diy custom lcd display manufacturer

Looking to take your project to the next level in terms of functionality and appearance? A custom LCD display might be the thing that gets you there, at least compared to the dot-matrix or seven-segment displays that anyone and their uncle can buy from the usual sources for pennies. But how does one create such a thing, and what are the costs involved? As is so often the case these days, it’s simpler and cheaper than you think, and [Dave Jones] has a great primer on designing and specifying custom LCDs.

The video below is part of an ongoing series; a previous video covered the design process, turning the design into a spec, and choosing a manufacturer; another discussed the manufacturer’s design document approval and developing a test plan for the module. This one shows the testing plan in action on the insanely cheap modules – [Dave] was able to have a small run of five modules made up for only $138, which included $33 shipping. The display is for a custom power supply and has over 200 segments, including four numeric sections, a clock display, a bar graph, and custom icons for volts, amps, millijoules, and watt-hours. It’s a big piece of glass and the quality is remarkable for the price. It’s not perfect – [Dave] noted a group of segments on the same common lines that were a bit dimmer than the rest, but was able to work around it by tweaking the supply voltage a bit.

We’re amazed at how low the barrier to entry into custom electronics has become, and even if you don’t need a custom LCD, at these prices it’s tempting to order one just because you can. Of course, you can also build your own LCD display completely from scratch too.

Liquid Crystal Displays or more commonly known as LCDs are one of the most common electronic components which help us interact with an equipment or a device. Most personal portable equipment and even gigantic industrial equipment utilize a custom segment display to display data. For many portable consumer electronics, a segment LCD display is one of the biggest contributors to the overall cost of the device, hence designing a custom segment display can drive the cost down while also utilizing the display area in the most optimum manner. These displays have the lowest cost per piece, low power requirements, and a low tooling fee too.

At first thought, designing a custom segment LCD might look like a Herculean task, but trust me that it is easier than it seems. In this article, we have summarised and compared the display types and available technologies which are required to construct a custom segment LCD. We have also provided a flowchart that can act as a step-by-step guide while you design your own custom LCD. We have also provided the process we followed, a require gathering sheet we used for communicating our needs to the manufacturer, and a few other data and the quotation we received from the manufacturer.

Icons: A silhouette of any shape can be placed on the glass which enhances the ability to display data. For example, a symbol of a heart can be made to denote heart rate or an icon for a low battery to show that the battery needs to be charged. Icons are counted as a single pixel or segment and can give a lot more details than similar-sized text.

LCD Bias– It denotes the number of different voltage levels used in driving the segments, static drives (explained later in this article) only have 2 voltage levels or 2 bias voltage while multiplex drives have multiple voltage levels. For example, 1/3 will have 4 bias voltages.

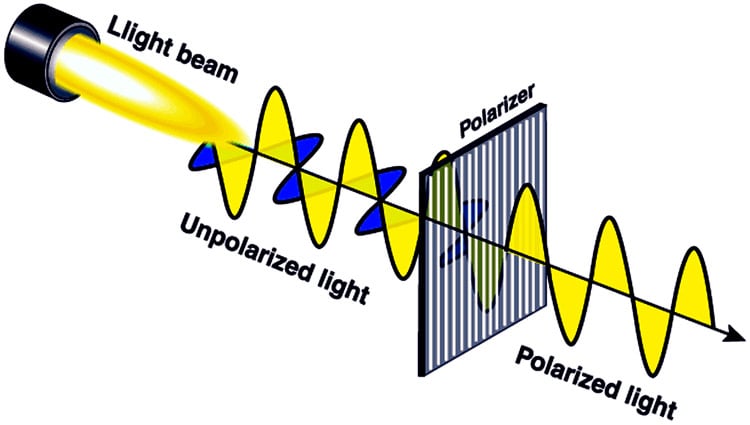

LCDs utilizes the light modulating properties of liquid crystals which can be observed by using polarizing filters. Polarizing filters are special materials that have their molecules aligned in the same direction. If the light waves passing through polarisers have the same orientation as the filter, then the molecules of lights are absorbed by the filter, hence reducing the intensity of light passing through it, making it visible.

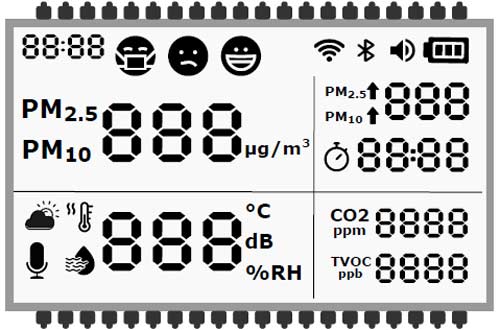

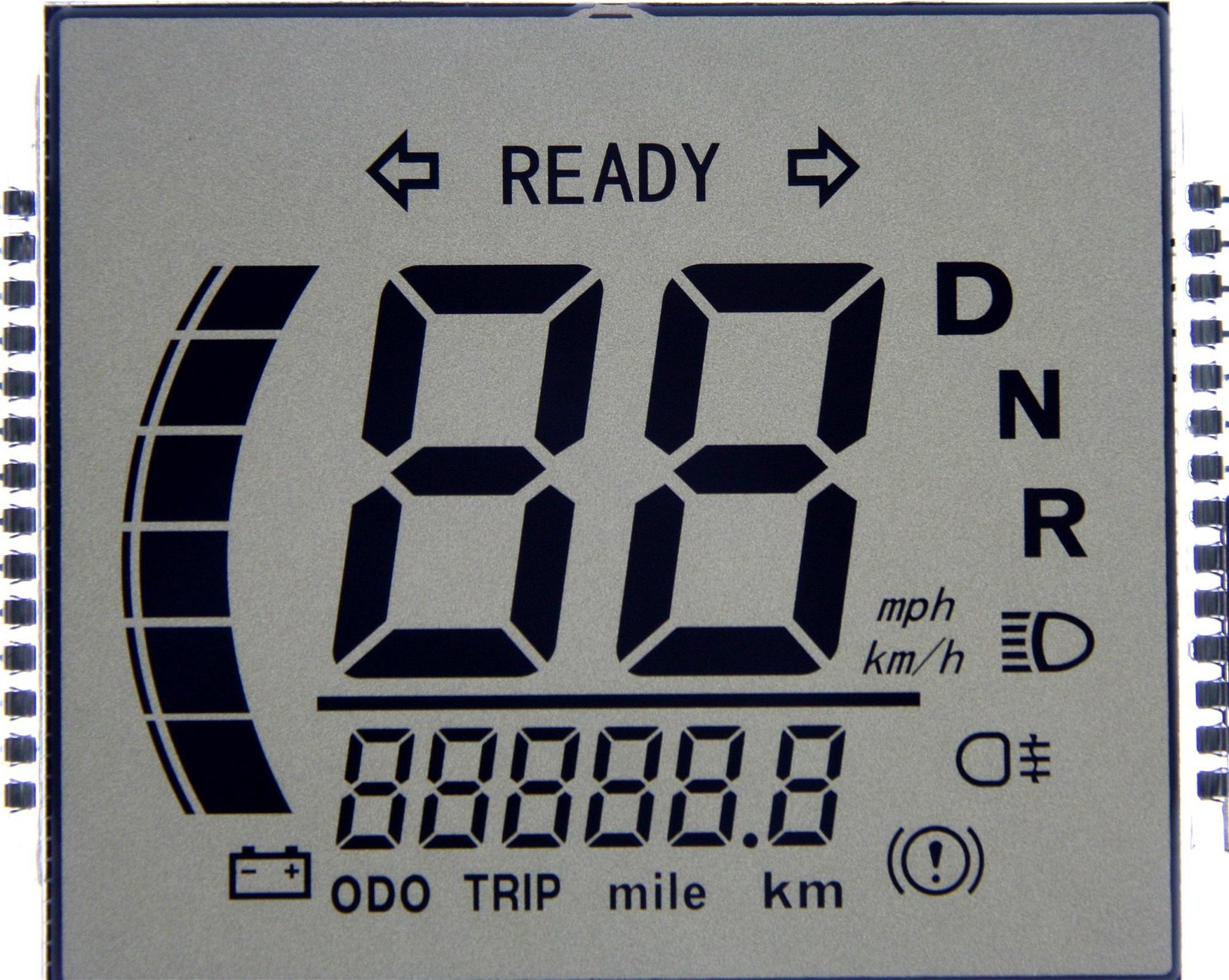

A custom LCD is important for maximizing the efficiency of the display area by adding custom symbols and characters. It also helps in reducing the cost and improving energy efficiency of the product. A higher number of custom symbols and specified placement of numerical and alphanumerical characters make the display more informative and readable for the user. This makes it look better than the plain old boring displays we get in the market. Furthermore, we can specify the viewing angle, contrast, and other specifications which can increase durability or give a better value for money for our intended usage. A typical Custom Segment display is shown below, we will also show you how to design and fabricate the same further in the article.

The LCD display doesn’t emit any light of its own, therefore it requires an external source of illumination or reflector to be readable in dark environments.

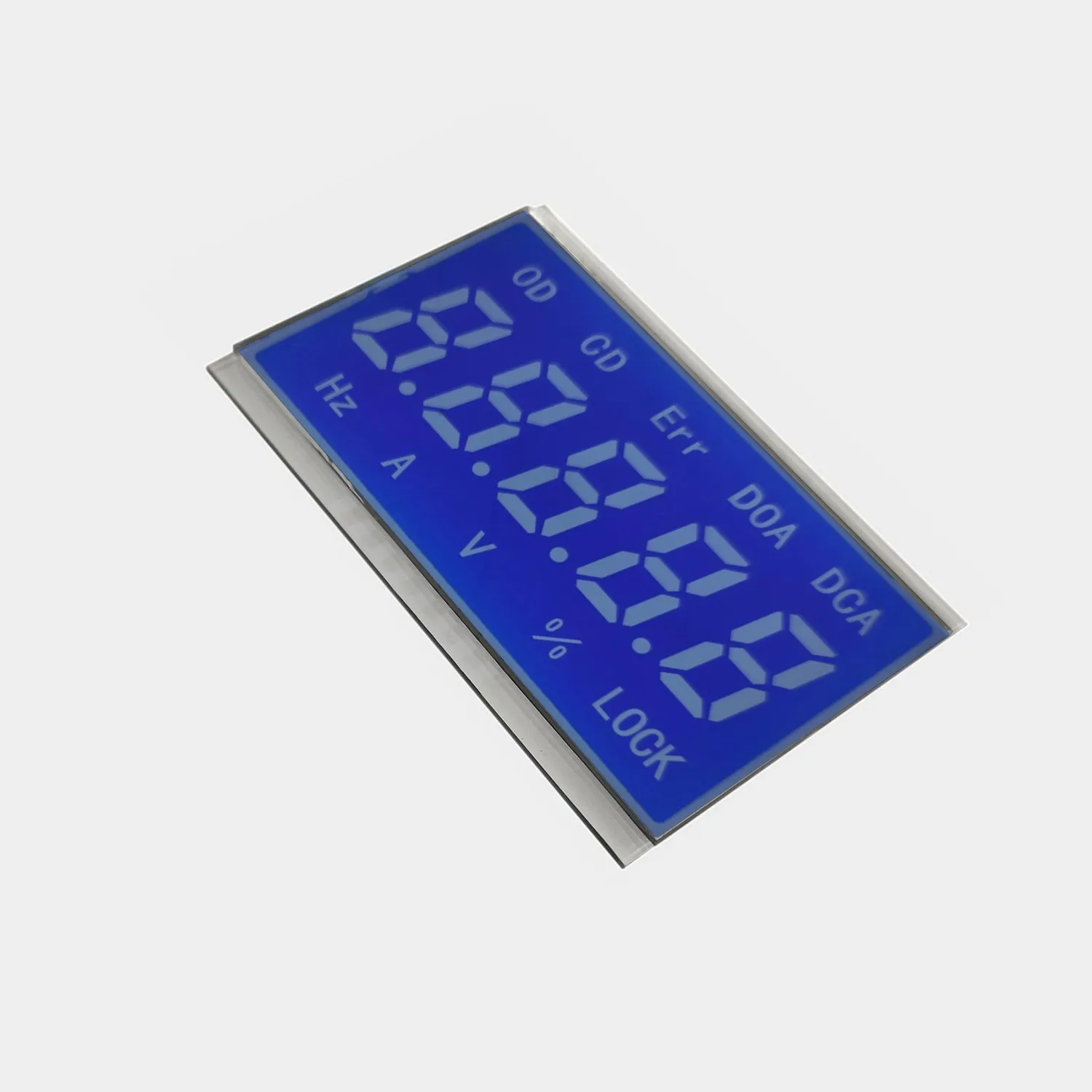

While designing a custom segment LCD display, we have the leverage of choosing a lot of parameters that affect the final product. From the color of the display to the illumination technique and color of illumination as well as the type of input pins. Some important considerations we need to take while designing a custom 7 segment display are - the type of display, i.e. positive or negative, illumination method, driving technique, polarising type, and connection method. All these design criteria are explained below:

Positive and negative displays can be easily distinguished by the colour of the background and characters. Some common differences between the positive and negative displays are:

So, which one should you choose? When the displays are to be used in areas with higher ambient light, we should select positive segment LCD display as it has better visibility than negative segment LCD displays without using a backlight.

As we know that LED displays don’t emit any light, hence to illuminate it and make it visible in a dark environment, we can use different methods of illumination. The most common LCD Illumination methods are compared below:

For displays that need to be used for budget-friendly devices that should be small and rugged, LED lights are preferred for the displays due to the high durability and low cost of operations. For high brightness, CCFL and Incandescent lights can be used.

A polarizer film is the most important component of an LCD display, which makes it possible to display characters by controlling the light. There are 3 types of polarizers that can be used in the LCD display, the properties and difference are given below:

Displays can be categorized into two types, passive displays, and active display, passive displays are simpler to construct as they have 2 connections at each segment, the conductors comprise of an Indium Tin Oxide to create an image, whereas the active displays use thin-film transistors (TFT) arranged in a grid. The name is due to its ability to control each pixel individually.

If your displays have fewer segments, then static LCD drive is preferred as it is easier to control and cheaper to construct, and has a better contrast ratio. But let’s say that if the number of segments in the display are more than 30-40 then a multiplex LCD drive should be preferred as it has multiple common pins, hence reducing the total number of pins required to drive the display.

Choosing a connector type!!! For the prototyping phase or if you need to connect your LCD display on a Microcontroller directly, a pin type connector is the best and most economical option you have. If you need to connect your LCD display in a final product with a high volume of production which also requires to be extremely durable, but at the same time should not take up a lot of space, a Flex type LCD Connector will work best for you

LCDs have limited viewing angles and when seen from an angle they lose contrast and are difficult to be observed. The viewing angle is defined by the angles perpendicular to the center of the display towards its right, left, up, and down which are denoted by the notations 3:00, 9:00, 12:00, and 6:00 respectively. The viewing angle of LCD can be defined as the angle w.r.t. to the bias angle at which the contrast of segments is legible.

To improve the viewing angle in an LCD, a Bias is incorporated in the design which shifts the nominal viewing angle with an offset. Another technique is to increase the Voltage, it affects the bias angle, making the display crisper when viewed from a direction.

For example, the viewing angle of a TN type TFT LCD is 45-65 degrees. Extra-wide polarising film (EWP) can increase the viewing angle by 10 degrees, using an O film polariser can make the viewing angles 75 degrees but these come at a cost of reduced contrast.

LCD Control chip or LCD driver chips can be mounted on the flex cable, display, or externally on a PCB. The placement of LCD control chip can affect the cost and size of the display. The 2 most common methods of chip placement are-Chip of Board (COB)and Chip on Glass(COG) which are described below:

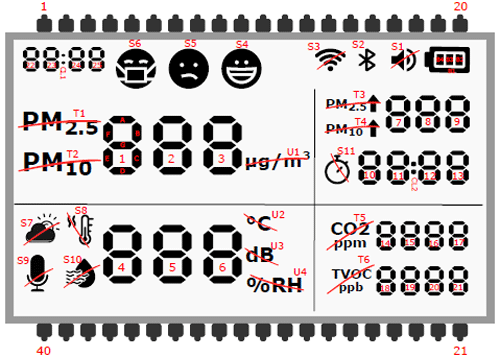

We planned to design an air quality monitoring system for which we needed a custom segment LCD panel for an air quality monitoring device. Our product needs to display the following data: 2.5-micron and 10-micron particulate matter (PM) suspended in the air; the units should be in parts per million (PPM). CO2 in the air in PPM along with total volatile organic compounds present in the air in parts per billion (PPB). To make the product more usable, we included time in 24-hour format, Temperature in ºC, Battery status, loudspeaker status, Bluetooth status, and Wi-Fi status. And for some personal touch, we also added how good the air quality in the room is by using 3 different smileys.

We realized that it was impossible to provide all these data in a generic LCD available in the market, thus decided to build a custom LCD for our project.

A step-by-step flowchart is shown below to walk you through each and every step of selecting components and getting your custom segment LCD manufactured.

We started by listing down our requirements and drew a mock-up of the display on paper. After finalizing the placement of all the segments and icons on the prototype sketch of the display, we then decided which all icons and segments have to be kept on for the whole time and which needs to be driven. Realizing that there are too many segments, characters and icons, hence we selected a multiplex drive with 8 common pins which helped us bring down the total pins from an estimated 180 pins to less than 40 pins.

Since the device was meant to be used inside houses and offices, which are more often than not well lit and protected from environmental conditions, we opted for a positive mode display. For superior contrast ratio and better viewing angle, we chose a Film Super Twisted Nematic Display (FSTN) with a drive condition of 1/8 Duty and bias of 1/4.

Usually, the displays are mounted at a height of 4.5 feet from the ground, thus the viewing direction was selected to be 12"O clock with an operating frequency of 64Hz. We selected a Transmissive polarizer for the front glass and a reflective polarizer for the rear glass so that the natural light can pass through the front panel and the display can achieve the maximum contrast without the need for backlighting and we opted for the pin type connectors as they are easy for prototyping and are suitable for harsh environment with a lot of vibrations and shocks which best suited our purpose.

In the above image of a custom display design, we sent to the manufacturer, the red lines over multiple characters indicate that all these are considered as a single segment. For the sake of simplicity, we added test like T, S, U, B to denote Text, Symbols, Units, and Battery respectively. These characters were followed by numbers to simplify communication between us and the manufacturer. For example, if we needed any particular text or symbol to remain on, we can easily specify that to the manufacturer by using the corresponding text for that segment.

We mailed our requirements to multiple LCD manufacturers, (you will find a lot of LCD manufacturers on the Internet). Most LCD manufacturers have competitive pricing, and reply within a week. A sample requirement sheet is shown above which a customer needs to fill to specify all the details to the manufacturer.

This is a sample Custom Segment LCD quotation we got from one of the manufacturers. As you can see, the cost is based on the quantity. Higher the quantity, lower the cost. Apart from the cost per quantity, there is one more component called tooling fees. Tooling fee is a one-time fee charged by the manufacturer. It is for the technical design, support, and customization of the product. Customization of PCB or tooling of LCD can drive the tooling price higher or lower.

A custom segment LCD can help you personalize your product while also saving the overall cost of your product. The whole process will take you around 2-3 months, which will include the designing phase, prototyping phase, and getting your custom segment LCDs delivered to your doorstep. Higher ordering quantity will reduce the cost per piece of each unit, thus driving down the cost of your final product.

The process to take your LCD idea from a concept to having prototype samples in hand is simple and requires just the few steps listed below. (Download PDF)

In many cases, FocusLCDs’ lead time for custom LCD samples is as little as 6-7 weeks after you approve our counter drawings and data sheet. This lead time increases by 4-6 weeks between November to early February due to Chinese New year. Standard production orders for custom displays have a lead time of 10-12 weeks, which can increase by 2-4 weeks during Chinese New year.

Focus Display Solutions offers several LCD technologies. The majority of these displays can be customized to fit your need. Below is a short introduction to each type of LCD.

Ultra-Wide Viewing Display (UWVD) is a new technology that is named after one of its most notable characteristics – it is viewable from all angles. In addition to the viewing angle, this technology provides a better contrast than other options and can allow for multiple colors. Call one of our design specialists today to see if UWVD is the right technology for you.

Thin-Film-Transistor Liquid Crystal Displays (TFTs) are perhaps the most encountered display technology we see daily. Often seen in cell phones, tablets, cameras and countless other devices, this technology offers several hundreds of thousands of colors with a high pixel count to offer supreme visual clarity. In addition, all TFTs are available off the shelf with resistive and capacitive touch panel options.

Character LCDs have been around since the 1950s and are still very common. These displays offer 256 selectable characters and are available with several different font tables to show a variety of languages. They are most commonly known for their ease of programming wide variety of sizes, character arrays and colors.

New Vision Display is a custom LCD display manufacturer serving OEMs across diverse markets. One of the things that sets us apart from other LCD screen manufacturers is the diversity of products and customizations we offer. Our LCD portfolio ranges from low-cost monochrome LCDs to high-resolution, high-brightness color TFT LCDs – and pretty much everything in between. We also have extensive experience integrating LCD screen displays into complete assemblies with touch and cover lens.

Sunlight readable, ultra-low power, bistable (“paper-like”) LCDs. Automotive grade, wide operating/storage temperatures, and wide viewing angles. Low tooling costs.

Among the many advantages of working with NVD as your LCD screen manufacturer is the extensive technical expertise of our engineering team. From concept to product, our sales and technical staff provide expert recommendations and attentive support to ensure the right solution for your project.

In addition, our extensive technology portfolio and manufacturing capabilities enable us to deliver high-quality products that meet the unique specifications of any application. To learn more about what makes us the display manufacturer for your needs, get in touch with us today.

As a leading LCD panel manufacturer, NVD manufactures custom LCD display solutions for a variety of end-user applications: Medical devices, industrial equipment, household appliances, consumer electronics, and many others. Our state-of-the-art LCD factories are equipped to build custom LCDs for optimal performance in even the most challenging environments. Whether your product will be used in the great outdoors or a hospital operating room, we can build the right custom LCD solution for your needs. Learn more about the markets we serve below.

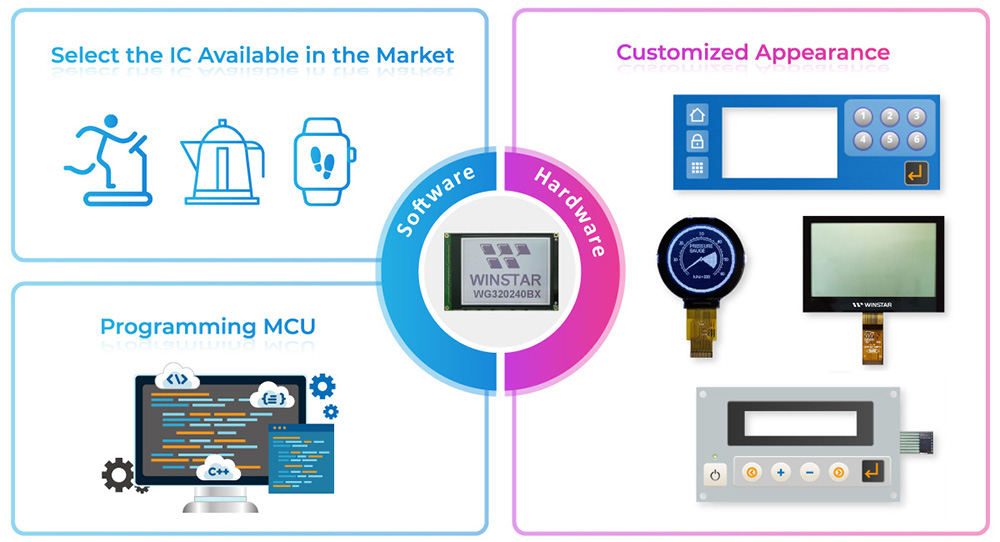

Except the available standard LCD/TFT/OLED display products, Winstar provides tailor made displays. The extensive portfolio makes it possible to create tailor-made solutions for customers to fit their application. We have the advanced display technologies available to use in your design and if there is anything you want to change about one of our existing LCD/TFT/OLED displays, we can make it happen. With more than 23 years experience, our sales and engineering team will be with you through the entire development process and will ensure the semi or fully customization a successful display tailored made to the individual application.

Our LCD/TFT/OLED custom design solutions are available in different options according to customer requirements. Winstar can offer various options on backlight type, pin and connector, cable, resistive touch screen (RTP) and projected capacitive (PCAP) touch screen or anti-reflective or anti-glare coating, or custom cover lens, ZIF PPC or customized PCB board or a fully custom solution for your product application, as well as System Integrated Solution.

Orient Display is a company that specializes in manufacturing LCD displays, touch panels, OLED displays with competitive prices. The company was founded in 1996 by specializing in fields of production, R&D, quality controls. Thanks for the management and employee’s continuous hardworking and enormous effort and shareholder continuous investment over years, Orient Display factory is now the world’s leading custom LCD manufacturer in flat panel industry and is listed as a public company in China stock market. Now, Orient Display factory has 2 production lines that can produce PMOLED and AMOLED custom display modules. Factories have complete quality and environment management system, ISO9001, ISO/IATF16949, ISO14001, IECQ QC080000. Orient Display takes around 18% market share in global automotive market and is No.1 in automotive capacitive touch screen.

Orient Display has supported customers with custom LCD displays for tens of thousands of types and models for automotive, appliances, medical, smart homes, point of sales, industrial advices, etc. Whether your design requires a small custom LCD display glass, or a fully customized LCD module, or custom monitors and displays equipped with complicated embedded control board with touch panels, our experienced engineers in North America, Europe or in China factory will assist you in designing your customized displays.

Orient Display customer service sends quotation to you (might come with technical suggestions according to your targeted applications). The time will depend on the complexity of the project and the time to source components, normally, it takes 1-3 days for custom LCD glass panels, 2-5 days for custom LCD display modules or touch panels.

Orient Display engineers provide custom LCD display counter-drawings for you to approve with your signature on the drawing. The drawings might be modified several times until the designs are fully achieved your technical requirements. There can be a lot of technical discussions at this stage. The time our engineers take to arrange drawings also depend on the complexity of the project. Normally, it takes 1-3 days for custom LCD glass panels, 2-5 days for custom LCD display modules or touch panels.

After your drawing approval, Orient Display will start to make samples or prototypes for you to test. The lead time also varies depending on the production complexity and component/material sourcing. Normally, it takes 4-6 weeks for custom LCD glass panels, 8-10 weeks for custom LCD display modules or touch panels.

After your sample / prototype approval, Orient Display is ready for production. Orient Display welcomes trial production between the prototypes to large scale production so that you have the opportunity to fully test the custom LCD display or touch panel to run well in your designed products.

Congratulations! You have accomplished the journey of the idea, design, prototype and production in the market. The journey can take from 3 months to 3 years. Whatever the voyage, Orient Display’s engineers, customer services are proud to be part of your design. Our happiness is based on your success.

Dimensions (Specification / Drawing / Sketch of the LCD, if available). If it is a drop-in replacement, it is great to provide files in dwg. or dxf. format.

LCD Mode Preference if you have an idea or let us to decide (TN Positive/Negative, STN Positive YG, STN Negative Blue, STN Positive Gray, FSTN Positive, FSTN Negative, FFSTN Negative);

Dimensions (Specification / Drawing / Sketch of the LCD module, if available). If it is a drop-in replacement, it is great to provide files in dwg. or dxf. format.

LCD Mode Preference if you have an idea or let us to decide (TN Positive/Negative, STN Positive YG, STN Negative Blue, STN Positive Gray, FSTN Positive, FSTN Negative, FFSTN Negative);

Fully custom made TFT LCD display module can be very expensive, the NRE ranges from $80,000 to $1M depending on the size and the resolution of the LCD display and the generation of the production line the LCD display to be produced. For over 99% of our projects, we are talking about the modifications of the standard TFT LCD display. There are a lot of standard color TFT displays available in the market. You are highly likely to find one matching your requirement. If you can’t find a suitable one on our website, please check with our engineers, we have a database in factory with much more types.

Dimensions (Specification / Drawing / Sketch of the LCD module, if available). If it is a drop replacement, it is great to provide files in dwg. or dxf. format.

The above information can be overwhelming. Actually, we design a lot of touch panel and LCD custom display projects without being provided detailed information. Our engineers and customer service can quickly decide the parameters based on the customer’s application. Please feel free to contact our engineers for details.

Since 2001 we’ve provided product development, engineering design services, and turn-key solutions for all industries. Work with our engineers to develop the ideal display for your unique application.

For more than 20 years, Newhaven Display International has provided custom display solutions worldwide across various industries including medical, agriculture, industrial, handheld, audio/video, automotive, consumer, appliance, security, casino, military, energy, POS, test & measurement, and telecom.

Our US-based engineering staff works together to help you prototype, design, test, build, and manufacture your custom display solution to perfectly fit your application and make your product a success. Keep in mind that minimum order quantities (MOQ) and NRE may apply depending on your custom solution request.

Easily modify any connectors on your display to meet your application’s requirements. Soldering for pin headers, boxed headers, right angles headers, and any other connectors which your display may require.

Equip your display with a custom cut cover glass to improve durability. Choose from a variety of cover glass thicknesses and get optical bonding to protect against moisture and debris.

Custom backlight configurations can be made with voltage/input current, brightness or colors/NVIS. Perhaps it is just changing the assembly type from array to side LEDs.

We have complete control over our display products" design, manufacturing, and quality control processes. Our USA based Engineers will work with you on a prototype to validate and test your design.

Cable Customization Touchscreen Add-Ons Interface Customization Connector Customization PCB Modifications Cover Glass Additions Mounting Add-Ons Custom Backlight Keypads

The industry is flooded with manufacturers of varying capabilities, resources, commitment to quality and pre/post sales support. Some of these manufacturers will produce average quality displays without the needed enhancements that your customers expect today.

E3 Displays is all about making the manufacturing of your perfect display simple. We’ll guide you through an easy process to help you built your product so you never have to worry about low quality, inferior technology, unnecessary enhancements, and post sales continued support. Let’s make your business thrive.

Mimo Monitors can create a custom-size LCD monitor to almost any specification. Whether it is a minor modification to an existing design, or by utilizing our extensive experience in the industry, we can almost always build what you need.

What we are going to deliver is an industrial open frame monitor, in other words a “bare bones” display sans housing or bezel. These types of displays are meant for integration into kiosks, equipment, or other enclosures. The major advantage to an open frame monitor is that the external design will not change for some time. Therefore, the enclosure it is built into will not need to change for many years.

Aspect ratio - The ratio of the width of the display to the height. Current televisions are 16:9, Old televisions are 4:3 – 16:9, 16:10 and 4:3 are the most popular. Every other aspect ratio is less popular, but any aspect ratio can be created by resizing a panel.

Resolution - The number of pixels in the display – This will depend somewhat on the aspect ratio chosen. Higher resolution is better, but remember the pixel size on a 65” 1080p HDTV is actually 15x worse than on a 800x480 7” display. In other words, resolution doesn’t matter as much as sizes get smaller. Common resolutions are 800x480, 1024x600, 1280x800, 1366x768 1920x1080

Viewing Angle - This will depend on the technology of the LCD panel. TN vs. VA vs. IPS. More here (http://www.tnpanel.com/tn-vs-ips-va/) . In general, the better the viewing angle, the more expensive the resulting display. Typical are 150x140, 170x170 and 179x179. Or more commonly wide viewing angle or standard viewing angle.

Brightness or Luminance - It is the level of light emitted by an LCD display monitor. Luminance is reported in nits or cd/m2. They are actually the same thing. This matters for indoor and outdoor viewing and also if you want to draw people toward the display for advertising. Typical indoor brightness is 150 nits, indoor advertising is 300, bright indoor advertising is 700 and outdoor panels are 1000+

Interface to computer - How the video and optionally touch information is transmitted. Typical options are DVI (digital video), VGA (analog video), HDMI (digital video with audio), DisplayPort (newest digital format) and DisplayLink. Touch is almost exclusively USB at this time. This chooses the number of cables in the solution

Single Cable –DisplayLink has an advantage that video information, touch information, and power are transmitted over a single USB connection. Read 5 Reasons to Choose a USB Powered Monitor to learn how they can meet your needs.

Touch panel - Optional human interface for interactivity. Typical choices are Display Only, Resistive (4 or 5 wire), and Capacitive touch options. Our blog discusses the advantages and disadvantages of capacitive touchscreens. SAW is another touch technology that is becoming less and less common.

Since 1990, AccuView is dedicated to delivering fully customized LCD display solutions for our customers. Our strength lies in understanding and meeting our customers" EXACT requirements coupled with AccuView"s comprehensive manufacturing capabilities and expertise to deliver the right LCD display solution. Let AccuView be your total video solution provider.

Once it’s recognized that a custom display will be a better design and lead to a lower overall system-level cost it’s time to dive into the actual tooling costs.

There are many factors that go into determining the upfront tooling. There’s also due diligence to be performed prior to making this commitment to ensure that this new custom display supplier will effectively support you over the long term.

Customization can either be semi-custom or fully custom. Semi-custom is where some attributes of a standard product are modified to fit the application. In contrast, fully custom is where the design is started from scratch and each component is designed from the ground up.

Semi-custom is typically the preferred option to start with. And in the case of color TFT, it’s typically the only option, as the TFT panel comes with a significant tooling and minimum order quantity (MOQ) such that the customization costs outweigh the drawbacks of using the closest standard TFT glass platform available.

b) Custom color TFT displays— the bulk of this cost comes from the TFT glass cell at $70K–$200K depending on the type of TFT cell used (standard TN or IPS). The balance of the module is an additional $5,000 – $15,000.

f) Touch panels— resistive touch panels cost approximately $2,500, while capacitive touch panels can range between $4,000 and $10,000. If a standard capacitive touch sensor can be used, and only a custom top surface is customized, the tooling can be reduced to only $1,500.

g) Backlights— monochrome display backlights are less complex and cheaper to tool at $2,000 – $4,000. The color counterpart, due to its high brightness requirement, will run between $4,000 and $10,000.

Now that we’ve reviewed some of the costs associated with custom displays, here are some tips you can use to make sure that you move forward with the right partner that will then support this custom display for the long term.

Many LCD display manufacturers try to accommodate all order volumes they receive. While this allows them to serve a wider range of customers, it makes them less specialized for serving certain types of customers. As a result, your specific production volumes may be prohibitively expensive.

Seek out a display manufacturer who is optimized to handle your specific production needs for LCD displays. This is necessary to get the display for the right cost and the appropriate level of support.

Always start with a semi-custom approach. Use the available standard products to base the new design on, and then keep modifying as needed. This results in the lowest tooling costs and an easier design process. And in the case of color TFT, unless you are developing the next iPhone, design your display based on one of the standard glass platforms readily available. Then from there, redesign the backlight and the mechanical and electrical interface for your specific application.

Behind every great company are happy customers. Find out whether your supplier has them. Make sure that when this experience is handed off from your supplier’s sales and design team, the production team is just as good and accommodating. This can be accomplished through references and audits.

Initiating a successful relationship for a new custom display is all about having an open and transparent relationship with the right partner. And by designing the ideal custom or semi-custom display with this partner, you can ensure you’re getting the best possible solution for your company.

For over 20 years we"ve been helping clients worldwide by designing, developing, & manufacturing custom LCD displays, screens, and panels across all industries.

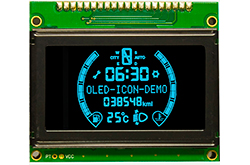

Newhaven Display has extensive experience manufacturing a wide array of digital display products, including TFT, IPS, character displays, graphic displays, LCD modules, COG displays, and LCD panels. Along with these products, we specialize in creating high-quality and affordable custom LCD solutions. While our focus is on high-quality LCD products, we also have a variety of graphic and character OLED displays we manufacture.

As a longtime leader in LCD manufacturing, producing top-quality LCD modules and panels is our highest priority. At Newhaven Display, we’re also incredibly proud to uphold our reputation as a trusted and friendly custom LCD manufacturing company.

As a custom LCD manufacturing company, we ensure complete control of our custom displays" reliability by providing the industry"s highest quality standards. Our design, development, production, and quality engineers work closely to help our clients bring their products to life with a fully custom display solution.

Our excellent in-house support sets Newhaven Display apart from other display manufacturers. Modifications in the customization process are completed at our Illinois facility, allowing us to provide an exceptionally fast turnaround time.

Customer support requests sent by phone, email, or on our support forum will typically receive a response within 24 hours. For custom LCD project inquiries, our response time can take a few days or weeks, depending on the complexity of your display customization requirements. With different production facilities and a robust supply chain, we are able to deliver thefastest turnaround times for display customizations.

We work hard to ensure that personalized support is available and highly reliable. Our extended support center is available through our website, including example codes, IC datasheets, font tables, engineering changes, a video library, and answers to frequently asked questions. You can visit our knowledge center and community forum, where you can find answers, browse topics, and talk to other engineers in the display and electronics field.

Our excellent in-house support and custom display modifications set Newhaven Display apart from other LCD display manufacturers. From TFTs, IPS, sunlight readable displays, HDMI modules, EVE2 modules, to COG, character, and graphic LCDs, our modifications in the customization process are completed at our Illinois facility, allowing us to provide quality and fast turnaround times.

As a display manufacturer, distributor, and wholesaler, we are able to deliver the best quality displays at the best prices. Design, manufacturing, and product assembly are completed at our headquarters in Elgin, Illinois. Newhaven Display International ensures the best quality LCD products in the industry in this newly expanded facility with a renovated production and manufacturing space.

With assembly facilities in the US, manufacturing facilities in China, and distribution channels worldwide, we pride ourselves on delivering high-quality custom display solutions quickly to locations worldwide.

Microtips Technology is a leading custom lcd module manufacturer and we offer a full array of products and services. We have the most advances display technologies available to use in your design and if there is anything you want to change about one of our displays, we can make it happen. All of our displays are fully customizable to your specification and can include extra features like a capacitive touchscreen, an anti-reflective or anti-glare coating, or custom cover glass. Our sales and engineering staff will be with you through the entire process and will ensure our custom lcd display and your end product look their very best.

Asia has long dominated the display module TFT LCD manufacturers’ scene. After all, most major display module manufacturers can be found in countries like China, South Korea, Japan, and India.

However, the United States doesn’t fall short of its display module manufacturers. Most American module companies may not be as well-known as their Asian counterparts, but they still produce high-quality display products for both consumers and industrial clients.

In this post, we’ll list down 7 best display module TFT LCD manufacturers in the USA. We’ll see why these companies deserve recognition as top players in the American display module industry.

STONE Technologies is a leading display module TFT LCD manufacturer in the world. The company is based in Beijing, China, and has been in operations since 2010. STONE quickly grew to become one of the most trusted display module manufacturers in 14 years.

Now, let’s move on to the list of the best display module manufacturers in the USA. These companies are your best picks if you need to find a display module TFT LCD manufacturer based in the United States:

Planar Systems is a digital display company headquartered in Hillsboro, Oregon. It specializes in providing digital display solutions such as LCD video walls and large format LCD displays.

Planar’s manufacturing facilities are located in Finland, France, and North America. Specifically, large-format displays are manufactured and assembled in Albi, France.

Another thing that makes Planar successful is its relentless focus on its customers. The company listens to what each customer requires so that they can come up with effective display solutions to address these needs.

Microtips Technology is a global electronics manufacturer based in Orlando, Florida. The company was established in 1990 and has grown into a strong fixture in the LCD industry.

What makes Microtips a great display module TFT LCD manufacturer in the USA lies in its close ties with all its customers. It does so by establishing a good rapport with its clients starting from the initial product discussions. Microtips manages to keep this exceptional rapport throughout the entire client relationship by:

Displaytech is an American display module TFT LCD manufacturer headquartered in Carlsbad, California. It was founded in 1989 and is part of several companies under the Seacomp group. The company specializes in manufacturing small to medium-sized LCD modules for various devices across all possible industries.

The company also manufactures embedded TFT devices, interface boards, and LCD development boards. Also, Displaytech offers design services for embedded products, display-based PCB assemblies, and turnkey products.

Displaytech makes it easy for clients to create their own customized LCD modules. There is a feature called Design Your Custom LCD Panel found on their site. Clients simply need to input their specifications such as their desired dimensions, LCD configuration, attributes, connector type, operating and storage temperature, and other pertinent information. Clients can then submit this form to Displaytech to get feedback, suggestions, and quotes.

Clients are assured of high-quality products from Displaytech. This is because of the numerous ISO certifications that the company holds for medical devices, automotive, and quality management. Displaytech also holds RoHS and REACH certifications.

A vast product range, good customization options, and responsive customer service – all these factors make Displaytech among the leading LCD manufacturers in the USA.

Products that Phoenix Display offers include standard, semi-custom, and fully-customized LCD modules. Specifically, these products comprise Phoenix Display’s offerings:

Phoenix Display also integrates the display design to all existing peripheral components, thereby lowering manufacturing costs, improving overall system reliability, and removes unnecessary interconnects.

Clients flock to Phoenix Display because of their decades-long experience in the display manufacturing field. The company also combines its technical expertise with its competitive manufacturing capabilities to produce the best possible LCD products for its clients.

True Vision Displays is an American display module TFT LCD manufacturing company located at Cerritos, California. It specializes in LCD display solutions for special applications in modern industries. Most of their clients come from highly-demanding fields such as aerospace, defense, medical, and financial industries.

The company produces several types of TFT LCD products. Most of them are industrial-grade and comes in various resolution types such as VGA, QVGA, XGA, and SXGA. Clients may also select product enclosures for these modules.

All products feature high-bright LCD systems that come from the company’s proprietary low-power LED backlight technology. The modules and screens also come in ruggedized forms perfect for highly-demanding outdoor industrial use.

Slow but steady growth has always been True Vision Display’s business strategy. And the company continues to be known globally through its excellent quality display products, robust research and development team, top-of-the-line manufacturing facilities, and straightforward client communication.

LXD Incorporated is among the earliest LCD manufacturers in the world. The company was founded in 1968 by James Fergason under the name International Liquid Xtal Company (ILIXCO). Its first headquarters was in Kent, Ohio. At present, LXD is based in Raleigh, North Carolina.

All of their display modules can be customized to fit any kind of specifications their clients may require. Display modules also pass through a series of reliability tests before leaving the manufacturing line. As such, LXD’s products can withstand extreme outdoor environments and operates on a wide range of temperature conditions.

Cystalfontz America is a leading supplier and manufacturer of HMI display solutions. The company is located in Spokane Valley, Washington. It has been in the display solutions business since 1998.

Crystalfontz takes pride in its ISO 9001 certification, meaning the company has effective quality control measures in place for all of its products. After all, providing high-quality products to all customers remains the company’s topmost priority. Hence, many clients from small hobbyists to large top-tier American companies partner with Crystalfontz for their display solution needs.

We’ve listed the top 7 display module TFT LCD manufacturers in the USA. All these companies may not be as well-known as other Asian manufacturers are, but they are equally competent and can deliver high-quality display products according to the client’s specifications. Contact any of them if you need a US-based manufacturer to service your display solutions needs.

We also briefly touched on STONE Technologies, another excellent LCD module manufacturer based in China. Consider partnering with STONE if you want top-of-the-line smart LCD products and you’re not necessarily looking for a US-based manufacturer. STONE will surely provide the right display solution for your needs anywhere you are on the globe.

We are industry leader offer the most advanced form of optical bonding. Applied between protective glass and touchscreen, plastic, filter, TFT LCD, or TFT panel.

In both LCD and OLED displays, producing these cells – which are highly complex – is by far the most difficult element of the production process. Indeed, the complexity of these cells, combined with the levels of investment needed to achieve expertise in their production, explains why there are less than 30 companies in the whole world that can produce them. China, for instance, has invested more than 300 billion yuan (approximately $45 billion USD) in just one of these companies – BOE – over the past 14 years.

Panox Display has been involved in the display industry for many years and has built strong and long-term partner relationships with many of the biggest OLED and LCD panel manufacturers. As a result, we are able to offer our clients guaranteed access to display products from the biggest manufacturers.

LG Display was, until 2021, the No. 1 display panel manufacturer in the world. Owned by LG Group and headquartered in Seoul, South Korea, it has R&D, production, and trade institutions in China, Japan, South Korea, the United States, and Europe.

Founded in 2001, AUO – or AU Optronics – is the world’s leading TFT-LCD panel manufacturer (with a 16% market share) that designs, develops, and manufactures the world’s top three liquid crystal displays. With panels ranging from as small as 1.5 inches to 46 inches, it boasts one of the world"s few large-, medium -and small-sized product lines.

AUO offers advanced display integration solutions with innovative technologies, including 4K2K ultra-high resolution, 3D, ultra-thin, narrow bezel, transparent display, LTPS, OLED, and touch solutions. AOU has the most complete generation production line, ranging from 3.5G to 8.5G, offering panel products for a variety of LCD applications in a range of sizes, from as small as 1.2 inches to 71 inches.

Now Sharp is still top 10 TV brands all over the world. Just like BOE, Sharp produce LCDs in all kinds of size. Including small LCD (3.5 inch~9.1 inch), medium LCD (10.1 ~27 inch), large LCD (31.5~110 inch). Sharp LCD has been used on Iphone series for a long time.

Beside those current LCDs, the industrial LCD of Sharp is also excellent and widely used in public facilities, factories, and vehicles. The Sharp industrial LCD, just means solid, high brightness, super long working time, highest stability.

Since its establishment, Truly Semiconductors has focused on researching, developing, and manufacturing liquid crystal flat panel displays. Now, after twenty years of development, it is the biggest small- and medium-sized flat panel display manufacturer in China.

Truly’s factory in Shanwei City is enormous, covering an area of 1 million square meters, with a net housing area of more than 100,000 square meters. It includes five LCD production lines, one OLED production line, three touch screen production lines, and several COG, LCM, MDS, CCM, TAB, and SMT production lines.

Its world-class production lines produce LCD displays, liquid crystal display modules (LCMs), OLED displays, resistive and capacitive touch screens (touch panels), micro camera modules (CCMs), and GPS receiving modules, with such products widely used in the smartphone, automobile, and medical industries. The LCD products it offers include TFT, TN, Color TN with Black Mark (TN type LCD display for onboard machines), STN, FSTN, 65K color, and 262K color or above CSTN, COG, COF, and TAB modules.

In its early days, Innolux attached great importance to researching and developing new products. Mobile phones, portable and mounted DVD players, digital cameras, games consoles, PDA LCDs, and other star products were put into mass production and quickly captured the market, winning the company considerable market share.

Looking forward to the future, the group of photoelectric will continue to deep LCD display field, is committed to the development of plane display core technology, make good use of global operations mechanism and depth of division of labor, promise customers high-quality products and services, become the world"s top display system suppliers, in 2006 in the global mobile phone color display market leader, become "Foxconn technology" future sustained rapid growth of the engine.

Founded in June 1998, Hannstar specializes in producing thin-film transistor liquid crystal display panels, mainly for use in monitors, notebook displays and televisions. It was the first company in Taiwan to adopt the world’s top ultra-wide perspective technology (AS-IPS).

The company has three LCD factories and one LCM factory. It has acquired state-of-the-art TFT-LCD manufacturing technology, which enables it to achieve the highest efficiency in the mass production of thin-film transistor liquid crystal display production technology. Its customers include many of the biggest and most well-known electronics companies and computer manufacturers in Taiwan and overseas.

In 2002, it signed an IPS patent authorization contract with Hitachi of Japan and started to plan a 5th-generation plant to make the product line more complete and meet the needs of different customers.

TCL CSOT – short for TCL China Star Optoelectronics Technology (TCL CSOT) – was founded in 2009 and is an innovative technology enterprise that focuses on the production of semiconductor displays. As one of the global leaders in semiconductor display market, it has bases in Shenzhen, Wuhan, Huizhou, Suzhou, Guangzhou, and India, with nine panel production lines and five large modules bases.

TCL CSOT actively produces Mini LED, Micro LED, flexible OLED, printing OLED, and other new display technologies. Its product range is vast – including large, medium, and small panels and touch modules, electronic whiteboards, splicing walls, automotive displays, gaming monitors, and other high-end display application fields – which has enabled it to become a leading player in the global panel industry.

EDO (also known as EverDisplay Optonics) was founded in October 2012 and focuses on the production of small- and medium-sized high-resolution AMOLED semiconductor display panels.

The company opened its first production line – a 4.5-generation low-temperature polysilicon (LTPS) AMOLED mass production line – in 2014, which started mass producing AMOLED displays in November 2014.

In order to ramp up production output, the company began construction of a 6th-generation AMOLED production line in December 2016, with a total investment of 27.3 billion yuan (almost $4 billion USD). The line, which has a production capacity of 30,000 glass substrates per month, produces flexible and rigid high-end AMOLED displays for use in smartphones, tablet pens, vehicle displays, and wearable devices.

Tianma Microelectronics was founded in 1983 and listed on the Shenzhen Stock Exchange in 1995. It is a high-tech enterprise specializing in the production of liquid crystal displays (LCD) and liquid crystal display modules (LCM).

After more than 30 years of development, it has grown into a large publicly listed company integrating LCD research and development, design, production, sales, and servicing. Over the years, it has expanded by investing in the construction of STN-LCD, CSTN-LCD, TFT-LCD and CF production lines and module factories across China (with locations in Shenzhen, Shanghai, Chengdu, Wuhan and Xiamen), as well R&D centers and offices in Europe, Japan, South Korea and the United States.

The company"s marketing network is all over the world, and its products are widely used in mobile phones, MP3/MP4 players, vehicle displays, instrumentation, household appliances, and other fields. In terms of technical level, product quality, product grade, and market share, it ranks at the forefront of the domestic industry and has become a leading enterprise in the field of small- and medium-sized displays.

JDI (Japan Display Inc.) was established on November 15, 2011, as a joint venture between the Industrial Innovation Corporation, Sony, Hitachi, and Toshiba. It is dedicated to the production and development of small-sized displays. It mainly produces small- and medium-sized LCD display panels for use in the automotive, medical, and industrial fields, as well as personal devices including smartphones, tablets, and wearables.

Although Sony’s TVs use display panels from TCL CSOT (VA panel), Samsung. Sony still produces the world’s best micro-OLED display panels. Sony has many micro OLED model such as 0.23 inch, 0.39 inch, 0.5 inch, 0.64 inch, 0.68 inch, 0.71 inch. Panox Display used to test and sell many of them, compare to other micro OLED manufacuturers, Sony`s micro OLEDs are with the best image quality and highest brightness (3000 nits max).

An LCD is (liquid-crystal display) is a smooth screen Electronically modified device that uses the light modulating liquid crystals properties that combine with polarizers.

Liquid crystals don’t release light directly, normally it will need backlight to show the inner icons and letters. But reflective LCDs do not need backlight, it has a reflective polarizer to show the inner icons and letters.

Custom LCDs are prepared to display general-purpose optional images or hidden low information content. LCDs can be positive or negative, depending on the applications of final products. Positive mode is white background and black letters; Negative mode is black background and white letters.

To be frank, custom LCDs are easy to understand. You can pick up a LCD from your daily applications as an example. Like a clock, normally it is TN, positive reflective mode, 6 o’clock, temperature range is 0 to 50 degrees, because it is used in homes.

The most complex question is which place will the LCD be applied. If you can figure that out, then it will be easy to choose which kind of LCD you need. Then we can make custom designs for that.

LCDs are used in LCD televisions, aircraft cockpit displays, instrument panels, computer monitors, and indoor and outdoor signage in a wide range of applications.

Small custom LCD screens are popular in portable consumer and LCD projectors devices such as watches, calculators, digital cameras, digital clocks, and smartphones or mobile telephones.

LCDs are slowly easily replaced, which have a wider color range, sizes that can be easily available in different shapes, and have a slow consumption time.

We always support our customers with custom LCD modules from medical, automotive, and test appliances to industrial applications. Whether your idea needs a small LCD module or even completely specialized experienced customer support, our team guides you and helps you design your custom display screen.

The process works with you supplying your dimensions and sharing artwork. Our specialist will guide you and guide you on the most practical design for your project. This process includes the need for a brief design of LCD, the type of interface, power consumption backlight options, space constraints, temperature ranges, viewing angles etc.

Sometimes it is used as a good option for businesses wanting a simple display with effective cost. Such types of panels are used for that type of product, like thermometers and power meters. If you do not know which kind of display is best or not to use, you should ask yourself: Do you need color display features and graphics? If your display does not need all the whistles of graphics and color options, you must use a monochrome display that is a sensible choice for growing your business.

Graphic LCDs are a common option for applications that need to display many different ideas. You need the ability to display several different font sizes and fonts. It also can provide optimal sunlight legibility with low consumption power.

Sometimes they are a good option for businesses that are looking for a simple display that is cost-effective. Segment LCDs show fixed images and icons and letters. So its power consumption is much less than graphic LCDs.(Here we treat other factors the same). Although it showed fixed information, the design of it is more complex than a graphic LCD, because its inner logic circuits cost more time to design.

Custom LCD screens are available in various sizes ranging from small digital watches to very large televisions or used as glass or plastic panels, where LCDs use two glass panels.

The largest LCD we can make is 460*360mm. Because the whole glass panel size is 470*370mm, we need to cut 5mm on each side to keep the glass in good condition.

There is a higher interest in a small custom LCD Display module. As a common rule, the larger the size of the screen, the more expensive the cost of the display. At present, the minimum size of the display that we have designed and mass-produced can reach 10*10mm.

Different companies hold different advantages on LCDs. Some may be professional in graphics and some may be good at segments. And some may be good at TFT, others are good at OLED. Different companies also have their strength on different sizes of LCDs.

And normally, we differ from other companies in our customer’s applications. Most of our customers are car factories, bike factories, and motorcycle factories. Also industrial meters factories.

Ms.Josey

Ms.Josey

Ms.Josey

Ms.Josey