tft display durability factory

![]()

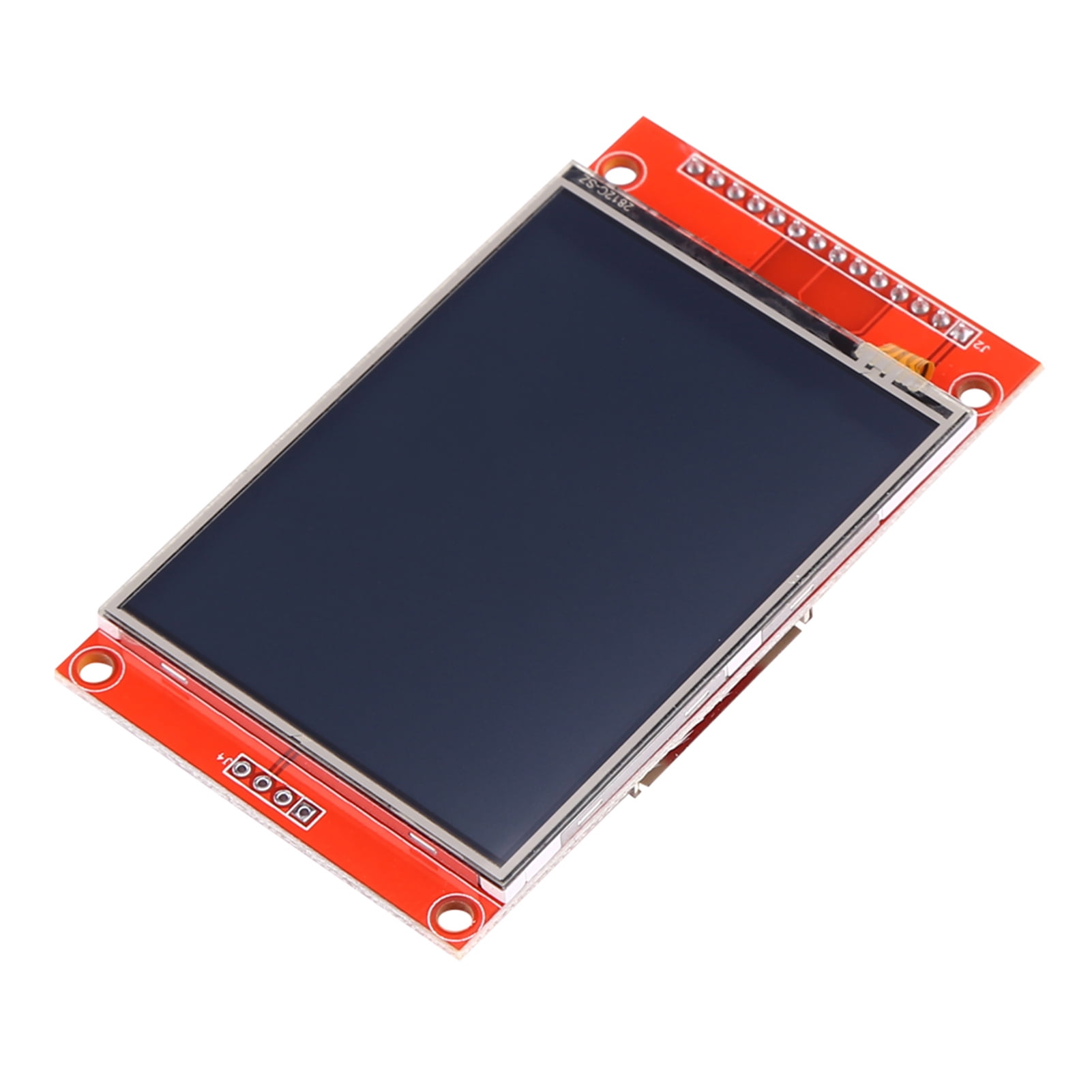

TFT displays are full color LCDs providing bright, vivid colors with the ability to show quick animations, complex graphics, and custom fonts with different touchscreen options. Available in industry standard sizes and resolutions. These displays come as standard, premium MVA, sunlight readable, or IPS display types with a variety of interface options including HDMI, SPI and LVDS. Our line of TFT modules include a custom PCB that support HDMI interface, audio support or HMI solutions with on-board FTDI Embedded Video Engine (EVE2).

For many years, TFT displays have been the dominating technology in visualization. TFT LCDs are all around in our daily lives — in consumer and automotive applications, in our business environments, in healthcare, and within communication devices, home appliances, and factory automation products. While there are many LCD products available today, they’re not all suitable for every application. This is especially the case for industrial LCD monitors. To determine the best LCD display for your application, it’s important to understand your target market and its unique design issues.

The vast majority of LCD displays are designed for consumer devices such as smartphones, cameras, tablet computers, and gaming devices. But they have very different requirements than those for industrial applications. Due to very competitive pricing and quick production cycles, consumer display modules don’t always incorporate the durability, reliability, and advanced features required to survive in an industrial environment. Product life cycles are also typically much shorter in consumer applications. Screens manufactured for these applications are generally only available for one, in best case two years.

In contrast, display modules for industrial applications require Long product life cycles— often up to ten years or more. Plus, when an industrial module is discontinued by the manufacturer, a successor product should be backward-compatible so as to fit into the existing enclosure without requiring a redesign of the entire system.

The ability to withstand temperature variations as well as shock and vibration is also a key consideration when selecting displays for today’s industrial applications. They must be resilient enough to withstand frequent bumps or jiggles by machine operators and surrounding equipment, and also must be able to handle various operating temperatures.

Industrial displays are typically housed in an enclosure as part of a larger piece of equipment. In these situations, the heat generated by the surrounding equipment gets trapped within the enclosure, which can be detrimental to many displays. Therefore, it’s important to keep the real storage and operating temperature requirements in mind when choosing a display. While measures can be taken to dissipate the generated heat — such as using fans within the enclosure — the most efficient way to ensure compliance with the storage and operating temperature requirements is to select a display that is optimized for these types of environments. Fortunately, improvements in liquid-crystal materials have made it possible to extend the operating temperature ranges of LCDs from –30 to 80°C presently.

It’s important that displays used in industrial applications support clear and precise viewing from multiple angles under a variety of ambient light conditions. The brighter the environment, the more difficult it can be to read a standard transmissive LCD display with a typical brightness of 250 to 300 cd/m2. NVD has developed displays that can perform in the 800-cd/m2-and-higher range by implementing high-efficiency LEDs for the backlight unit– if necessary, in combination with special brightness enhancement films.

Increasing the display’s contrast ratio is another effective way that display manufacturers can improve display readability in bright environments. Typical contrast ratios for non-industrial displays are in the range of 200:1 to 300:1, which may not be sufficient when a machine operator is viewing the display from a distance. Displays with contrast ratios around 500:1 or greater are better suited for industrial environments. Another benefit of this method is that it doesn’t increase power consumption.

Multi-angle readability is another key selection factor. In a typical industrial environment, a machine operator is more likely to be positioned at an off-angle rather than right in front of the screen. Implementing a display designed for consumer applications typically doesn’t work well in this situation, as there is image distortion and color shifting when viewed at an angle. But, a number of technologies have been employed to improve off-angle viewing in displays, making them suitable for industrial applications. Some film-based technologies yield viewing angles of 160º horizontally and 140º vertically, but in some cases, this is still not sufficient. In-plane switching technology (IPS), multi-domain vertical alignment (MVA), and fringe field switching (FFS)offer alternatives. These proprietary technologies are able to achieve viewing angles of almost 90-degrees into all four directions without any color shift.

Size and resolution also play a role in overall readability. Displays between 2 and 15-inch diagonal sizes are used most often in industrial applications. These sizes provide sufficient area to view figures, waveforms, and other graphical data without taking up too much real estate on a piece of equipment.

From an aspect ratio 4:3 initially, industrial displays are now shifting to wide formats with WVGA to WXGA resolutions. The wide-aspect format enables users to view longer waveforms and more data on a single display. These display modules can also be designed to incorporate touch-key functions, allowing equipment manufacturers to skip physical switches and buttons and design HMIs based more on software than hardware.

New Vision Display’s experts are prepared to assist in defining appropriate solutions for all applications and in helping find the right balance between manufacturing cost and performance.

We have thousands of standard products that are in stock and available from our Seattle, WA and Hong Kong warehouses to support fast product development and preproduction without MOQ. The stock covers TN, STN LCD display panels, COB, COG character LCD display, graphic LCD display, PMOLED, AMOLED display, TFT display, IPS display, high brightness and transflective, blanview sunlight readable display, super high contrast ratio display, lightning fast response displays, efficient low power consumption display, extreme temperature range display, HMI display, HDMI display, Raspberry Pi Display, Arduino display, embedded display, capacitive touch screen, LED backlight etc. Customers can easily purchase samples directly from our website to avoid time delays with setting up accounts and credit terms and shipping within 24 hours.

Many of our customers require customized OEM display solutions. With over two decades of experience, we apply our understanding of available display solutions to meet our customer’s requirements and assist from project concept to mass production. Using your ideas and requirements as a foundation, we work side by side with you to develop ideas/concepts into drawings, build prototypes and to final production seamlessly. In order to meet the fast changing world, we can provide the fastest turnaround in the industry, it takes only 3-4 weeks to produce LCD panels samples and 4-6 weeks for LCD display module, TFT LCD, IPS LCD display, and touch screen samples. The production time is only 4-5 weeks for LCD panels and 5-8 weeks for LCD display module, TFT LCD, IPS LCD display, and touch screen.

If you want to buy a new monitor, you might wonder what kind of display technologies I should choose. In today’s market, there are two main types of computer monitors: TFT LCD monitors & IPS monitors.

The word TFT means Thin Film Transistor. It is the technology that is used in LCD displays. We have additional resources if you would like to learn more about what is a TFT Display. This type of LCDs is also categorically referred to as an active-matrix LCD.

These LCDs can hold back some pixels while using other pixels so the LCD screen will be using a very minimum amount of energy to function (to modify the liquid crystal molecules between two electrodes). TFT LCDs have capacitors and transistors. These two elements play a key part in ensuring that the TFT display monitor functions by using a very small amount of energy while still generating vibrant, consistent images.

Industry nomenclature: TFT LCD panels or TFT screens can also be referred to as TN (Twisted Nematic) Type TFT displays or TN panels, or TN screen technology.

IPS (in-plane-switching) technology is like an improvement on the traditional TFT LCD display module in the sense that it has the same basic structure, but has more enhanced features and more widespread usability.

Both TFT display and IPS display are active-matrix displays, neither can’t emit light on their own like OLED displays and have to be used with a back-light of white bright light to generate the picture. Newer panels utilize LED backlight (light-emitting diodes) to generate their light hence utilizing less power and requiring less depth by design. Neither TFT display nor IPS display can produce color, there is a layer of RGB (red, green, blue) color filter in each LCD pixels to produce the color consumers see. If you use a magnifier to inspect your monitor, you will see RGB color in each pixel. With an on/off switch and different level of brightness RGB, we can get many colors.

Winner. IPS TFT screens have around 0.3 milliseconds response time while TN TFT screens responds around 10 milliseconds which makes the latter unsuitable for gaming

Winner. the images that IPS displays create are much more pristine and original than that of the TFT screen. IPS displays do this by making the pixels function in a parallel way. Because of such placing, the pixels can reflect light in a better way, and because of that, you get a better image within the display.

As the display screen made with IPS technology is mostly wide-set, it ensures that the aspect ratio of the screen would be wider. This ensures better visibility and a more realistic viewing experience with a stable effect.

Winner. While the TFT LCD has around 15% more power consumption vs IPS LCD, IPS has a lower transmittance which forces IPS displays to consume more power via backlights. TFT LCD helps battery life.

Normally, high-end products, such as Apple Mac computer monitors and Samsung mobile phones, generally use IPS panels. Some high-end TV and mobile phones even use AMOLED (Active Matrix Organic Light Emitting Diodes) displays. This cutting edge technology provides even better color reproduction, clear image quality, better color gamut, less power consumption when compared to LCD technology.

This kind of touch technology was first introduced by Steve Jobs in the first-generation iPhone. Of course, a TFT LCD display can always meet the basic needs at the most efficient price. An IPS display can make your monitor standing out.

Beijing STONE Technology co., ltd was established in 2010 and devoted itself to manufacturing and developing high-quality intelligent TFT LCD display modules.

Our vision is to become one of the world"s top display manufacturers in the industrial intelligent field. And providing top-quality products and professional technical services to customers all over the world.

The modules come with a UART TFT serial interface that can be controlled by any MCU through simple but powerful instruction set like the 8051 series, AVR series, MSP430 Series, STM32 series, MC9S12, and Arduino series, among others.

Each TFT display LCD module has a wide range of applications, such as automated system control, vending machine functionality, intelligent lockers, electricity equipment (oiling machine, EV charger), elevators, smart home and office, precision instruments, and much more.

To date, we have delivered custom display solutions to over 3000 customers around the world. Our TFT LCD modules have been widely praised for their quality and performance and that is in large part thanks to our partners, including NI, Siemens, ThyssenKrupp, and many others. These long-term cooperative relationships have been mutually beneficial and we hope to continue a long history of success.

AMOLED and TFT are two types of display technology used in smartphones. AMOLED (active-matrix organic light-emitting diode) displays are made up of tiny organic light-emitting diodes, while TFT (Thin-Film Transistor) displays use inorganic thin-film transistors.

AMOLEDs are made from organic materials that emit light when an electric current is passed through them, while TFTs use a matrix of tiny transistors to control the flow of electricity to the display.

Refresh Rate: Another key difference between AMOLED and TFT displays is the refresh rate. The refresh rate is how often the image on the screen is updated. AMOLED screens have a higher refresh rate than TFT screens, which means that they can display images more quickly and smoothly.

Response Time: The response time is how long it takes for the pixels to change from one colour to another. AMOLED screens have a shorter response time than TFT screens..

Colour Accuracy/Display Quality: AMOLED screens are more accurate when it comes to displaying colours. This is because each pixel on an AMOLED screen emits its own light, which means that the colours are more pure and true to life. TFT screens, on the other hand, use a backlight to illuminate the pixels, which can cause the colours to appear washed out or less vibrant.

Viewing Angle: The viewing angle is the angle at which you can see the screen. AMOLED screens have a wider viewing angle than TFT screens, which means that you can see the screen from more angles without the colours looking distorted.

Power Consumption: One of the main advantages of AMOLED displays is that they consume less power than TFT displays. This is because the pixels on an AMOLED screen only light up when they need to, while the pixels on a TFT screen are always illuminated by the backlight.

Production Cost: AMOLED screens are more expensive to produce than TFT screens. This is because the manufacturing process for AMOLED screens is more complex, and the materials used are more expensive.

Availability: TFT screens are more widely available than AMOLED screens and have been around for longer. They are typically used in a variety of devices, ranging from phones to TVs.

Usage: AMOLED screens are typically used in devices where power consumption is a concern, such as phones and wearable devices. TFT screens are more commonly used in devices where image quality is a higher priority, such as TVs and monitors.

AMOLED and TFT are two different types of display technology. AMOLED displays are typically brighter and more vibrant, but they are more expensive to produce. TFT displays are cheaper to produce, but they are not as bright or power efficient as AMOLED displays.

The display technology that is best for you will depend on your needs and preferences. If you need a screen that is bright and vibrant, then an AMOLED display is a good choice. If you need a screen that is cheaper to produce, then a TFT display is a good choice. However, if you’re worried about image retention, then TFT may be a better option.

Nauticomp Inc.provides world-class fully customizable touchscreen displays for commercial and industrial settings. With features like sunlight readability, brightness adjustability, infrared lighting, full backlighting, all-weather capabilities, etc., our displays are second to none. Contact us today to learn more.

TFT is an abbreviation for Thin Film Transistor, a flat panel display used to improve the operation and utility of LCD screens. In order to portray an appearance to the audience, a liquid crystal display (LCD) utilizes a crystalline-filled fluid to modify rear lighting polarized origin through the use of an electromagnetic force among two relatively thin metal wires such as indium oxide (ITO). However, color TFT displays are associated with this method, which can be employed in both divided and pixelated display systems.

With motion pictures displayed on an LCD, the intrinsic sluggish rate of increase between liquid phases over a significant number of pixel components can be an issue due to capacitance impacts, which can create a blurring of the visuals. Placing a high-velocity LCD control device inside the formation of a thin-film transistor immediately next to the cell component just on a glass screen, the issue of LCD picture speed may be substantially improved, and image blur can be eliminated for all useful purposes entirely.

Organic light-emitting diodes (AMOLEDs) are a type of flat light-emitting advanced technologies that are created by interspersing a succession of organic thin sheets over two conducting conductors. An electrical charge causes a brilliant light to be produced when the current flows. AMOLED displays are light-emitting screens that do not require a backlight, making them thinner and more energy-efficient than liquid crystal displays (LCDs) (which will need a white backlight).

AMOLED displays are not only thin and fuel-intensive, but they also deliver the highest image quality available, so they can be made translucent, elastic, bendable, or even rollable and stretchy in the future, allowing for a variety of applications. AMOLEDs are a revolutionary technology in terms of display devices! It is possible to create an AMOLED by sandwiching a sequence of thin films across phase conductors. Electric charge causes a brilliant light to be emitted when the current flows through the coil.

The color display is fantastic. Color intensity, sharpness, and luminance settings that are second to none and can be customized to meet the needs of any application.

Half-Life has been expanded. TFT displays have a far longer half-life than its LED equivalents, and they are available in a number of sizes, which might have an effect on the device"s half-life based on the phone"s usage as well as other variables. Touch panels for TFT screens can be either resistant or capacitance in nature.

Due to the apparent glass panels, there is limited functionality. For instance, there are ineffective for outdoor use because the glass can display glares from its natural lighting)

They rely on backlight to give illumination rather than generating their own light. Hence they require constructed light-creating diodes (LEDs) in their backlit display framework to ensure enough brightness.

Due to the fact that AMOLED displays inherently emit illumination, they do not need a backlight when used on a monitor screen. Conversely, LCDs require backlights since the liquid crystals themselves are incapable of producing light under their own. Direct light emission from AMOLED displays also allows for the developing of lightweight display devices than others using TFT LCDs.

LCD displays have a higher brightness than AMOLED panels. This is owing to the LCD"s usage of led backlight, which may provide a brilliant illumination of the entire display. Despite the fact that AMOLEDs produce high levels of brilliance from their illumination, they will never be able to match the intensity of LCD lighting.

LCD screens use less power than AMOLED displays, which provides a slight advantage. The amount of energy consumed by AMOLED displays is dependent on the intensity of the screen. Lowered luminance results in lower energy usage, however, it might not be the best solution because the contrast would suffer as a result of the decreased brightness. In some situations, such as when to use an AMOLED device in direct sunlight, it is not an optimal situation.

However, the backlit keys of TFT displays account for the majority of their power usage. TFT screens" efficiency is considerably improved when the backlight is set to a lesser brightness level than the default setting. For example, replacing the light of an LCD TV with just an Led flash will have no effect on the image quality, but will result in lower power usage than replacing the light of an AMOLED TV.

With the exception of phones, numerous other technologies make use of displays to allow customers to engage in direct communication with them. To determine whether or not TFT LCD will be able to withstand the development of AMOLED innovation, we should first review the benefits of LCD technology. The backlighting quality ensures that whites are strong and brightness is superb but will deplete a battery much more quickly than just an AMOLED display. Furthermore, the cost of LCD screens is a considerable consideration. In addition to being less expensive and more easily accessible, they are produced in standard industry sizes, allowing them to be purchased for innovative products with relative ease.

Super Mobile HR TFT LCDs provide brilliant, vivid images outdoors where it is bright, but their visibility is poor indoors, where ambient light levels are lower.

Thus, though the display panel is transflective, it provides high transmittance and excellent image quality on a par with conventional transmissive TFT-LCDs.

The High Transmission Advanced TFT-LCD is suitable for applications where indoor use is of primary importance but outdoor use is occasionally necessary.

Victronix is one of the leading manufacturers and suppliers of oem 10.1inch 1024*600 tft durable monitor and pos and gps. With a professional factory and strict quality control system, we can assure you the high quality of our oem 10.1inch 1024*600 tft durable monitor and pos and gps. Please feel free to buy low price and customized bulk products with us. We can offer you quotation and free sample if necessary.

is a high quality TFT factory and supplier, specific for LCD (liquid crystal display) display insmall and medium-sized screens (typically 16″ and less).

According to the characteristics of the industry, the system built-in a variety of industry display templates, intelligent split screen technology to support the screen video, pictures, text and other forms of free arrangement of content.

Luminance is an important quality characteristic of a TFT-LCD display. Consumers prefer to have a TFT-LCD display with enough luminance. Several control factors in manufacturing a TFT-LCD display may affect the luminance of a TFT-LCD display. Tuning the control factors using a trial and error method incurs significant overhead in time and resources such as the material and the workforce. Therefore, a more efficient method is required for tuning the control factors in manufacturing TFT-LCD displays. To fine-tune the control factors, we need to perform experiments to find the luminance of TFT-LCD displays for different settings of the control factors. An experiment to find the luminance for a specific parameter setting of the control factors requires about 1.5 months for the case company. To reduce the time in fine-tuning the control factors, we should not perform too many experiments in a new method. In this paper, we first used the traditional Taguchi method to find a control factors’ setting to enhance the luminance of TFT-LCD displays. However, because the Taguchi method allows only a few fixed levels for each control factor, it usually cannot find the global optimal setting for the control factors. Therefore, this paper proposes to improve the Taguchi method by incorporating the Taguchi method with the neural network and the genetic algorithm. In the proposed method, we used the data collected from the Taguchi method to train a neural network to predict the luminance of a TFT-LCD display for a given control factors’ setting. Then, we used a genetic algorithm to search for the global optimal control factors’ setting using the predicted luminance of a control factors’ setting as the fitness value of the setting.

The case company is a TFT-LCD display manufacturer in Taiwan. In performing the optical film lamination step in the liquid crystal module assembly process (LCM), the case company observed color streaks, as shown in Figure 1, on some of their TFT-LCD displays. The color streaks reduced the luminance of the TFT-LCD displays. Therefore, to enhance the luminance of TFT-LCD displays, the optical film lamination step needs to be optimized. The optical film lamination step consists of five stages: the raw material inspection, the soft-to-hard lamination, the circuit test, the protection film lamination, and the clean process, as shown in Figure 2. According to a failure analysis performed by the case company, the color streaks on a TFT-LCD display were mainly due to improper setting of control factors in the soft-to-hard lamination stage. Therefore, this paper focuses on optimizing the soft-to-hard lamination stage to improve the luminance of TFT-LCD displays.

For the quality improvement purpose, engineers of the case company selected five positions, as shown in Figure 3, on a TFT-LCD substrate to measure their corresponding values of luminance. The luminance of a TFT-LCD display is the average of the five values of luminance of the selected positions. The case company manufactured about 5000 TFT-LCD displays per day. Therefore, the TFT-LCD displays’ average luminance at a specific date was calculated by averaging the luminance of all the TFT-LCD displays made at that particular date. Figure 4 shows the trend chart for the TFT-LCD displays’ average luminance. The average of the average luminance at all dates in a selected time interval is defined as the baseline, the red line shown in Figure 4. Before fine-tuning the control factors in the sot-to-hard lamination stage, the baseline was 17.03, which was less than the required minimum luminance of 25. Thus, to enhance the TFT-LCD display’s luminance, one needs to find a setting of the control factors such that the baseline is larger than the required minimum luminance of 25. Therefore, we propose in this paper a new method that combines the Taguchi method, a neural network, and a genetic algorithm to fine-tune the setting of control factors in the soft-to-hard lamination stage to enhance the TFT-LCD displays’ luminance.

Ms.Josey

Ms.Josey

Ms.Josey

Ms.Josey