crt tft lcd led oled and amoled made in china

What are the key differences between leading electronic visual displays available in the market? Such are the times that we live in that today most of us cannot possibly imagine a life without an electronic device. In fact, we have managed to surround ourselves and depend on a growing number of electronic appliances. Several of these devices - as it happens - also have an electronic visual display; be it a mobile phone, a tablet, a desktop monitor or the television set. Without a doubt, these electronic screen devices have revolutionised the way we lead our lives now as all of the four devices have become increasingly commonplace to the point of becoming basic necessities. Which brings to our blog topic: what exactly is an electronic screen and which are the leading screen technologies available today? Read on to know more…

An electronic screen or an electronic visual display, informally called a screen, is basically a device used to display / present images, text, or video transmitted electronically, without creating a permanent record. As mentioned earlier, electronic visual displays include television sets, computer monitors, and digital signage in information appliances. As per the definition, an overhead projector (along with screen onto which the text, images, or video is projected) can also be called an electronic visual display.

1. Cathode Ray Tube (CRT) display:A vacuum tube containing one or more electron guns and a phosphorescent screen, the cathode-ray tube (CRT) is used to display images. It modulates, accelerates, and deflects electron beams onto the screen to make the images. The images could be electrical waveforms (oscilloscope), pictures (television, computer monitor) or radar targets. CRTs have also been used as memory devices, wherein the visible light from the fluorescent material (if any) does not really have any significant meaning to a visual observer, but the visible pattern on the tube face could cryptically represent the stored data. In television sets and computer monitors, the front area of the tube is scanned systematically and repetitively in a pattern called a raster. Thanks to the intensity of each of the three electron beams - one for each additive primary color (red, green, and blue) - being controlled with a video signal as a reference, an image is produced. In modern CRT monitors and TVs, magnetic deflection bends the beams; magnetic deflection is essentially a varying magnetic field generated by coils and driven by electronic circuits around the neck of the tube, although electrostatic deflection is often used in oscilloscopes, a type of electronic test instrument. CRT is one of the older screen/ display technologies.

2. Flat-Panel display: Flat-panel displays are electronic viewing technologies that are used to allow people to see content (still images, moving images, text, or other visual material) in a range of entertainment, consumer electronics, personal computer, and mobile devices, and several kinds of medical, transportation and industrial equipment. They are much lighter and thinner than traditional cathode ray tube (CRT) television sets and video displays and are typically less than 10 centimetres (3.9 in) thick. Flat-panel displays can be classified under two display device categories: volatile and static. Volatile displays need pixels to be periodically electronically refreshed to retain their state (say, liquid-crystal displays). A volatile display only shows an image when it has battery or AC mains power. Static flat-panel displays rely on materials whose color states are bistable (say, e-book reader tablets from Sony), and they retain the text or images on the screen even when the power is off. In recent times, flat-panel displays have almost completely replaced old CRT displays. Most flat-panel displays from the 2010s use LCD and/or LED technologies. Majority of the LCD screens are back-lit as color filters are used to display colors. Being thin and lightweight, flat-panel displays offer better linearity and have higher resolution than the average consumer-grade TV from the earlier decades. The highest resolution for consumer-grade CRT TVs was 1080i, whereas many flat-panels can display 1080p or even 4K resolution.

3. Plasma (P) display: A plasma display panel (PDP) is a type of flat panel display that uses small cells containing plasma; ionized gas that responds to electric fields. Earlier, plasma displays were commonly used in larger televisions (30 inches and larger). But since more than a decade now, they have lost almost all market share due to competition from low-cost LCDs and more expensive but high-contrast OLED flat-panel displays. Companies stopped manufacturing plasma displays for the United States retail market in 2014, and for the Chinese market in 2016.

4. Electroluminescent display (ELD):Electroluminescent Displays (ELDs) are screens that make use of electroluminescence. Electroluminescence (EL) is an optical and electrical phenomenon where a material emits light in response to an electric current passed through it, or to a strong electric field.

So ELD then is a kind of flat panel display produced by sandwiching a layer of electroluminescent material between two layers of conductors. When the current flows, the layer of material emits radiation in the form of visible light. Basically, electroluminescence works by exciting atoms by passing an electric current through them, leading them to emit photons. By varying the material being excited, the color of the light being emitted is changed. The actual ELD is built using flat, opaque electrode strips running parallel to each other, covered by a layer of electroluminescent material, followed by another layer of electrodes, running perpendicular to the bottom layer. This top layer has to be transparent so as to allow light to escape. At each intersection, the material lights, creating a pixel.

5. Liquid Crystal Display (LCD): A liquid-crystal display (LCD) is a flat-panel display or other electronically modulated optical device that makes use of the light-modulating properties of liquid crystals. Liquid crystals do not give out light directly; they use a backlight or reflector to create images in color or monochrome. LCDs display arbitrary images like in a general-purpose computer display or fixed images with low information content, that can be displayed or hidden, such as preset words, digits, and seven-segment displays, like in a digital clock. They use the same core technology, apart from the fact that arbitrary images are made up of a large number of small pixels, while other displays have larger elements. LCDs could be on (positive) or off (negative), as per the polarizer arrangement. For instance, a character positive LCD with a backlight has black lettering on a background the same color as the backlight, and a character negative LCD has a black background with the letters matching the backlight color. Blue LCDs typically get their characteristic appearance from optical filters being added to white.

LCD screens are being used in several applications such as LCD televisions, computer monitors, instrument panels, aircraft cockpit displays, and indoor and outdoor signage. Small LCD screens are seen in portable consumer devices such as digital cameras, watches, calculators and mobile telephones, including smartphones. LCDs are also found in consumer electronics products such as DVD players, video game devices and clocks. It is interesting to note that these displays are available in a wide range of screen sizes as compared to CRT and plasma displays. Also, while LCD screens have replaced heavy, bulky cathode ray tube (CRT) displays in almost all applications, they are slowly being replaced by OLEDs, which can be easily made into different shapes, and boast other advantages such as having a lower response time, wider color gamut, virtually infinite color contrast and viewing angles, lower weight for a given display size and a slimmer profile and potentially lower power consumption. OLEDs, however, are more expensive for a given display size and they can suffer from screen burn-in when a static image is displayed on a screen for a long time (for instance, the table frame for an airline flight schedule on an indoor sign), not to mention that there is currently no way to recycle OLED displays. LCD panels, on the other hand, are susceptible to image persistence but they rarely suffer image burn-in as they do not use phosphors, plus they can be recycled, although this technology is not exactly common as yet. Not surprisingly, attempts have been made to increase the lifespan of LCDs in the form of quantum dot displays, which provide performance to that of an OLED display, but the Quantum dot sheet that gives these displays their characteristics can not yet be recycled. LCDs are also more energy-efficient and can be disposed of more safely than a CRT display.

6. Light-Emitting Diode (LED) display:An LED display is a flat panel display that uses an array of light-emitting diodes as pixels for a video display. Their brightness lets them be used outdoors where they are visible in the sun for store signs and billboards. It was in 1962 that LED diodes first came into being; this was when the first practical LED was invented by General Electric’s Nick Holonyak Jr. This was also when they were mainly red in color. While the early models had a monochromatic design, the efficient Blue LED completing the color triad became available in the market only in the late 1980s. Today, large displays use high-brightness diodes to generate a wide spectrum of colors. In fact, recently, LEDs have also become a popular choice among destination signs on public transport vehicles and variable-message signs on highways. LED displays can offer general illumination in addition to visual display, as when used for stage lighting or other decorative (as opposed to informational) purposes. Several big corporations such as Apple, Samsung and LG are currently looking to develop MicroLED displays. These displays are easily scalable, and help with making the production process more streamlined. That said, production costs continue to be quite high and thus remain a limiting factor.

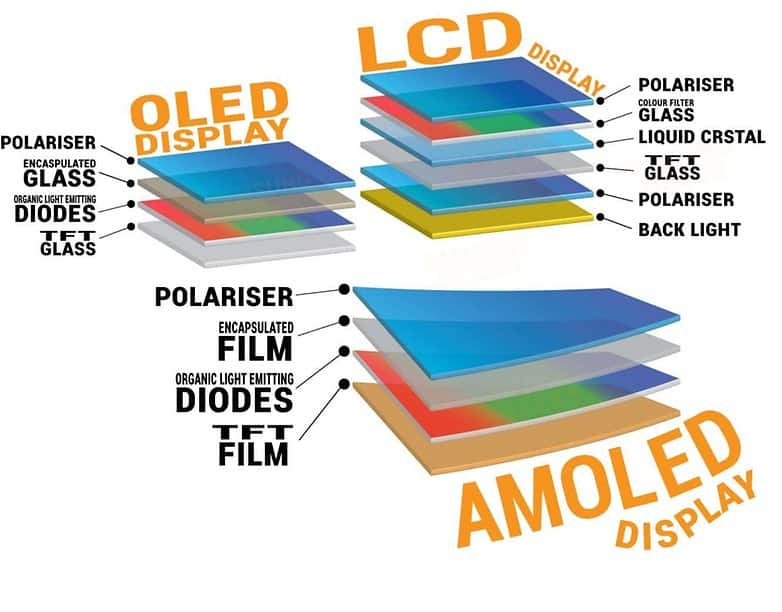

7. Organic Light-Emitting Diode OLED display: An organic light-emitting diode (OLED), also called an organic EL (organic electroluminescent) diode, is a light-emitting diode (LED), where the emissive electroluminescent layer is a film of organic compound that gives out light in response to an electric current. The organic layer is located between two electrodes, at least one of which is transparent. OLEDs are used to build digital displays in devices such as television screens, computer monitors, portable systems such as smartphones, handheld game consoles and digital assistants. Typically, an OLED display works without a backlight because it emits visible light. This means that it can display deep black levels and can be thinner and lighter than a liquid crystal display (LCD). In low ambient light conditions, say in a dark room, an OLED screen can achieve a higher contrast ratio than an LCD, irrespective of whether the LCD uses an LED backlight or cold cathode fluorescent lamps.

Also important to note an OLED display can be driven with a passive-matrix (PMOLED) or active-matrix (AMOLED) control scheme. In the former, each row (and line) in the display is controlled sequentially, one by one, as opposed to in the AMOLED where a thin-film transistor backplane is used to directly control and switch each individual pixel on or off, thus offering higher resolution and larger display sizes.

Lastly, there are two main families of OLED: those based on small molecules and those making use of polymers. A big area of research is the development of white OLED devices for use in solid-state lighting applications.

8. Active-Matrix Organic Light-Emitting Diode (AMOLED) display: AMOLED (Active-Matrix Organic Light-Emitting Diode) is a display device technology being used in smartwatches, mobile devices, laptops, televisions, media players and digital cameras. As mentioned earlier, it is a type of OLED; rather a specific type of thin-film-display technology where organic compounds form the electroluminescent material. What distinguishes it from PMOLED is the active matrix technology behind the addressing of pixels. An AMOLED display basically comprises an active matrix of OLED pixels generating light (luminescence) upon electrical activation that have been positioned or integrated onto a thin-film transistor (TFT) array, which in turn operates as a series of switches to control the current flowing to each individual pixel. AMOLED technology has continued to work towards consuming low power, becoming low-cost and offering scalability (mainly by offering larger sizes.

9. Super AMOLED display: Super AMOLED is essentially an AMOLED display but it is a term coined for marketing purposes by leading device manufacturers. It is used to denote AMOLED displays that come with an integrated digitizer, i.e. the layer that detects touch is integrated into the screen, instead of overlaid on top of it. The display technology however is not an improvement on the AMOLED. For instance, Samsung claims that Super AMOLED displays reflect one-fifth as much sunlight as the first generation AMOLED. In fact, Super AMOLED displays that are part of the Pentile matrix family, are also at times known as SAMOLED. Other variations of this term include Super AMOLED Advanced, Super AMOLED Plus, HD Super AMOLED, HD Super AMOLED Plus and Full HD Super AMOLED.

10. Quantum Dot (QD) display:A quantum dot display is a display device that uses quantum dots (QD), basically semiconductor nanocrystals that can generate pure monochromatic red, green, and blue light. Photo-emissive quantum dot particles are used in a QD layer which converts the backlight to give out pure basic colors that in turn enhance display brightness and color gamut by decreasing light loss and color crosstalk in RGB color filters. This technology is used in LED-backlit LCDs, though it applies to other display technologies as well (such as white or blue/UV OLED).

Among devices employing QD screens, one can find electro-emissive or electroluminescent quantum dot displays, which are currently an experimental type of display based on quantum-dot light-emitting diodes (QD-LED). These displays are similar to active-matrix organic light-emitting diode (AMOLED) and MicroLED displays, as in light is produced directly in each pixel by applying an electric current to inorganic nano-particles. QD-LED displays are supposed to support large, flexible displays and not degrade as readily as OLEDs, making them good bets for flat-panel TV screens, digital cameras, mobile phones and handheld game consoles. As of 2018, all commercial products like LCD TVs that use quantum dots and are called QLED, use photo-emissive particles, whereas electro-emissive QD-LED TVs are only to be found in laboratories today.

We always hear LCD, LED, OLED and AMOLED, but what is the principle of these four? And what"s the differences between LED and LCD, LED and OLED, AMOLED and OLED?

The full name of LCD is "Liquid Crystal Display". As a substitute for CRT display, its lightweight and cheap characteristics are the two most important factors that occupy the market. The LED refers to the backlight source of the LCD, before the OLED is listed, the LCD panel itself can not glow and need backlight support, this and the advertising box on the street is a working nature, the content on the light box can not be seen at night, can only be seen inside the light box.

According to the difference of "backlight", LCD can be divided into "CCFL display" (cold cathode fluorescent lamp) and "LED display" (light emitting diode). If it is distinguished according to the "working principle", LCD can be divided into TN-LCD, TFT-LCD, STN-LCD and FSTN-LCD, etc., and the main difference between them lies in the "twisting angle of liquid crystal molecules". At present, most of the mainstream LCD displays on the market are products like TFT-LCD, and the others are relatively few.

In other words, LCD contains LED, and the full name of LED should be "LED backlit LCD screen". Compared with CCFL, it has the advantages of "small size" and "low power consumption". It achieves "higher brightness" while taking into account both thinness and lightness, but it is slightly inferior in color performance, so in professional drawing LCD, traditional CCFL is mostly used as backlight source.

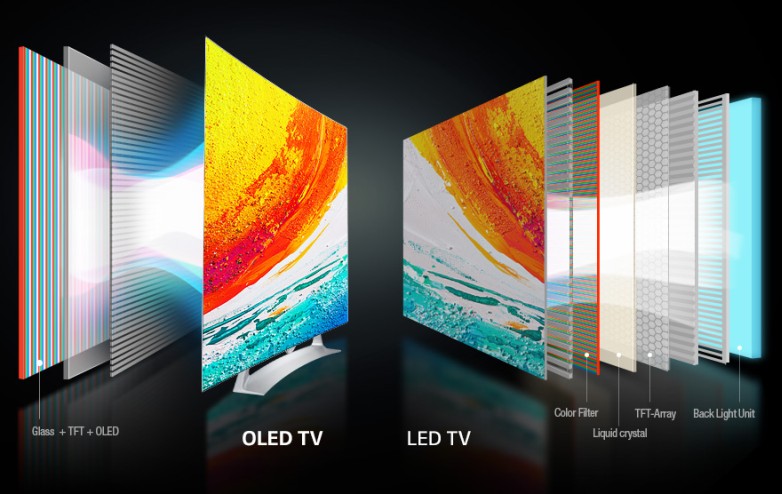

a. the glowing principle of LED screen is different from that of OLED screen. The LED panel has a light-emitting layer, which is composed of several red light-emitting diodes, which uses the molecular deflection of the liquid crystal layer to show different images; each pixel of OLED can emit monochromatic light, so it does not need the light-emitting layer, but can directly drive the organic film to emit light by current.

b. the structure of the LED screen is different from that of the OLED screen. The structure of the LED screen is more complex, but it is composed of several layers; but the OLED is very thin because it does not need backlight, so the OLED screen is about 1/3 of the thickness of the LED screen, or even thinner; the OLED panel also has a bendable feature, which is completely impossible for the LED panel to do.

c. The display effect of LED screen is different from that of OLED screen. The LED screen can generally achieve 72% of the color gamut of NTSC, while the color of OLED is more conspicuous, reaching NTSC 100%, which can meet the needs of the more demanding color gamut such as BT 2020, but there may be problems of color temperature and color deviation.

d. LED screens have a longer life than OLED screens. There is no burning screen on the LED screen, and it is easy to burn the screen if the OLED screen has been used for a long time, and LED has more advantages in terms of service life.

AMOLED originated from OLED display technology, and it is also an extension of OLED technology. It can be said that AMOLED belongs to OLED, but OLED does not belong to AMOLED. In addition, the two are also different in the field of active luminescence control and application.

The main materials used for AMOLED screens and OLED screens are different. The AMOLED screen is a screen based on AMOLED material, while the OLED screen uses a very thin organic coating and glass substrate (or flexible organic substrate) that glows as the current passes through.

In addition, the AMOLED screen has the characteristics of faster response, higher contrast and wider viewing angle. The OLED display screen can be made lighter, thinner, with a larger viewing angle, and can greatly save power consumption.

This website is using a security service to protect itself from online attacks. The action you just performed triggered the security solution. There are several actions that could trigger this block including submitting a certain word or phrase, a SQL command or malformed data.

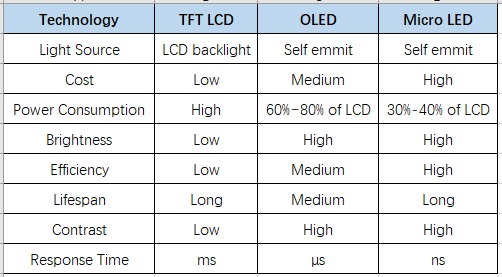

TFT LCD is a mature technology. OLED is a relatively new display technology, being used in more and more applications. As for Micro LED, it is a new generation technology with very promising future. Followings are the pros and cons of each display technology.

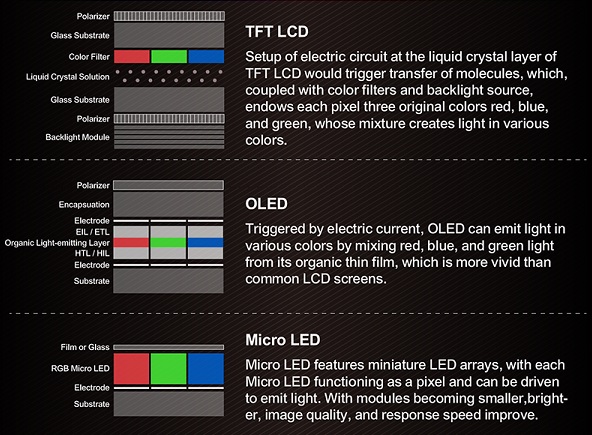

TFT Liquid Crystal Display is widely used these days. Since LCD itself doesn"t emit light. TFT LCD relies on white LED backlight to show content. This is an explanation of how TFT LCD works.

Relatively lower contrast:Light needs to pass through LCD glasses, liquid crystal layer, polarizers and color filters. Over 90% is lost. Also, LCD can not display pure black.

Organic Light-Emitting Diode is built from an electro-luminescent layer that contains organic compounds, which emit light in response to an electric current. There are two types of OLED, Passive Matrix OLED (PMOLED) and Active Matrix OLED (AMOLED). These driving methods are similar to LCD"s. PMOLED is controlled sequentially using a matrix addressing scheme, m + n control signals are required to address a m x n display. AMOLED uses a TFT backplane that can switch individual pixels on and off.

Low power consumption and flexible: OLED doesn"t rely on backlight and consumes less power. OLED is essentially created on plastic film. It is bendable and easy to process.

High contrast and vivid color: OLED emits light itself, can produce very bright image with beautiful color. And because OLED can be turned off, it can produce true black.

Stroboscopic effect: most OLED screen uses PWM dimming technology. Some people who are easy perceive stroboscopic frequency may have sore eyes and tears.

Micro LED, sometimes called μLED is made up of tiny LED, measure less than 100μm. Another way of looking at this is that MicroLEDs are simply traditional LEDs shrunk down and placed into an array.

Replacing organic material with inorganic GaN material eliminates the need of polarizing and encapsulation layer, found in OLED. Micro LED is smaller and thinner, consumes less power.

A wide variety of custom oled options are available to you, such as ntsc(60hz), 100 hz.You can also choose from hotel tv, portable tv custom oled,As well as from ntsc, secam, and pal. and whether custom oled is > 55", 65 inches, or >70inches.

Flat-panel displays are thin panels of glass or plastic used for electronically displaying text, images, or video. Liquid crystal displays (LCD), OLED (organic light emitting diode) and microLED displays are not quite the same; since LCD uses a liquid crystal that reacts to an electric current blocking light or allowing it to pass through the panel, whereas OLED/microLED displays consist of electroluminescent organic/inorganic materials that generate light when a current is passed through the material. LCD, OLED and microLED displays are driven using LTPS, IGZO, LTPO, and A-Si TFT transistor technologies as their backplane using ITO to supply current to the transistors and in turn to the liquid crystal or electroluminescent material. Segment and passive OLED and LCD displays do not use a backplane but use indium tin oxide (ITO), a transparent conductive material, to pass current to the electroluminescent material or liquid crystal. In LCDs, there is an even layer of liquid crystal throughout the panel whereas an OLED display has the electroluminescent material only where it is meant to light up. OLEDs, LCDs and microLEDs can be made flexible and transparent, but LCDs require a backlight because they cannot emit light on their own like OLEDs and microLEDs.

Liquid-crystal display (or LCD) is a thin, flat panel used for electronically displaying information such as text, images, and moving pictures. They are usually made of glass but they can also be made out of plastic. Some manufacturers make transparent LCD panels and special sequential color segment LCDs that have higher than usual refresh rates and an RGB backlight. The backlight is synchronized with the display so that the colors will show up as needed. The list of LCD manufacturers:

Organic light emitting diode (or OLED displays) is a thin, flat panel made of glass or plastic used for electronically displaying information such as text, images, and moving pictures. OLED panels can also take the shape of a light panel, where red, green and blue light emitting materials are stacked to create a white light panel. OLED displays can also be made transparent and/or flexible and these transparent panels are available on the market and are widely used in smartphones with under-display optical fingerprint sensors. LCD and OLED displays are available in different shapes, the most prominent of which is a circular display, which is used in smartwatches. The list of OLED display manufacturers:

MicroLED displays is an emerging flat-panel display technology consisting of arrays of microscopic LEDs forming the individual pixel elements. Like OLED, microLED offers infinite contrast ratio, but unlike OLED, microLED is immune to screen burn-in, and consumes less power while having higher light output, as it uses LEDs instead of organic electroluminescent materials, The list of MicroLED display manufacturers:

Sony produces and sells commercial MicroLED displays called CLEDIS (Crystal-LED Integrated Displays, also called Canvas-LED) in small quantities.video walls.

LCDs are made in a glass substrate. For OLED, the substrate can also be plastic. The size of the substrates are specified in generations, with each generation using a larger substrate. For example, a 4th generation substrate is larger in size than a 3rd generation substrate. A larger substrate allows for more panels to be cut from a single substrate, or for larger panels to be made, akin to increasing wafer sizes in the semiconductor industry.

2015, sold to giantplus and tce photomasks, gen 3 still operated by giantplus, gen 4 line sold to giantplus, equipment sold and line demolished, remainder operated by tce

Cantwell, John; Hayashi, Takabumi (January 4, 2019). Paradigm Shift in Technologies and Innovation Systems. Springer Nature. ISBN 9789813293502 – via Google Books.

"Samsung Display has halted local Gen-8 LCD lines: sources". THE ELEC, Korea Electronics Industry Media. August 16, 2019. Archived from the original on April 3, 2020. Retrieved December 18, 2019.

"TCL to Build World"s Largest Gen 11 LCD Panel Factory". www.businesswire.com. May 19, 2016. Archived from the original on April 2, 2018. Retrieved April 1, 2018.

"Panel Manufacturers Start to Operate Their New 8th Generation LCD Lines". 대한민국 IT포털의 중심! 이티뉴스. June 19, 2017. Archived from the original on June 30, 2019. Retrieved June 30, 2019.

"Samsung Display Considering Halting Some LCD Production Lines". 비즈니스코리아 - BusinessKorea. August 16, 2019. Archived from the original on April 5, 2020. Retrieved December 19, 2019.

Herald, The Korea (July 6, 2016). "Samsung Display accelerates transition from LCD to OLED". www.koreaherald.com. Archived from the original on April 1, 2018. Retrieved April 1, 2018.

www.etnews.com (30 June 2017). "Samsung Display to Construct World"s Biggest OLED Plant". Archived from the original on 2019-06-09. Retrieved 2019-06-09.

Colantonio, Andrea; Burdett, Richard; Rode, Philipp (2013-08-15). Transforming Urban Economies: Policy Lessons from European and Asian Cities. Routledge. ISBN 9781134622160. Archived from the original on 2019-01-01. Retrieved 2019-06-09.

Shilov, Anton. "LG"s New 55+ inch OLED Plant in China Opens: Over 1m+ per Year". www.anandtech.com. Archived from the original on 2019-09-14. Retrieved 2019-12-18.

"China"s BOE to have world"s largest TFT-LCD+AMOLED capacity in 2019". ihsmarkit.com. 2017-03-22. Archived from the original on 2019-08-16. Retrieved 2019-08-17.

Shilov, Anton. "JOLED Starts Construction of New Printed OLED Facility". www.anandtech.com. Archived from the original on 2019-06-30. Retrieved 2019-06-30.

The widest range of microprocessor cores for almost all application markets. Explore ARM. Performance, power & cost requirements for almost all application markets, processors are crucial. The system performance depends heavily on its hardware; this article will guide you through a study of the ARM Processor and be of great assistance in your decision-making.

Before 2003, there are classic ARM Processors which are including ARM7(ARMv4 Architecture), ARM9(ARMv5 Architecture), ARM11(ARMv6 Architecture). ARM7 has no MMU (memory management unit), cannot run multi-user multi-process system such as Linux and WinCE. Only can run system such as ucOS and ucLinux which do not need MMU. ARM9 and ARM11 are embedded CPUs with MMU, which can run Linux.

Simply put, Cortex-A series are suitable for applications that have high computing requirements, run rich operating systems, and provide interactive media and graphics experience. Cortex-R are suitable for that require reliability, high availability, fault tolerance, maintainability and real-time response. Cortex-M series are aimed at cost and power-sensitive MCUs and end applications.

The Cortex-A category of processors is dedicated to Linux and Android devices. Any devices – starting from smartwatches and tablets and continuing with networking equipment – can be supported by Cortex-A processors.

The set of common features for A-processors includes a media processing engine (NEON), a tool for security purposes (Trustzone), and various supported instruction sets (ARM, Thumb, DSP etc.)

The main features of Cortex-A processors are top performance and brilliant power efficiency closely bundled to provide users with the best service possible

Cortex-A5: The Cortex A5 is the smallest and lowest power member of the Cortex A series, but it can still demonstrate multicore performance, it is compatible with A9 and A15 processors.

Cortex-A7: The power consumption of A7 is nearly the same as A5, But the performance provided by the A7 is 20% higher than A5 as well as full architectural compatibility with Cortex-A15 and Cortex-A17. The Cortex-A7 is an ideal choice for cost -sensitive smartphone and tablet implementations.

Contrex-A15:The Cortex-A15 is the highest performance member of this series, providing twice the performance than A9. A15 finds its application in high-end devices, low-power servers, and wireless infrastructure. This is the first processor support for data management and virtual environment solutions.

Contrex-A50: Contrex-A50, latest series, are built on the ARMv8 architecture and bring with them support for Arch64-bit an energy-efficient system. An obvious reason for the move to 64-bit is the support of more than 4GB of physical memory, which is already achieved on Cortex-A15 and Cortex-A7.

Cortex-R processors target high-performance real-time applications such as hard disk controllers, networking equipment media players, and other similar devices, Furthermore, it also great support for the automotive industry such as airbags, braking systems and engine management.

Cortex-R4: Cortex-R4 is well suited for automotive applications. It can be clocked up to 600 MHz, has an 8-stage pipeline with dual-issue, pre-fetch and a low latency interrupt system making it ideal for safety critical systems.

Cortex-R5: Cortex-R5 extends features offered by R4 and adding increased efficiency, reliability and enhance error management. The dual-core implementation makes it possible to build very powerful, flexible systems with real-time responses.

Cortex-R7:The Cortex-R7 significantly extends the performance. They feature an 11-stage pipeline and enable both out-of-order execution and high-level branch prediction. Tools can be implemented for lock-step, symmetric, and asymmetric multiprocessing. The generic interrupt controller is another significant feature that should be mentioned.

Cortex-M designed specifically to target MCU market. The Cortex-M series is built on the ARMv7-M architecture (used for Cortex-M3 and Cortex-M4), and the smaller Cortex-M0+ is built on the ARMv6-M architecture. It is safe to say that the Cortex-M has become for the 32-bit world what the 8051 is for the 8-bit – an industry-standard core supplied by many vendors. The Cortex-M series can be implemented as a soft core in an FPGA, for example, but it is much more common to find them implemented as MCU with integrated memories, clocks and peripherals. Some are optimized for energy efficiency, some for high performance and some are tailored to a specific market segment such as smart metering

Cortex-M0:The Cortex-M0+ uses the Thumb-2 instruction set and has a 2-stage pipeline. Significant features are the bus for single-cycle GPIO and the micro trace buffer.

Cortex-M3&M4: The Cortex-M3 and Cortex-M4 are very similar cores. Each offers a 3-stage pipeline, multiple 32-bit busses, clock speeds up to 200 MHz and very efficient debug options. The significant difference is the Cortex-M4 core’s capability for DSP. The Cortex-M3 and Cortex-M4 share the same architecture and instruction set (Thumb-2). If your application requires floating point math, you will get this done considerably faster on a Cortex-M4 than you will on a Cortex-M3. That said, for an application that is not using the DSP or FPU capabilities of the Cortex-M4, you will see the same level of performance and power consumption on a Cortex-M3. In other words, if you need DSP functionality, go with a Cortex-M4. Otherwise, the Cortex-M3 will do the job.

ARM processors offer a variety of capabilities for different purposes. With a little bit of thought and investigation, you will be able to find the right processor that suits your application needs. whether it’s for a high-end tablet or an ultra-low-cost wireless sensor node.

It is a challenge to make the right choice of Cortex core and turn the idea into reality. But a team of experienced professionals can take care of all the issues and implement concepts of any complexity.

Orient Display has focused on ARM processor-related technologies for many years, and has accumulated rich experience in the development and implementation of ARM architecture products. While continuously launching development platforms and core board that meet the general needs of the market, it also addresses the individual project needs of customers. Provide customized services.

Our hardware team can produce prototypes in the shortest time according to your design ideas and needs. Our software team can help you customize all the functions of the cutting driver layer.

Gaspar, D. J. & Polikarpov, E. OLED Fundamentals: Materials, Devices, and Processing of Organic Light-Emitting Diodes. (Taylor & Francis Group, Boca Raton, FL, 2015).

Tull, B. R. et al. High brightness, emissive microdisplay by integration of III-V LEDs with thin film silicon transistors. SID Symp. Digest Tech. Papers46, 375–377 (2015).

Takeda, A. et al. A super-high image quality multi-domain vertical alignment LCD by new rubbing-less technology. SID Symp. Digest Tech. Papers29, 1077–1080 (1998).

Lee, S. H., Lee, S. L. & Kim, H. Y. Electro-optic characteristics and switching principle of a nematic liquid crystal cell controlled by fringe-field switching. Appl. Phys. Lett.73, 2881–2883 (1998).

Kim, H. J. et al. Optical efficiency enhancement in wide color gamut LCD by a patterned quantum dot film and short pass reflector. SID Symp. Digest Tech. Papers47, 827–829 (2016).

Soh, M. Y. et al. Design and characterization of micro-LED matrix display with heterogeneous integration of GaN and BCD technologies. IEEE Trans. Electron Devices66, 4221–4227 (2019).

Ahn, H. A., Hong, S. K. & Kwon, O. K. An active matrix micro-pixelated LED display driver for high luminance uniformity using resistance mismatch compensation method. IEEE Trans. Circuits Syst. II: Express Briefs65, 724–728 (2018).

Chaji, G. R. & Nathan, A. Parallel addressing scheme for voltage-programmed active-matrix OLED displays. IEEE Trans. Electron Devices54, 1095–1100 (2007).

Templier, F. et al. A novel process for fabricating high-resolution and very small pixel-pitch GaN LED microdisplays. SID Symp. Digest Tech. Papers48, 268–271 (2017).

Templier, F. et al. Advanced solutions for high-performance GaN MicroLED displays. Proceedings of SPIE 10918, Gallium Nitride Materials and Devices XIV. (SPIE, San Francisco, 2019).

Takita, Y. et al. Highly efficient deep-blue fluorescent dopant for achieving low-power OLED display satisfying BT.2020 chromaticity. J. Soc. Inf. Disp.26, 55–63 (2018).

Olivier, F. et al. Shockley-Read-Hall and Auger non-radiative recombination in GaN based LEDs: a size effect study. Appl. Phys. Lett.111, 022104 (2017).

Chen, S. M., Sun, X. W. & Kwok, H. S. Hybrid analog-digital driving method for high definition AMOLED. SID Symp. Digest Tech. Papers45, 1514–1517 (2014).

Hosoumi, S. et al. Ultra-wide color gamut OLED display using a deep-red phosphorescent device with high efficiency, long life, thermal stability, and absolute BT.2020 red chromaticity. SID Symp. Digest Tech. Papers48, 13–16 (2017).

Utsumi, Y. et al. Improved contrast ratio in IPS-Pro LCD TV by using quantitative analysis of depolarized light leakage from component materials. SID Symp. Digest Tech. Papers39, 129–132 (2008).

Hoffman, D. M., Stepien, N. N. & Xiong, W. The importance of native panel contrast and local dimming density on perceived image quality of high dynamic range displays. J. Soc. Inf. Disp.24, 216–228 (2016).

Guarnieri, G., Albani, L. & Ramponi, G. Minimum-error splitting algorithm for a dual layer LCD display—part I: background and theory. J. Display Technol.4, 383–390 (2008).

Guarnieri, G., Albani, L. & Ramponi, G. Minimum-error splitting algorithm for a dual layer LCD display—part II: implementation and results. J. Display Technol.4, 391–397 (2008).

Daly, S. et al. Viewer preferences for shadow, diffuse, specular, and emissive luminance limits of high dynamic range displays. SID Symp. Digest Tech. Papers44, 563–566 (2013).

Nishimura, J. et al. Super bright 8K LCD with 10,000 nit realized by excellent light-resistance characteristics of IGZO TFT backplane. SID Symp. Digest Tech. Papers51, paper 3.1 (2020).

Daly, S. & Feng, X. F. Bit-depth extension: overcoming LCD-driver limitations by using models of the equivalent input noise of the visual system. J. Soc. Inf. Display13, 51–66 (2005).

Guo, W. J. et al. The impact of luminous properties of red, green, and blue mini-LEDs on the color gamut. IEEE Trans. Electron Devices66, 2263–2268 (2019).

Kim, H. M. et al. Ten micrometer pixel, quantum dots color conversion layer for high resolution and full color active matrix micro-LED display. J. Soc. Inf. Disp.27, 347–353 (2019).

Chen, H. W. et al. Liquid crystal display and organic light-emitting diode display: present status and future perspectives. Light: Sci. Appl.7, 17168 (2018).

AU Optronics Corp. AUO Showcases Mini LED Backlit LCDs Across Diverse Verticals to Seize Smart Living Market Opportunities. https://www.auo.com/en-global/New_Archive/detail/News_Archive_Technology_190513 (2019).

Handschy, M. A., McNeil, J. R. & Weissman, P. E. Ultrabright head-mounted displays using LED-illuminated LCOS. Proceedings of SPIE 6224, Helmet- and Head-Mounted Displays XI: Technologies and Applications. (SPIE, Florida, 2006).

Zhang, L. et al. Monochromatic active matrix micro-LED micro-displays with >5,000 dpi pixel density fabricated using monolithic hybrid integration process. SID Symp. Digest Tech. Papers49, 333–336 (2018).

Fan, R., Zhang, X. N. & Tu, Z. T. Influence of ambient temperature on OLED lifetime and uniformity based on modified equivalent lifetime detection. J. Soc. Inf. Disp.27, 597–607 (2019).

LCD manufacturers are mainly located in China, Taiwan, Korea, Japan. Almost all the lcd or TFT manufacturers have built or moved their lcd plants to China on the past decades. Top TFT lcd and oled display manufactuers including BOE, COST, Tianma, IVO from China mainland, and Innolux, AUO from Tianwan, but they have established factories in China mainland as well, and other small-middium sizes lcd manufacturers in China.

China flat display revenue has reached to Sixty billion US Dollars from 2020. there are 35 tft lcd lines (higher than 6 generation lines) in China,China is the best place for seeking the lcd manufacturers.

The first half of 2021, BOE revenue has been reached to twenty billion US dollars, increased more than 90% than thesame time of 2020, the main revenue is from TFT LCD, AMoled. BOE flexible amoled screens" output have been reach to 25KK pcs at the first half of 2021.the new display group Micro LED revenue has been increased to 0.25% of the total revenue as well.

Established in 1993 BOE Technology Group Co. Ltd. is the top1 tft lcd manufacturers in China, headquarter in Beijing, China, BOE has 4 lines of G6 AMOLED production lines that can make flexible OLED, BOE is the authorized screen supplier of Apple, Huawei, Xiaomi, etc,the first G10.5 TFT line is made in BOE.BOE main products is in large sizes of tft lcd panel,the maximum lcd sizes what BOE made is up to 110 inch tft panel, 8k resolution. BOE is the bigger supplier for flexible AM OLED in China.

As the market forecast of 2022, iPhone OLED purchasing quantity would reach 223 million pcs, more 40 million than 2021, the main suppliers of iPhone OLED screen are from Samsung display (61%), LG display (25%), BOE (14%). Samsung also plan to purchase 3.5 million pcs AMOLED screen from BOE for their Galaxy"s screen in 2022.

Technology Co., Ltd), established in 2009. CSOT is the company from TCL, CSOT has eight tft LCD panel plants, four tft lcd modules plants in Shenzhen, Wuhan, Huizhou, Suzhou, Guangzhou and in India. CSOTproviding panels and modules for TV and mobile

three decades.Tianma is the leader of small to medium size displays in technologyin China. Tianma have the tft panel factories in Shenzhen, Shanhai, Chendu, Xiamen city, Tianma"s Shenzhen factory could make the monochrome lcd panel and LCD module, TFT LCD module, TFT touch screen module. Tianma is top 1 manufactures in Automotive display screen and LTPS TFT panel.

Tianma and BOE are the top grade lcd manufacturers in China, because they are big lcd manufacturers, their minimum order quantity would be reached 30k pcs MOQ for small sizes lcd panel. price is also top grade, it might be more expensive 50%~80% than the market price.

Panda electronics is established in 1936, located in Nanjing, Jiangshu, China. Panda has a G6 and G8.6 TFT panel lines (bought from Sharp). The TFT panel technologies are mainly from Sharp, but its technology is not compliance to the other tft panels from other tft manufactures, it lead to the capacity efficiency is lower than other tft panel manufacturers. the latest news in 2022, Panda might be bougt to BOE in this year.

Established in 2005, IVO is located in Kunsan,Jiangshu province, China, IVO have more than 3000 employee, 400 R&D employee, IVO have a G-5 tft panel production line, IVO products are including tft panel for notebook, automotive display, smart phone screen. 60% of IVO tft panel is for notebook application (TOP 6 in the worldwide), 23% for smart phone, 11% for automotive.

Besides the lcd manufacturers from China mainland,inGreater China region,there are other lcd manufacturers in Taiwan,even they started from Taiwan, they all have built the lcd plants in China mainland as well,let"s see the lcd manufacturers in Taiwan:

Chimei Innolux Corporation was the successor company, and it initially preserved the Chimei name. In order to differentiate itself from the ChiMei brand, the company was renamed "Innolux Corporation" in December 2012.

Innolux"s 14 plants in Taiwan possess a complete range of 3.5G, 4G, 4.5G, 5G, 6G, 7.5G, and 8.5G-8.6G production line in Taiwan and China mainland, offering a full range of large/medium/small LCD panels and touch-control screens.including 4K2K ultra-high resolution, 3D naked eye, IGZO, LTPS, AMOLED, OLED, and touch-control solutions,full range of TFT LCD panel modules and touch panels, including TV panels, desktop monitors, notebook computer panels, small and medium-sized panels, and medical and automotive panels.

AUO is the tft lcd panel manufacturers in Taiwan,AUO has the lcd factories in Tianma and China mainland,AUOOffer the full range of display products with industry-leading display technology,such as 8K4K resolution TFT lcd panel, wide color gamut, high dynamic range, mini LED backlight, ultra high refresh rate, ultra high brightness and low power consumption. AUO is also actively developing curved, super slim, bezel-less, extreme narrow bezel and free-form technologies that boast aesthetic beauty in terms of design.Micro LED, flexible and foldable AMOLED, and fingerprint sensing technologies were also developed for people to enjoy a new smart living experience.

Hannstar was found in 1998 in Taiwan, Hannstar display hasG5.3 TFT-LCD factory in Tainan and the Nanjing LCM/Touch factories, providing various products and focus on the vertical integration of industrial resources, creating new products for future applications and business models.

driver, backlight etc ,then make it to tft lcd module. so its price is also more expensive than many other lcd module manufacturers in China mainland.

Maclight is a China based display company, located in Shenzhen, China. ISO9001 certified, as a company that more than 10 years working experiences in display, Maclight has the good relationship with top tft panel manufacturers, it guarantee that we could provide a long term stable supply in our products, we commit our products with reliable quality and competitive prices.

Maclight products included monochrome lcd, TFT lcd module and OLED display, touch screen module, Maclight is special in custom lcd display, Sunlight readable tft lcd module, tft lcd with capacitive touch screen. Maclight is the leader of round lcd display. Maclight is also the long term supplier for many lcd companies in USA and Europe.

If you want tobuy lcd moduleorbuy tft screenfrom China with good quality and competitive price, Maclight would be a best choice for your glowing business.

Searching for the best TFT LCD module manufacturers in India? Well, that is admittedly a daunting task. With the growing number of TFT LCD display suppliers and manufacturers, it’s truly hard to pick which ones are reputable and which ones are not.

STONE Technologies is a proud manufacturer of superior quality TFT LCD modules and LCD screens. The company also provides intelligent HMI solutions that perfectly fit in with its excellent hardware offerings.

There is also a downloadable design software called STONE Designer. This is a completely free GUI design software you can use to create responsive digital module-ready user interfaces.

STONE TFT LCD modules come with a microcontroller unit that has a 1GHz Cortex-A8 CPU. Such a module can easily be transformed into an HMI screen. Simple hexadecimal instructions can be used to control the module through the UART port. Furthermore, you can seamlessly develop STONE TFT LCD color user interface modules and add touch control, features to it.

You can also use a peripheral MCU to serially connect STONE’s HMI display via TTL. This way, your HMI display can supply event notifications and the peripheral MCU can then execute them. Moreover, this TTL-connected HMI display can further be linked to microcontrollers such as:

Becoming a reputable TFT LCD manufacturer is no piece of cake. It requires a company to pay attention to detail, have excellent manufacturing processes, the right TFT display technology, and a consumer’s mindset.

Hence, we’ve rounded up 7 famous and reputable Indian LCD module manufacturers. These companies all produce quality display and screen-related products such as:

Videocon Industries Ltd is a well-known Indian manufacturer of TFT display modules, color TVs, home appliances, and consumer electronics. Videocon is a large company based in Mumbai, India.

Videocon has several manufacturing plants across different countries. It also boasts of several brands under its name, including Videocon Telecom, DigiWorld, Next, and Planet M.

The company takes pride in being India’s pioneer in color TV production and retail. Before the advent of the TFT display module, Videocon has been the world’s third-largest picture tube (CRT) manufacturer.

Videocon is popular for its high-quality products. Videocon manufactures an LCD display screen for LCD TV sets. A lot of Indians trust Videocon’s television sets.

Videocon assembles and manufactures their TFT LCD module products in world-class factories. The company’s main factories are in India. However, they also have manufacturing plants in Mainland China, Mexico, Poland, and Italy.

All of Videocon’s TFT LCD display products passed strict quality control checks. Testing is done throughout the entire manufacturing and assembly process. Furthermore, quality checks are done from the raw materials phase until the products’ release.

Videocon’s TFT display screens and TVs are affordable of good quality. The company knows how to manufacture quality TV sets at pocket-friendly prices since it is a pioneer in the Indian color TV industry.

Videocon’s mobile phone range is equipped with the latest touch LCD display technology. Smartphones are assembled in the company’s TFT touch screen factory. Hence, customers are ensured of high-performance mobile phones with a crisp touch screen LCD display.

To sum it up, Videocon Industries Limited is a strong TFT LCD display manufacturer. The company’s quality manufacturing plants, good end-products, and affordable prices make it among the famous TF LCD manufacturers in India.

Teronix is an Indian electronics company based in New Delhi. It specializes in TV sets with LED and LCD screen module technology. The company also offers a range of smart mobiles and power banks.

Teronix has been in the electronics industry since 2017. But the company has proven that it has what it takes to be a reputable LCD manufacturer in India. Teronix has risen to popularity among Indian consumers because of the following qualities:

The company’s products are all high-quality and durable. Teronix sees to it that its range of smart LCD and LED TVs, along with their other products, reach their customers in good condition, and perform at their best all the time.

Teronix knows that good quality LCD module and other electronic parts are the cores of high-performance products. Hence, their assembly and product research units are stocked with the latest technology to produce the best possible products. Furthermore, Teronix’s research and assembly hubs are strategically located in Delhi.

Special teams are assigned to run quality control tests for all of Teronix’s products. Tests are done before and after launch to ensure that their LED TV range and power banks are all working well with no defects. Also, Teronix has a minimum quality test duration of 3 years.

BPL Limited is a recognized Indian leader in health care equipment and consumer electronics. The Bangalore-based company operates business groups which include:

The company started manufacturing televisions and telecom equipment in the 1980s. BPL joined forces with Japanese company Sanyo in 2006 to strengthen BPL’s consumer electronics brand, including TF-LCD display products and color televisions. The joint venture ended in 2007, leaving BPL to focus on its healthcare equipment sector.

1. BPL takes pride in its superior-quality television sets. The TVs are made with combinations of TFT-LCD display and LED output. The products are manufactured by third-party TFT LCD suppliers. Then, the TV parts are assembled at a plant in Baddi, Himachal Pradesh.

2. BPL also takes the lead when it comes to medical display equipment. BPL uses different combinations of TFT display, VGA output, LED, and touch LCD display to manufacture the following devices:

3. The company upholds strict quality standards in all TFT LCD display products. This is achieved through quality tests at all stages of production and assembly. Even the third-party suppliers providing the raw materials for TFT-LCD modules are required to run through tests to ensure quality.

4. BPL is known to create innovative products ever since its heydays. This continues up to now, as BPL strives to improve market research to manufacture better televisions, consumer electronics, and healthcare equipment.

In a nutshell, BPL continues to be an industry leader in India’s consumer electronics and medical equipment industries. BPL provides households and health facilities with top-notch TFT-LCD display module sets used in televisions and health monitoring equipment. And in recent years, BPL has clearly shown no signs of slowing down.

Dixon Technologies Limited is a long-standing company providing consumer electronics, LED and LCD TVs, light fixtures, appliances, mobile phones, and CCTV systems. The company was founded in 1993 with its current headquarters in New Delhi and Uttar Pradesh.

Dixon’s creed is providing consumers with world-class products at affordable prices. Consequently, the company is among the top TFT LCD manufacturers in India because:

Dixon develops, creates, and markets their products all on their own. The company boasts of its end-to-end product and solution suite. This means that Dixon:

Dixon is proud to create its products in local factories. For instance, the company has an LCD display module factoryin Tirupati, Andhra Pradesh. Furthermore, the company also operates three facilities in Uttarakhand and three more in Noida, Uttar Pradesh.

Dixon is an Original Design Manufacturer (ODM) company. This means that the company takes its designs from its Research and Development Center. Eventually, Dixon turns them into original products that stand out on the market.

Reasonable prices also make Dixon’s LCD module products and TVs appealing to the public. Couple that with features that are on par with the world’s best TV sets. Dixon believes that quality shouldn’t be sacrificed at the expense of affordability.

In conclusion, Dixon Technologies (India) Limited is among India’s famous TFT LCD manufacturers simply because it provides original, feature-packed, high-quality, and pocket-friendly products to both tech companies and end-consumers.

Oriole Electronics is an electronics company based in Mumbai. It was established in 1972 and is among the famous long-standing TFT LCD manufacturers in India.

Oriole is an Original Equipment Manufacturer (OEM). Hence, the company produces high-quality products marketed under its name. However, product parts and components are sourced from reputable third-party suppliers.

Oriole’s strongest quality lies in its extensive experience in the TFT LCD and electronics industry. The company’s experience puts them at an edge against many younger industry competitors. All these thanks to several insights and expertise the company collected since 1972.

Furthermore, Oriole is dedicated to meeting its client’s needs as much as it can. The company partners with its customers throughout the product cycle, making sure that client inputs are incorporated into the products’ final design and functionality. This type of customer partnership uniquely reflects Oriole’s commitment to creating products that truly meet its customers’ various needs.

Another Oriole advantage is its in-house Research and Development team. Oriole’s R&D team conceptualizes products for its customers. They also formulate quality control guidelines that are strictly implemented during the production and testing phases. All these things are done to ensure the highest quality of Oriole’s TFT, LCD modules, and other product ranges.

Speaking of quality, Oriole is also ISO 9001:2008 certified. This credential ultimately proves the company’s utmost dedication to quality processes. Also, this ensures consistent operations of Oriole’s TFT LCD display factory network throughout India.

To wrap it all up, Oriole Electronics is indeed a quality display module manufacturer in India. Superior quality products, customized services, and affordable rates – all of these are testaments to Oriole’s good reputation.

RandServ proudly provides and even encourages custom manufacturing services. The company responds to unique client needs by creating LCD display modules and designs according to customer requirements. RandServ lets clients specify custom shapes, display sizes, and interactive touch support integration.

Another good point of RandServ is its superior-quality product range. The company may be new to the industry, but its products are made with world-class technology and attention to detail. RandServ’s electronic, TFT, LCD, and LED technologies make their end-products among the most long-lasting and robust electronic/digital products in the Indian market today.

Businesses across several industries tend to neglect ethical business practices. But not RandServ. The company takes pride in its clean business practices and integrity. Commitment to ethical standards enabled RandServ to steadily grow as a reputable LCD screen manufacturer.

In conclusion, RandServ Systems deserves a spot in our 7 famous TFT LCD manufacturers list mainly because of three things – cutting-edge LCD and digital products, customized client services, and high regard for ethical business practices.

Royal Display India is a reputable TFT display supplier and manufacturer based in Mumbai. Royal Display is relatively new, being in the business since 2003. But the company didn’t let their newness stop them from growing into a successful LCD display supplier and manufacturer.

A major factor that Royal Display holds in regard is value for money. The company keeps this in mind when creating and supplying display modules to their clients. Furthermore, Royal Display firmly believes that people need not shell out several bucks to get world-class quality products.

Another considerable advantage of Royal Display is its spacious manufacturing and warehousing units. Both are located in Maharashtra. The manufacturing unit boasts of specialized techniques used to produce modules for TFT, LCD, and OLED. Meanwhile, the warehouse unit is large enough to accommodate bulk orders from clients.

To wind this up, Royal Display is a young yet quality manufacturer for LCD modules and other related display screens in India. The company continues to grow with its plethora of quality display products coupled with many satisfied clients.

To conclude, Teronix is a young but reputable and promising LCD manufacturer in India. Lots of satisfied customers flock to them because of their dedication to high-quality products and top-notch manufacturing technologies.

To conclude this post, we’ve rounded up 7 Famous TFT LCD Manufacturers in India. Some of them are industry pioneers, while some are novices. However, we’re sure all these reputable companies will be a good source of products for all your display module needs.

STONE provides a full range of 3.5 inches to 15.1 inches of small and medium-size standard quasi TFT LCD module, LCD display, TFT display module, display industry, industrial LCD screen, under the sunlight visually highlight TFT LCD display, industrial custom TFT screen, TFT LCD screen-wide temperature, industrial TFT LCD screen, touch screen industry. The TFT LCD module is very suitable for industrial control equipment, medical instruments, POS system, electronic consumer products, vehicles, and other products.

With all the hype about wearable devices, drones, UGV (unmanned ground vehicle), curve devices etc.. Quantum: Dots are taking a quantum leap: If you have not known about the idea behind quantum dot, it’s sole purpose is to enhance the LCD viewing quality; or some people may say Quantum dot was developed to outperform, compete, or equalize the playing field with OLED displays. Thenano-structure of this technology from a covalent bonds of electrons, is when one of the excited particles excites by an external light source, which then absorbs the energy and re-emits the light in a different color. Quantum dot has known for its energy efficiency, brightness and its versatility as well.

Many LCD module manufacturer firms note that 15% to 25% of the total cost of each LCD come from backlight units and inverters. This is the reason why manufacturers now aim to increase panel transmissivity, as doing so would dramatically reduce the need for backlight lamps, inverters, and optical films, and consequently reduce the total panel costs.Read More

Sometimes, professionals or business owners who need a raft of information to stay on top of the game must have a way to see everything organized on one screen. Other circumstances, however, warrant spreading the data out across several screens and have interactive functions. Mike Gordon of the Honolulu Star-Advertiser has an example that has long been grounded in reality – the multi-function displays at the main office set of reimagined police series Hawaii Five-0.Read More

As OLEDs ramps up for a great year, so does it’s capabilities, the next big thing in making the world a brighter place. Similarly LEDs, these two products had advances and promise lower power consumption and diffused of brightness which is easier on the eyes. Have you seen any sci-fi movies like Star-Trek, Galactica which utilize bright flat futuristic lights, OLED have the ability to make this happen quickly. Many manufacturers are looking into many options, with OLED and embracing its potentials. Many of these manufactures are, #LG Electronics, RayStar Optronics, #Samsung, Acuity Brand, LED, Philips etc…. even though we have many of these big names looking into the potential of OLEDs , we are still under the notion that OLEDs are very expensive...Read More

Have you use Chromecast the digital stick before, to stream videos, and what have you, well you going to love this one. This form of technology change the way we work with pc, during Computer Architecture class, my professor would always ask; when buying a great computer what’s the most valuable thing you need to know? Some say price, while others proclaim user friendly, but even though most of these are great answers, lets dig a little deeper. There are 3 things to consider when buying a computer, speed, (efficiency) memory (capacity) and size(sociability). Does Moore’s law (the number of transistors per square inch on a integrated circuit will double every 2 years) still keeps up even today...Read More

Innovations in technology have seen a shift in demand for display modules, with the need for TFT LCD surpassing that for AMOLED displays. Both technologies are projected to lead the volume of production in succeeding years, with TFT LCDs forecasted to capture half the market by 2017. Among their applications, portable computers or laptops, as well as smartphones, are the fastest-growing, while television screens also continue to be a high-demand area.

LCD (liquid crystal display) is a display module composed of tiny crystals ca

Ms.Josey

Ms.Josey

Ms.Josey

Ms.Josey