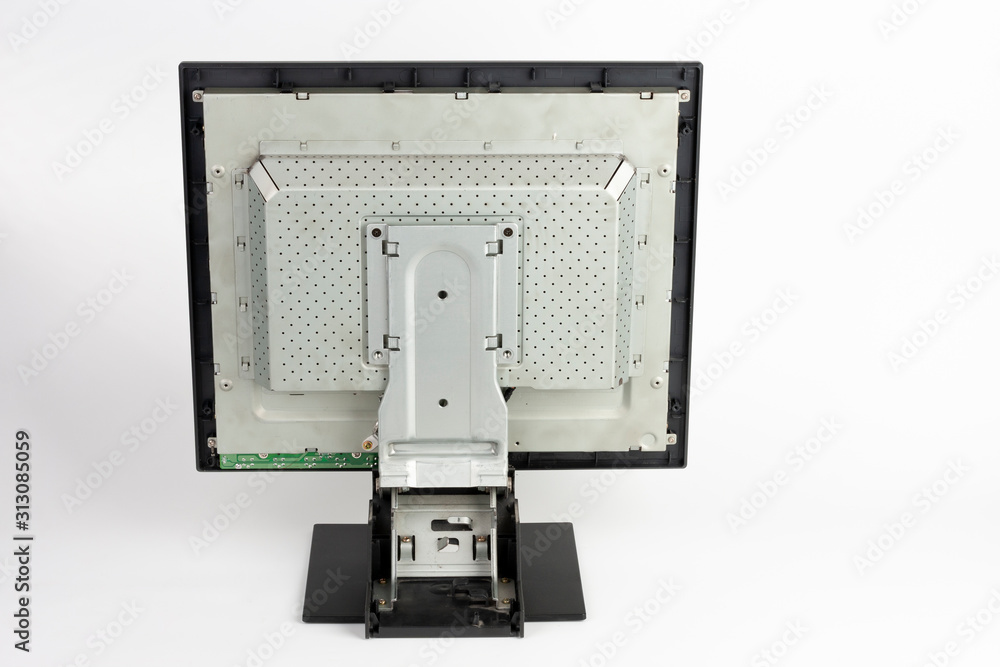

plastic lcd display in stock

FPD (Flat Panel Display), LCD (Liquid Crystal Display), and TFT (Thin Film Transistor Display) - Flat panel displays are electronic viewing technologies used to enable people to see content in a range of entertainment, consumer electronics, personal computer, and mobile devices, and many types of medical, transportation and industrial equipment. A liquid-crystal display (LCD) is a flat-panel display or other electronic visual display that uses the light-modulating properties of liquid crystals. Liquid crystals do not emit light directly. LCDs are used in a wide range of applications including computer monitors, televisions, instrument panels, aircraft cockpit displays, and indoor and outdoor signage. Small LCD screens are common in portable consumer devices such as digital cameras, watches, calculators, and mobile telephones, including smartphones. A thin-film-transistor liquid-crystal display (TFT LCD) is a variant of a liquid-crystal display (LCD) that uses thin-film transistor (TFT) technology to improve image qualities such as addressability and contrast. TFT LCDs are used in appliances including television sets, computer monitors, mobile phones, handheld video game systems, personal digital assistants, navigation systems and projectors. TFT LCDs are also used in car instrument clusters because they allow the driver to customize the cluster, as well as being able to provide an analogue-like display with digital elements. The production of these panels utilize a variety of materials for testing, and handling including LCD Lift Pins made from Celazole® PBI, and Vespel® PI.

First, the KEP KAL-D06 Miniature LCD Display is a low cost display for customers looking for an inexpensive way to read flow remotely. Secondly, it’s so easy to install.

This is one of our most popular display products. Ultimately it’s a cheap way to get quick readings from another location. Moreover, customers can use it custom to their needs.

Simplicity is key. In fact, the KEP KAL-D06 Miniature LCD Display was designed to save you money. Lastly it doesn’t take a genius to understand how to use it.

New: A brand-new, unused, unopened, undamaged item in its original packaging (where packaging is applicable). Packaging should be the same as what is found in a retail store, unless the item was packaged by the manufacturer in non-retail packaging, such as an unprinted box or plastic bag. See the seller"s listing for full details.See all condition definitionsopens in a new window or tab

Plastic substrates for flexible displays are well known for their mechanical benefits such as thinness, lightness and flexibility, but their optical advantages are less cited. This blog post aims to shed light on the optical advantages of using plastic substrates as an alternative to glass for LCD.

Before I describe the optical advantages of plastic substrates, I should briefly explain the structure of a glass LCD and that of a plastic LCD and how they compare in terms of thinness and lightness.

Glass LCDs consist of a glass backplane containing the thin-film transistors (TFTs) and a glass frontplane containing the colour filter. In between these sheets of glass is the liquid crystal (LC) cell – the optical switch that shutters the light from passing through to the viewer.

The thickness of these glass sheets can vary depending on the size and performance of the display and is often in the range of 400-700 microns (μm) for each glass sheet, during processing. For some high-end ultra-slim LCDs the 400μm glass can be further thinned in post-processing down to 200μm – allowing for thinner notebooks and tablets, for example.

Organic LCDs (OLCD) consist of organic TFTs built directly onto a plastic film and commonly use a plastic called tri-acetyl cellulose (TAC) film for the substrate which is typically just 40μm thick. For a 13” notebook screen, for example, moving from glass to TAC can reduce thickness and weight by at least 0.5mm and 100g respectively.

The mechanical advantages of plastic OLCD over glass LCD are further enhanced by the technology’s excellent optical performance, much of which originates from the extreme thinness of plastic TAC substrates compared to glass.

There’s a common optical effect in displays that reduces image quality, called sparkle. You may not have heard of it, but you’re probably familiar with it. Have you ever seen the little coloured pixels on your smartphone screen when a drop of water lands on the surface? This happens as a result of refraction, causing the viewer to perceive the pixels in a different location to their actual positon. The same effect occurs in a more subtle way with a dry screen because of surface imperfections on the front of the display, such as scratches or other roughness, causing the perceived location of the pixel beneath the glass to be changed.

A similar effect can be seen when you are standing in a swimming pool trying look down at your feet - the apparent location appears to move around as a result of the surface ripples on the water. However, in much shallower water the effect is significantly reduced. For the same reason, moving to thinner plastic substrates in displays naturally reduces the degree of sparkle that is seen – meaning a crisper uniform image on the display compared to glass-based displays.

Over the past decade LCD display contrast, particularly in TVs has continued to improve. LCD displays work by having a bright light source (backlight) sitting under the liquid crystal display pixels. Each pixel (cell) is like a window with a pair of curtains that can be opened and closed to let the backlight through - making that pixel bright or dark. However, with LCD displays, even when the curtains are completely closed, a very small amount of light still gets through, which limits how black the display can appear.

Nevertheless, LCD has continued to improve its ability to show black. In recent years this has been achieved with more sophisticated backlights that contain local dimming – allowing the brightness of the light to reduce in areas of the display where the curtains all needed to be closed (fully or partially). This is achieved by having an array of LEDs across the backlight that can be individually controlled in brightness.

An alternative to this is the so called “dual cell” structure where one display pixel (cell) is placed on top of a second display pixel. This is equivalent to having two pairs of curtains in your window – akin to a blackout blind. This means a simple, low-cost backlight can be used, and excellent blacks can be achieved. These sorts of dual cell structures have been built on glass for some time. However, combining two conventional cells requires four sheets of glass – making the TV thicker, more costly, and causing other performance limitations.

For an OLCD that uses 40μm TAC film this means that ultra-high contrast dual cells can be built and still be thinner than today’s ‘single cell’ glass LCDs, and can be manufactured in a simpler way at lower cost with higher optical performance.

The new depth meter groove processing gives better appearance, smooth slip and accurate result. Advanced Inductive Electromagnetic Sensor on site LCD digital reading shows one inch for versatility when measuring, very convenient. Wide Application: Widely used in all types of DIY measurements and archaeological measurements. The product is lightweight, easy to carry, very convenient.

The Victor 1000 is a great addition to any desktop. Features an angled LCD display that is easy on the eyes. Environmentally friendly, this calculator is manufactured with 50% recycled plastic.

A liquid-crystal display (LCD) is a flat-panel display or other electronically modulated optical device that uses the light-modulating properties of liquid crystals. Liquid crystals do not emit light directly, instead using a backlight or reflector to produce images in color or monochrome. LCDs are available to display arbitrary images (as in a general-purpose computer display) or fixed images with low information content, which can be displayed or hidden, such as preset words, digits, and seven-segment displays, as in a digital clock. They use the same basic technology, except that arbitrary images are made up of a large number of small pixels, while other displays have larger elements. LCDs can either be normally on (positive) or off (negative), depending on the polarizer arrangement. For example, a character positive LCD with a backlight will have black lettering on a background that is the color of the backlight, and a character negative LCD will have a black background with the letters being of the same color as the backlight. Optical filters are added to white on blue LCDs to give them their characteristic appearance.

LCDs are used in a wide range of applications, including LCD televisions, computer monitors, instrument panels, aircraft cockpit displays, and indoor and outdoor signage. Small LCD screens are common in portable consumer devices such as digital cameras, watches, calculators, and mobile telephones, including smartphones. LCD screens are also used on consumer electronics products such as DVD players, video game devices and clocks. LCD screens have replaced heavy, bulky cathode ray tube (CRT) displays in nearly all applications. LCD screens are available in a wider range of screen sizes than CRT and plasma displays, with LCD screens available in sizes ranging from tiny digital watches to very large television receivers. LCDs are slowly being replaced by OLEDs, which can be easily made into different shapes, and have a lower response time, wider color gamut, virtually infinite color contrast and viewing angles, lower weight for a given display size and a slimmer profile (because OLEDs use a single glass or plastic panel whereas LCDs use two glass panels; the thickness of the panels increases with size but the increase is more noticeable on LCDs) and potentially lower power consumption (as the display is only "on" where needed and there is no backlight). OLEDs, however, are more expensive for a given display size due to the very expensive electroluminescent materials or phosphors that they use. Also due to the use of phosphors, OLEDs suffer from screen burn-in and there is currently no way to recycle OLED displays, whereas LCD panels can be recycled, although the technology required to recycle LCDs is not yet widespread. Attempts to increase the lifespan of LCDs are quantum dot displays, which offer similar performance as an OLED display, but the Quantum dot sheet that gives these displays their characteristics can not yet be recycled.

Since LCD screens do not use phosphors, they rarely suffer image burn-in when a static image is displayed on a screen for a long time, e.g., the table frame for an airline flight schedule on an indoor sign. LCDs are, however, susceptible to image persistence. The LCD screen is more energy-efficient and can be disposed of more safely than a CRT can. Its low electrical power consumption enables it to be used in battery-powered electronic equipment more efficiently than CRTs can be. By 2008, annual sales of televisions with LCD screens exceeded sales of CRT units worldwide, and the CRT became obsolete for most purposes.

These displays are not constructed to be touched. It"s very important to exercise care in the handling of a liquid crystal display. The tiny dots that make up the images on the screen are each a separate transistor/crystal. Pressure can "crack" pixels easily, and when the pixels are damaged, black spots fill those areas of your monitor.

Isopropyl alcohol at 100% would not be something you"d want to soak a piece of plastic in, but in a 50/50 combination with water (or even less) it will dissolve finger-print oil and many other marking agents and evaporate quite fast (thus while it may HARM plastic if left exposed it doesn"t get the chance) and it"s evaporation process forces the water around it to also evaporate quickly.

Ms.Josey

Ms.Josey

Ms.Josey

Ms.Josey