tft lcd driver principle supplier

LAPIS Technology"s display drivers realize uniform and fast pixel charging for 8K 120Hz, 75-inch, and larger panels with the unique technology of panel load charging.

LAPIS Technology"s display drivers use high-speed point-to-point interface technology *2 (4Gbps), which enables large amounts of display data transfer in a short time.Our products have been used in many panels with high refresh rates such as 360Hz.

We have thousands of standard products that are in stock and available from our Seattle, WA and Hong Kong warehouses to support fast product development and preproduction without MOQ. The stock covers TN, STN LCD display panels, COB, COG character LCD display, graphic LCD display, PMOLED, AMOLED display, TFT display, IPS display, high brightness and transflective, blanview sunlight readable display, super high contrast ratio display, lightning fast response displays, efficient low power consumption display, extreme temperature range display, HMI display, HDMI display, Raspberry Pi Display, Arduino display, embedded display, capacitive touch screen, LED backlight etc. Customers can easily purchase samples directly from our website to avoid time delays with setting up accounts and credit terms and shipping within 24 hours.

Many of our customers require customized OEM display solutions. With over two decades of experience, we apply our understanding of available display solutions to meet our customer’s requirements and assist from project concept to mass production. Using your ideas and requirements as a foundation, we work side by side with you to develop ideas/concepts into drawings, build prototypes and to final production seamlessly. In order to meet the fast changing world, we can provide the fastest turnaround in the industry, it takes only 3-4 weeks to produce LCD panels samples and 4-6 weeks for LCD display module, TFT LCD, IPS LCD display, and touch screen samples. The production time is only 4-5 weeks for LCD panels and 5-8 weeks for LCD display module, TFT LCD, IPS LCD display, and touch screen.

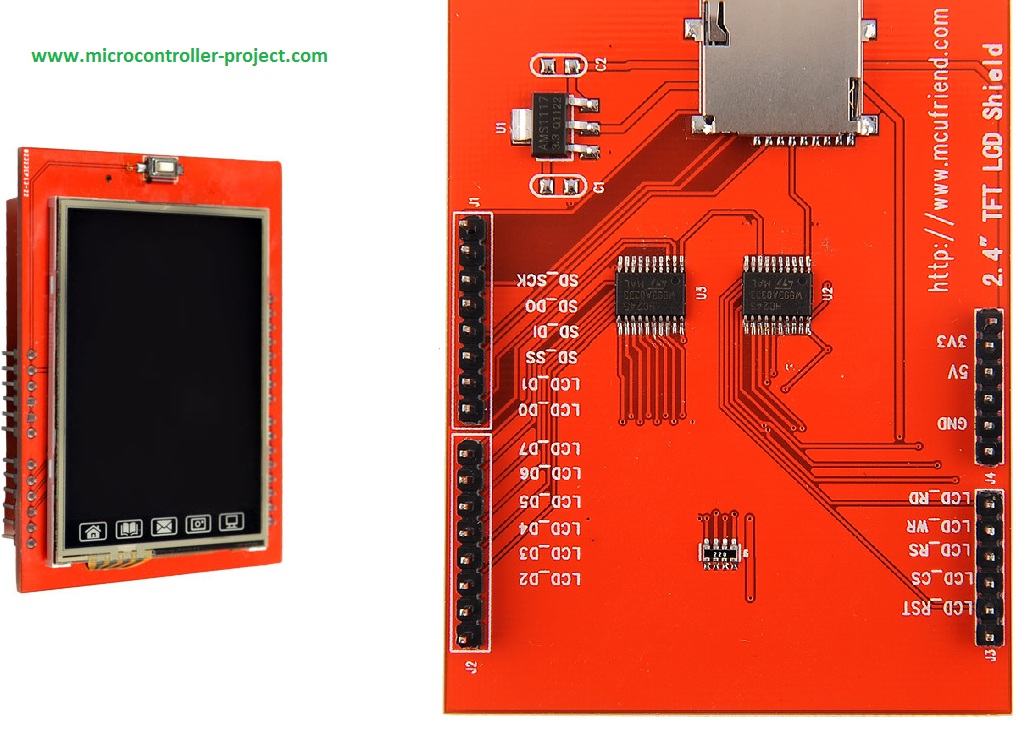

In order to follow the market tread, Orient Display engineers have developed several Arduino TFT LCD displays and Arduino OLED displays which are favored by hobbyists and professionals.

Although Orient Display provides many standard small size OLED, TN and IPS Arduino TFT displays, custom made solutions are provided with larger size displays or even with capacitive touch panel.

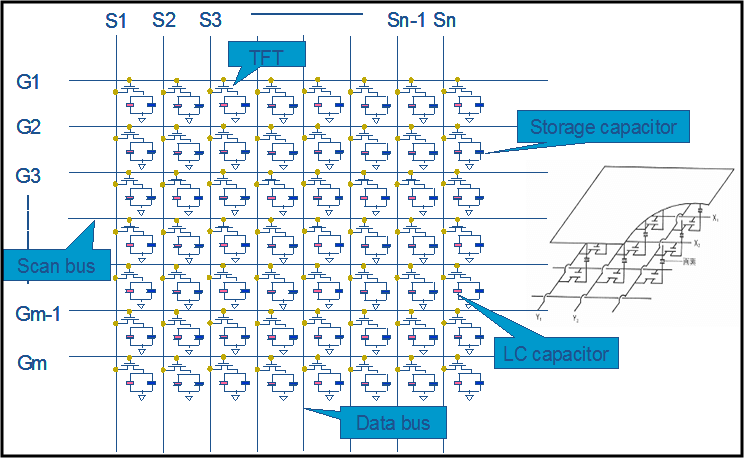

The action of the TFT element is similar to a switch (Switch), and the role of the liquid crystal element is similar to that of a capacitor, i.e., the Switch of the ON/OFF updates / holds the stored voltage values of the capacitor.

The following figure is an equivalent circuit of TFT pixels. The Gate Line connects all the TFT gate electrodes on the same column, while the Source Line connects all the TFT source electrodes on the same line.

When ON, the data of the Source Line is written to the liquid crystal capacitor. At this point, the TFT element is low impedance (RON), and when the OFF is Line, the TFT element is high impedance (ROFF), which prevents leakage of the Source data.

The signals coming in from the Interface Connector include power VDD, data signals, and control signals. The VDD goes into DCDC Converter and becomes a 3.3V digital supply voltage DVDD, which needs to be powered by SOURCE, IC, GATE, IC, and T/CON. The other is analog supply voltage AVDD. It supplies power to the Gamma section, the Source IC. From DCDC, there are TFT open voltage Von and turn off voltage Voff. Data signals and control signals are entered into the T/CON, which generates control timing and is transmitted to the Source, IC, and gate IC along with the data. The Gamma circuit is used to generate the Gamma reference voltage, which is sent to the source IC, and the voltage values corresponding to each gray level are changed by the DA converter in the Source IC. The Vcom (CF reference voltage) is generated by the VCOM circuit and is typically introduced from the PCB board to the panel via Source, IC, and Gate IC

Our goal is to provide high quality products at competitive prices, and top-notch service to customers around the world. We are ISO9001, CE, and GS certified and strictly adhere to their quality specifications for Tft Lcd Controller Ic, Automotive Lcd Panel, Square Lcd Panel, Lcd Character Modules,Industrial Tft-Lcd Screen. Our Enterprise Core Principle: The prestige 1st ;The quality guarantee ;The customer are supreme. The product will supply to all over the world, such as Europe, America, Australia,Lahore, Haiti,New Delhi, Australia.With high quality, reasonable price, on-time delivery and customized & personalized services to help customers achieve their goals successfully, our company has got praise in both domestic and foreign markets. Buyers are welcome to contact us.

The liquid crystal cannot emit light by itself, and the backlight should be added behind the LCD panel. A few years ago, CCFL cold cathode backlighting was the dominant market application, but with the development of technology, the LED backlight has gradually replaced the traditional CCFL backlight.

(Hong Kong – 08 Oct, 2004) – With respect to the increasing demand on TFT module for smart phone application, Solomon Systech Limited launched today their first single chip TFT LCD driver IC SSD1278 which supports 176×220 (QCIF+) resolution and 262K color smart phone system. SSD1278 is a single chip solution that includes gate/source driver blocks and power management circuit. SSD1278 with RGB interface, which is supported by common image processors/graphic controllers, is a perfect solution for speedy data transfer when using CMOS/CCD camera in the smart phone system.

SSD1278 is the smallest (with only 20.9 x 1.4mm² die size) and the simplest solution commercially available for QCIF+ resolution in the amorphous TFT display. The advantages of the small die size are not only in cost reduction of the module but also achievement of compact design of the phone. The smaller die allows thinner contact ledge at the LCD module and therefore smaller overall physical size. Besides, the advanced design technology from Solomon Systech achieves low power consumption in the TFT LCD module system. This is one of the essential factors in all portable systems. In an actual measurement of a 1.9″, 176×220 QCIF+ display module using Solomon Systech’s TFT driver SSD1278, the module power consumption at 262k color, 60Hz frame frequency and line inversion is only 8mW, while the power consumption at frame inversion is even 7mW. These low power consumption values enable Solomon Systech to become one of the most competitive TFT LCD driver suppliers in the market.

The mobile phone has been improved by adding colorful display, video clip, camera function and PDA features. In order to cope with the demand on features enhancement, a new innovative mobile phone system has been created. Nowadays, the smart phone system does not only include the MCU and DSP blocks but also an image processor that can help on the MPEG4 acceleration, JPEG Codec, 2D/3D graphic engine and so on. As image processor has already sufficient display SRAM on chip, only a RAMless driver like SSD1278 is needed in order to optimize the smart phone system. This structure eliminates the duplication of RAM at the driver IC and improves overall efficiency and cost of the system. Therefore, SSD1278 is the most suitable RAMless solutions for a smart phone system and this would be the trend in the future handset market.

Compared with ordinary LCDs, TFT LCDs provide very clear images/text with shorter response times. TFT LCDs are increasingly being used to bring better visual effects to products.

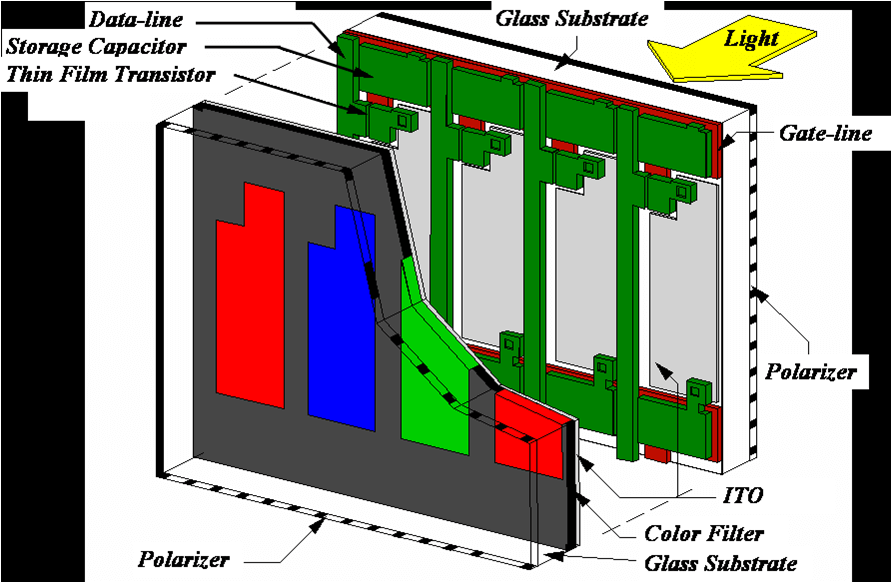

TFT stands for “thin film transistor”. The transistor of a color TFT LCD is composed of a thin film of amorphous silicon deposited on glass. It acts as a control valve to provide the appropriate voltage to the liquid crystal for each sub-pixel. This is why TFT LCDs are also known as active matrix displays.

TFT LCDs have a liquid crystal layer between a glass substrate formed by the TFT and transparent pixel electrodes and another glass substrate with a color filter (RGB) and a transparent counter electrode. Each pixel in the active matrix is paired with a transistor that includes a capacitor, which gives each sub-pixel the ability to retain its charge without sending a charge every time it needs to be replaced. This means that TFT LCDs are more responsive.

To understand how a TFT LCD works, we must first grasp the concept of a field effect transistor (FET), which is a transistor that uses an electric field to control the flow of current. It is a component with three terminals: source, gate and drain. fet controls the flow of current by applying a voltage to the gate, thereby changing the conductivity between the drain and source.

Using the FET, we can build a circuit as follows. The data bus sends a signal to the source of the FET, and when SEL SIGNAL applies a voltage to the gate, a drive voltage is generated on the TFT LCD panel. A sub-pixel is lit. A TFT LCD display contains thousands or millions of such driver circuits.

Color TFT LCD from 1.8 inch ~ 15 inch, there are different resolutions and interfaces. How to choose the right TFT LCD, you can refer to the previous article “LCD | How to choose a liquid crystal display module

Our exclusive relationship with Kyocera Display in Japan allows for unprecedented collaboration of research and development, guaranteeing access to state-of-the-art TFT manufacturing at the Kyocera facility in Yasu, Japan. Using a Gen 3.5 manufacturing infrastructure, the product line is versatile in its ability to support both LTPS and aSi technologies.

Custom display interface boards (DIBs) are available for bespoke TFT-LCD orders. This critical electronic component provides signals to the LCD glass integrated row and column drivers. Our DIBs include built-in-tests to report abnormal system functions on a high-reliability field-programmable gate arrays (FPGA) platform. These self-monitoring capabilities are essential in safety-critical applications and are a part of hardware design strategies to satisfy any RTCA DO-254 requirements.

A thin-film-transistor liquid-crystal display (TFT LCD) is a variant of a liquid-crystal display that uses thin-film-transistor technologyactive matrix LCD, in contrast to passive matrix LCDs or simple, direct-driven (i.e. with segments directly connected to electronics outside the LCD) LCDs with a few segments.

In February 1957, John Wallmark of RCA filed a patent for a thin film MOSFET. Paul K. Weimer, also of RCA implemented Wallmark"s ideas and developed the thin-film transistor (TFT) in 1962, a type of MOSFET distinct from the standard bulk MOSFET. It was made with thin films of cadmium selenide and cadmium sulfide. The idea of a TFT-based liquid-crystal display (LCD) was conceived by Bernard Lechner of RCA Laboratories in 1968. In 1971, Lechner, F. J. Marlowe, E. O. Nester and J. Tults demonstrated a 2-by-18 matrix display driven by a hybrid circuit using the dynamic scattering mode of LCDs.T. Peter Brody, J. A. Asars and G. D. Dixon at Westinghouse Research Laboratories developed a CdSe (cadmium selenide) TFT, which they used to demonstrate the first CdSe thin-film-transistor liquid-crystal display (TFT LCD).active-matrix liquid-crystal display (AM LCD) using CdSe TFTs in 1974, and then Brody coined the term "active matrix" in 1975.high-resolution and high-quality electronic visual display devices use TFT-based active matrix displays.

The circuit layout process of a TFT-LCD is very similar to that of semiconductor products. However, rather than fabricating the transistors from silicon, that is formed into a crystalline silicon wafer, they are made from a thin film of amorphous silicon that is deposited on a glass panel. The silicon layer for TFT-LCDs is typically deposited using the PECVD process.

Polycrystalline silicon is sometimes used in displays requiring higher TFT performance. Examples include small high-resolution displays such as those found in projectors or viewfinders. Amorphous silicon-based TFTs are by far the most common, due to their lower production cost, whereas polycrystalline silicon TFTs are more costly and much more difficult to produce.

The twisted nematic display is one of the oldest and frequently cheapest kind of LCD display technologies available. TN displays benefit from fast pixel response times and less smearing than other LCD display technology, but suffer from poor color reproduction and limited viewing angles, especially in the vertical direction. Colors will shift, potentially to the point of completely inverting, when viewed at an angle that is not perpendicular to the display. Modern, high end consumer products have developed methods to overcome the technology"s shortcomings, such as RTC (Response Time Compensation / Overdrive) technologies. Modern TN displays can look significantly better than older TN displays from decades earlier, but overall TN has inferior viewing angles and poor color in comparison to other technology.

The transmittance of a pixel of an LCD panel typically does not change linearly with the applied voltage,sRGB standard for computer monitors requires a specific nonlinear dependence of the amount of emitted light as a function of the RGB value.

Less expensive PVA panels often use dithering and FRC, whereas super-PVA (S-PVA) panels all use at least 8 bits per color component and do not use color simulation methods.BRAVIA LCD TVs offer 10-bit and xvYCC color support, for example, the Bravia X4500 series. S-PVA also offers fast response times using modern RTC technologies.

TFT dual-transistor pixel or cell technology is a reflective-display technology for use in very-low-power-consumption applications such as electronic shelf labels (ESL), digital watches, or metering. DTP involves adding a secondary transistor gate in the single TFT cell to maintain the display of a pixel during a period of 1s without loss of image or without degrading the TFT transistors over time. By slowing the refresh rate of the standard frequency from 60 Hz to 1 Hz, DTP claims to increase the power efficiency by multiple orders of magnitude.

Due to the very high cost of building TFT factories, there are few major OEM panel vendors for large display panels. The glass panel suppliers are as follows:

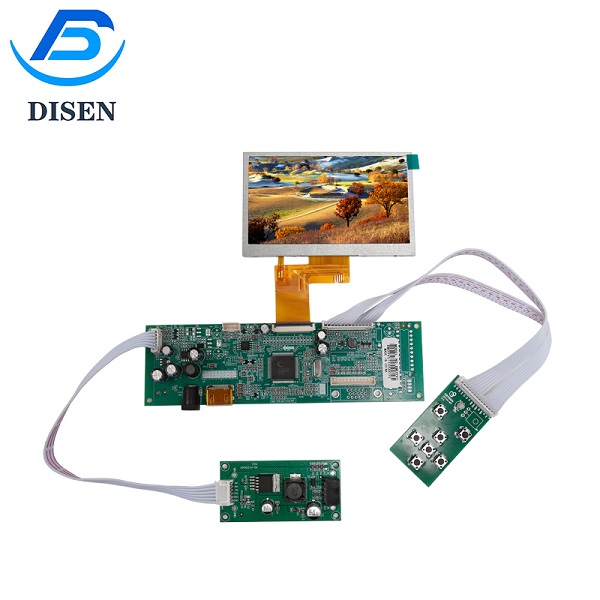

External consumer display devices like a TFT LCD feature one or more analog VGA, DVI, HDMI, or DisplayPort interface, with many featuring a selection of these interfaces. Inside external display devices there is a controller board that will convert the video signal using color mapping and image scaling usually employing the discrete cosine transform (DCT) in order to convert any video source like CVBS, VGA, DVI, HDMI, etc. into digital RGB at the native resolution of the display panel. In a laptop the graphics chip will directly produce a signal suitable for connection to the built-in TFT display. A control mechanism for the backlight is usually included on the same controller board.

The low level interface of STN, DSTN, or TFT display panels use either single ended TTL 5 V signal for older displays or TTL 3.3 V for slightly newer displays that transmits the pixel clock, horizontal sync, vertical sync, digital red, digital green, digital blue in parallel. Some models (for example the AT070TN92) also feature input/display enable, horizontal scan direction and vertical scan direction signals.

New and large (>15") TFT displays often use LVDS signaling that transmits the same contents as the parallel interface (Hsync, Vsync, RGB) but will put control and RGB bits into a number of serial transmission lines synchronized to a clock whose rate is equal to the pixel rate. LVDS transmits seven bits per clock per data line, with six bits being data and one bit used to signal if the other six bits need to be inverted in order to maintain DC balance. Low-cost TFT displays often have three data lines and therefore only directly support 18 bits per pixel. Upscale displays have four or five data lines to support 24 bits per pixel (truecolor) or 30 bits per pixel respectively. Panel manufacturers are slowly replacing LVDS with Internal DisplayPort and Embedded DisplayPort, which allow sixfold reduction of the number of differential pairs.

Kawamoto, H. (2012). "The Inventors of TFT Active-Matrix LCD Receive the 2011 IEEE Nishizawa Medal". Journal of Display Technology. 8 (1): 3–4. Bibcode:2012JDisT...8....3K. doi:10.1109/JDT.2011.2177740. ISSN 1551-319X.

K. H. Lee; H. Y. Kim; K. H. Park; S. J. Jang; I. C. Park & J. Y. Lee (June 2006). "A Novel Outdoor Readability of Portable TFT-LCD with AFFS Technology". SID Symposium Digest of Technical Papers. AIP. 37 (1): 1079–82. doi:10.1889/1.2433159. S2CID 129569963.

Since the reference voltages are connected to all channels, many DACs may use the same reference voltage. The more DACs there are connected to a single reference voltage, the larger the required C-DAC settling time. This study simulates the settling time for different numbers of connected DACs using a 0.35-μm 5-V CMOS model. Figure 11 shows the simulated results where the settling time is measured at 99.9% of its final voltage for a full swing (0.266 V ~ 4.75 V). The settling time is 5.2 μs when 200 DACs are connected to a single reference voltage. Although a column driver IC contains several hundreds or even up to a thousand DACs, these DACs are distributed to 256 (28) reference voltages. This means that not all the DACs are connected to a single reference voltage. A typical UXGA (1600×1200) display has a pixel clock frequency of 162 MHz and a horizontal scanning time of 9.877 μs [4]. Hence, the proposed column driver is suitable for UXGA displays.

Due to the limited silicon area, the proposed LCD column driver has only four channels. The 10-bit LCD column driver with R-DAC and C-DAC was fabricated using a 0.35-μm 5-V CMOS technology. Table I shows the device sizes used in the proposed column driver, where Rtop, Rmid, Rbot, and Ri are designated in Figure 7. Figure 12 is a photograph of the die. Except for the resistor string of the R-DAC, the die area is 0.2×1.26 mm2 for four channels. Each RGB digital input code is 10-bits wide.

The Differential Nonlinearity (DNL) and Integral Nonlinearity (INL) are typically measured for a DAC. However, it is difficult to determine these two specifications for a nonlinear DAC. To demonstrate the performance of the proposed circuit, the nonlinear gamma voltages are not applied to the R-string and the resistor values of the resistor string are made equal. Since an LCD panel needs several column drivers, the uniformity of different drivers is very important. Figure 13 shows the measured transfer curves of a DAC for eight off-chip column drivers. To show the deviation between different chips, Figure 14 provides an

enlarged view of the transfer curves, where the maximum deviation is 3.5 mV from the mean. This deviation is mainly due to process variations. The approach in this study uses no error correction. Hence, the deviation can be reduced by applying an offset canceling technique to the buffer amplifier. Figures 15(a) and (b) show the DNL values for positive and negative polarities, respectively. Figures 16(a) and (b) show the INL values for positive and negative polarities, respectively. The combination of R-DACs and C-DACs creates two groups of DNL values. The maximum DNL and INL values are 3.83 and 3.84 LSB, respectively. This study uses a 1-LSB voltage of 2.44mV to calculate the INL and DNL values. The linearity, however, is less important than the deviations between off-chip drivers for LCD drivers [2].

Figure 17 shows the measured output waveforms of two neighboring channels under dot inversion for the RGB digital inputs of ‘1111111111.’ Here, the voltage levels for negative and positive polarities are 0.266 V and 4.75 V, respectively. A load resistor of 5 kΩ and a capacitor of 90 pF were used. Figure 18 shows a similar waveform for ‘0000000000’ inputs, where the corresponding voltage levels for negative and positive polarities are 2.425 V and 2.598 V, respectively. These two figures show that the settling time is within 3 μs, which is smaller than that of previously published work [2] and standard UXGA displays [5]. Table II summarizes the performance of the proposed column driver IC. The average area per channel is 0.063 mm2, which is smaller than the reported areas of fully R-DAC-based column drivers [5, 8]. These experimental results show that the proposed column driver is suitable for UXGA LCD-TV applications.

The provided display driver example code is designed to work with Microchip, however it is generic enough to work with other micro-controllers. The code includes display reset sequence, initialization and example PutPixel() function.

Please see the DT028CTFT for reference designs. The schematics between the B and the C are the same with the exception that the B does not have the IPS interface.

Ms.Josey

Ms.Josey

Ms.Josey

Ms.Josey