.96″ 128×64 (optional), power supply with UPS (optional), U.FL (I-PEX) antenna mount(s), and ExCard extension modules support.

SPI0 is permanently reserved for cache access to the flash chip. SPI1 is connected to the same pins via an arbiter and is used to write to flash. You can use SPI1 to also write to other peripherals connected in parallel with the flash (but with another /CS), however, this is tricky to implement because it means you can"t simultaneously access flash anymore. Thats why it"s not in the driver yet.

This article will introduce the ov7670 camera module connection with the STONE display module. displaying camera images through a serial display module. The methods and code described in this article are for individual developer testing only and cannot guarantee commercial stability.

STONE STVC070WT-01 is a 7-inch display module with a resolution of 800*480. This display module can be purchased from STONE’s official website or from STONE’s online shopping platform link.

Display module development way is simple, the MCU only need through UART send an instruction to the STONE, the contents of the display module, control is ok, the same principle when a user touches the STONE display screen, display module and related instructions sent to MCU through UART, and then MCU to control the corresponding devices (such as motor rotation, light switch, etc.).

STVC070WT-01 is a TFT display and touch controller. It includes a processor, control program, driver, flash, RS232/RS485/TTL port, touch screen, power supply, etc., is a powerful display system

The operating system is simple and can be controlled by any single-chip microcomputer.STVC070WT-01 can be used to perform all basic functions, such as text display, image display, curve display, touch function, video and audio function, etc.

The serial command frame of the TFT LCD module consists of five data blocks, all of which are represented in hexadecimal format. The way data is transferred to MSB.For example, for 0x1234, 0x12 is sent first, and then 0x34 is sent.

Click the arrow button to generate the configuration file, and then download the configuration file to the display module to display the UI interface we designed.

In the previous content, I introduced the relevant development operation of STONE STVC070WT-01. In the following content, I will focus on the STM32 MCU and the VO7670 camera. Before we do that, let’s take a look at how the hardware part of the project connects.

The power adapter is 12V and needs to power the STONE stvc070wt-01 display module and power the MCU module and OV7670 through the dc-dc step-down to 5 volts.

Since the default communication mode of STONE STVC070WT-01 is uart-TTL, we do not need the interface of RS232 for switching connection, and remove the interface of RS232:

OV7670 is a kind of image sensor, the operating temperature is -30℃-70℃, the analog voltage is 2.5-3.0v, the photosensitive array is 640*480, and the power consumption is 60mW/15fps.Less than 20uA in dormancy.

Small size, low operating voltage, providing all the features of a single VGA camera and image processor. Through SCCB bus control, you can input the whole frame, sub-sampling, window, and other ways of various resolution 8-bit image data. The product’s VGA image reaches a maximum of 30 frames per second. Users have complete control over image quality, data format, and transmission. All image processing functions including gamma curve, white balance, saturation, chroma, etc. can be programmed through the SCCB interface. By reducing or eliminating optical or electronic defects such as fixed pattern noise, tail support, floating, and so on, image quality can be improved to obtain clear and stable color images.

The device is small in size, low in working voltage, and provides all the functions of a single VGA camera and image processor. Through SCCB bus control, you can output the whole frame, sub-sampling, window, and other ways of various resolution 8-bit image data. The product’s VGA image reaches a maximum of 30 frames per second. Users have complete control over image quality, data format, and transmission. All image processing processes including gamma curve, white balance, degree, color, etc. can be programmed through the SCCB interface.OmniVision image sensor USES unique sensor technology to improve the image quality by reducing or eliminating optical or electronic defects such as fixed pattern noise, tail support, floating, etc., to obtain clear and stable color images.

Automatic black level calibration and other automatic control functions. At the same time support color saturation, hue, gamma, sharpness, and other Settings.

The sequence generator has the following functions: whole sequence control and frame rate generation (output in 7 different formats), internal signal generator 535 and distribution, frame rate timing, automatic exposure control, and output of external timing (VSYNC, HREF/HSYNC, and PCLK).

The A/D converter operates at an A frequency of 12M, fully synchronized with the pixel frequency (the conversion frequency is related to the frame rate).

The A/D range product and A/D range control jointly set the A/D range and maximum, allowing the user to adjust the brightness of the image based on the application.

Since the pixel clock (PCLK) of OV7670 can reach up to 24Mhz, we use the IO port of STM32F103ZET6 to directly grasp, which is very difficult and takes up a lot of CPU (IO port can be captured by reducing the output frequency of PCLK, but it is not recommended).

In this project, I used RGB565 mode, and the image data captured was the original data of RGB, which was then transferred to the STONE display module through UART.

This is a simple version of j-link that only supports SWD debugging and downloading, not JTAG. But for STM32 chip development, SWD debugging is enough.

The data receiving of the STONE display module can only receive 255 bytes at a time, while the image size of a single RGB565 data is 240*320*2=153600Byte= 153.6kb, so it needs to be sub distributed.

In addition, due to the limitation of serial communication rate, the effect of picture real-time refresh is not very good. The serial port baud rate is configured to 921600, which is also the highest communication baud rate for the STONE serial display module.

Finally, the code is downloaded to the STM32 chip, and then the completed circuit board is connected to the display screen, and the power supply is guaranteed to be stable. You can see the pictures taken by VO7670 through the STONE display module.

OV7670 image sensor, small size, low voltage, providing single-chip VGA camera and image processor all the features. Through the SCCB bus control, you can output the entire frame, sub-sampling, taking a variety of windows, etc.

Resolution 8 affect the data. The product is VGA image up to 30 frames / sec. Users can fully control the image quality, data formats and transmission.

Omni Vision image sensor applications unique sensor technology, by reducing or eliminating optical or electronic defects such as fixed pattern noise, prop tail, floating powder, etc., to improve image quality, get a clear and stable color image.

OV7670 VGA Camera + FIFO Buffer AL422B, based on the popular OV7670 image sensor. With the onboard 384KB FIFO chip AL422B the camera module can buffer an entire VGA frame at 30fps frame rate, and it enables the low speed microcontroller boards to take photos.The camera module is powered from a single +3.3V power supply.

Espressif Systems is a fabless semiconductor company providing cutting-edge low power WiFi SoCs and wireless solutions for wireless communications and Internet of Things applications. ESP8266EX and ESP32 are some of our products.

Right now I"m working to integrate the data plotter and the image viewer features in the main repository of qSerialTerm. Everything should be ready by next week.

In particular, you should check that you are receiving correct data using the default configuration. Then, test that your SCCB interface is working, you should be able to read the OV7670 registers and see their default values.

When doing the YCbCr -> RGB conversion, be sure to use floats/double when carrying out the operations and then limit the obtained R, G, B values between 0 and 255.

Dang not sure how I missed that one. I was using integer. Even with that change I did not get good color image. I had to use register settings I got from Linux driver to get a good image. Not sure why.

About qSerialTerm, it is a quite useful program. The only reason I have not used is that I would have to compile the program myself. That means I have to setup the whole QT environment. Untill now all my time was used up in debugging the camera.

I"m getting a "correct" color image using the above conversion equations, in the sense that the image doesn"t get distorted. But the colors are no good, because instead of green I see magenta and so on.

I have tested the conversion equations against Octave"s rgb2ycbcr function, and it works fine. Maybe the OV7670 follows another conversion standard?. I have also tried switching Cb <-> Cr without any noticeable change in the color output.

We currently have an OV7670 which correctly gives us test patterns, however gives us terribly saturated images with completely incorrect colours. Are you able to share those register settings, or some us advice about how to set this device up for normal looking images? Thanks very much,

I am currently working on real time image processing using FPGA. For that i am using OV7670 camera module. I have got real time video but with wrong colors(mostly magneta color). Can you please mail me the correct color settings?

if I want to use an external clock, do I have to connect the oscillator between XCLK and ground directly or do I need to add a capacitor in series (XCLK - oscillator - cap - GDN)? If yes, which value for the capacitor?

I have a ceramic resonator @ 16Mhz (http://it.rs-online.com/web/p/risonatori-ceramici/5266154/), but it has 3 pins instead of two. Searching on google I"ve seen the the the central pin must be connected to the ground, but I"m stuck with the others two.

Ceramic resonator require an active oscillator circuit. These active oscillators are usually integrated inside microcontrollers, and you have access to it via two pins usually labelled OSC_IN and OSC_OUT.

The OSC_OUT pin won"t have enough current drive and no clock will be produced. This implies that neither your microcontroller nor the OV7670 will work.

I"m using BeagleBone with QNX. But BeagleBone seems not provide an external clock. If I use an external oscillator (crystal) do I have connect one pin to the XCLK and one to the ground without capacitors?

I"ve just found a pin with an external clock on BeagleBone... :) (my fault!) In this case I suppose I have to connect the pin directly to the XCLK (sharing the same GND). Right?

The STM32 F2/F4 microcontrollers have a DCMI peripheral that simplifies the data reception from the camera. I don"t know if the BeagleBone have something similar.

i have interfaced ov7690 with stm32f4 and PIC. i get data in both rgb565 and yuv422 and reconstuct the image . but the image is not so good. u can look my post at

What do you mean with "the image is not so good"? Are you getting a clear image with the wrong colors or are you getting random pixels? Does the grayscale (only the Y channel) image looks clear?

AFAIK in YUV422 mode, getting the right colors with the OV7670 requires some heavy calibration, as stated by brijesh in his/her comment; but the grayscale version should look clear like the image I posted.

Hi Jorge, nice page you have here, seems you have been studying quite a fair bit on OV7670. I am also working on something similar but using AVR uC instead (Atmega16/32) with OV7670 FIFO version and works pretty well.

I am using YUV mode and using the YUV422 equations give me a pretty good looking image, a bit soft but not bad (http://thinksmallthings.wordpress.com/2012/11/03/ov7670-yuv-demystified/).

I"am unable to read proper image data, SCCB works fine for me and I can read registers, but for example when i"m reading frames with my lens covered i get some random numbers - where as you wrote there should be 128 0 pattern. I"m using camera mode with FIFO buffer embedded. Could you send me your code for reading frames ? Or will you be able to help me with this ? I"m using STM32F103VC

I haven"t used the OV7670 FIFO version and I used the STM32F4 which has a Digital Camera Interface (DCMI) that the STM32F1 doesn"t have. That"s the reason my code won"t really help.

Make sure you are supplying a correct clock (12-24 MHz) to the OV7670 XCLK pin. The SCCB works WITHOUT the XCLK, so a working SCCB doesn"t guarantee a working parallel interface (D0-D7).

I"ve just tried to get SCCB working on my OV7670 (like yours: no FIFO) and it looks like it doesn"t work at all until I connect clock source to XCLK pin. After successful test implementation (got 0x80 from 0x01 register etc) i tried to disconnect XCLK signal and it simply stopped working. So it seems to me that XCLK is necessary for SCCB operation.

In the module I use, (ov7970 without fifo) the DVDD pad (core voltage) is simply filtered to ground via capacitor thus ov7670 will generate 1.8 from DOVDD. This requires the DOVDD to range from 2.45V to 3V.

The (blue) model I used in this post has internal LDO regulators. You must have the (black?) model that is wired directly. I have also used the latter with a 3.3V supply and a series Schottky diode.

You need to drive the XCLK pin with a clock signal to make the OV7670 parallel interface (D0-D7) work to get any image data out of it. Also a user reported here that driving the XCLK pin is also necessary to get the SCCB interface working.

Wow, Jorge, it looks like your post has struck a chord with a number of users! If I may throw another question into the fray, I am thinking about using a microprocessor (thinking mbed, but not sure yet) to sample from multiple OV7670s. I don"t need to capture every frame from every camera, just be able to grab a picture from camera 1, then from 2, etc. at whatever rate the processor can manage. Any thoughts on how one might do this with some sort of bus, or would this require a separate processor for each camera?

(1) Hooking multiple OV7670s to the same uC will require a digital circuit to act as a multiplexer and will increase the capacitive load of the logic lines (XCLK, D0-D7), which can degrade or totally corrupt the data.

(3) The OV7670 outputs raw data, that means each frame of 640x480 color pixels equals a minimum of 600 KiB (YUV422 format). This implies you can"t keep one frame in the uC RAM memory (usually less than 200 KiB), so you"ll need to stream the frame to a bigger memory as soon as possible.

I have only the following parts which are OV7670 and Arduino uno board. I wrote my code and I have to cheange the clock function code to either read or write in the registers of the camera"OV7670". But, I can"t get any response from the camera.

You got me there. I don"t have experience with Linux when it comes to accessing peripherals, for this post I used a microcontroller without OS. AFAIK, Linux is more restrictive on specific memory/register access.

My wild guess, is that you"ll need to create a C/C++ project and link/add the necessary Linux drivers (either a parallel interface or the image sensor interface + network interfaces). After that, pretty much everything is specific to your NGW100 board.

"**: On some models the VDD is directly connected to the OV7670 sensor AVDD and DOVDD, in this case VDD should be below 3.0V. With this model I have used a 3.3V supply with a series Schottky diode without problems.

**: There are other models (like the blue one I used in this post) which contain LDO regulators between the VDD and the OV7670 sensor AVDD and DOVDD. I"m not sure how much input voltage these regulators can stand, but I have used 3.3V directly without problems."

Could you please have a look and tell me which kind of supply I need to provide to this camera? And maybe also where are LDO regulators placed (if there are...)?

Hi Jorge, I am trying to store the data in an array that captured from OV7670. I"d like to implement in Keil 4. Can you send me this project? I will surely compensate your effort (which an amount we both agree :) adnanoktar41@hotmail.com

I don"t think you can interface this version of the OV7670 module with a 8 bit uC, because the data is streamed at very high speeds and your uC RAM is way too small.

You might have more luck with the FIFO version (I don"t have experience with that version). But then again, a 8 bit uC has very little RAM so you would be able to process a very scaled down (in resolution) image. If you are using the uC as a buffer to a higher speed interface, then the lack of DMA and processing power will make the uC a bottleneck.

Not true I got it working with an arduino uno I get about 1fps at qvga. Also this is the version without the fifo see http://forum.arduino.cc/index.php?topic=159557.0 and check out my github project for working code https://github.com/ComputerNerd/arduino-camera-tft

On every PCLK transition you should read D0-D7 (one byte), these bytes you read should be a Cb byte, then a Y byte, next a Cr byte, a Y byte again, and the cycle repeats with Cb and so on. (Assuming you are correctly synchronized by HREF and VSYNC)

"A PCLK of 24 MHz will produce 30 fps, a PCLK of 12 MHz will produce 15 fps and so on. All this is independent of the format of the image (VGA, CIF, QCIF, etc)."

I mean, in my purpose I just need to sample the Y component and I can sample it only on the 2nd (and 4th and so on...) rising edge of a 24Mhz PCLK: so pratically I"m working with a 12Mhz pixel clock!

In order to have 30fps and assuming that I"m using the default parameters, I need to feed the XCLK of the camera with a 48Mhz clock... Is my idea right?

Take a look at the Figure 6 of the datasheet. Say XCLK is 24 MHz, and using the default SCCB configuration PCLK would be 24 Mhz. From the figure, t_plck is the period of PCLK and t_p = 2 * t_pclk.

t_p is two clock cycles of PCLK, i.e. the necessary time to grab a pixel (on the formats of the OV7670, on average each pixel is equivalent to 2 bytes).

For VGA, you have 480 lines of 640 pixels. Each line lasts t_l = 784 * t_p, with HREF active only for 640 * t_p. Next, each frame lasts t_f = 510 * t_l, but you only get lines during 480 * t_l.

I"ve only worked with YCbCr422, but for other formats like RGB565, the t_p = 2 * t_pclk should hold. For other image sizes t_f and t_l also hold, is the active part of HREF what gets shorter and the the numbers of transmitted lines also gets reduced.

In conclusion, XCLK should be 24 MHz and you should read the D0-D7 pins only on every even (2, 4, ...) rising edge. You"ll end up with 30 fps, but each pixel will be 1 byte (Y component) long.

can we intrface ov7670 with pic16 and wnted to know about the rgb output format of ov7670 ?how will the camera capture the image ?will we require a video sync separator?

Finally, you might want to check my last post (the link is the end of this post) with 3 demos about using the STM32F4, the OV7670 and qSerialTerm, the source code is available.

I"m working with this Camera and with the STM32F4 and i manage to get values from the Camera but i"m having trouble making the serialTerm work. It complains about me not having the serialport.h library. I did like it says in the wiki, i got serialport first i installed the library it says there and i installed Qtcreator for ubuntu and then i just opened your serialTerm project and did "play" and i get that error. Can you help me?

I just checked that the last commit to the qtserialport library introduced a compilation error, this is the reason why qSerialTerm can"t find the library, it"s because qtserialport didn"t got build and didn"t got installed.

I"m using the same exact set up you have here for a school project and I can successfully communicate with the camera via I2C routines. The next step I"m trying to do is configure the DCMI to capture the image and store in an internal buffer to verify that the DCMI is collecting the data. My problem is I never get anything in the DCMI->DR register although the Vsync and Hsync are being triggered in the SR. I think I"m messing up in the configuration of the DCMI and DMA. Think you could help me out?

I"ve read over the examples you provided there but I"m developing in .C not .cpp. I understand the translation over to C but maybe you could explain a few things. You mention that the Discovery board cannot be used because all of the DCMI pins cannot be accessed but I"m not certain that is the case. Also I assumed that the DCMI would also handle the complete capture of a frame such that it automatically determines when vsync and hsync occurs and clears the flags after capturing the data and transferring it through the dma ect. Is this true or do I need to create a routine that handles the actual capture when thos flags are set?

If you configure correctly both the DCMI and the DMA, the only thing that you need to do is: (1) start a capture on the DCMI (set the CAPTURE bit high) and (2) wait for the capture complete interrupt. After that, all the data will be in the memory region you selected for the DMA.

Even so as long as the Vsync Hsync and Pclk are not interfere with other components on the board, some sort of data should be in the buffer. Even if the data is wrong that would be better than where I am. So I can assume since we are both using the same Vsync Hsync and Pclk pins that I have something configured incorrectly with either my DCMI and or my DMA since nothing is being stored in my buffer.

I am not receiving anything in the RIS register at all. the only registers that change are the config registers during init. the Sr register sets the vsync and hsync after dcmi_cmd() and only the capture bit gets set when the dcmi_capturecmd() is called. So basically the stm is not recognizing the hsync and vsync signals coming in it seems... Does this sound like it could be a hardware problem. that those components are effecting the way PA4 PA6 and PB7 are supposed to be working?

+ Leave the XCLK running, and poll the HSYNC, VSYNC and PCLK pins using the GPIO module, not the DCMI module. This would rule out the possibility of a badly configured DCMI.

+ Leave the XCLK running, hook a logic analyzer or an oscilloscope to the HSYNC, VSYNC and PCLK pins, and by looking at the signals you"ll know whether the other components on the board distort those signals or not.

I"ll try to help as long as my experience and time allow me. I"ve received a lot of help in my life, and this feels like a good way to retribute that. :)

I am fairly new to i2c and would like a quick start using the 0v7670 cam and the arduino uno. Would you happen to have code I can run to test the functionality of my cam. The simplest configuration of the cam would be nice. Perhaps being able to save to an sd card the image taken. Thanks a lot.

2) It"s not I2C it"s SCCB, there are minor differences. And you don"t need SCCB to get frames from the camera, you need a parallel interface. The SCCB is for configuration, but the camera works well with the default configuration.

3) There is a link at the bottom of this post, that contains source code of 3 demos using the STM32F4 and the OV7670. That code won"t work with your arduino but it will give you an idea of how to work with the camera.

Hi. We are working with the OV7670 and also the OV7725 sensor. Found out the hard way that the OV7725 MUST have an external clock fed into the sensor. Our OV7670 is the version that features an onboard 24 Mhz clock source so it was not required. Can you confirm if your version of the module needs an external clock ? Is your I2C (SCCB) bus working ? We found that even the I2C bus NACKed without the external clock source. We fixed the issue by applying 25 Mhz into pin 8 for our OV7725 module (wayengineer.com, China). Soon we will work with the "raw" OV7670 (no FIFO) after we validate the version with FIFO in our design.

I have an OV7670 on order and have a few questions. I"m using an Arduino Uno which has a 3.3V out, but not, I guess, at sufficient rating for the camera. Also, the camera has 3V IO pins while the Arduino uses 5V. Where do I get these lower voltages from? I have seen level shifters, is this what I need? Sorry about the simlest of questions, from the look of posts here this may be the least of hurdles in front of me.

a) Did you receive your OV7670 module ? Please post the details on your sensor as they most definitely vary from vendor to vendor. Is your module the "raw" sensor (without FIFO) or with FIFO and oscillator ?

b) Likely there is enough current @ 3.3 volts from your Arduino to supply the sensor. However, before you go there, share the details on the sensor so we can confirm if you have onboard regulators to properly lower the (multiple) voltages required by the actual OV7670 sensor itself. Next, the voltage swing for the I/O should be lowered to 3.3 volts or perhaps even lower, again depending on the version of the module you actually purchase. Our module is being interfaced with the AL422B fifo which is operating @ 3.3 volts so we are fine with I/O @ 3.3 volts. The pins we have seen on the module, except for the I2C Clock and I2C Data, are all unidirectional. So, it is possible to purchase level shifters that will lower the voltage to suit the module from 5 volts to say 2.8 volts, etc. More on this later after we know about your module :)

Hi Jorge. Many thanks for this great webpage. It has helped a lot to better understand the OV7670 (we have one with FIFO & 24 Mhz oscillator) we have sourced from one of the offshore vendors.

If we cover the module, the values will turn into 80(hex) and 00 but again in varying order. Perhaps we are not extracting the values properly from the AL422B FIFO ?

We will map to a local LCD screen within a few days but wanted to confirm the BLACK color output. The results that are posted are without priming the sensor. Thanks again !!

No that is correct the ov7670 outputs yuv422 by default. If you are sending it to an lcd you may want to set it to rgb565 mode but be aware that rgb565 mode is very bad quality. If your microcontroller is fast enough try converting from yuv422 to rgb565 in real-time that results in a much better image.

Hi to everyone I have buyed this camera http://dx.com/p/ov7670-al422b-fifo-cmos-camera-module-w-dupont-cable-for-smart-car-153842, im trying to connect it to the STM32F4discovery board using the bit bang version of SCCB, but I cant get the camera to work, I dont know if the delay time (500) is the problem, the STM32 is running at 144MHZ Im trying to see the waveform in the osciloscope but nothing happens, what it could be? thnks in advance

Hi, well the camera is working, but the colors are wrong, it shows purple instead of white, what registers should I change in order to get RGB 565? in somewhere I did read that purple color is white without green component however I can see the green bar in the test pattern I will apreciate any help thank you

we are getting distorted picture, we found is that some of the pixels are getting missed within each frame of total 640 frames (for vga mode 640x480) and hence we are neither able to get full picture size nor good colors of an image".

I"m having an inordinate amount of difficulty getting my camera module to respond to my bit-banged SCCB, which is based directly off the code helpfully provided by the author of this blog post. Could someone please point me in the right direction?

You"ll see a start condition, setup to write to 42, sub address 0, an ACK (by the master...the slave has never once ACKed or NACKed). Then a stop condition, start condition, and phase two, which is setup a read at 43, then the clock line is pulsed 8 times, at which point the slave doesn"t assert the data line. This process then repeats for subaddress 1, 2, etc.

3. I had a few places where I was inadvertently driving the Don"t Care bits without setting my SIOD line to input mode, and I think that it could"ve been preventing the slave from asserting it when it wanted.

a. Start condition, 8 bits for the bus address for write, 1 D/C bit, 8 bits for the register memory address, 1 D/C bit, Stop condition. Start condition, 8 bits for the bus address for read, then pulse the clock to read 8 bits and then 1 NACK/ACK bit (or maybe it"s a D/C). Stop condition.

5. Another big issue was that the datasheet just says the write address is 42 and the read address is 43. What they neglect to make explicit is that it"s 0x42 and 0x43, not 42d and 43d! Sheesh. Maybe it was clear to everyone else, but not to me.

A logic analyzer and (to a lesser extent) an oscilloscope helped immeasurably in solving this. (The output you see in that screenshot is from the Saleae Logic analyzer.)

https://my.st.com/public/STe2ecommunities/mcu/Lists/cortex_mx_stm32/Flat.aspx?RootFolder=%2fpublic%2fSTe2ecommunities%2fmcu%2fLists%2fcortex_mx_stm32%2fSTM32F4Discovery%20%2b%20DCMI%20%2b%20OV7660%20%28OV7670%29&FolderCTID=0x01200200770978C69A1141439FE559EB459D7580009C4E14902C3CDE46A77F0FFD06506F5B&TopicsView=https%3A%2F%2Fmy%2Est%2Ecom%2Fpublic%2FSTe2ecommunities%2Fmcu%2FLists%2Fcortex_mx_stm32%2FAllItems%2Easpx¤tviews=9

How much min pixel clock can give good image. If my controller is slow speed and I don"t want more than 1FPS then can I lower the PCLK less than 1Mhz?

I believe the PCLK frequency is determined by the XCLK and the scaling factor in the SCALING_PCLK_DIV register. The maximum scaling value is 16, so XCLK / 16 = PCLK_min. If you want any slower than that you"ll have to lower XCLK, which has a minimum of 10 MHz. So 10 MHz/16 MHz = 625 kHz = PCLK_min.

If you scale PCLK down with PCLK_SCALING_DIV, does that reduce the horizontal resolution? When I set it to be as slow as it can go, I get 480 HREFs interrupts (480 height) but 24 times less than the number of PCLK interrupts I need to cover every pixel (assuming 3 bytes per pixel, so it"s actually less). So my resolution is something crazy, like 80 x 480.

Here are the 3.5 QVGA 4.3 WQVGA 5.7 QVGA 7 WVGA TFT LCD modules, and always trying to stay in LCD technology in the forefront of our current technology products, including COG, COF, TAB, SMT. Believe that through our cooperation, the displayed a better world.Character LCD Module . click here

Thank you for your great forum here. I used it to get multiple things clear with my Deal Extreme ov7670 with fifo. I use the stm32F103 with a 2.4" TFT in rgb565 mode. I am past all trouble with sccb and I get good qqvga images on my TFT (I scaled to qqvga because the amount of data is less then).

My "problem" is the colors look reasonable with daylight but when it gets darker its way off. I know its a cheap camera but maybe you found a way to deal with this?

Hi Jorge, thank you for the really informative post on the OV7670. I was wondering if you have any experience with similar modules, but with a higher resolution? I"d like to experiment with something >3MP.

Thanks for this very useful tutorial! I was thinking about buying this camera and then writing a tutorial on it, but you have already made a good tutorial, so now I just need to buy the camera :-)

Great post!! Helped me with some issues I had with the OV7670. I managed to get it running von an AVR uC (and more). For all the AVR freaks out there: https://github.com/arndtjenssen/ov7670

hello I wanted to know if you think it is possible to use a different module than the OV7670. I wanted to have a much higher resolution type 12/14 Mpx but with 1 frame per minute.

If it"s like the OV7670, make sure PWDN and RESET are in proper states, supply 3V3 and GND, and pulse XCLK at a valid frequency. At that point you should start to see the OV7670 driving HREF, VSYNC, PCLK, and D0-D7. I"m not sure if it"s necessary, but I think you"re also supposed to pull-up SIOC and SIOD.

I have a OV7670 camera without FIFO. In order to test it, before try to get an image, I wish to read valid pixel data and print them trough the serial port.

I have connected output pins d0 to d7, href, vsync, to digital input pines of ARDUINO MEGA 2560 board, and the camera is powered by 3.3 V from ARDUINO board.

I need some help to control this camera, if you know any way to view images (don’t care the format, I’m not changing registers, I use the default configuration) only with arduino mega board and a PC it will be great, and useful to my project.

Finally i made the OV7670+FIFO module work with STM32F103, it took me months and a lot of tests (trying different versions of OV7670 without FIFO i got just random data...), by now i can say that the registers are a real pain, and there are LOT of things that can get messed up just by modifying one bit of any register, and that there even are reserved registers that must be set to an adequate value, i don"t know why but even the output sequence (first and second byte ) gets swapped by a register that is unknown. Here I publish the register values that worked to RGB565, QVGA (XCLK signal is given by a 25MHZ osc).

Diego, thanks so much for pasting your registers. I, too, have spent months trying to work with this camera, and I"ve tried multiple OV7670s with and without FIFO buffers. I"m also trying to use RGB565 with QVGA, and your register values have gotten me closer than my previous attempts.

- Do NOT write more registers and more registers just to make things work, things dont fix up, they actually mess up, as an example i got the camera to work, but if i write some more registers it screw up again!

- The registers that i provided should work if you feed the camera with an 24MHz clock signal, you can either provide it with a crystal, or with the MCO pin of your stm32f.

- Even when registers say "disable AEC" or whatever, AEC values do have an impact on the output, so dont just trust that disabled features wont affect. In particular case check that AEC, AGC, AWB have coherent values and same case for YUV

Ask anything else, because i tend to forget things with time, i just dont know why this 0v7670 works so fine all over the internet, but with some people like us it is a real pain...

I write one set of function for control sccb bus, I see at the oscilloscope and I think is correct but ov7670 don"t respond.... for test my code I try to control one sensor with bus i2c and it respond....

Almost forgot to tell you, make SURE that PWDN and RST pins are connected, dont just trust that they have pull up/down resistors. My registers worked, but if i dont connect this pins i get totally random data

Thanks for the replies, Xavier! I forgot to mention that I"m using the one with a FIFO buffer, so the RST and PWDN pins are already connected. However, I"ll dump my registers and check the things you indicated. The FIFO version should feed it with 24 MHz.

I use the reset registers feature (writing a 1 to some register and then a 0, to get it to reset to default values), but considering how sensitive this stupid camera is, maybe the default values are wrong?

I dumped the registers and sometimes default values for 0x00 to 0x04 are wrong, so better write them, i checked all the registers, when you dump them most of them have its default values and don"t worry to much about it

Does anybody can comment schematics how RST and PWDN pins should be connected to STM32 pins? And what pins configuration I need to setup for those. My pilot still not starting up...

One thing I found is that in the modern OV7670 the RST is active low, but in an older datasheet it"s active high- so be careful- for modern OV7670 chips, RST should be high for normal operation (and PWDN should be low for normal operation).

but I just can"t get anything... I can"t get any signal from the camera when I have my SIOD configured in input, like if the camera was dead. Here the sequence is simple : Start, write 0x42, write 0x02, stop, start, write, 0x43, read SIOD, stop. But nothing appears.

You could start by getting the write working by observing that the data pins live and then write to the sleep register which should make the camera stop responding.

Yep, XCLK at 16MHz, and I have all the video data outputs OK. I tried what you proposed, writing 0x11 at 0x09, but nothing works, I still have outputs on d0-d7... I tried pulling UP with 10k, with 22ohm serial to the stm32f4, but nothing... And when I simply pull up with 10k, without 22ohm serial, and if I use the I2C standard (All Open drains I/O), I have this signal :

Ok finally I got it to work perfectly. It needed to have a 30k pull up resistor, all open drain, and my sioc signal was not good enough, in the sense it was not a good clock signal, needed to change a few delays in my bit bang sccb algorithm. Now it is perfect. :)

I"m trying to implement my own bit-bang SCCB version too, but can"t get response from OV7670. The SCCB specifications at hand are very vague, that"s why I have to make sure that what I send could be understood by OV7670. Could you please provide me with timing diagram of voltage on SIOD and SIOC pins during simple transaction (e.g. start, address 0x42, write bite, 9th bit, subaddress, 9th bit, stop)?

Is it possible to use subwindowing to get a higher framerate? I want capture a total of a hundred pixels with resolutions ranging from 2x50 to 10x10. I need 1000+ frames per second for my project. I looked into using a optical mouse but they are usual only 15x15 and capturing the indivual pixel data for each frame is very slow compared to a camera.

Is it possible to use subwindowing to get a higher framerate? I want capture a total of a hundred pixels with resolutions ranging from 2x50 to 10x10. I need 1000+ frames per second for my project. I looked into using a optical mouse but they are usual only 15x15 and capturing the indivual pixel data for each frame is very slow compared to a camera.

I am interfacing omnivision"s (ov5640)image sensor with the FPGA and was able to capture raw frame in YUV422 format through the digital video port (DVP) parallel output interface.Now I am trying to capture the JPEG compressed output.The datasheet doesnot provide much detail of the JPEG mode and Since I have never studied JPEG mode I am unable to understand what the sensor will output in this mode(what bytes mean e.g. in raw yuv mode I knew the bytes coming are luma and chroma intensity values) and Whether the sensor will output only the scan data or it will ouput all other necessary headers and info. that is required to make a complete JPEG file.I will be thankful for any help

I"m giving the camera 8Mhz clock signal from XCLK pins. But the camera does not give I2C ACK signal from the line. I send from the device address 0x42. I"m sending the camera device my address wrong.

What kind of wires are you using to connect camera to micro controller. due to the impedance mismatch I2C SCL line will distorted. always use thin small lengrh wires to connect camera with micro controller

sir, i m dng a project with arduino UNO..i have a camera module ov7670 which i want to connect to UNO board..for capturing and save it into the sd card i need a arduino code for it i m trying from 10 dys can any 1 help me.. my email id: sharanfrndz@gmail.com

I was wondering if there was a way to get higher then 30fps by sampling a very small array of pixels (30x40). You said that that the framerate is set by the clock speed and the image resolution. Is it possible then to go beyond 30fps (I need something around 200-400FPS) by sampling a very low resolution image (at least 20x20)

Thank you for your post and replies for above comments. They were really useful for me to sucess with STM32F4 discovery board connecting to OV7660 camera module. OV 7660 is almost same as OV7670 . I included all the details on my blog. Thanks again for your help.

I´m trying to interface OV7670 but I have a problem with output data. Camera still returns data on parallel bus Y: <5 Cb: >123 Cr: >123 and data wont change when I remove the cover -> still returns black image. Can anyone help please? Can be the problem, that XCLK runs only at about 2MHz?

I"m trying to implement my own bit-bang SCCB version, but can"t get response from OV7670. The SCCB specifications at hand are very vague, that"s why I have to make sure that what I send could be understood by OV7670. Could you please provide me with timing diagram of voltage on SIOD and SIOC pins during simple transaction (e.g. start, address 0x42, write bite, 9th bit, subaddress, 9th bit, stop)?

hello sir, thank you for a very in-depth post. maybe you can help me with my question; http://www.instructables.com/community/arduino-wifi-time-lapse-camera/

I can confirm that the OV7670 blue boards required input on XCLK for the SCCB to respond. No FIFO, with onboard 3.0v and 1.8v regulators. That is with default register values. There may be some value to change that but you would have to communicate with it to change it. Chicken Vs. The Egg.

After I made some bit-bang code, PIC32EP series, for write and read all seemed good. Most of which I ported over old code from another project. However the data for read operations was 50/50 consistent. 1/2 the time the camera did not ACK (drop the 9th bit low) after sending it the first phase or even second phase ID address. My issue was I did not toggle the SDA (SIOD) line before toggling the clock. The PIC32EP series is 5 times faster than my older chipset!! 14.2nanoseconds between the two. Its a 70mips pic for goodness sake. After a day it dawned on me I need to add some extra delays before toggling the clock line SCL(SDIOC)

Main tip for SCCB control. Make sure you toggle data way before toggling clock. If you have no scope around, start with 10microseconds between the two. Just send in a loop the ID address. If you dont get an ACK each time, you need to fix your code before bothering to do anything else.

Upps, meant PIC24EP. I wish Microchip would come out with a 32bit version. Not the borrowed from someone else"s 32bit micros they sell, real genuine microchip instruction set based 32bit micro.

And another thing: is it really true that you can"t get a bigger framerate with lower image formats? Is there any way around? Could I try to take a limited number of lines from the camera and then force it to restart the pixel parsing?

First of all I would like to say great blog! I learned a lot about pixel formats and the OV7670. Would it be possible for you to send me the windows 7 installer .exe file for this version of qSerialTerm or the most up to date one? I downloaded QT Creator and your source code only to painfully realize I had no idea what I was doing... It would be greatly appreciated!

In YUY2 format, the data can be treated as an array of unsigned char values, where the first byte contains the first Y sample, the second byte contains the first U (Cb) sample, the third byte contains the second Y sample, and the fourth byte contains the first V (Cr) sample, as shown in the following diagram.

If the image is addressed as an array of little-endian WORD values, the first WORD contains the first Y sample in the least significant bits (LSBs) and the first U (Cb) sample in the most significant bits (MSBs). The second WORD contains the second Y sample in the LSBs and the first V (Cr) sample in the MSBs.

This format is the same as the YUY2 format except the byte order is reversed—that is, the chroma and luma bytes are flipped (Figure 4). If the image is addressed as an array of two little-endian WORD values, the first WORD contains U in the LSBs and Y0 in the MSBs, and the second WORD contains V in the LSBs and Y1 in the MSBs.

Aat least this byte order in the Format YUY2, ie. YUYV is the default output for the default register settings of the registers TSLB and COM13. Using these registers you can also swap the bytes according to your wishes.

am looking few years that some guys comes into the market they called themselves hacker, carder or spammer they rip the peoples with different ways and it’s a badly impact to real hacker now situation is that peoples doesn’t believe that real hackers and carder scammer exists. Anyone want to make deal with me any type am available but first I‘ll show the proof that am real then make a deal like

am looking few years that some guys comes into the market they called themselves hacker, carder or spammer they rip the peoples with different ways and it’s a badly impact to real hacker now situation is that peoples doesn’t believe that real hackers and carder scammer exists. Anyone want to make deal with me any type am available but first I‘ll show the proof that am real then make a deal like

i have been doing this for two years and its 100percent guaranteed and sure. ripping and scamming is for low lives. before any transfer you pay 70percent before transfer and

Previously I was unable to capture 320x240x2-byte frames due to memory limitations on the ESP32. But the LCD has its own frame-buffer memory sufficient for this task.

So when we take a snapshot, we detach the camera from the data bus and allow the ESP32 to read back the image data from the LCD framebuffer in useful sized chunks.

The ESP32 can then send the data chunk-by-chunk to a host PC over a serial interface, or perhaps store a file in the SPIFFS file system, or on a Micro SD card.

Because the eight camera data lines no longer come into the ESP32, I free up enough GPIO pins for some extra control signals, reading the touch screen, and having a second serial port to transmit the image to a host PC.

The "common bus" shared between three devices - the camera, the ESP32, and the LCD, requires that we are able to detach the camera data or the ESP32 data from the bus. So the ESP32 takes on the role of bus controller.

To achieve this I added two common ICs to the design: a 74LS244N bus line driver sits between the camera data lines and the LCD bus lines. It allows me to tri-state the 8 camera data lines (put the output pins into high impedance so that the ESP32 / LCD can use the bus without interference).

The 74LS244N driver only has 8 lines, I needed a 9th one for the pixel clock (PCLK). When the camera data is flowing onto the bus, we need its pixel clock (PCLK) to also be routed to the LCD_WR clock line on the LCD. But when the ESP32 is using the shared bus, it needs control of the LCD_WR line. I implemented a 2-input A/B multiplexor to route either PCLK or a GPIO line to LCD_WR using a single 74LS00N chip. The 74LS00N contains four 2-input NAND gates, enough logic to build a multiplexor for 2 inputs.

In addition, I used a 74LS244N bus driver IC and a 74LS00N quad NAND gate IC that I happened to have available. This bus driver is now obsolete, but there are plenty of newer 74LS244x replacements that should do the job as well or better.

The camera data flows through the bus driver onto shared wires that also connect to the LCD and the ESP32. The bus driver has two enable lines - each controls 4 bus output lines. Here I tied the two enable lines together so that a single GPIO pin from the ESP32 can allow the camera data through, or block the data by tri-stating the output lines.

In software, by toggling this tri-state control GPIO line, we allocate the bus to either allow Camera->LCD communication, or LCD<-->ESP32 communication.

When we give the bus to the camera, we also tri-state the ESP32 GPIOs (in fact, making them INPUT is good enough) so that the camera and ESP32 devices do

The VGA timing specs from the camera datasheet (QVGA and QQVGA are subsampled from this timing) have what I call a CountDown interval - the time between the rising edge of VSYNC and the rising edge of the first HREF on the first scan line) of 20 line times. At 25 fps VGA the CountDown interval is 1568 microseconds - and a bit longer for QVGA, which is what we use.

this time that our main loop can take the bus away from the camera and can overlay our own pixels onto the existing image, or set up the destination area for the next data to the LCD, look for touch events, etc.

We also set a camera register that allows us to blank PCLK when no pixel data is present: our LCD doesn"t understand the camera synchronization, and any free-running or spurious clock pulses would cause it to latch invalid data from the bus. This frees us from strict at-the-exact-PCLK timing constraints - it doesn"t matter if we detach or attach the camera onto the bus at any time during CountDown.

This library enables you to use ISR-based PWM channels on AVR ATmega164, ATmega324, ATmega644, ATmega1284 with MCUdude MightyCore, to create and output PWM any GPIO pin

This library enables you to use Hardware-based PWM channels on Arduino AVR ATtiny-based boards (ATtiny3217, etc.), using megaTinyCore, to create and output PWM to pins.

This library enables you to use ISR-based PWM channels on Arduino AVR ATtiny-based boards (ATtiny3217, etc.), using megaTinyCore, to create and output PWM any GPIO pin.

Small low-level classes and functions for Arduino: incrementMod(), decToBcd(). strcmp_PP(), PrintStr, PrintStrN, printPad{N}To(), printIntAsFloat(), TimingStats, formUrlEncode(), FCString, KString, hashDjb2(), binarySearch(), linearSearch(), isSorted(), reverse(), and so on.

Cyclic Redundancy Check (CRC) algorithms (crc8, crc16ccitt, crc32) programmatically converted from C99 code generated by pycrc (https://pycrc.org) to Arduino C++ using namespaces and PROGMEM flash memory.

Write decimal numbers, hex numbers, temperature, clock digits, characters, and strings to the seven segment LED modules supported by the AceSegment library.

Date, time, timezone classes for Arduino supporting the full IANA TZ Database to convert epoch seconds to date and time components in different time zones.

Useful Arduino utilities which are too small as separate libraries, but complex enough to be shared among multiple projects, and often have external dependencies to other libraries.

Fast and compact software I2C implementations (SimpleWireInterface, SimpleWireFastInterface) on Arduino platforms. Also provides adapter classes to allow the use of third party I2C libraries using the same API.

Enables Bluetooth® Low Energy connectivity on the Arduino MKR WiFi 1010, Arduino UNO WiFi Rev.2, Arduino Nano 33 IoT, Arduino Nano 33 BLE and Nicla Sense ME.

ESP32 + LwIP ENC28J60, including ESP32-S2, ESP32-S3 and ESP32-C3, Connection and Credentials Manager using AsyncWebServer, with enhanced GUI and fallback Web ConfigPortal.

ESP32 + LwIP W5500 / ENC28J60, including ESP32-S2, ESP32-S3 and ESP32-C3, Connection and Credentials Manager using AsyncWebServer, with enhanced GUI and fallback Web ConfigPortal.

ESP32 + LwIP W5500, including ESP32-S2, ESP32-S3 and ESP32-C3, Connection and Credentials Manager using AsyncWebServer, with enhanced GUI and fallback Web ConfigPortal.

(ESP8266 + LwIP W5500 / W5100(S) / ENC28J60) Connection and Credentials Manager using AsyncWebServer, with enhanced GUI and fallback Web ConfigPortal.

Simple Async HTTP Request library, supporting GET, POST, PUT, PATCH, DELETE and HEAD, on top of AsyncTCP library for ESP32/S2/S3/C3, WT32_ETH01 (ESP32 + LAN8720), ESP32 using LwIP ENC28J60, W5500, W6100 or LAN8720.

Simple Async HTTP Request library, supporting GET, POST, PUT, PATCH, DELETE and HEAD, on top of AsyncTCP libraries, such as AsyncTCP, ESPAsyncTCP, AsyncTCP_STM32, etc.. for ESP32 (including ESP32_S2, ESP32_S3 and ESP32_C3), WT32_ETH01 (ESP32 + LAN8720), ESP32 with LwIP ENC28J60, W5500 or W6100, ESP8266 (WiFi, W5x00 or ENC28J60) and currently STM32 with LAN8720 or built-in LAN8742A Ethernet.

Simple Async HTTP Request library, supporting GET, POST, PUT, PATCH, DELETE and HEAD, on top of AsyncTCP_RP2040W library for RASPBERRY_PI_PICO_W with CYW43439 WiFi.

Simple Async HTTPS Request library, supporting GET, POST, PUT, PATCH, DELETE and HEAD, on top of AsyncTCP_SSL library for ESP32/S2/S3/C3, WT32_ETH01 (ESP32 + LAN8720), ESP32 using LwIP ENC28J60, W5500, W6100 or LAN8720.

Simple Async HTTPS Request library, supporting GET, POST, PUT, PATCH, DELETE and HEAD, on top of AsyncTCP_SSL library for ESP32 (including ESP32_S2, ESP32_S3 and ESP32_C3), WT32_ETH01 (ESP32 + LAN8720) and ESP32 with LwIP ENC28J60, W5500 or W6100.

Fully Asynchronous UDP Library for ESP8266 using W5x00 or ENC28J60 Ethernet. The library is easy to use and includes support for Unicast, Broadcast and Multicast environments.

Fully Asynchronous UDP Library for RASPBERRY_PI_PICO_W using CYW43439 WiFi with arduino-pico core. The library is easy to use and includes support for Unicast, Broadcast and Multicast environments.

Fully Asynchronous UDP Library for Teensy 4.1 using QNEthernet. The library is easy to use and includes support for Unicast, Broadcast and Multicast environments.

ESP32 + LwIP LAN8720, including WT32-S1, ESP32-S2, ESP32-S3 and ESP32-C3, Connection and Credentials Manager using AsyncWebServer, with enhanced GUI and fallback Web ConfigPortal.

This library provides a low-level facility for context switching between multiple threads of execution and contains an implementation of asymmetric stackful coroutines on an AVR micro-controller.

The last hope for the desperate AVR programmer. A small (344 bytes) Arduino library to have real program traces and to find the place where your program hangs.

This library enables you to use Hardware-based PWM channels on AVR-based boards, such as Nano, UNO, Mega, Leonardo, 32u4, etc., to create and output PWM.

This library enables you to use ISR-based PWM channels on AVR-based boards, such as Mega-2560, UNO,Nano, Leonardo, etc., to create and output PWM any GPIO pin.

Enable inclusion of both ESP32 Blynk BT/BLE and WiFi libraries. Then select one at reboot or run both. Eliminate hardcoding your Wifi and Blynk credentials and configuration data saved in either LittleFS, SPIFFS or EEPROM.

Simple Ethernet Manager for MultiBlynk for Teensy, SAM DUE, SAMD21, SAMD51, nRF52, ESP32, ESP8266, RP2040-based (Nano_RP2040_Connect, RASPBERRY_PI_PICO) boards, etc. with or without SSL, configuration data saved in

Ms.Josey

Ms.Josey

Ms.Josey

Ms.Josey