connecting an arduino to lcd module made in china

@Railroader Thanks for your advice, although I felt that it was a little patronising. But I guess that since the Arduino is primarily targeted at schoolchildren and for educational purposes, that"s a fair enough assumption of my age and career.

I am aware that there are better alternatives for screens that can be found for under £15. I was curious what was in a £15 quid projector and bought it for that reason. Disassembling it was fun and has already netted me lenses, heatsinks, and LEDs etc. for other projects which is worth more than its cost. The reason I asked was because a) I am loathe to bin the LCD and hence contribute to our electronic waste problems, and b) I am specifically looking for LEDs (most of the displays on eBay and Amazon are OLEDs) as I want to make an ESP32-controlled projector as a project. Non-OLEDs are difficult to find on eBay/Amazon nowadays. Hence I was asking on the off-chance that this screen might be similar to something else in Occidental part of the world that I could use.

From what you say it feels its very unlikely for there to be a shortcut and I"ll have decode the signals manually. Designing and manufacturing (or finding a 30 pin adapter) is not a problem but I can"t justify to myself spending the better part of my weekends in a month to decode the signals just to use it when I can spend £10 buying an SPI LCD from eBay which does the exact same thing. I"ll probably bite the bullet and do that.

Shame about having to bin the screen though. I have found the schematics for the GM8284DD chip and probably with a magnifying glass would be able to make out the LCD connections (RGB input etc.) on the circuit board but again, I"m not sure if its that cost-efficient spending that many weekends working on it...

This website is using a security service to protect itself from online attacks. The action you just performed triggered the security solution. There are several actions that could trigger this block including submitting a certain word or phrase, a SQL command or malformed data.

Many drawing and writing primitives are provided: single pixel plotting, lines, circles, triangles, rectangles (with square and rounded corners), and corresponding filled shapes. Text and numeric values, may be placed anywhere on the screen in a variety of sizes. Bitmapped shapes can be scrolled or moved about the screen and the whole screen can be rotated.

Points are defined by their Cartesian co-ordinates, (x, y). The origin (0, 0) is at the top left of the screen. Increasing the y value moves down the screen. The addressable dimensions of the SSD1306 screen are 128 pixels left to right (0, 1, 2, …, 127) and 64 pixels from top to bottom (0, 1, 2, …, 63). The pixel in the bottom right corner is (127, 63).

(x0, y0) and (x1, y1) would define the first two positions, while h is the height and w the width of an object. A radius is r. All dimensions are in pixels. The colour is specified by c, SSD1306_WHITE or SSD1306_BLACK.

These are based on the system used for printing to the Serial monitor with print() and println(). The font included with the library is 5 pixels wide and 7 pixels tall but prints into a 6x8 pixel space.

None of these instructions will produce a change on the screen without a display.display(); method. If your script does not appear to be working check you have included this line at the bottom of your screen changing code.

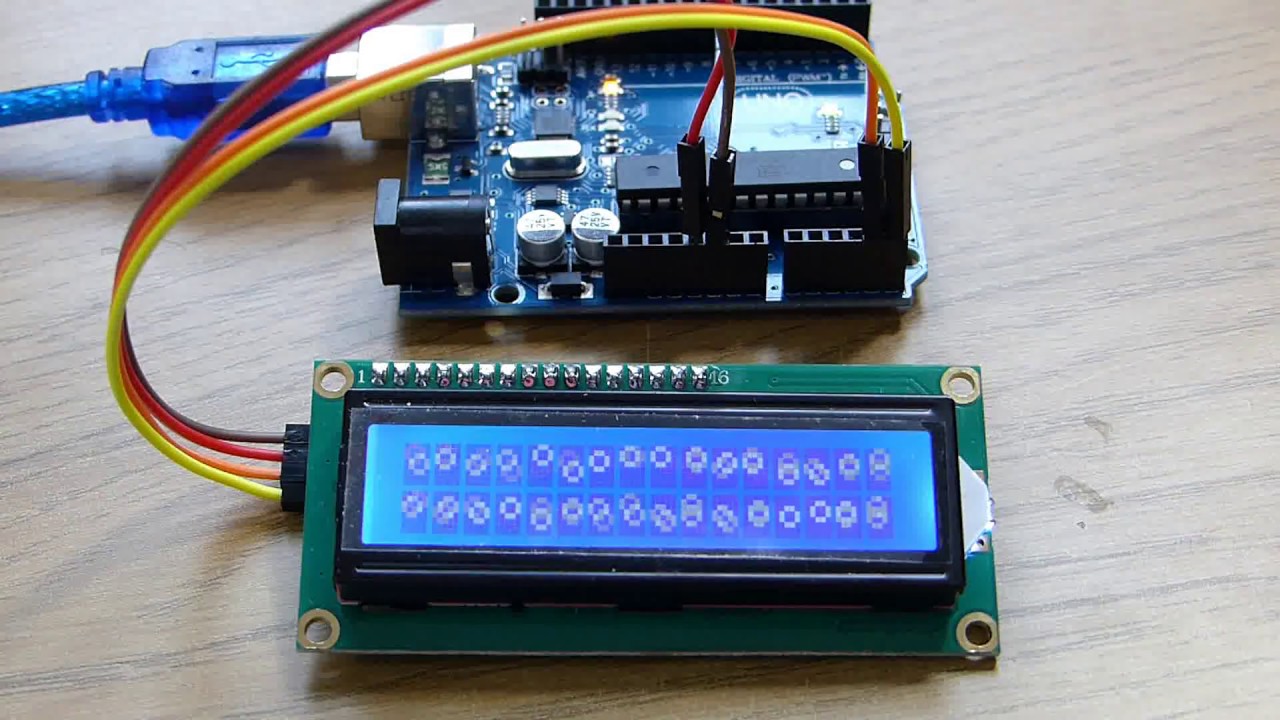

In this Arduino tutorial we will learn how to connect and use an LCD (Liquid Crystal Display)with Arduino. LCD displays like these are very popular and broadly used in many electronics projects because they are great for displaying simple information, like sensors data, while being very affordable.

You can watch the following video or read the written tutorial below. It includes everything you need to know about using an LCD character display with Arduino, such as, LCD pinout, wiring diagram and several example codes.

An LCD character display is a unique type of display that can only output individual ASCII characters with fixed size. Using these individual characters then we can form a text.

If we take a closer look at the display we can notice that there are small rectangular areas composed of 5×8 pixels grid. Each pixel can light up individually, and so we can generate characters within each grid.

The number of the rectangular areas define the size of the LCD. The most popular LCD is the 16×2 LCD, which has two rows with 16 rectangular areas or characters. Of course, there are other sizes like 16×1, 16×4, 20×4 and so on, but they all work on the same principle. Also, these LCDs can have different background and text color.

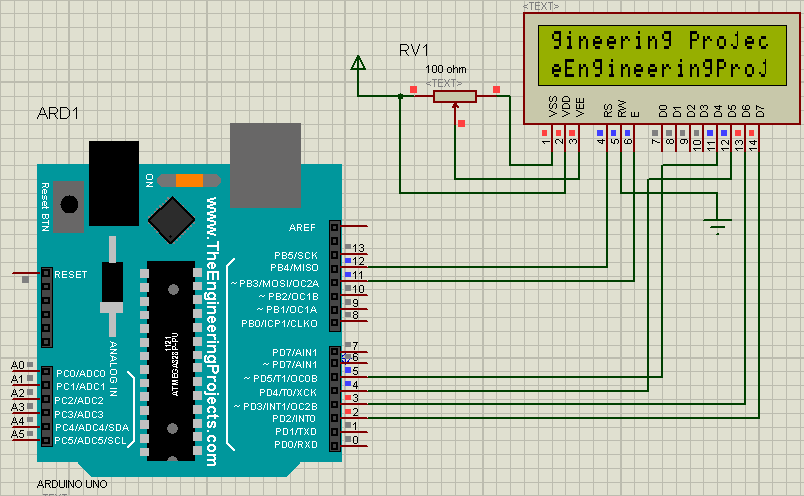

It has 16 pins and the first one from left to right is the Groundpin. The second pin is the VCCwhich we connect the 5 volts pin on the Arduino Board. Next is the Vo pin on which we can attach a potentiometer for controlling the contrast of the display.

Next, The RSpin or register select pin is used for selecting whether we will send commands or data to the LCD. For example if the RS pin is set on low state or zero volts, then we are sending commands to the LCD like: set the cursor to a specific location, clear the display, turn off the display and so on. And when RS pin is set on High state or 5 volts we are sending data or characters to the LCD.

Next comes the R/W pin which selects the mode whether we will read or write to the LCD. Here the write mode is obvious and it is used for writing or sending commands and data to the LCD. The read mode is used by the LCD itself when executing the program which we don’t have a need to discuss about it in this tutorial.

Next is the E pin which enables the writing to the registers, or the next 8 data pins from D0 to D7. So through this pins we are sending the 8 bits data when we are writing to the registers or for example if we want to see the latter uppercase A on the display we will send 0100 0001 to the registers according to the ASCII table. The last two pins A and K, or anode and cathode are for the LED back light.

After all we don’t have to worry much about how the LCD works, as the Liquid Crystal Library takes care for almost everything. From the Arduino’s official website you can find and see the functions of the library which enable easy use of the LCD. We can use the Library in 4 or 8 bit mode. In this tutorial we will use it in 4 bit mode, or we will just use 4 of the 8 data pins.

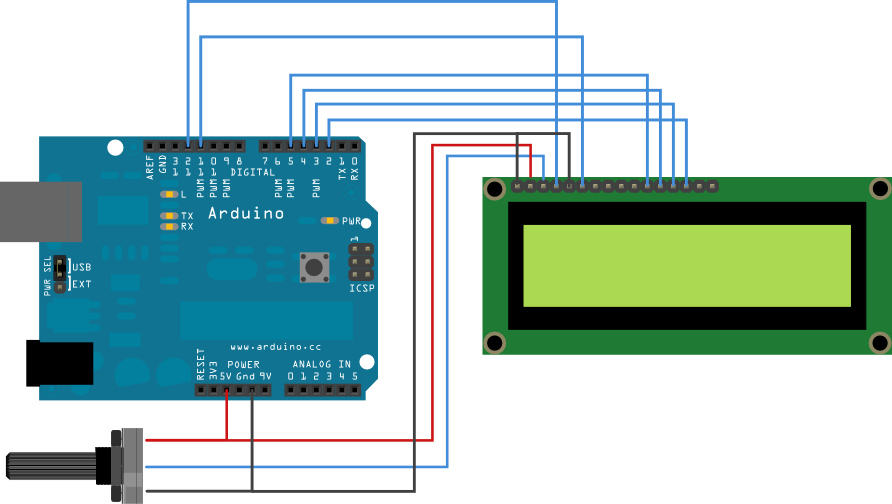

We will use just 6 digital input pins from the Arduino Board. The LCD’s registers from D4 to D7 will be connected to Arduino’s digital pins from 4 to 7. The Enable pin will be connected to pin number 2 and the RS pin will be connected to pin number 1. The R/W pin will be connected to Ground and theVo pin will be connected to the potentiometer middle pin.

We can adjust the contrast of the LCD by adjusting the voltage input at the Vo pin. We are using a potentiometer because in that way we can easily fine tune the contrast, by adjusting input voltage from 0 to 5V.

Yes, in case we don’t have a potentiometer, we can still adjust the LCD contrast by using a voltage divider made out of two resistors. Using the voltage divider we need to set the voltage value between 0 and 5V in order to get a good contrast on the display. I found that voltage of around 1V worked worked great for my LCD. I used 1K and 220 ohm resistor to get a good contrast.

There’s also another way of adjusting the LCD contrast, and that’s by supplying a PWM signal from the Arduino to the Vo pin of the LCD. We can connect the Vo pin to any Arduino PWM capable pin, and in the setup section, we can use the following line of code:

It will generate PWM signal at pin D11, with value of 100 out of 255, which translated into voltage from 0 to 5V, it will be around 2V input at the Vo LCD pin.

Here’s a simple code through which we can explain the working principle of the Liquid Crystal library. This is the code of the first example from the video:

First thing we need to do is it insert the Liquid Crystal Library. We can do that like this: Sketch > Include Library > Liquid Crystal. Then we have to create an LC object. The parameters of this object should be the numbers of the Digital Input pins of the Arduino Board respectively to the LCD’s pins as follow: (RS, Enable, D4, D5, D6, D7). In the setup we have to initialize the interface to the LCD and specify the dimensions of the display using the begin()function.

The cursor() function is used for displaying underscore cursor and the noCursor() function for turning off. Using the clear() function we can clear the LCD screen.

In case we have a text with length greater than 16 characters, we can scroll the text using the scrollDisplayLeft() orscrollDisplayRight() function from the LiquidCrystal library.

We can choose whether the text will scroll left or right, using the scrollDisplayLeft() orscrollDisplayRight() functions. With the delay() function we can set the scrolling speed.

The first parameter in this function is a number between 0 and 7, or we have to reserve one of the 8 supported custom characters. The second parameter is the name of the array of bytes.

So, we have covered pretty much everything we need to know about using an LCD with Arduino. These LCD Character displays are really handy for displaying information for many electronics project. In the examples above I used 16×2 LCD, but the same working principle applies for any other size of these character displays.

I hope you enjoyed this tutorial and learned something new. Feel free to ask any question in the comments section below and don’t forget to check out my full collection of 30+ Arduino Projects.

In this Arduino touch screen tutorial we will learn how to use TFT LCD Touch Screen with Arduino. You can watch the following video or read the written tutorial below.

For this tutorial I composed three examples. The first example is distance measurement using ultrasonic sensor. The output from the sensor, or the distance is printed on the screen and using the touch screen we can select the units, either centimeters or inches.

The next example is controlling an RGB LED using these three RGB sliders. For example if we start to slide the blue slider, the LED will light up in blue and increase the light as we would go to the maximum value. So the sliders can move from 0 to 255 and with their combination we can set any color to the RGB LED, but just keep in mind that the LED cannot represent the colors that much accurate.

The third example is a game. Actually it’s a replica of the popular Flappy Bird game for smartphones. We can play the game using the push button or even using the touch screen itself.

As an example I am using a 3.2” TFT Touch Screen in a combination with a TFT LCD Arduino Mega Shield. We need a shield because the TFT Touch screen works at 3.3V and the Arduino Mega outputs are 5 V. For the first example I have the HC-SR04 ultrasonic sensor, then for the second example an RGB LED with three resistors and a push button for the game example. Also I had to make a custom made pin header like this, by soldering pin headers and bend on of them so I could insert them in between the Arduino Board and the TFT Shield.

Here’s the circuit schematic. We will use the GND pin, the digital pins from 8 to 13, as well as the pin number 14. As the 5V pins are already used by the TFT Screen I will use the pin number 13 as VCC, by setting it right away high in the setup section of code.

As the code is a bit longer and for better understanding I will post the source code of the program in sections with description for each section. And at the end of this article I will post the complete source code.

I will use the UTFT and URTouch libraries made by Henning Karlsen. Here I would like to say thanks to him for the incredible work he has done. The libraries enable really easy use of the TFT Screens, and they work with many different TFT screens sizes, shields and controllers. You can download these libraries from his website, RinkyDinkElectronics.com and also find a lot of demo examples and detailed documentation of how to use them.

After we include the libraries we need to create UTFT and URTouch objects. The parameters of these objects depends on the model of the TFT Screen and Shield and these details can be also found in the documentation of the libraries.

Next we need to define the fonts that are coming with the libraries and also define some variables needed for the program. In the setup section we need to initiate the screen and the touch, define the pin modes for the connected sensor, the led and the button, and initially call the drawHomeSreen() custom function, which will draw the home screen of the program.

So now I will explain how we can make the home screen of the program. With the setBackColor() function we need to set the background color of the text, black one in our case. Then we need to set the color to white, set the big font and using the print() function, we will print the string “Arduino TFT Tutorial” at the center of the screen and 10 pixels down the Y – Axis of the screen. Next we will set the color to red and draw the red line below the text. After that we need to set the color back to white, and print the two other strings, “by HowToMechatronics.com” using the small font and “Select Example” using the big font.

Next is the distance sensor button. First we need to set the color and then using the fillRoundRect() function we will draw the rounded rectangle. Then we will set the color back to white and using the drawRoundRect() function we will draw another rounded rectangle on top of the previous one, but this one will be without a fill so the overall appearance of the button looks like it has a frame. On top of the button we will print the text using the big font and the same background color as the fill of the button. The same procedure goes for the two other buttons.

Now we need to make the buttons functional so that when we press them they would send us to the appropriate example. In the setup section we set the character ‘0’ to the currentPage variable, which will indicate that we are at the home screen. So if that’s true, and if we press on the screen this if statement would become true and using these lines here we will get the X and Y coordinates where the screen has been pressed. If that’s the area that covers the first button we will call the drawDistanceSensor() custom function which will activate the distance sensor example. Also we will set the character ‘1’ to the variable currentPage which will indicate that we are at the first example. The drawFrame() custom function is used for highlighting the button when it’s pressed. The same procedure goes for the two other buttons.

drawDistanceSensor(); // It is called only once, because in the next iteration of the loop, this above if statement will be false so this funtion won"t be called. This function will draw the graphics of the first example.

getDistance(); // Gets distance from the sensor and this function is repeatedly called while we are at the first example in order to print the lasest results from the distance sensor

So the drawDistanceSensor() custom function needs to be called only once when the button is pressed in order to draw all the graphics of this example in similar way as we described for the home screen. However, the getDistance() custom function needs to be called repeatedly in order to print the latest results of the distance measured by the sensor.

Here’s that function which uses the ultrasonic sensor to calculate the distance and print the values with SevenSegNum font in green color, either in centimeters or inches. If you need more details how the ultrasonic sensor works you can check my particular tutorialfor that. Back in the loop section we can see what happens when we press the select unit buttons as well as the back button.

Ok next is the RGB LED Control example. If we press the second button, the drawLedControl() custom function will be called only once for drawing the graphic of that example and the setLedColor() custom function will be repeatedly called. In this function we use the touch screen to set the values of the 3 sliders from 0 to 255. With the if statements we confine the area of each slider and get the X value of the slider. So the values of the X coordinate of each slider are from 38 to 310 pixels and we need to map these values into values from 0 to 255 which will be used as a PWM signal for lighting up the LED. If you need more details how the RGB LED works you can check my particular tutorialfor that. The rest of the code in this custom function is for drawing the sliders. Back in the loop section we only have the back button which also turns off the LED when pressed.

In order the code to work and compile you will have to include an addition “.c” file in the same directory with the Arduino sketch. This file is for the third game example and it’s a bitmap of the bird. For more details how this part of the code work you can check my particular tutorial. Here you can download that file:

drawDistanceSensor(); // It is called only once, because in the next iteration of the loop, this above if statement will be false so this funtion won"t be called. This function will draw the graphics of the first example.

getDistance(); // Gets distance from the sensor and this function is repeatedly called while we are at the first example in order to print the lasest results from the distance sensor

In this Arduino touch screen tutorial we will learn how to use TFT LCD Touch Screen with Arduino. You can watch the following video or read the written tutorial below.

For this tutorial I composed three examples. The first example is distance measurement using ultrasonic sensor. The output from the sensor, or the distance is printed on the screen and using the touch screen we can select the units, either centimeters or inches.

The next example is controlling an RGB LED using these three RGB sliders. For example if we start to slide the blue slider, the LED will light up in blue and increase the light as we would go to the maximum value. So the sliders can move from 0 to 255 and with their combination we can set any color to the RGB LED, but just keep in mind that the LED cannot represent the colors that much accurate.

The third example is a game. Actually it’s a replica of the popular Flappy Bird game for smartphones. We can play the game using the push button or even using the touch screen itself.

As an example I am using a 3.2” TFT Touch Screen in a combination with a TFT LCD Arduino Mega Shield. We need a shield because the TFT Touch screen works at 3.3V and the Arduino Mega outputs are 5 V. For the first example I have the HC-SR04 ultrasonic sensor, then for the second example an RGB LED with three resistors and a push button for the game example. Also I had to make a custom made pin header like this, by soldering pin headers and bend on of them so I could insert them in between the Arduino Board and the TFT Shield.

Here’s the circuit schematic. We will use the GND pin, the digital pins from 8 to 13, as well as the pin number 14. As the 5V pins are already used by the TFT Screen I will use the pin number 13 as VCC, by setting it right away high in the setup section of code.

As the code is a bit longer and for better understanding I will post the source code of the program in sections with description for each section. And at the end of this article I will post the complete source code.

I will use the UTFT and URTouch libraries made by Henning Karlsen. Here I would like to say thanks to him for the incredible work he has done. The libraries enable really easy use of the TFT Screens, and they work with many different TFT screens sizes, shields and controllers. You can download these libraries from his website, RinkyDinkElectronics.com and also find a lot of demo examples and detailed documentation of how to use them.

After we include the libraries we need to create UTFT and URTouch objects. The parameters of these objects depends on the model of the TFT Screen and Shield and these details can be also found in the documentation of the libraries.

Next we need to define the fonts that are coming with the libraries and also define some variables needed for the program. In the setup section we need to initiate the screen and the touch, define the pin modes for the connected sensor, the led and the button, and initially call the drawHomeSreen() custom function, which will draw the home screen of the program.

So now I will explain how we can make the home screen of the program. With the setBackColor() function we need to set the background color of the text, black one in our case. Then we need to set the color to white, set the big font and using the print() function, we will print the string “Arduino TFT Tutorial” at the center of the screen and 10 pixels down the Y – Axis of the screen. Next we will set the color to red and draw the red line below the text. After that we need to set the color back to white, and print the two other strings, “by HowToMechatronics.com” using the small font and “Select Example” using the big font.

Next is the distance sensor button. First we need to set the color and then using the fillRoundRect() function we will draw the rounded rectangle. Then we will set the color back to white and using the drawRoundRect() function we will draw another rounded rectangle on top of the previous one, but this one will be without a fill so the overall appearance of the button looks like it has a frame. On top of the button we will print the text using the big font and the same background color as the fill of the button. The same procedure goes for the two other buttons.

Now we need to make the buttons functional so that when we press them they would send us to the appropriate example. In the setup section we set the character ‘0’ to the currentPage variable, which will indicate that we are at the home screen. So if that’s true, and if we press on the screen this if statement would become true and using these lines here we will get the X and Y coordinates where the screen has been pressed. If that’s the area that covers the first button we will call the drawDistanceSensor() custom function which will activate the distance sensor example. Also we will set the character ‘1’ to the variable currentPage which will indicate that we are at the first example. The drawFrame() custom function is used for highlighting the button when it’s pressed. The same procedure goes for the two other buttons.

drawDistanceSensor(); // It is called only once, because in the next iteration of the loop, this above if statement will be false so this funtion won"t be called. This function will draw the graphics of the first example.

getDistance(); // Gets distance from the sensor and this function is repeatedly called while we are at the first example in order to print the lasest results from the distance sensor

So the drawDistanceSensor() custom function needs to be called only once when the button is pressed in order to draw all the graphics of this example in similar way as we described for the home screen. However, the getDistance() custom function needs to be called repeatedly in order to print the latest results of the distance measured by the sensor.

Here’s that function which uses the ultrasonic sensor to calculate the distance and print the values with SevenSegNum font in green color, either in centimeters or inches. If you need more details how the ultrasonic sensor works you can check my particular tutorialfor that. Back in the loop section we can see what happens when we press the select unit buttons as well as the back button.

Ok next is the RGB LED Control example. If we press the second button, the drawLedControl() custom function will be called only once for drawing the graphic of that example and the setLedColor() custom function will be repeatedly called. In this function we use the touch screen to set the values of the 3 sliders from 0 to 255. With the if statements we confine the area of each slider and get the X value of the slider. So the values of the X coordinate of each slider are from 38 to 310 pixels and we need to map these values into values from 0 to 255 which will be used as a PWM signal for lighting up the LED. If you need more details how the RGB LED works you can check my particular tutorialfor that. The rest of the code in this custom function is for drawing the sliders. Back in the loop section we only have the back button which also turns off the LED when pressed.

In order the code to work and compile you will have to include an addition “.c” file in the same directory with the Arduino sketch. This file is for the third game example and it’s a bitmap of the bird. For more details how this part of the code work you can check my particular tutorial. Here you can download that file:

drawDistanceSensor(); // It is called only once, because in the next iteration of the loop, this above if statement will be false so this funtion won"t be called. This function will draw the graphics of the first example.

getDistance(); // Gets distance from the sensor and this function is repeatedly called while we are at the first example in order to print the lasest results from the distance sensor

As a 2inch IPS display module with a resolution of 240 * 320, it uses an SPI interface for communication. The LCD has an internal controller with basic functions, which can be used to draw points, lines, circles, and rectangles, and display English, Chinese as well as pictures.

The 2inch LCD uses the PH2.0 8PIN interface, which can be connected to the Raspberry Pi according to the above table: (Please connect according to the pin definition table. The color of the wiring in the picture is for reference only, and the actual color shall prevail.)

The example we provide is based on STM32F103RBT6, and the connection method provided is also the corresponding pin of STM32F103RBT6. If you need to transplant the program, please connect according to the actual pin.

The LCD supports 12-bit, 16-bit, and 18-bit input color formats per pixel, namely RGB444, RGB565, and RGB666 three color formats, this demo uses RGB565 color format, which is also a commonly used RGB format.

For most LCD controllers, the communication mode of the controller can be configured, usually with an 8080 parallel interface, three-wire SPI, four-wire SPI, and other communication methods. This LCD uses a four-wire SPI communication interface, which can greatly save the GPIO port, and the communication speed will be faster.

Note: Different from the traditional SPI protocol, the data line from the slave to the master is hidden since the device only has display requirement.

CPOL determines the level of the serial synchronous clock at idle state. When CPOL = 0, the level is Low. However, CPOL has little effect to the transmission.

PS: If you are using the system of the Bullseye branch, you need to change "apt-get" to "apt", the system of the Bullseye branch only supports Python3.

Framebuffer uses a video output device to drive a video display device from a memory buffer containing complete frame data. Simply put, a memory area is used to store the display content, and the display content can be changed by changing the data in the memory.

There is an open source project on github: fbcp-ili9341. Compared with other fbcp projects, this project uses partial refresh and DMA to achieve a speed of up to 60fps

Note: The script will replace the corresponding /boot/config.txt and /etc/rc.local and restart, if the user needs, please back up the relevant files in advance.

We have carried out the low-level encapsulation, if you need to know the internal implementation can go to the corresponding directory to check, for the reason that the hardware platform and the internal implementation are different

2.We use Dev libraries by default. If you need to change to BCM2835 or WiringPi libraries ,please open RaspberryPi\c\Makefile and modify lines 13-15 as follows:

If you need to draw pictures, or display Chinese and English characters, we provide some basic functions here about some graphics processing in the directory RaspberryPi\c\lib\GUI\GUI_Paint.c(.h).

Select image buffer: The purpose of the selection is that you can create multiple image attributes, there can be multiple images buffer, you can select each image you create.

Mirror: indicates the image mirroring mode. MIRROR_NONE, MIRROR_HORIZONTAL, MIRROR_VERTICAL, MIRROR_ORIGIN correspond to no mirror, horizontal mirror, vertical mirror, and image center mirror respectively.

Set points of the display position and color in the buffer: here is the core GUI function, processing points display position and color in the buffer.

The fill color of a certain window in the image buffer: the image buffer part of the window filled with a certain color, usually used to fresh the screen into blank, often used for time display, fresh the last second of the screen.

Draw rectangle: In the image buffer, draw a rectangle from (Xstart, Ystart) to (Xend, Yend), you can choose the color, the width of the line, whether to fill the inside of the rectangle.

Draw circle: In the image buffer, draw a circle of Radius with (X_Center Y_Center) as the center. You can choose the color, the width of the line, and whether to fill the inside of the circle.

Write Ascii character: In the image buffer, use (Xstart Ystart) as the left vertex, write an Ascii character, you can select Ascii visual character library, font foreground color, font background color.

Write English string: In the image buffer, use (Xstart Ystart) as the left vertex, write a string of English characters, you can choose Ascii visual character library, font foreground color, font background color.

Write Chinese string: in the image buffer, use (Xstart Ystart) as the left vertex, write a string of Chinese characters, you can choose character font, font foreground color, font background color of the GB2312 encoding

Write numbers: In the image buffer,use (Xstart Ystart) as the left vertex, write a string of numbers, you can choose Ascii visual character library, font foreground color, font background color.

Display time: in the image buffer,use (Xstart Ystart) as the left vertex, display time,you can choose Ascii visual character font, font foreground color, font background color.;

2. The module_init() function is automatically called in the INIT () initializer on the LCD, but the module_exit() function needs to be called by itself

Python has an image library PIL official library link, it do not need to write code from the logical layer like C, can directly call to the image library for image processing. The following will take 1.54inch LCD as an example, we provide a brief description for the demo.

The first parameter defines the color depth of the image, which is defined as "1" to indicate the bitmap of one-bit depth. The second parameter is a tuple that defines the width and height of the image. The third parameter defines the default color of the buffer, which is defined as "WHITE".

The first argument is a tuple of four elements. (20,10) is the coordinate value in the upper left corner of the rectangle, and (70,60) is the coordinate value in the lower right corner of the rectangle. Fill =" WHITE" means BLACK inside, and outline="BLACK" means the color of the outline is black.

Draw an inscribed circle in the square, the first parameter is a tuple of 4 elements, with (150, 15) as the upper left corner vertex of the square, (190, 55) as the lower right corner vertex of the square, specifying the level median line of the rectangular frame is the angle of 0 degrees, the second parameter indicates the starting angle, the third parameter indicates the ending angle, and fill = 0 indicates that the the color of the line is white.

The first parameter is the coordination of the enclosing rectangle. The second and third parameters are the beginning and end degrees of the circle. The fourth parameter is the fill color of the circle.

Note: Each character library contains different characters; If some characters cannot be displayed, it is recommended that you can refer to the encoding set ro used.

The first parameter is a tuple of 2 elements, with (40, 50) as the left vertex, the font is Font2, and the fill is the font color. You can directly make fill = "WHITE", because the regular color value is already defined Well, of course, you can also use fill = (128,255,128), the parentheses correspond to the values of the three RGB colors so that you can precisely control the color you want. The second sentence shows Micro Snow Electronics, using Font3, the font color is white.

While I was looking for a TFT display for a project with Arduino, I found on several webstores some displays based on the ST7735 chip by Sitronix (datasheet).

Based on its datasheet, the ST7735 chip has a SPI (Serial Peripheral Interface) interface, but the pin names on the silk screen of my display “seem” to suggest an I2C interface (SDA, SCL…):

First identify – based on your Arduino board – which pins correspond to the different signals of the SPI bus. For the others, you can freely choose between the remaining pins.

(as you see, I connected the BLK pin directly to Vcc to have the backlight always on. You can also connect it to an Arduino digital pin to be able to control the backlight via software, for example if you need to save power).

Adafruit wrote a fantastic tutorial to explain how to use them, here I only want to show you how to setup the display for the connections I made earler:

If you’re using a board based on the esp32 chip and you need to display bitmap images, give a look to my library, SPIFFS_ImageReader, which perfectly integrates with the ones by Adafruit!

Since the use of an LCD requires many microcontroller pins, we will reduce that number using serial communication, which is basically sending "packages" of data one after another, using only two pins of our microcontroller , pins SDA and SCL which are the analog pins A4 and A5 of the Arduino NANO or pro mini.

First of all we connect i2c pins module as shown in the schematic. Power the LCD module to 5 volts and connect the ground as well. The SDA pin of the i2c module conected to arduinio A5 and the SCL pin to A4. We connect the arduino to USB and we are ready to program. In order to make the LCD work we need to inport the LCD library for arduino.

As the maker movement has increasingly grown, we’d like to share the way to use Arduino and begin with controlling the LCD module. Yes, we’d like to start from LCD module instead of installation since makers can find lots of related information from the Internet. So we’ll have less basic introduction here.

After reading this article and manipulating, you will have the basic understanding of I2C bus and LCD, and learn the way to connect modules with Arduino, use basic program to control your LCD module, and think about the applications. The advanced control techniques will be explained in the future articles.

I2C Bus enables 2 devices to communicate with each other in a stable, high-speed, bidirectional way and with the least I/O pins. I2C Bus utilizes 2 lines to communicate, Serial Data Line (SDA) and Serial Clock Line (SCL), so that the protocol I2C uses is also called “bidirectional” protocol.

What’s more special is I2C Bus allows multiple devices to share the common communication lines. Thus, I2C Bus could control the communication function.

Here we use Arduino as the main board to control; pin A4 and A5 on the board are SDA and SCL pins respectively. To use I2C function, you would need to use Wire Library, which is the built-in library of Arduino IDE.

LCD is the abbreviation of liquid-crystal display; it’s a commonly-used display device and utilized everywhere in our daily life, from watches, calculators, TV to bulletin board.

This LCD module is the basic one and the most commonly-used character display; The voltage is 5V. The voltage level Arduino I/O Port uses is 5V so that we choose the LCD module. Besides, the LCD module can display 16 characters per line and there are 2 such lines. Also, the module uses I2C protocol. Thus, there are 4 pins on the module, including Vcc, GND, SDA, and SCL.

It is also easy to connect the wires. Firstly, you need to connect pin Vcc of the module to Arduino pin 5V, connect pin GND to Arduino pin GND, and connect pin SDA to Arduino pin A4. Lastly, connect pin SCL to Arduino pin A5 to complete the wiring.

Before introducing the sample, we’d like you to download the 3rd party libraries of I2C_LCD first. You can download the files here, decompress, and install. In this sample, the version we use is NewliquidCrystal_1.3.4. The followings are the codes we use for this sample.

Then, at the setting of initialization, LCD backlight will be controlled to blink 3 times. The first line will display “ICshop&MakerPRO” for one second, and the second line will display “Hello, Maker!” for 8 seconds. Then all the display will be cleared.

Hope all of you successfully complete the I2C_1602_LCD module display with the description mentioned above. If you failed, please check the wiring or you bought a defective device.

So next, you could think of if you can use the module to make a clock or environment sensors. You might have tons of ideas now! Why don’t you connect a LCD module in your next project?

Arduino (open-source hardware and software company, project, and user community that designs and manufactures single-board microcontrollers and microcontroller kits for building digital devices. Its hardware products are licensed under a CC BY-SA license, while the software is licensed under the GNU Lesser General Public License (LGPL) or the GNU General Public License (GPL),manufacture of Arduino boards and software distribution by anyone. Arduino boards are available commercially from the official website or through authorized distributors.

Arduino board designs use a variety of microprocessors and controllers. The boards are equipped with sets of digital and analog input/output (I/O) pins that may be interfaced to various expansion boards ("shields") or breadboards (for prototyping) and other circuits. The boards feature serial communications interfaces, including Universal Serial Bus (USB) on some models, which are also used for loading programs. The microcontrollers can be programmed using the C and C++ programming languages, using a standard API which is also known as the Arduino Programming Language, inspired by the Processing language and used with a modified version of the Processing IDE. In addition to using traditional compiler toolchains, the Arduino project provides an integrated development environment (IDE) and a command line tool developed in Go.

The Arduino project began in 2005 as a tool for students at the Interaction Design Institute Ivrea, Italy,sensors and actuators. Common examples of such devices intended for beginner hobbyists include simple robots, thermostats, and motion detectors.

The name Arduino comes from a bar in Ivrea, Italy, where some of the project"s founders used to meet. The bar was named after Arduin of Ivrea, who was the margrave of the March of Ivrea and King of Italy from 1002 to 1014.

The Arduino project was started at the Interaction Design Institute Ivrea (IDII) in Ivrea, Italy.BASIC Stamp microcontroller at a cost of $50. In 2003 Hernando Barragán created the development platform Casey Reas. Casey Reas is known for co-creating, with Ben Fry, the Processing development platform. The project goal was to create simple, low cost tools for creating digital projects by non-engineers. The Wiring platform consisted of a printed circuit board (PCB) with an ATmega128 microcontroller, an IDE based on Processing and library functions to easily program the microcontroller.Arduino.

Following the completion of the platform, lighter and less expensive versions were distributed in the open-source community. It was estimated in mid-2011 that over 300,000 official Arduinos had been commercially produced,

At the end of 2008, Gianluca Martino"s company, Smart Projects, registered the Arduino trademark in Italy and kept this a secret from the other co-founders for about two years. This was revealed when the Arduino company tried to register the trademark in other areas of the world (they originally registered only in the US), and discovered that it was already registered in Italy. Negotiations with Martino and his firm to bring the trademark under the control of the original Arduino company failed. In 2014, Smart Projects began refusing to pay royalties. They then appointed a new CEO, Federico Musto, who renamed the company Arduino SRL and created the website arduino.org, copying the graphics and layout of the original arduino.cc. This resulted in a rift in the Arduino development team.

At the World Maker Faire in New York on 1 October 2016, Arduino LLC co-founder and CEO Massimo Banzi and Arduino SRL CEO Federico Musto announced the merger of the two companies.

In April 2017, Wired reported that Musto had "fabricated his academic record... On his company"s website, personal LinkedIn accounts, and even on Italian business documents, Musto was, until recently, listed as holding a Ph.D. from the Massachusetts Institute of Technology. In some cases, his biography also claimed an MBA from New York University." Wired reported that neither university had any record of Musto"s attendance, and Musto later admitted in an interview with Wired that he had never earned those degrees.open source licenses, schematics, and code from the Arduino website, prompting scrutiny and outcry.

By 2017 Arduino AG owned many Arduino trademarks. In July 2017 BCMI, founded by Massimo Banzi, David Cuartielles, David Mellis and Tom Igoe, acquired Arduino AG and all the Arduino trademarks. Fabio Violante is the new CEO replacing Federico Musto, who no longer works for Arduino AG.

In October 2017, Arduino announced its partnership with ARM Holdings (ARM). The announcement said, in part, "ARM recognized independence as a core value of Arduino ... without any lock-in with the ARM architecture". Arduino intends to continue to work with all technology vendors and architectures.

Under Violante"s guidance, the company started growing again and releasing new designs. The Genuino trademark was dismissed and all products were branded again with the Arduino name. As of February 2020, the Arduino community included about 30 million active users based on the IDE downloads.

In August 2018, Arduino announced its new open source command line tool (arduino-cli), which can be used as a replacement of the IDE to program the boards from a shell.

Arduino is open-source hardware. The hardware reference designs are distributed under a Creative Commons Attribution Share-Alike 2.5 license and are available on the Arduino website. Layout and production files for some versions of the hardware are also available.

Although the hardware and software designs are freely available under copyleft licenses, the developers have requested the name Arduino to be exclusive to the official product and not be used for derived works without permission. The official policy document on the use of the Arduino name emphasizes that the project is open to incorporating work by others into the official product.-duino.

An early Arduino boardRS-232 serial interface (upper left) and an Atmel ATmega8 microcontroller chip (black, lower right); the 14 digital I/O pins are at the top, the 6 analog input pins at the lower right, and the power connector at the lower left.

Most Arduino boards consist of an Atmel 8-bit AVR microcontroller (ATmega8,ATmega328, ATmega1280, or ATmega2560) with varying amounts of flash memory, pins, and features.Arduino Due, based on the Atmel SAM3X8E was introduced in 2012.shields. Multiple and possibly stacked shields may be individually addressable via an I2C serial bus. Most boards include a 5 V linear regulator and a 16 MHz crystal oscillator or ceramic resonator. Some designs, such as the LilyPad,

Arduino microcontrollers are pre-programmed with a boot loader that simplifies the uploading of programs to the on-chip flash memory. The default bootloader of the Arduino Uno is the Optiboot bootloader.RS-232 logic levels and transistor–transistor logic (TTL) level signals. Current Arduino boards are programmed via Universal Serial Bus (USB), implemented using USB-to-serial adapter chips such as the FTDI FT232. Some boards, such as later-model Uno boards, substitute the FTDI chip with a separate AVR chip containing USB-to-serial firmware, which is reprogrammable via its own ICSP header. Other variants, such as the Arduino Mini and the unofficial Boarduino, use a detachable USB-to-serial adapter board or cable, Bluetooth or other methods. When used with traditional microcontroller tools, instead of the Arduino IDE, standard AVR in-system programming (ISP) programming is used.

The Arduino board exposes most of the microcontroller"s I/O pins for use by other circuits. The Diecimila,Duemilanove,Unopulse-width modulated signals, and six analog inputs, which can also be used as six digital I/O pins. These pins are on the top of the board, via female 0.1-inch (2.54 mm) headers. Several plug-in application shields are also commercially available. The Arduino Nano and Arduino-compatible Bare Bones Boardbreadboards.

Many Arduino-compatible and Arduino-derived boards exist. Some are functionally equivalent to an Arduino and can be used interchangeably. Many enhance the basic Arduino by adding output drivers, often for use in school-level education,

Arduino and Arduino-compatible boards use printed circuit expansion boards called shields, which plug into the normally supplied Arduino pin headers.3D printing and other applications, GNSS (satellite navigation), Ethernet, liquid crystal display (LCD), or breadboarding (prototyping). Several shields can also be made do it yourself (DIY).

Some shields offer stacking headers which allow multiple shields to be stacked on top of an Arduino board. Here, a prototyping shield is stacked on two Adafruit motor shield V2s.

Adafruit Datalogging Shield with a Secure Digital (SD) card slot and real-time clock (RTC) chip along with some space for adding components and modules for customization

Adafruit Motor Shield with screw terminals for connection to motors. Officially discontinued, this shield may still be available through unofficial channels.

A program for Arduino hardware may be written in any programming language with compilers that produce binary machine code for the target processor. Atmel provides a development environment for their 8-bit AVR and 32-bit ARM Cortex-M based microcontrollers: AVR Studio (older) and Atmel Studio (newer).

The Arduino integrated development environment (IDE) is a cross-platform application (for Microsoft Windows, macOS, and Linux) that is written in the Java programming language. It originated from the IDE for the languages brace matching, and syntax highlighting, and provides simple one-click mechanisms to compile and upload programs to an Arduino board. It also contains a message area, a text console, a toolbar with buttons for common functions and a hierarchy of operation menus. The source code for the IDE is released under the GNU General Public License, version 2.

The Arduino IDE supports the languages C and C++ using special rules of code structuring. The Arduino IDE supplies a software library from the Wiring project, which provides many common input and output procedures. User-written code only requires two basic functions, for starting the sketch and the main program loop, that are compiled and linked with a program stub main() into an executable cyclic executive program with the GNU toolchain, also included with the IDE distribution. The Arduino IDE employs the program avrdude to convert the executable code into a text file in hexadecimal encoding that is loaded into the Arduino board by a loader program in the board"s firmware.

From version 1.8.12, Arduino IDE windows compiler supports only Windows 7 or newer OS. On Windows Vista or older one gets "Unrecognized Win32 application" error when trying to verify/upload program. To run IDE on older machines, users can either use version 1.8.11, or copy "arduino-builder" executable from version 11 to their current install folder as it"s independent from IDE.

On September 14, 2022, the Arduino IDE 2.0 was officially released as stable.Eclipse Theia Open Source IDE. The main features available in the new release are:

setup(): This function is called once when a sketch starts after power-up or reset. It is used to initialize variables, input and output pin modes, and other libraries needed in the sketch. It is analogous to the function main().

loop(): After setup() function exits (ends), the loop() function is executed repeatedly in the main program. It controls the board until the board is powered off or is reset. It is analogous to the function while(1).

Most Arduino boards contain a light-emitting diode (LED) and a current-limiting resistor connected between pin 13 and ground, which is a convenient feature for many tests and program functions.Hello, World!, is "blink", which repeatedly blinks the on-board LED integrated into the Arduino board. This program uses the functions pinMode(), digitalWrite(), and delay(), which are provided by the internal libraries included in the IDE environment.

The open-source nature of the Arduino project has facilitated the publication of many free software libraries that other developers use to augment their projects.

There is also a threading tool, named Protothreads. Protothreads are described as "extremely lightweight stackless threads designed for severely memory constrained systems, such as small embedded systems or wireless sensor network nodes.

Di Tore, Stefano; Todino, Michele Domenic; Plutino, Antonia (2019). "Le wearable technologies e la metafora dei sei cappelli per pensare a supporto del seamless learning". Professionalità. 4 (II): 118–13. ISSN 0392-2790.

Di Tore, Stefano; Todino, Michele; Sibilio, Maurizio (2019-04-30). "Disuffo: Design, prototyping, and development of an open-source educational robot". Form@re - Open Journal per la Formazione in Rete (in Italian). 19 (1): 106–116. doi:10.13128/FORMARE-24446. S2CID 181368197.

Dunkels, A.; Schmidt, O.; Voigt, T. (2005). Using Protothreads for Sensor Node Programming. Proceedings of the REALWSN 2005 Workshop on Real-World Wireless Sensor Networks Presented at the REALWSN 2005 Workshop on Real-World Wireless Sensor Networks.

![]()

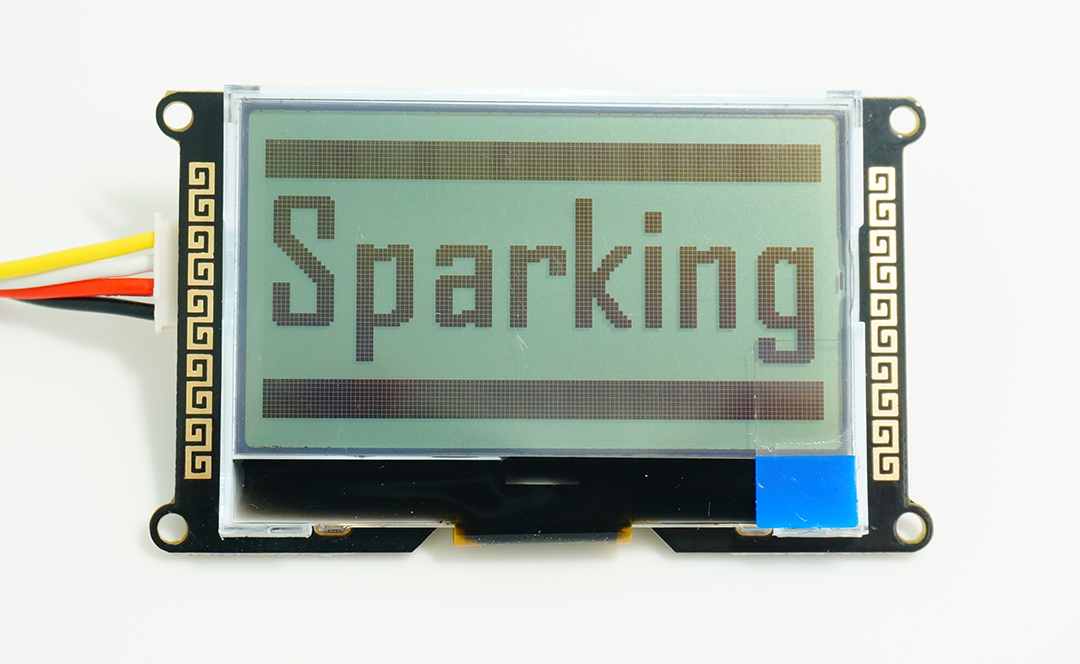

I2C_LCD is an easy-to-use display module, It can make display easier. Using it can reduce the difficulty of make, so that makers can focus on the core of the work.

We developed the Arduino library for I2C_LCD, user just need a few lines of the code can achieve complex graphics and text display features. It can replace the serial monitor of Arduino in some place, you can get running informations without a computer.

More than that, we also develop the dedicated picture data convert software (bitmap converter)now is available to support PC platform of windows, Linux, Mac OS. Through the bitmap convert software you can get your favorite picture displayed on I2C_LCD, without the need for complex programming.

Select the board: Click Tools > Board > "Arduino Duemilanove or Diecimila"(Seeeduino V3.0 Or early version), "Arduino Uno"(Seeeduino Lotus or Seeeduino V4.0).

Ms.Josey

Ms.Josey

Ms.Josey

Ms.Josey