lcd panel layer thcikenss manufacturer

Display device technology and performance is advancing at a remarkable pace. The design and manufacture of Liquid Crystal and Light Emitting Diode Displays that include touch screen layers is very demanding. These display components and assemblies can be characterized with Bristol Instruments non-contact thickness gauges to sub-micron accuracy.

![]()

In both LCD and OLED displays, producing these cells – which are highly complex – is by far the most difficult element of the production process. Indeed, the complexity of these cells, combined with the levels of investment needed to achieve expertise in their production, explains why there are less than 30 companies in the whole world that can produce them. China, for instance, has invested more than 300 billion yuan (approximately $45 billion USD) in just one of these companies – BOE – over the past 14 years.

Panox Display has been involved in the display industry for many years and has built strong and long-term partner relationships with many of the biggest OLED and LCD panel manufacturers. As a result, we are able to offer our clients guaranteed access to display products from the biggest manufacturers.

LG Display was, until 2021, the No. 1 display panel manufacturer in the world. Owned by LG Group and headquartered in Seoul, South Korea, it has R&D, production, and trade institutions in China, Japan, South Korea, the United States, and Europe.

Founded in 2001, AUO – or AU Optronics – is the world’s leading TFT-LCD panel manufacturer (with a 16% market share) that designs, develops, and manufactures the world’s top three liquid crystal displays. With panels ranging from as small as 1.5 inches to 46 inches, it boasts one of the world"s few large-, medium -and small-sized product lines.

AUO offers advanced display integration solutions with innovative technologies, including 4K2K ultra-high resolution, 3D, ultra-thin, narrow bezel, transparent display, LTPS, OLED, and touch solutions. AOU has the most complete generation production line, ranging from 3.5G to 8.5G, offering panel products for a variety of LCD applications in a range of sizes, from as small as 1.2 inches to 71 inches.

Now Sharp is still top 10 TV brands all over the world. Just like BOE, Sharp produce LCDs in all kinds of size. Including small LCD (3.5 inch~9.1 inch), medium LCD (10.1 ~27 inch), large LCD (31.5~110 inch). Sharp LCD has been used on Iphone series for a long time.

Beside those current LCDs, the industrial LCD of Sharp is also excellent and widely used in public facilities, factories, and vehicles. The Sharp industrial LCD, just means solid, high brightness, super long working time, highest stability.

Since its establishment, Truly Semiconductors has focused on researching, developing, and manufacturing liquid crystal flat panel displays. Now, after twenty years of development, it is the biggest small- and medium-sized flat panel display manufacturer in China.

Truly’s factory in Shanwei City is enormous, covering an area of 1 million square meters, with a net housing area of more than 100,000 square meters. It includes five LCD production lines, one OLED production line, three touch screen production lines, and several COG, LCM, MDS, CCM, TAB, and SMT production lines.

Its world-class production lines produce LCD displays, liquid crystal display modules (LCMs), OLED displays, resistive and capacitive touch screens (touch panels), micro camera modules (CCMs), and GPS receiving modules, with such products widely used in the smartphone, automobile, and medical industries. The LCD products it offers include TFT, TN, Color TN with Black Mark (TN type LCD display for onboard machines), STN, FSTN, 65K color, and 262K color or above CSTN, COG, COF, and TAB modules.

In its early days, Innolux attached great importance to researching and developing new products. Mobile phones, portable and mounted DVD players, digital cameras, games consoles, PDA LCDs, and other star products were put into mass production and quickly captured the market, winning the company considerable market share.

Looking forward to the future, the group of photoelectric will continue to deep LCD display field, is committed to the development of plane display core technology, make good use of global operations mechanism and depth of division of labor, promise customers high-quality products and services, become the world"s top display system suppliers, in 2006 in the global mobile phone color display market leader, become "Foxconn technology" future sustained rapid growth of the engine.

Founded in June 1998, Hannstar specializes in producing thin-film transistor liquid crystal display panels, mainly for use in monitors, notebook displays and televisions. It was the first company in Taiwan to adopt the world’s top ultra-wide perspective technology (AS-IPS).

The company has three LCD factories and one LCM factory. It has acquired state-of-the-art TFT-LCD manufacturing technology, which enables it to achieve the highest efficiency in the mass production of thin-film transistor liquid crystal display production technology. Its customers include many of the biggest and most well-known electronics companies and computer manufacturers in Taiwan and overseas.

TCL CSOT – short for TCL China Star Optoelectronics Technology (TCL CSOT) – was founded in 2009 and is an innovative technology enterprise that focuses on the production of semiconductor displays. As one of the global leaders in semiconductor display market, it has bases in Shenzhen, Wuhan, Huizhou, Suzhou, Guangzhou, and India, with nine panel production lines and five large modules bases.

TCL CSOT actively produces Mini LED, Micro LED, flexible OLED, printing OLED, and other new display technologies. Its product range is vast – including large, medium, and small panels and touch modules, electronic whiteboards, splicing walls, automotive displays, gaming monitors, and other high-end display application fields – which has enabled it to become a leading player in the global panel industry.

In the first quarter of 2022, TCL CSOT’s TV panels ranked second in the market, 55 inches, 65 " and 75 inches second, 8K, 120Hz first, the first, interactive whiteboard and digital sign plate; LTPS flat panel, the second, LTPS and flexible OLED fourth.

EDO (also known as EverDisplay Optonics) was founded in October 2012 and focuses on the production of small- and medium-sized high-resolution AMOLED semiconductor display panels.

Tianma Microelectronics was founded in 1983 and listed on the Shenzhen Stock Exchange in 1995. It is a high-tech enterprise specializing in the production of liquid crystal displays (LCD) and liquid crystal display modules (LCM).

After more than 30 years of development, it has grown into a large publicly listed company integrating LCD research and development, design, production, sales, and servicing. Over the years, it has expanded by investing in the construction of STN-LCD, CSTN-LCD, TFT-LCD and CF production lines and module factories across China (with locations in Shenzhen, Shanghai, Chengdu, Wuhan and Xiamen), as well R&D centers and offices in Europe, Japan, South Korea and the United States.

The company"s marketing network is all over the world, and its products are widely used in mobile phones, MP3/MP4 players, vehicle displays, instrumentation, household appliances, and other fields. In terms of technical level, product quality, product grade, and market share, it ranks at the forefront of the domestic industry and has become a leading enterprise in the field of small- and medium-sized displays.

JDI (Japan Display Inc.) was established on November 15, 2011, as a joint venture between the Industrial Innovation Corporation, Sony, Hitachi, and Toshiba. It is dedicated to the production and development of small-sized displays. It mainly produces small- and medium-sized LCD display panels for use in the automotive, medical, and industrial fields, as well as personal devices including smartphones, tablets, and wearables.

Although Sony’s TVs use display panels from TCL CSOT (VA panel), Samsung. Sony still produces the world’s best micro-OLED display panels. Sony has many micro OLED model such as 0.23 inch, 0.39 inch, 0.5 inch, 0.64 inch, 0.68 inch, 0.71 inch. Panox Display used to test and sell many of them, compare to other micro OLED manufacuturers, Sony`s micro OLEDs are with the best image quality and highest brightness (3000 nits max).

While there are many different manufacturers of LCD monitors, the panels themselves are actually only manufactured by a relatively small selection of companies. The three main manufacturers tend to be Samsung, AU Optronics and LG.Display (previously LG.Philips), but there are also a range of other companies like Innolux and CPT which are used widely in the market. Below is a database of all the current panel modules manufactured in each size. These show the module number along with important information including panel technology and a detailed spec. This should provide a detailed list of panels used, and can give you some insight into what is used in any given LCD display.

Note:These are taken from manufacturer product documentation and panel resource websites. Specs are up to date to the best of our knowledge, and new panels will be added as and when they are produced. Where gaps are present, the detail is unknown or not listed in documentation. The colour depth specs are taken from the manufacturer, and so where they specify FRC and 8-bit etc, this is their listing. Absence of such in the table below does not necessarily mean they aren’t using FRC etc, just that this is how the manufacturer lists the spec on their site.

Purchasing an LCD monitor can be a difficult task at the best of times. Knowledgeable buyers have to consider many aspects of their future screen, not just basing a decision on price and marketing hype. Of course decisions are ultimately driven by a buyers budget, but one must always consider the things which will make the screen suitable to their uses, which are where technologies, features, connections and design come into play. Panel technology is not always discussed by manufacturers but is one of the most important aspects to consider when buying a new screen as it will tell you a lot about the real-life performance you can expect from the display, and ensure you are buying a screen suitable for your requirements. Fortunately we are here to help and you can read our in depth panel technologies article to help you in your quest.

One thing which many buyers will be unaware of is that all LCD displays are supplied with a protective filter layer on the front of the panel itself. This coating is used to protect the panel from damage, filter and diffuse the light output and in many cases reduce glare from other light sources in your workspace. What is also tricky to understand is that different panels can have different types of coating, varying considerably by panel technology and manufacturers. This article is designed to help highlight some of those differences so that readers can make an informed decision about their next monitor purchase.

The most common type of protective coating is ‘Anti-Glare’ (AG). This is often described as a matte coating as it is non-reflective to the user since it diffuses rather than reflects ambient light. It provides a method for manufacturers to avoid glare on the viewing surface from other light sources and has been used in the LCD monitor market for many years since the first TFT displays started to emerge.

This matte coating is included as an outer polarizing later which has been coarsened by mechanical or chemical processes. This achieves a surface coating which is not smooth and so can diffuse ambient light rather than reflect it. What is particularly important to understand is that this AG coating can be applied to panels with varying thicknesses, which has an impact on the anti-glare properties, but also on the underlying image of the screen. Where the coating is particularly thick and aggressive, the image from the screen can deteriorate as the light being emitted is also affected. This can have some impact on contrast and colour vibrancy and the perceived image can sometimes look dull as a result. Sharpness degradation can also occur in some extreme cases where AG coating is too thick. Users may also sometimes see the graininess of the coating, particularly when viewing white or light backgrounds. This can be particularly distracting for office work and images can look grainy or dirty if the coating is too aggressive. I would point out that not everyone would even notice this at all, and many users are perfectly happy with their screens even where aggressive AG is used. It’s just something to be wary of in case you have found problems with image quality in the past or are susceptible to it.

Some users have even taken matters into their own hands and removed the AG coating from their screens to produce a glossy surface. This will of course void your warranty and should be done with caution and entirely at the users risk. We mention it here as the above images are a good demonstration of the aggressive coating applied to the screen in some cases. You can see from the top picture the film being peeled off to leave a glossy reflective surface underneath. The second image is of course exaggerated quite a lot but you can see how the image is affected when the photograph is taken with the AG coating in front, on the right hand side. Of course this is far less obvious when the coating is in contact with the surface of the screen but it’s a fairly good demonstration of the coating being used in some cases (note, these were taken from an LG.Display IPS panel on the Dell U2312HM).

It is important to realise that different manufacturers tend to use different levels of AG coating, often linked to the panel technology they are developing. See our following sections for more information about specific panel manufacturers and technologies.

As an alternative some manufacturers choose to supply their screens with a glossy screen surface. This gives somewhat of a “wow factor” when you first see the screen and has often been used by manufacturers like Apple for their screens and tablets. The glossy panel coating is sometimes combined with a glass protective layer to give a hard exterior surface to the display and to emphasise that overall glossy appearance.

Where glass coatings are applied as an additional protective layer buyers should also be aware that there is sometimes the risk of trapped dust or particles behind the glass which can become an annoyance over time. Some screens are completely free from this, but it’s just something to be aware of (e.g. dust issues were found on some Hazro’s HZ27WA/C/D screens where glass layers were used). Glass layers are also often provided on touch-screen displays for that added level of protection.

Glossy screen coatings have been offered over the years in several forms including older models featuring Sony X-Black, Acer CrystalBrite and NEC OptiClear technologies. Apple have used glossy coatings on their Cinema Displays for many years and in fact a lot of the modern glossy offerings are based on IPS panels. More recently other manufacturers like Hazro (HZ27WA/C/D) and DGM (IPS-2701WPH) have produced screens based on the 27” glossy IPS panels available. Samsung have also released their first glossy PLS panel in the Samsung S27B970D.

As we’ve already mentioned, the type of coating applied to a panel is very dependent on the manufacturer and the technology being used. Trends have emerged over the years and here is a summary of the typical coating usage from different panel solutions:

LG.Display IPS – These panels are often criticised for their aggressive AG coating. Where AG is used it is normally very aggressive and some people find the images are too grainy or dirty looking. As an example the Dell UltraSharp series (U2410, U2412M, U2711, U3011) are all using aggressive AG coating on their IPS panels. Some IPS panels are provided with a glossy screen coating as an alternative which avoids issues with grainy coating, but can result in distracting reflections.

AU Optronics AMVA – Modern versions of these panels are provided with a light AG coating which is sometimes referred to as semi-gloss. It is not overly grainy or obtrusive.

Samsung PLS – early versions of the panels were provided with a light AG coating, similar to that of AMVA panels although not quite as low haze. It was not overly grainy or distracting. More recently PLS panels have also been supplied with a glass glossy coating. The technology is in its infancy and so it is hard to establish a future trend.

TN Film panels – these are nearly always provided with AG coating although some glossy models have been produced from time to time. Coating tends to vary but is normally considered to be ‘medium’ in terms of its aggressiveness. Not as aggressive as the IPS panels, but not “semi-gloss” like AMVA offerings.

Above is a comparison of macro images taken of varying panel types. This was designed to capture the structure of the panel at a pixel level but can also be used to demonstrate the coating type being used and the resulting image clarity. You will see that the aggressive AG coating of the IPS panels leads to a blurry and grainy image, but the glossy equivalent leaves a clear and crisp view of the underlying pixels. TN Film is a medium AG coating and while not as aggressive as the IPS AG coating, it can lead to noticeable graininess in some cases. AMVA has a light AG coating and as you can see does not deteriorate the image quality too much.

This hopefully gives you a summary of the common types of coating used on the main panel technologies in the market. Of course there are always variations and so we will try to discuss the coatings in our reviews so you have an idea.

LCD displays are being used in a wide variety of applications, including LCD TVs, personal computers, cell phones and car navigation systems. Konica Minolta Opto supplies the important cellulose triacetate film (TAC film), which protects the polarizer,

This thin film increases the viewing angle of LCD screens through uniform control of phase difference and wavelength scattering characteristics. Adding a viewing angle expansion function to polarizer protection film helps decrease the thickness of LCDs.

One of the advantages of designing a custom display is the ability to reduce your LCD display’s thickness by selecting a thin ITO glass; which is key to a thin LCD module.

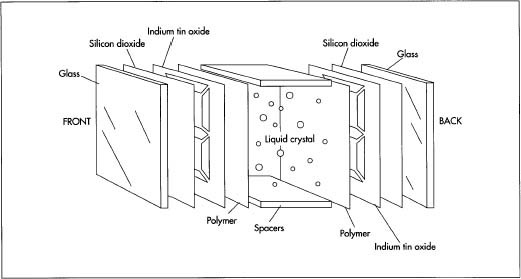

The structure of the LCD is very basic, but a special glass called ITO glass is used in constructing the display. Three sides of the ITO glass are glued together with an adhesive or epoxy. Both the ITO glass and the nematic fluid used are transparent. There is a small gap of one or two millimeters between the top and bottom layer of glass. A nematic fluid is then injected between the layers. Finally, a cap is placed on the fourth side to keep the fluid from leaking out.

A polarizer is applied on both the top and bottom layer of glass. The polarizer on the top layer is always Transmissive, whereas the bottom layer can be Reflective, Transflective or Transmissive. For more details on the different types of polarizers, please read our article: LCD Polarizers.

ITO glass can be cut to custom dimensions, but smaller sized glass can add a significant cost increase to the overall cost of the LCD. The reason for the increased cost is the amount of labor and time required to add a polarizer to the small piece of glass.

Many times customers require the display to be as thin as possible; one method to achieve a thin LCD module is to select a thinner ITO glass. Keep in mind that the thinner the glass, the more expensive and the higher the fallout rate.

Note:Fallout rate does not mean failures of the LCD’s in the field; fallout is when the display fails on the manufacturing line. If the display fails in production, it is discarded before it is shipped to the customer.Once the display passes QA (Quality Assurance) it will operate normally for the life of the product.

It is possible to add a backlight to the monochrome display to make the display readable in low or no light conditions. The challenge of adding a LED backlight is that it increases the thickness of the LCD by as much as 5mm to 9mm.

In the photo above, a segmented LCD is combined with a LED backlight and backlight diffuser. A printed circuit board (PCB) is used to hold the assembly together. As the backlights name suggests, a light is placed behind the bottom layer of ITO glass.

Note: A backlight diffuser’s job function is similar to the lamp shade used on a table lamp. It disperses the light from each led to provide a more uniform appearance. Without the diffuser, there would be hot and cold spots on the display. A hot spot is where the backlight is too close to the LCD glass and it is overly bright; the area around the hot spot is dimmer and is referred to as a ‘cold spot’.

There are four methods to reduce the thickness of the LCD display/backlight combination; thereby creating a thin LCD module. However, these solutions do not apply to TFTs, VFDs, LEDs or OLEDs (Organic Light Emitting Diodes).

In the integration the backlight is sandwiched between the LCD and PCB. The LCD’s leads (pins) are then soldered to the PCB securely holding the backlight in place. This helps to create a thin LCD module.

Advantages of a PCB mounted LED backlight:The PCB combines the backlight and the LCD; this is great in applications that operating in environments of heavy vibration.

It is possible to build the PCB with only one or two layers to reduce the thickness, but current design practices call for a separate plane for power and ground. Also, a thinner board may not be as strong.

Another way to combine the LCD and the LED backlight is to use either a plastic clip to bind them together, or to use an epoxy or adhesive. There are advantages and disadvantages to both, but we suggest the plastic clip solution.

This method requires a one-time tooling fee to design and prototype a small, flexible plastic clip that holds the backlight and display together. The clip only adds a few pennies to the overall cost of the LCD combination.

This method is accomplished without any tooling cost and only adds a penny or two to the overall cost of the LCD assembly, but we do not recommend this approach.

An edge-lit display means that the LEDs are not placed behind the bottom layer of glass, but along the edge between the two layers of glass. This alone helps to create a thin LCD module.

Disadvantages to an Edge-lit display:One of the Challenges of this solution is that it increases the size of the overall display in the X and Y directions (Length and Width). Which means the sides of backlight will stick out beyond the LCD.

Side-lit displays work well for smaller size LCDs, but create hot spots around the edges if the display is too large. This is more evident with a white LED edge-lit; since white LEDs are much brighter than other colors and sometimes need to be dimmed to reduce their starkness.

EL backlights are AC (Alternating Current) driven, this requires an inverter either on the LCD or on the customers’ board. Inverters add extra cost and labor.

LEDs are DC (Direct Current) driven and do not require an inverter. Many times the voltage for the LED backlight is the same as for the LCD which means one less power supply is required.

LCD displays and touch screens are in demand. They offer a sleeker, less cumbersome alternative to a mouse and keyboard or wired touch pad. And since the user can interact directly with the device’s interface, the possibilities for innovation are endless — from elevators and mobile medical equipment to industrial automation.

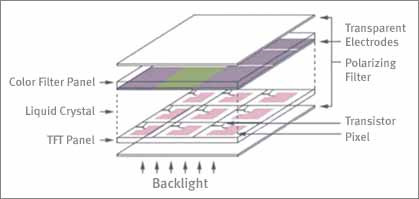

For many years, electronic device manufacturers generally incorporated five to seven layers of touch screen technology in the manufacture of their products — the LCD panel layers, the touch sensor layer, and the protective top cover or outer glass. Typically a touch screen is mounted on top of the LCD display and either secured with a high-performance double-sided tape, which leaves an air gap, or a silicone gel, called optical bonding, that fills air gaps and enhances readability.

Since 2012, in-cell and on-cell touch screen technologies have taken the high volume consumer segments by storm, in particular, smartphones and tablets. Born out of similar strategies of combining layers for improved functionality, in-cell technology incorporates touch sensors into the actual LCD display panel. On-cell or G2 technology moves the touch sensor to the top cover or outer glass layer.

With fewer layers, in-cell and on-cell touch screens provide designers and engineers the ability to develop much thinner devices, locate touch sensors close to the displays, create better color saturation and visual clarity, and reduce glare. All of which make users feel like they are actually touching the display and not just the outer glass layer.

Fewer layers are beneficial to a manufacturing process as well. It reduces costs by integrating the touch screen sensor as one of the layers of the LCD display, and optical bonding takes place as part of the initial production line, eliminating the need for a secondary bonding process.

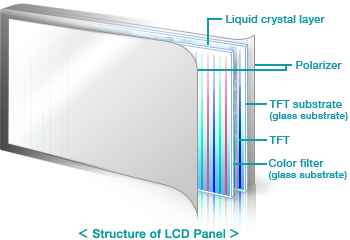

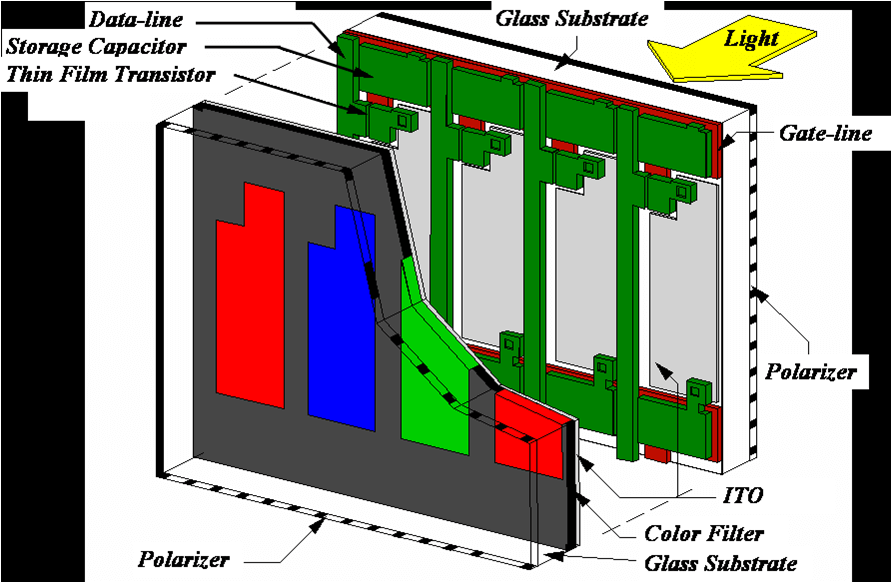

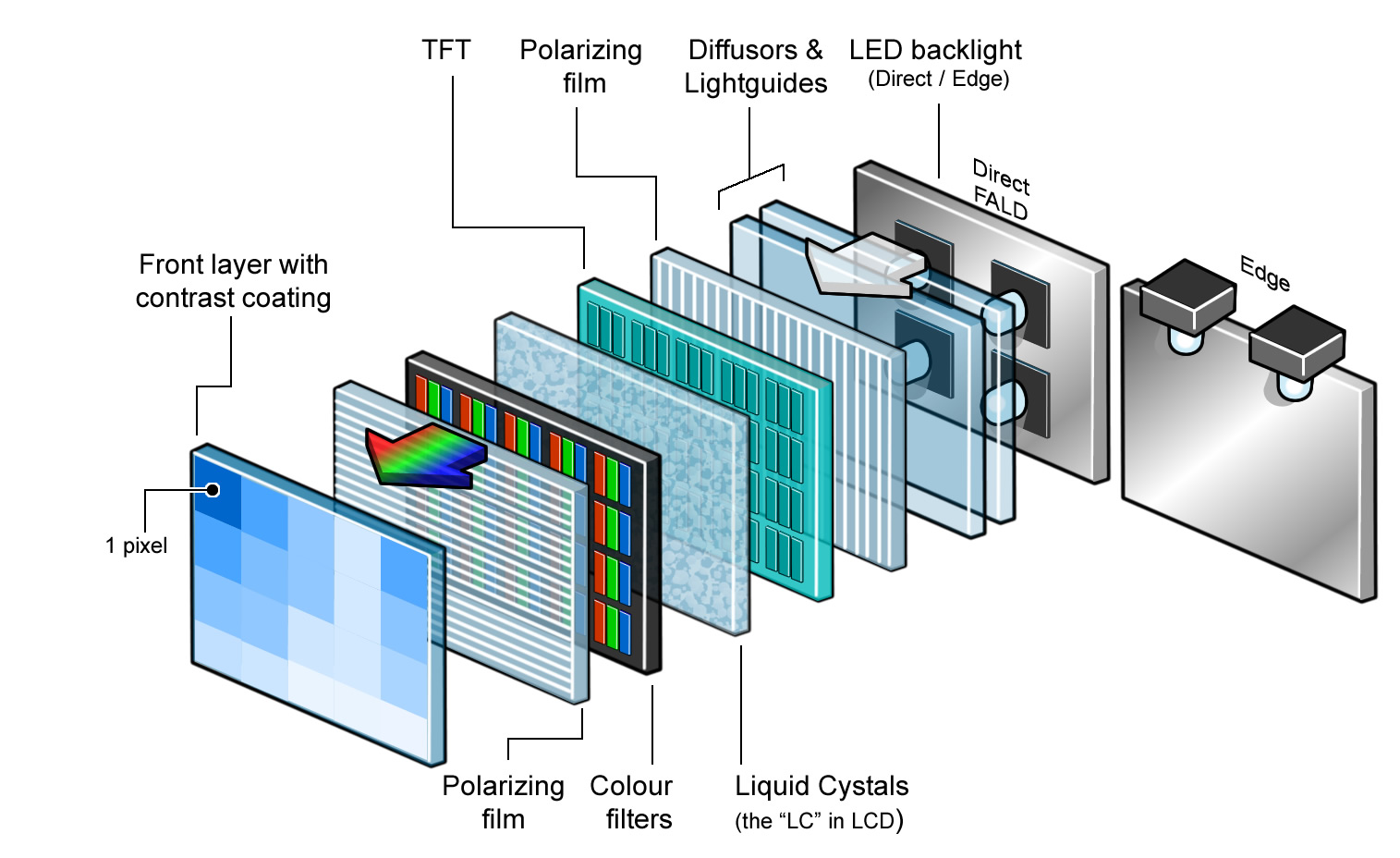

In general, there are two types of displays in the market today: active matrix liquid crystal display (AMLCD) and AMOLED. In its simplicity, the fundamental components required to make up the display are the same for AMLCD and AMOLED. There are four layers of a display device (FIGURE 1): a light source, switches that are the thin-film-transistor and where the gases are mainly used, a shutter to control the color selection, and the RGB (red, green, blue) color filter.

Technology trends TFT-LCD (thin-film-transistor liquid-crystal display) is the baseline technology. MO / White OLED (organic light emitting diode) is used for larger screens. LTPS / AMOLED is used for small / medium screens. The challenges for OLED are the effect of < 1 micron particles on yield, much higher cost compared to a-Si due to increased mask steps, and moisture impact to yield for the OLED step.

Although AMLCD displays are still dominant in the market today, AMOLED displays are growing quickly. Currently about 25% of smartphones are made with AMOLED displays and this is expected to grow to ~40% by 2021. OLED televisions are also growing rapidly, enjoying double digit growth rate year over year. Based on IHS data, the revenue for display panels with AMOLED technol- ogies is expected to have a CAGR of 18.9% in the next five years while the AMLCD display revenue will have a -2.8% CAGR for the same period with the total display panel revenue CAGR of 2.5%. With the rapid growth of AMOLED display panels, the panel makers have accel- erated their investment in the equipment to produce AMOLED panels.

There are three types of thin-film-transistor devices for display: amorphous silicon (a-Si), low temperature polysilicon (LTPS), and metal oxide (MO), also known as transparent amorphous oxide semiconductor (TAOS). AMLCD panels typically use a-Si for lower-resolution displays and TVs while high-resolution displays use LTPS transistors, but this use is mainly limited to small and medium displays due to its higher costs and scalability limitations. AMOLED panels use LTPS and MO transistors where MO devices are typically used for TV and large displays (FIGURE 3).

This shift in technology also requires a change in the gases used in production of AMOLED panels as compared with the AMLCD panels. As shown in FIGURE 4, display manufacturing today uses a wide variety of gases.

Silane: SiH4 is one of the most critical molecules in display manufacturing. It is used in conjunction with ammonia (NH3) to create the silicon nitride layer for a-Si transistor, with nitrogen (N2) to form the pre excimer laser anneal a-Si for the LTPS transistor, or with nitrous oxide (N2O) to form the silicon oxide layer of MO transistor.

There are two main competing display technologies in the market today: LCD and OLED. The mature and dominant technology is the Liquid Crystal Display (LCD), while the up-and-coming challenger is the Organic Light Emitting Diode Display (OLED display). The main difference between LCD and OLED displays is how they create the light and the colors of the image being displayed. This leads to application dependent strengths and weaknesses of either technology.

OLEDs operate via a solid-state technology, where the individual pixels can emit light in various colors and intensity without the need for an additional light source or color filter. The light-emitting portion of an OLED display is comprised of multiple layers of very specific organic semiconductor materials which can be adjusted to emit light in specific wavelengths. These organic layers have a typical thickness in the order of 100nm. In addition, no backlight is required, allowing for a very thin display module.

The organic layers beginning on the cathode side of the device consist of several electron transport layers, a recombination layer and end with a hole transport layer on the anode side. The electron transport layers in the OLED stack-up allow movement of electrons from the cathode toward holes supplied from the anode. The electrons and holes recombine in the emissive recombination layer of the film stack-up. This recombination relaxes the energy levels of the electrons, which produces an emission of light. The wavelength of the emitted light is dependent on the chemical composition of the organic materials used in the recombination layer. The intensity of the light is controlled by the amount of current flowing through the OLED’s organic layers. In OLEDs, the individual pixels can emit red, green, or blue light, or – alternatively – they emit white light, which must then pass through color filters.

In LCD display technology, the individual pixels modulate light. An applied voltage changes the orientation of liquid crystal molecules that – in conjunction with a pair of polarizers – function as a light shutter by either blocking or allowing light to pass through. LCD displays, therefore, require an additional light source, either from reflected ambient light or more commonly from a “backlight” (an array of LEDs arranged behind or next to the LCD panel). LCD color can be created by adding color filters to the individual pixels. Because OLED displays don’t require the additional backlight, polarizers, or color filter components of an LCD module, they can be made much thinner than LCD displays of equivalent size and resolution.

OLED display technology can offer power-saving advantages over LCDs, which is important, especially for battery-powered applications such as mobile phones. An OLED’s power consumption will vary with image content and brightness, as light is generated only at the individual pixels needed to display the image. A dark image or a graphic on a black background will consume much less power than bright images or graphics. In contrast, LCD backlights must be ON while the display operates. It’s possible to control individual zones of the backlight separately to save power, but this added complexity is usually only applied in larger displays.

OLEDs can achieve a much higher contrast ratio if reflections from the front surface are carefully controlled. If no current flows through an OLED pixel, it does not emit any light. In contrast the shutter effect of an LCD pixel does not block 100% of the light. Depending on the specific LCD technology used and the angle of observation, a small percentage of the light generated in the backlight can escape. This can wash out dark areas of an image. It is possible but expensive to limit this light leakage to a point where the contrast of an LCD and OLED display become perceptually equivalent.

RGB OLEDs naturally generate a narrow bandwidth of light. This leads to very saturated primary colors and a wide color gamut. This enables OLED technology to display colors which are not easily accessible to LCDs unless RGB backlights or quantum dots are used. Often OLED colors are used “as is”, however, for very high image color fidelity, such high color saturation needs to be electronically ‘tuned down’, to match the color bandwidth of the rendering chain.

LCDs offer an advantage over OLEDs in applications where a continuous static image is required. The light emitting materials in OLEDs are affected by luminance decay as a function of the total amount of current that has passed through the pixel. This decay differs for red, green and blue. The dimming effect is subtle, but when adjacent pixels are illuminated at the same time it can become noticeable as an undesired brightness variation or color shift. LCDs don’t suffer from this dimming effect, which makes them a more suitable solution for applications with static images or images with static elements.

Another advantage of LCD technology is the wide variety of different variations to choose from. Depending on the application certain trade-offs can be very attractive. An example is much lower cost for a laptop display compared to a tablet. This is achieved by allowing poor image performance when viewed from the direction the is usually blocked by the keyboard. In a tablet where good viewing performance is required from any direction, much higher cost LCDs or OLEDs must be used.

They can be used to replace old TN LCDs or add dynamic push buttons on industrial equipment. They can be customized to various resolutions, FPC configurations, colors, custom shaped OLED displays (e.g. octagonal, round, etc.) and can even be made into flexible and transparent displays. Thanks to their versatility, OLED display panel suppliers can offer some exciting capabilities for their customers – things that were previously impossible with LCDs.

As an experienced LCD and OLED panel supplier, New Vision Display can help you find the right technology for your application. Contact us via the below form to discuss your project.

One of the industry’s leading oxide panel makers selected Astra Glass as its backplane glass substrate because it has the inherent fidelity to thrive in high-temperature oxide-TFT glass fabrication for immersive high-performance displays.

One of the industry’s leading oxide panel makers selected Astra Glass as its backplane glass substrate because it has the inherent fidelity to thrive in high-temperature oxide-TFT glass fabrication for immersive high-performance displays.

LCD panelscan be categorized as flat-panel displays. What makes them distinct from other display technologies is the layer of liquid crystal material within. In this thin layer, liquid crystal molecules are aligned between two glass substrates. On the inner surfaces of each of those substrates lie electrodes that control charge carriers like electrons that then interact with the liquid crystals, creating an electric field that runs through them; this, in turn, can change the alignment of the crystals, also changing the overall behavior of the molecules. On the opposite sides of the substrate, polarizers are used to control the levels of light passage, affecting the overall image of the display.

Unlike CRT monitors, LCD monitors cannot illuminate themselves, and so they require a light source: the backlight. This backlight is most frequently made of the well-known LEDs which stand for light-emitting diodes. Sourced from the backlight, light is moved through the back polarizer and back substrate, into the liquid crystals. Now, the light waves can behave in a variety of ways. Backlight used in LCD displays can be LED (Light Emitting Diode) backlight or CCFL (Cold Cathode Fluorescent Lamp) backlight. LED backlights use less power which becomes more popular, while CCFL is lower cost for large size LCD displays such as large LCD TV. Recently, quantum dots technology is used to increase the LCD contrast.

Electrodes are the controlling factors of the liquid crystal behavior, and thus also the light behavior. By conducting or not conducting a current into the crystal layer, the light may or may not be able to pass through the liquid crystals in a manner that will allow passage through the polarizer. Because of this role, electrodes in LCDs are often made of indium tin oxide (ITO). ITO has good conducting properties and can also make for a transparent electrode which is essential to the appearance of displays today.

How the electrodes affect the liquid crystal alignment can vary depending on the method of alignment used (twistednematic,multi-domain,in-planeswitching). For example, twisted nematic liquid crystals are oriented in a twist when no electric field is present which then polarizes the light passing through the layer; when the electrodes apply the field in full, the twist will straighten out, no longer polarizing the light, and so no light passes. In each of these alignment types, the electrodes are placed differently within the structure, altering the properties of the display, such as width of viewing angle, power consumption, and response time. Despite these different alignment methods, the liquid crystal layer’s purpose remains the same: to polarize the light so that the polarized light passes through to the surface of the display. By polarizing the light transmitted from the backlight, the liquid crystal molecules play a role in how much of the light passes through the polarizing filters, whether it be all, none, or a partial amount.

Second: The thickness of the embroidery thread should be uniform, the thickness should be just suitable for the embroidery board grid, and it should be corrosion resistant. The embroidered work with uneven thickness of embroidery thread is very ugly. If the embroidery thread is too thin, the bottom plate will be exposed, which will affect the appearance of the finished product. If it is too thick, the thread will not be drawn smoothly during embroidery. Easy to damage the embroidery board. The principle of MVA (MULTI-DOMAIN VERTICAL align MENT) technology is to increase protrusions to form multiple visible areas. The liquid crystal molecules are not completely arranged vertically in a static state. After a voltage is applied, the liquid crystal molecules are arranged horizontally so that light can pass through each layer. MVA technology increases the viewing angle to over 160 degrees and provides a shorter response time than IPS and TN+FILM. This technology was developed by Fujitsu, and currently Taiwan Chi Mei (Chi Mei is a subsidiary of Chi Mei in mainland China) and Taiwan AUO are authorized to use this technology.

ViewSonic’s VX2025WM is the representative of this type of panel. The horizontal and vertical viewing angles are both 175 degrees. There is basically no visual blind angle, and it also promises no bright spots. The viewing angle is divided into parallel and vertical viewing angles. The horizontal angle is liquid crystal. The vertical axis is the center, moving left and right, you can clearly see the angle range of the image. The vertical angle is centered on the parallel central axis of the display screen, moving up and down to clearly see the angle range of the image.

We are all familiar with LCD (liquid crystal display) technology from our daily life. Your phone, your TV, your laptop all have LCD screens - the latest technology is increasing the resolution for an optimal viewing experience (HD, 4K, etc.).

Yes, of course. Similar to a DLP printer, in a LCD printer an entire layer is flashed with UV light and cured at once. But the light source is an array of LEDs exposing UV light through a LCD screen. Only the area that needs to be cured, will be exposed.

In most printers the light power of the light source changes over time - the higher the quality of the printer components, the longer you can expect the lifespan of your light source to be. A light source that does not send equally bright light through the LCD screen will inevitably cause failed prints.

With LCD technology, the build platform dips in the resin, lifts up and light shoots through the LCD panel and one layer is cured. To finish one 3D print, this happens hundreds of times.

With most slicing software you can individually set the layer thickness - the default setting is usually 100 micron. With a low value for the layer thickness, you achieve very smooth applications.

Ackuretta SOL is an exception. A 3D print made with 70 micron and one at 100 micron layer thickness showed that there"s only a 10 to 30 minute increase in printing time. Which means even the most intricate dental applications can be made same day and chairside.

In comparison, a SLA 3D printer by another manufacturer advertises the ability to produce prints with a 25 micron layer thickness but that comes at the cost of printing for over 17 hours - being highly inconvenient if you want to keep an efficient workflow.

XY Resolution and layer thickness is a central matter in 3D printing. It defines the smoothness of your prints and since dental applications are often used intraorally, they must have a natural feel to them. So you should make sure that you buy a printer that can perform accordingly.

Ms.Josey

Ms.Josey

Ms.Josey

Ms.Josey