lcd panel taking advantage of fluorescent lamp pricelist

The main functionality of the Basic Input/Output System (BIOS) is to perform the initial hardware checks after the computer is powered on and start up the operating system.

Which of the acronyms listed below refers to a series of basic hardware diagnostic tests performed by the startup BIOS after the computer is powered on?

After replacing a modular hardware component inside computer case, the updated information about specific parameters of the new device can be stored in: (Select 2 answers)

After completing the initial diagnostics and assigning system resources, the startup BIOS program checks for information about secondary storage devices that might contain the OS. The list of devices and the order in which they should be checked can be found and arranged in the CMOS setup utility, and this option is commonly referred to as:

After launching Windows Virtual PC application technician receives error message stating that the Hardware-Assisted Virtualization (HAV) feature is not enabled on the computer. Which of the following steps might help in fixing this problem?

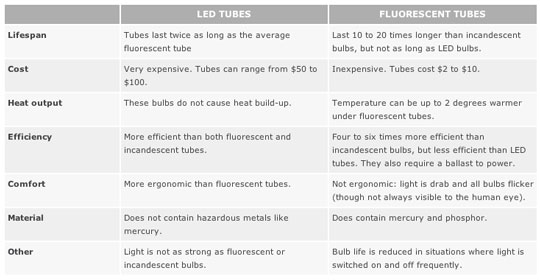

The light-emitting diode (LED) is today"s most energy-efficient and rapidly-developing lighting technology. Quality LED light bulbs last longer, are more durable, and offer comparable or better light quality than other types of lighting. Check out the top 8 things you didn"t know about LEDs to learn more.

LED is a highly energy-efficient lighting technology, and has the potential to fundamentally change the future of lighting in the United States. Residential LEDs -- especially ENERGY STAR rated products -- use at least 75% less energy, and last up to 25 times longer, than incandescent lighting.

Widespread use of LED lighting has a large potential impact on energy savings in the United States. By 2035, the majority of lighting installations are anticipated to use LED technology, and energy savings from LED lighting could top 569 TWh annually by 2035, equal to the annual energy output of more than 92 1,000 MW power plants.

Light Source: LEDs are the size of a fleck of pepper, and can emit light in a range of colors. A mix of red, green, and blue LEDs is sometimes used to make white light.

Direction: LEDs emit light in a specific direction, reducing the need for reflectors and diffusers that can trap light. This feature makes LEDs more efficient for many uses such as recessed downlights and task lighting. With other types of lighting, the light must be reflected to the desired direction and more than half of the light may never leave the fixture.

Heat: LEDs emit very little heat. In comparison, incandescent bulbs release 90% of their energy as heat and CFLs release about 80% of their energy as heat.

LED lighting is available in a wide variety of home and industrial products, and the list is growing every year. The rapid development of LED technology has resulted in increased product availability, improved manufacturing efficiency, and lower prices. Below are some of the most common types of LED products.

The high efficiency and directional nature of LEDs makes them ideal for many industrial uses. LEDs are increasingly common in street lights, parking garage lighting, walkway and other outdoor area lighting, refrigerated case lighting, modular lighting, and task lighting.

Recessed downlights are commonly used in residential kitchens, hallways, and bathrooms, and in a number of office and commercial settings. DOE estimates there are more than 600 million recessed downlights installed in U.S. homes and businesses.

With performance improvements and dropping prices, LED lamps can affordably and effectively replace 40, 60, 75, and even 100 Watt incandescent bulbs. It"s important to read the Lighting Facts Label to make sure the product is the right brightness and color for its intended use and location.

LEDs consume far less electricity than incandescent bulbs, and decorative LED light strings such as Christmas tree lights are no different. Not only do LED holiday lights consume less electricity, they also have the following advantages:

A compact fluorescent lamp (CFL), also called compact fluorescent light, energy-saving light and compact fluorescent tube, is a fluorescent lamp designed to replace an incandescent light bulb; some types fit into light fixtures designed for incandescent bulbs. The lamps use a tube that is curved or folded to fit into the space of an incandescent bulb, and a compact electronic ballast in the base of the lamp.

Compared to general-service incandescent lamps giving the same amount of visible light, CFLs use one-fifth to one-third the electric power, and last eight to fifteen times longer. A CFL has a higher purchase price than an incandescent lamp, but can save over five times its purchase price in electricity costs over the lamp"s lifetime.mercury,

The principle of operation remains the same as in other fluorescent lighting: electrons that are bound to mercury atoms are excited to states where they will radiate ultraviolet light as they return to a lower energy level; this emitted ultraviolet light is converted into visible light as it strikes the fluorescent coating, and into heat when absorbed by other materials such as glass.

CFLs radiate a spectral power distribution that is different from that of incandescent lamps. Improved phosphor formulations have improved the perceived color of the light emitted by CFLs, such that some sources rate the best "soft white" CFLs as subjectively similar in color to standard incandescent lamps.

White LED lamps compete with CFLs for high-efficiency lighting.General Electric has since stopped production of domestic CFL lamps in the United States in favour of LEDs.

Edmund Germer, Friedrich Meyer, and Hans Spanner patented a high-pressure vapor lamp in 1927.General Electric to create a practical fluorescent lamp, sold in 1938 and patented in 1941.1939 New York World"s Fair.

In 1980, Philips introduced its model SL*18, which was a screw-in or bayonet mount lamp with integral magnetic ballast.amalgam. This was the first successful screw-in replacement for an incandescent lamp, using new rare earth aluminum lattice phosphors to solve the problem of lumen depreciation that would normally occur quickly in such a thin tube; however, it wasn"t widely adopted, because of its large size, weight (over half a kilogram), pronounced 50 Hz flicker and 3-minute warm up time.Osram started selling its model Dulux EL, which was the first CFL to include an electronic ballast.

Volume was an issue in CFL development, since the fluorescent lamps had to fit in the same volume as comparable incandescent lamps. This required the development of new, high-efficacy phosphors that could withstand more power per unit area than the phosphors used in older, larger fluorescent tubes.

The rise of LED lighting, however, significantly affected CFL sales and production. As a result of decreasing cost and better features, customers increasingly migrated toward LEDs. In India, "nearly 60 per cent of the lighting market in India has been taken over by LEDs" by 2018.LED prices fell well below US$5 for a basic bulb in 2015.Energy Star rating.

There are two types of CFLs — integrated and non-integrated lamps, where CFL-i denotes an integrated ballast and CFL-ni denotes a non-integrated ballast. Integrated lamps combine the tube and ballast in a single unit. These lamps allow consumers to replace incandescent lamps easily with CFLs. Integrated CFLs work well in many standard incandescent light fixtures, reducing the cost of converting to fluorescent. 3-way lamps and dimmable models with standard bases are available.

Non-integrated CFLs have the ballast permanently installed in the luminaire, and usually only the fluorescent tube is changed at its end of life. Since the ballasts are placed in the light fixture, they are larger and last longer compared to the integrated ones, and they don"t need to be replaced when the tube reaches its end-of-life. Non-integrated CFL housings can be both more expensive and sophisticated. They have two types of tubes: a bi-pin tube designed for conventional ballast, e.g. with G23 or G24d plug-in base, and a quad-pin tube designed for an electronic ballast or a conventional ballast with an external starter. A bi-pin tube contains an integrated starter, which obviates the need for external heating pins but causes incompatibility with electronic ballasts.

Non-integrated CFLs can also be installed to a conventional light fixture using an adapter containing a built-in magnetic ballast. The adapter consists of a regular bulb screw, the ballast itself and a clip for the lamp"s connector.

CFLs have two main components: a magnetic or electronic ballast and a gas-filled tube (also called bulb or burner). Replacement of magnetic ballasts with electronic ballasts has removed most of the flickering and slow starting traditionally associated with fluorescent lighting, and has allowed the development of smaller lamps directly interchangeable with more sizes of incandescent light bulb.

Electronic ballasts contain a small circuit board with a bridge rectifier, a filter capacitor and usually two switching transistors, which are often insulated-gate bipolar transistors. The incoming AC current is first rectified to DC, then converted to high frequency AC by the transistors, connected as a resonant series DC to AC inverter. The resulting high frequency is applied to the lamp tube. Since the resonant converter tends to stabilize lamp current (and light emitted) over a range of input voltages, standard CFLs respond poorly in dimming applications and will experience a shorter lifespan and sometimes catastrophic failure. Special electronic ballasts (integrated or separate) are required for dimming service.

CFL light output is roughly proportional to phosphor surface area, and high output CFLs are often larger than their incandescent equivalents. This means that the CFL may not fit well in existing light fixtures.

To fit enough phosphor coated area within the approximate overall dimensions of an incandescent lamp, standard shapes of CFL tube are a helix with one or more turns, multiple parallel tubes, circular arc, or a butterfly.

Some CFLs are labeled not to be run base up, since heat will shorten the ballast"s life. Such CFLs are unsuitable for use in pendant lamps and especially unsuitable for recessed light fixtures. CFLs designed for use in such fixtures are available.cold-cathode CFLs or to replace such fixtures with those designed for CFLs.

Characteristic spectral power distributions (SPDs) for an incandescent lamp (left) and a CFL (right). The horizontal axes are in nanometers and the vertical axes show relative intensity in arbitrary units. Significant peaks of UV light are present for CFL even if not visible

CFLs emit light from a mix of phosphors, each emitting one band of color with some bands still in the ultraviolet range as can be seen on the light spectrum. Modern phosphor designs balance the emitted light color, energy efficiency, and cost. Every extra phosphor added to the coating mix improves color rendering but decreases efficiency and increases cost. Good quality consumer CFLs use three or four phosphors to achieve a "white" light with a color rendering index (CRI) of about 80, where the maximum 100 represents the appearance of colors under daylight or other sources of black-body radiation such as an incandescent light bulb (depending on the correlated color temperature).

Color temperature can be indicated in kelvins or mireds (1 million divided by the color temperature in kelvins). The color temperature of a light source is the temperature of a black body that has the same chromaticity (i.e. color) as the light source. A notional temperature, the correlated color temperature, the temperature of a black body that emits light of a hue that to human color perception most closely matches the light from the lamp, is assigned.

The color temperature is characteristic of black-body radiation; practical white light sources approximate the radiation of a black body at a given temperature, but will not have an identical spectrum. In particular, narrow bands of shorter-wavelength radiation are usually present even for lamps of low color temperature ("warm" light).

As color temperature increases, the shading of the white light changes from red to yellow to white to blue. Color names used for modern CFLs and other tri-phosphor lamps vary between manufacturers, unlike the standardized names used with older halophosphate fluorescent lamps. For example, Sylvania"s Daylight CFLs have a color temperature of 3500 K, while most other lamps called daylight have color temperatures of at least 5000 K. In United States, Energy Star"s specification provides a set of named color temperatures for certified luminaries.

CFLs typically have a rated service life of 6000–15,000 hours, whereas standard incandescent lamps have a service life of 750 or 1000 hours.voltage spikes, mechanical shock, frequency of cycling on and off, lamp orientation, and ambient operating temperature, among other factors.

The life of a CFL is significantly shorter if it is turned on and off frequently or is used in a totally enclosed fixture. In the case of a 5-minute on/off cycle the lifespan of some CFLs may be reduced to that of incandescent light bulbs. The US Energy Star program suggests that fluorescent lamps be left on when leaving a room for less than 15 minutes to mitigate this problem.exponential, with the fastest losses being soon after the lamp is first used. By the end of their lives, CFLs can be expected to emit 70–80% of their original light output.logarithmic. That is, while the human eye is highly sensitive to changes in the intensity of faint light sources, it is less sensitive to changes in the intensity of brighter light sources since the pupils compensate by dilating or constricting.

Fluorescent lamps get dimmer over their lifetime,Energy Star products in 2003–04, one quarter of tested CFLs no longer met their rated output after 40% of their rated service life.

Because the eye"s sensitivity changes with the wavelength, the output of lamps is commonly measured in lumens, a measure of the power of light as perceived by the human eye. The luminous efficacy of lamps is the number of lumens emitted for each watt of electric power used. The luminous efficacy of a typical CFL is 50–70 lumens per watt (lm/W) and that of a typical incandescent lamp is 10–17 lm/W.680 lm/W), CFL lamps have lighting efficiency ranges of 7–10%,

Because of their higher efficacy, CFLs use between one-seventh and one-third of the power of equivalent incandescent lamps.terawatt-hours (1.47 exajoules) per year, 2.5% of world electricity use. In the US, it is estimated that replacing all incandescents would save 80 TWh yearly.carbon dioxide (CO2) being emitted into the atmosphere. Exchanging ILs for efficient CFLs on a global scale would achieve annual CO2 reductions of 230 Mt (million tons), more than the combined yearly CO2 emissions of the Netherlands and Portugal.

If a building"s indoor incandescent lamps are replaced by CFLs, the heat emitted due to lighting is significantly reduced. In warm climates, or in office or industrial buildings where air conditioning is often required, CFLs reduce the load on the cooling system when compared to the use of incandescent lamps, resulting in savings in electricity in addition to the energy efficiency savings of the lamps. However, in cooler climates in which buildings require heating, the heating system must replace the reduced heat from lighting fixtures. In Winnipeg, Canada, it was estimated that CFLs would only generate 17% savings in energy compared to incandescent bulbs, as opposed to the 75% savings that could have been expected without space heating considerations.

While the purchase price of a CFL is typically 3–10 times greater than that of an equivalent incandescent lamp, a CFL lasts 8–15 times longer and uses two-thirds to three-quarters less energy. A US article stated "A household that invested $90 in changing 30 fixtures to CFLs would save $440 to $1,500 over the five-year life of the bulbs, depending on your cost of electricity. Look at your utility bill and imagine a 12% discount to estimate the savings."

CFLs are extremely cost-effective in commercial buildings when used to replace incandescent lamps. Using average U.S. commercial electricity and gas rates for 2006, a 2008 article found that replacing each 75 W incandescent lamp with a CFL resulted in yearly savings of $22 in energy usage, reduced HVAC cost, and reduced labour to change lamps. The incremental capital investment of $2 per fixture is typically paid back in about one month. Savings are greater and payback periods shorter in regions with higher electric rates and, to a lesser extent, also in regions with higher than U.S. average cooling requirements.

The current price of CFLs reflects the manufacturing of nearly all CFLs in China, where labour costs less. In September 2010, the Winchester, Virginia, General Electric plant closed,Osram Sylvania and the tiny American Light Bulb Manufacturing Inc. the last companies to make standard incandescent bulbs in the United States.

According to an August 2009 newspaper report, some manufacturers claimed that CFLs could be used to replace higher-power incandescent lamps than justified by their light output.

In addition to the wear-out failure modes common to all fluorescent lamps, the electronic ballast may fail, since it has a number of component parts. Ballast failures are usually due to overheating and may be accompanied by discoloration or distortion of the ballast enclosure, odors, or smoke.

Only some CFLs are labeled for dimming control. Using a dimmer with a standard CFL is ineffective and can shorten bulb life and void the warranty.wall sconces in a dining area. Below the 20% limit, the lamp may remain at 20% or flicker or the starter circuitry may stop and restart.

When a CFL is dimmed, its color temperature (warmth) stays the same. This is counter to incandescent light sources, where color gets redder as the light source gets dimmer. The Kruithof curve from 1934 described an empirical relationship between intensity and color temperature of visually pleasing light sources.

Voltage and current for a 120 V 60 Hz 30-watt compact fluorescent lamp. Because the current is heavily distorted, the power factor of this lamp is only 0.61. The lamp takes 29 watts, but 39 volt-amperes due to this distortion.

The input stage of a CFL is a rectifier, which presents a non-linear load to the power supply and introduces harmonic distortion on the current drawn from the supply.power quality, but significant quantities of them in a large facility can have an adverse effect. The power factor of CFLs does not significantly affect their energy-saving benefits for individual consumers, but their use in large numbers, such as in commercial applications or across millions of homes in a distribution system, could require infrastructure upgrades. In such cases, CFLs with low (below 30 percent) total harmonic distortion (THD) and power factors greater than 0.9 should be selected.

Electronic devices operated by infrared remote control can interpret the infrared light emitted by CFLs as a signal; this may limit the use of CFLs near televisions, radios, remote controls, or mobile phones. Energy Star certified CFLs must meet FCC standards, and so are required to list all known incompatibilities on the package.

CFLs are generally not designed or rated for outdoor use and some will not start in cold weather. CFLs are available with cold-weather ballasts, which may be rated to as low as −28.8 °C (−20 °F).Cold-cathode CFLs will start and perform in a wide range of temperatures due to their different design.

Incandescent lamps reach full brightness a fraction of a second after being switched on. As of 2009amalgam can take up to three minutes to reach full output.

According to the European Commission Scientific Committee on Emerging and Newly Identified Health Risks (SCENIHR) in 2008, CFLs may pose an added health risk due to the ultraviolet and blue light emitted. This radiation could aggravate symptoms in people who already suffer skin conditions that make them exceptionally sensitive to light. The light emitted by some single-envelope CFLs at distances of less than 20 cm (7.9 in) could lead to ultraviolet exposures approaching the current workplace limit set to protect workers from skin and retinal damage. However, industry sources claim the UV radiation received from CFLs is too small to contribute to skin cancer and the use of double-envelope CFLs "largely or entirely" mitigates any other risks.

Tests have shown that radiation exposure from CFLs is negligible at 150 centimeter distance from the source. At closer distances, comparisons show that CFLs emit less UVA (long wavelength) radiation than incandescent light bulbs. They do, however, emit higher levels of UVB (short wavelength) radiation.

A 2012 study comparing cellular health effects of CFL light and incandescent light found statistically significant cell damage in cultures exposed to CFL light. Spectroscopic analysis confirmed the presence of significant UVA and UVC radiation, which the study"s authors conjectured was attributable to damage in the bulbs" internal phosphor coatings. No cellular damage was observed following exposure to incandescent light of equivalent intensity. The study"s authors suggest that the ultraviolet exposure could be limited by the use of "double-walled" bulbs manufactured with an additional glass covering surrounding the phosphor-coated layer.

When the base of the bulb is not made to be flame-retardant, as required in the voluntary standard for CFLs, overheating of the electrical components in the bulb may create a fire hazard.

Net mercury emissions for CFL and incandescent lamps, based on EPA FAQ sheet, assuming average U.S. emission of 0.012 mg of mercury per kilowatt-hour and 14% of CFL mercury contents escapes to environment after land fill disposal

CFLs, like all fluorescent lamps, contain mercurymercury is poisonous, even these small amounts are a concern for landfills and waste incinerators where the mercury from lamps may be released and contribute to air and water pollution. In the U.S., lighting manufacturer members of the National Electrical Manufacturers Association (NEMA) have voluntarily capped the amount of mercury used in CFLs.RoHS law.

In areas where electric power is mostly generated in coal-fired stations, replacing incandescent bulbs by CFLs actually reduces mercury emissions. This is because the reduced electric power demand, reducing in turn the amount of mercury released by coal as it is burned, more than offsets the amount of mercury released from broken and discarded CFL bulbs.

In the United States, the U.S. Environmental Protection Agency estimated that if all 270 million CFLs sold in 2007 were sent to landfill sites, around 0.13 metric tons of mercury would be released, 0.1% of all U.S. emissions of mercury (around 104 metric tons that year).

Special handling instructions for breakage are not printed on the packaging of household CFL bulbs in many countries. The amount of mercury released by one bulb can temporarily exceed U.S. federal guidelines for chronic exposure.Chronic, however, implies exposure for a significant time, and it remains unclear what the health risks are from short-term exposure to low levels of elemental mercury.3 in air close to the carpet, even weeks after the initial breakage.

Health and environmental concerns about mercury have prompted many jurisdictions to require spent lamps to be properly disposed of or recycled, rather than being included in the general waste stream sent to landfills. Safe disposal requires storing the bulbs unbroken until they can be processed.

In the European Union, CFLs are one of many products subject to the WEEE recycling scheme. The retail price includes an amount to pay for recycling, and manufacturers and importers have an obligation to collect and recycle CFLs.

According to the Northwest Compact Fluorescent Lamp Recycling Project, because household users in the U.S. Northwest have the option of disposing of these products in the same way they dispose of other solid waste, in Oregon "a large majority of household CFLs are going to municipal solid waste". They also note the EPA"s estimates for the percentage of fluorescent lamps" total mercury released when they are disposed of in the following ways: municipal waste landfill 3.2%, recycling 3%, municipal waste incineration 17.55% and hazardous waste disposal 0.2%.

The first step of processing CFLs involves crushing the bulbs in a machine that uses negative pressure ventilation and a mercury-absorbing filter or cold trap to contain mercury vapor. Many municipalities are purchasing such machines.

In some places, such as Quebec and British Columbia in 2007, central heating for homes was provided mostly by the burning of natural gas, whereas electricity was primarily provided by hydroelectric power. An analysis of the impacts of a ban on incandescent light bulbs at that time introduced the notion that in such areas, heat generated by conventional electric light bulbs may have been significantly reducing the release of greenhouse gases from natural gas heating.tonnes in CO2 emissions in the province, equivalent to the annual emissions from more than 40,000 automobiles."

CFLs are produced for both alternating current (AC) and direct current (DC) input. DC CFLs are popular for use in recreational vehicles and off-the-grid housing. Various aid agency initiatives exist in developing countries to replace kerosene lamps, which have associated health and safety hazards, with CFLs powered by batteries, solar panels or wind power generators.

Due to the potential to reduce electric consumption and pollution, various organizations have encouraged the adoption of CFLs and other efficient lighting. Efforts range from publicity to encourage awareness, to direct handouts of CFLs to the public. Some electric utilities and local governments have subsidized CFLs or provided them free to customers as a means to reduce electric demand; and so delay further investments in generation.

In the United States, the Program for the Evaluation and Analysis of Residential Lighting (PEARL) was created to be a watchdog program. PEARL has evaluated the performance and Energy Star compliance of more than 150 models of CFL bulbs.

The UN Environment Programme (UNEP)/Global Environment Facility (GEF) initiative has developed "The Global Efficient Partnership Program", which focuses on country-led policies and approaches to enable the implementation of energy-efficient lighting, including CFLs, quickly and cost-effectively in developing and emerging countries.

In the United States and Canada, the Energy Star program labels lamps that meet a set of standards for efficiency, starting time, life expectancy, color, and consistency of performance. The intent of the program is to reduce consumer concerns due to variable quality of products.Energy Star Light Bulbs for Consumers is a resource for finding and comparing Energy Star qualified lamps. There is ongoing work in improving the "quality" (color rendering index) of the light.

In the United States, new standards proposed by the United States Department of Energy could result in LED lamps replacing CFLs. In the opinion of Noah Horowitz of the Natural Resources Defense Council, most CFL bulbs would not meet the standards.

The G24 (624Q2) and GU24 lamp fitting socket systems were designed to replace the traditional lamp sockets, so that incandescent bulbs are not installed in fixtures intended for energy efficient lamps only.

Masamitsu, Emily (May 2007). "The Best Compact Fluorescent Light Bulbs: PM Lab Test". Popular Mechanics. Archived from the original on April 26, 2007. Retrieved 2007-05-15.

Kane, Raymond; Sell, Heinz (2001). Revolution in Lamps: A Chronicle of 50 Years of Progress (Second ed.). The Fairmont Press. pp. 189–190. ISBN 978-0-88173-378-5.

"Barriers to Technology Diffusion: The Case of Compact Fluorescent Lamps" (PDF). Organisation For Economic co-Operation And Development. 30 October 2006. Archived (PDF) from the original on 2015-09-12.

"IEC 60969: Self-ballasted lamps for general lighting services: Performance requirements". Collaborative Labelling and Appliance Standards Program. Archived from the original on February 26, 2008. Retrieved 2007-12-24.

Damir, B (2012). "Longevity of light bulbs and how to make them last longer". RobAid. Archived from the original on 19 August 2015. Retrieved 4 January 2013.

Halsted, Charles P. (March 1993). "Brightness, Luminance, and Confusion". Information Display. Naval Air Warfare Center Warminster, PA. Archived from the original on September 22, 2007. Retrieved 2007-10-07. If the luminance of a viewed light source is increased 10 times, viewers do not judge that the brightness has increased 10 times. The relationship is, in fact, logarithmic: the sensitivity of the eye decreases rapidly as the luminance of the source increases. It is this characteristic that allows the human eye to operate over such an extremely wide range of light levels.

Matković, Krešimir (December 1997). Colour Science Basics: Human Vision. Tone Mapping Techniques and Color Image Difference in Global Illumination (PhD). Institut für Computergraphik eingereicht an der Technische Universität Wien (TU Wien). Retrieved 2007-10-07. It is interesting, that despite that incoming light can have a dynamic range of nearly 14 log units, the neural units can transfer the signal having the dynamic range of only about 1.5 log units. It is obvious that there is some adaptation mechanism involved in our vision. It means that we adapt to some luminance value, and then we can perceive data in a certain dynamic range near the adaptation level. One of the most important characteristics that changes with different adaptation levels is the just noticeable difference.

"Lighting". Energy Efficiency & Renewable Energy. United States Department of Energy. Archived from the original on October 15, 2011. Retrieved 2 October 2011.

Keefe, T. J. (2007). "The Nature of Light". Community College of Rhode Island. Archived from the original on June 12, 2010. Retrieved 18 September 2010.

"United States of America". En.lighten. United Nations Environment Programme. 2010. Archived from the original on April 2, 2012. Retrieved 2 October 2011.

Chernoff, Harry (2008-01-23). "The Cost-Effectiveness of Compact Fluorescents in Commercial Buildings". EnergyPulse. Archived from the original on February 20, 2008. Retrieved 2008-03-21.

Korovesis, Ph. N.; et al. (2004). "Influence of Large-Scale Installation of Energy Saving Lamps on the Line Voltage Distortion of a Weak Network Supplied by Photovoltaic Station". IEEE Transactions on Power Delivery. 19 (4): 1787–1793. doi:10.1109/TPWRD.2004.835432. S2CID 19975088.

Cunill-Solà, J.; Salichs, M. (2007). "Study and Characterization of Waveforms from Low-Watt (<25 W) Compact Fluorescent Lamps with Electronic Ballasts". IEEE Transactions on Power Delivery. 22 (4): 2305–2311. doi:10.1109/TPWRD.2007.899551. S2CID 11439733.

U.S. Dept. of Energy, Greening Federal Facilities, 2nd Edition, "Compact Fluorescent Lighting Archived May 11, 2011, at the Wayback Machine". DOE/GO=102001-1165 page 87. Retrieved 22 February 2007. "Even when low-temperature ballasts are used, lamps will not reach full brightness for several minutes in cold weather."

"Why does my compact fluorescent light bulb flicker or appear dim when I first turn it on?". Compact Fluorescent Light Bulb (CFL) FAQs. GE Lighting. Archived from the original on February 28, 2009. Retrieved 2009-06-15.

"Why does it take time for CFL bulbs to come up to full brightness?". Efficient Lighting FAQs. City of Fort Collins. Archived from the original on December 10, 2008. Retrieved 2009-06-15.

Nuzum-Keim, AD; Sontheimer, RD (2009). "Ultraviolet light output of compact fluorescent lamps: comparison to conventional incandescent and halogen residential lighting sources". Lupus. 18 (6): 556–60. doi:10.1177/0961203309103052. PMID 19395458. S2CID 206597819.

Mironava, T.; Hadjiargyrou, M.; Simon, M.; Rafailovich, M. H. (20 Jul 2012). "The Effects of UV Emission from Compact Fluorescent Light Exposure on Human Dermal Fibroblasts and Keratinocytes In Vitro". Photochemistry and Photobiology. 88 (6): 1497–1506. doi:10.1111/j.1751-1097.2012.01192.x. PMID 22724459. S2CID 2626216.

CPSC, Teng Fei Trading Inc. Announce Recall of Energy Saving Light Bulbs Archived January 8, 2013, at the Wayback Machine. U.S. Consumer Product Safety Commission press release. Accessed 1 January 2008.

"Frequently Asked Questions: Information on Compact Fluorescent Light Bulbs (CFLs) and Mercury" (PDF). energystar.gov. November 2010. Retrieved 2017-03-23. What are the mercury emissions caused by humans? Do CFLS that wind up in a landfill contribute to these emissions?

Ivanco, M.; Karney, B.W.; Waher, K.J. (25–26 October 2007). To Switch, or Not to Switch: A Critical Analysis of Canada"s Ban on Incandescent Light Bulbs. IEEE Electrical Power Conference. pp. 550–555. doi:10.1109/EPC.2007.4520391.

200 0000+ solar powered kerosene-lamp replacements assisted by aid agencies: http://www.ashdenawards.org/winners/mpgvm Archived 2011-05-11 at the Wayback Machine, http://www.ashdenawards.org/winners/Dlight10 Archived 2010-07-08 at the Wayback Machine, "Archived copy" (PDF). Archived from the original (PDF) on 2011-05-12. Retrieved 2010-06-30.link)

It is imperative to discuss the importance of checking for grounding of electrical appliances and other equipment. The nurse should provide examples of comm...

The purposed network architecture will consist of four deployable tough boxed server stack’s which will contain two Dell 1130 1U Rugged Dart Frogs server bla...

The fact that the electrical grid provides employees access to stay associated with one another, regardless of their location in the world, is an incredible ...

Edison originated the first electric grid and ever since, the electric grid has been rapidly expanding, spreading to millions of cities across the globe. Not...

The advance in technology implies incrementation in the number of devices, machines as well as systems which, require electrical energy to operate. Therefore,

You need to take into account the number of letters that will be used on your sign and the type of materials that will be used to make it. Traditional steel signs usually cost between $25 to $35 per sq. ft. while aluminum or plastic signs costs around $15 to $25 per sq. ft. The less costly signs will be manufactured out of urethane and costs between $5 to $15 per sq. ft. Lighted signs can cost more than $35 per sq. ft. while a neon sign can cost from $250 to $1,250 per sq. ft.

The biggest cost of making and installing signs depends on a couple of components. Indoor signs commonly cost less than an outdoor sign, because the weather may damage them. Lighted signs often cost more than signs that don’t use power. Furthermore, temporary signs for sales or promotional events cost less than a longer-lasting design like signs for business names or signs that target driving traffic.

Business signs provide a great first impression of the business and will ensure that people see the business during the day and at night. There are a lot of choices when it comes to the design, materials used, and the size of the sign.

This post explains to you how to choose a business sign that will give a big impression on possible customers. It covers how to decide on a sign that fits your budget. A big part of your sign will be your logo, so bear in mind a bad looking logo can spoil the impact of your sign.

Your business sign is one of the first things that possible customers see when they visit your store, so it’s important to choose a sign that reflects your brand, and the types of services you provide. Business signs can be made from a variety of materials like glass, wood, metal, and fabric.

Fabric signs are very favorable because of their flexibility, so any type of business can utilize one. They may be simple like a banner for a mall kiosk or more complex and built into a lightbox for a large retail store.

Plywood signs are affordable and simple, but elegant. 4-ft by 4-ft plywood signs start at $50 but that is without installation. Installation can reach costs of $192. The size of the type of paint and font or finish that you decide on as well as how big the sign influences the cost. These signs are subject to weather damage and might need to be replaced frequently.

Painted plywood signs are perfect for restaurants that are looking to give their establishment an old-timey look. They can even work for high-end retailers who are looking to provide a rustic theme or customized type of look. Read more about plywood signs.

These signs are strong and resistant to weather and provide you with a modern and clean feel or even a historic flavor. A two-sided sign that is 18 in. by 24 in. starts at $80 without installation. Large signs or adding texture and/or color adds to the cost, but you will typically see costs from $250 to $2,000. Based on the design, a punched metal sign can be utilized by any business that’s looking for a sleek, modern look or more of a retro display.

These are also known as LED or neon signs and the visual enticement for these signs is unlike any other. According to ArizonaCommercialSigns, a customized neon sign can start at around $200 and can increase up to $1,000 based on the complexity of the design and its size, they can end up in the $11,000 area. Smaller “off the shelf” types of neon lights are readily available.

These signs are professional, eye-catching and work well in a lot of locations, but they are more costly. According to WesternSignsAz, the average 4-ft by 8-ft metal sign can cost around $350 or more without installation. Installation can cost up to $450, depending on the size of the sign. Take into account, that for any material, the design will influence the signs price and a more complex sign design cost more. For example, if you use a metal signboard, with individually cut lettering, you’re going to pay a lot more than if the lettering was simply painted on the metal since there is more labor involved. These signs weather fairly well, but it is a good idea to budget for a little touch-up work every couple of years.

These signs are 3-dimensional, and the shadows they produce will add interest and texture. Based on the size of the lettering and the metal that it’s made of these signs start at around $250, without any custom design fees or installation. It is suggested that you have them lighted to get more attention to your business, particularly if you operate at night. You might pay between $350 to $550 or more, but your customer visibility will grow. Learn more about metal lettering and logo design costs.

These types of signs let you provide shade for your business, protection for your customers during bad weather, and charming looks. The cost for an awning storefront sign is based on the fabric and size of the awning and the hardware that is used to hang it. Nevertheless, these signs usually start at around $550 and increase in price.

It’s been reported that businesses that have awnings can see up to 30% in energy savings. They’re built to endure bad weather, which makes them a perfect selection. Due to their design, you can have your business name or logo placed on the front and sides of the awning that will increase the visibility for your customers.

The main thing to remember is that the sign cost will be included in the installation charge, and can vary, but it can range from $4,000 to $10,000according to AGCSigns. Depending on the design and size of your sign, an awning sign can be used for restaurants and cafes to make the business feel nostalgic or for those who want to have an unusual storefront.

Exterior business signs come in a lot of different colors and styles and may be custom designed to your specifications. According to HomeAdvisor, exterior sign costs can vary from $165 to $710 depending on the design, fabrication, and location it will be installed at. All these components will influence the price of the sign installation. More information about exterior signs.

According to ArizonaCommercialSigns, channel letter signs may cost you anywhere from $2,000 to $3,000, depending on how many letters you require how complex the fabrication is and the difficulty of where it is going to be installed at. All these components influence the pricing of its installation. More information about channel letter signs.

Professional sign companies provide a lot of services to their clients from designing the sign to manufacturing the sign, delivering it and then installing it. A lot of sign companies will offer to come to the business location and go over the needs of the client directly. Sign companies are also responsible for making sure that the sign meets zoning codes, local ordinances, and regulations. For example, a couple of cities have prohibited billboards, and the ADA has very harsh rules about signs that are required to be followed. Sometimes, the sign company will oversee the sign installation. The sign company is also responsible for the design process. This may be very useful if the sign needs to be installed in different locations throughout an area or if the sign is larger or if it needs to be installed in hard to reach area.

A lot of factors that influence the costs for a sign, like the number of colors in the design. Usually, a black and white sign costs a lot less than one with colors. In addition, if the sign design is complex, it costs more than a sign that only has a couple of words on it. Other factors that need to be considered is the material that the sign is made out and what the use of the sign will be. If a customer is holding a promotion, a less costly plastic sign is usually a better solution. Nevertheless, the business design needs to be made from a durable material that will lower costs in the long run.

It’s also important that the size of the sign be taken into account. Larger signs cost a lot more than a smaller sign. The installation will influence the total cost of the sign. Installing a billboard or neon sign will be more costly than installing a smaller non-lighted sign. Taking these factors into account can keep sign costs down.

Choosing a sign company that is right for your business will be selected based on their services, sign type that their client wants, and their cost. For longer-lasting signs, it’s important that you pick a sign company that will have the materials for your sign that you want to purchase. It is also essential to consider the design options that the company provides. There are a lot of factors that will include whether the company that is chosen can produce the sign with the needed size, if they can install the sign, and if they offer illumination if that’s what their client wants. Signs are a great way to market your business and are read fairly quickly, so it’s vital that the sign company has good design options and can produce the perfect sign that is used to grab the attention of potential customers.

You can save money on a sign by choosing a stock design rather than a custom design. While a lot of signs are custom made, the pre-made signs are a perfect way to save a little money. Stock signs are also available. As you buy more signs of the same kind the price will go down. In addition, those who think the signs could change over time need to consider getting a design that can be easily updated and may be done by the staff or business rather than the sign designer at a sign company to keep costs down.

A great tip is actually to place an order for your designs during the off-season as sign companies are usually busiest throughout the warmer seasons. If you place your order during winter, it may result in discounts or promos for your purchase as well as a shorter wait time.

Over the years, we have spoken with thousands of business owners who ask, “How much do business signs cost“. The truth is the cost of signs can vary greatly depending on the type and size, however, in our experience, most companies are interested in a lighted sign that attracts the attention of customers better.

A sign made of industrial aluminum with acrylic panels or a combination of vinyl inscriptions and digital printing usually runs about $5,000. This sign will provide many years of service before any maintenance is required. It is two-sided, so it can be seen on cars traveling in both directions. The business signs cost is reduced by using indirect lighting on the ground.

The sign of the main monument can be customized by adding additional colors, interior lighting, decorative effects or a foundation in the style of brickwork.

A 6 × 8 ‘dihedral sign is bigger and higher, so larger supports and support columns are required to handle the additional wind load and can cost upwards of $10,000. It has an extruded aluminum structure and swivel frames for easy maintenance. In cold weather, this sign will be internally illuminated by T12 fluorescent lights, fluorescent lamps operating on energy-efficient electronic ballasts. Persons are digitally printed in full color on vinyl with a 3/16 inch thick Lexan substrate. They can easily be replaced if the company name changes or the building gets a new tenant. The lower half of the sign has 3 tracks for 6 “replaceable copies of letters.

A 10 × 7 ‘tall double-sided, internally lit sign is also made of aluminum but has many user-defined functions. These signs can run anywhere from $15,00 – $30,000. It includes a Lexan face with an embossed copy, giving it a three-dimensional appearance. It uses internal LED lighting and real bowling balls as decorative ornaments. The stone base is a value, designed from aluminum, covered with digitally printed vinyl, to get a high-quality look at a lower cost than real masonry.

What makes this sign special is the addition of 3 x 7-inch full-color electronic message centers (EMC) on both sides of the sign. Enabled wireless software to change the text, the built-in graphic package, and training on the spot and on the Internet.

This sign can be updated to EMC with high resolution, which will be displayed even more in detail. When adding EMC, the business signs cost depends on the resolution. The resolution (clarity) is measured by the pixel pitch, the distance between the points of light measured in millimeters. The 20 mm pixel pitch will be more “grainy” than the 12 mm EMC for business signs. Small EMC with pixel pitch can display video clips with a frequency of 60 frames per second. An additional upgrade can be remote access off-site so that one operator can change the text or video on the signs in several places in the store.

For a more specific breakdown of our business signs cost, contact Davis Signs & Graphics today at (480) 945-0916. We also offer Business Signs in Ogden, Utah.

For small/medium size televisions, LCD is clearly the choice for those of you with limited power. The other great news is that they are getting cheaper as time goes on. Coles and a number of supermarkets are now selling 38 cm LCD televisions for under AUS$200.

I say "if" because they are designed to run off a 230V-12V regulated power supply. This is not the same as running it direct from a 12V solar system where the battery voltage can easily range from 11 to 15 volts. An even wider variance is possible with flat or failing batteries; a battery system being equalised to 15.5-16 volts etc.

There appears to be a few brands that can definitely be run off a battery and these are marketed to the caravan and yachting market. Majestic LCD televisions will operate between 10.9 and 15.5 volts. Xien sell a range for the marine industry. Sharp televisions are also sold as "12 volts" but come with a $140 special 12 V lead. I suggest this has a power conditioner on it. Dick Smith once sold (and may still do so) an AC/DC 15 inch model.

Most people assume that all the brands would operate satisfactorily but we are unable to recommend this without information from the manufacturers. If any of you have information or experience in this regard, please let me know.

The power "saving" of being able to run it direct is significant. From my observations, the 230 to 12V adapter supplied with the television is only about 50% efficient. By the time you then use an inverter to change your 12V to 230V, I estimate that you could be tripling your power consumption.

For those of you on 24 volts, an efficient 24 to 12V converter is a reasonable option. I tested the 15" Music TV using our 8A voltage reducer (APX-006 - discontinued) and it used a modest 1 amp on 24 volts.

For the "big end of town", a consumer magazine tested 4 popular brands of large LCD and Plasma televisions for power consumption. Interestingly, the 45/ 46 inch Plasma televisions used 260 –286 watts while the 42/43 inch Plasma televisions used significantly less (183- 186 watts). All four used between 0.67 and 1.4 watts on stand by.

There is no way that an LED lamp can be made 100% efficient due to the inevitable power loss in the driver of the lamp. For this sake, the power loss must be taken into account in the design phase of an LED lighting system. Typically, an LED driver is measured to have an efficiency ranging from 80% to 90%, while an LED driver with a high efficiency over 90% is a high price one. As illustrated in Figure 3, the driver"s efficiency is found as a function of load. It is noted that a load above 50% is recommended for optimized efficiency, namely minimized cost. For indoor use, an efficiency of 87% is highly recommended, while a lower one is recommended for outdoor use or for an extended lifetime.

The power loss leads to a drop in the lamp efficiency, and the number of LED lamps is determined so as to meet the total luminous flux requirement, expressed as:

LED operating current plays a critical role in the lighting efficiency and the lifetime thereof. A rise in the operating current brings about an enhanced output power and requires a smaller number of LEDs, but the price paid is a degraded efficiency, a larger sized LED driver and a shorter life cycle, since there is a high temperature drop across LED heat channels. The minimum, rather than typical, luminous flux requirement, as specified in an LED application note, must be met in the determination of the number of LED lamps. Accordingly, the number of LEDs, SLED, is given as:

where BS denotes the actual luminous flux, and BD the minimum flux emanating from each LED. Since each LED is an independent light source, an LED lamp provides a much longer life cycle than a conventional light source, and can be integrated with novel light sources into an existing lighting system.

Although LED is an energy efficient light source, a large amount of heat consumption is generated in an LED lighting system when a great number of high power LEDs operate concurrently. The efficiency of an LED is found to decrease with the operating current, namely, the operating temperature. In an effort to operate an LED at a high efficiency, the operating temperature must be kept low for sure. A significant heat dissipation improvement has been made using a heat sink to which a high power LED is mounted. In contrast, the outward transfer heat generated by an LED lamp cannot be made as efficient as in the preceding case, due to the thermally non conductive material used in a lamp case. In this context, a steep temperature rise brings about a degraded performance and a shortened lifetime. There is a great challenge when dealing with a theoretical thermal analysis on an LED lamp due to the thermal convection with complicated boundary conditions and the thermal conduction across multiple interfaces. As a matter of fact, there is no need to analyze the heat distribution in a non-equilibrium state, since merely an equilibrium state is the issue of interest. It is an extremely difficult task to evaluate the heat distribution in the interior of a lamp case across multiple interfaces, and what really matters in practical application is whether the temperature falls below the rating. A solution to this problem is the use of thermal resistance theory, an advantage over streamline thermal analysis in this case.

There is a huge difference between the operations of an LED, an incandescent lamp and a fluorescent lamp. Both an incandescent lamp and a fluorescent lamp are devices powered by AC 220 V, albeit a fluorescent lamp requires a rectifier circuit and a switch. Yet, an LED lamp is indeed a DC operated device, meaning that AC 220 V must be rectified into DC in advance. A low efficient LED driver will degrade the total efficiency of the lamp, according to which a way must be found to elevate the driver"s efficiency. In most cases, there are two ways to tune LED intensity, one of which is achieved by the change of DC driving current, and the other is made by pulse width modulation (PWM). The light intensity varies linearly with the driving current, until a threshold is reached. Light efficiency degradation is seen together with a large amount of heat at high driving currents. The light intensity is tuned according to the Talbot-Plateau law in a PWM scheme. Commercial LEDs are available with recommended driver circuits meeting EMI and other safety requirements, leading to a short design phase. Yet, there exists a problem that the drivers recommended are measured as a rule to demonstrate an efficiency of approximately 80%, and driver"s performance variation, affecting the life cycle together with the operating temperature of an LED, appears among those provided by LED manufacturers [10,11].

While the main LED and LCD difference lies in the technology the TV uses to project visuals on screen, each of the two technologies responds to projections and video in a different way.

An LED TV, owing to the technology it uses, flaunts a thinner screen with sharper edges. On the other hand, the two-layer display technology adds bulk to an LCD TV.

Backlight is an important difference between LCD and LED TVs. An LED TV backlight comes in two ways: edge lighting and full array lighting. Unlike an LCD TV that uses CCFL for backlight, most LED TVs use ‘light guides’ to project pictures on the screen. For example: the latest LED Sony TV and LG TV use the edge lit with local dimming technology to present bright visuals.

When comparing LCD vs LED on the parameter of brightness, an LED TV stands out as a winner. This is because it appoints an individual dimming and backlighting system, which in comparison to LCD, makes your projections more defined, authentic, and closer to reality.

LED TVs have superior black levels and employ dynamic contrast mechanisms as compared to LCDs. Colour precision is also more defined in case of LED TV.

LCDs project clear pictures for up to 165 degrees, but projections tend to distort beyond this point. However, LED TVs are equipped to offer you better clarity at all viewing angles.

LED TVs are more energy-efficient as these models use light emitting diodes (LED) for backlighting. These TVs consume less power as compared to cold cathode fluorescent lamps (CCFL), which most LCD TVs use. This results in a power savings of up to 30%.

Owing to the technology on offer, the price of LED TVs is higher as compared to LCD TVs. For instance, to buy an LED TV that is HD Ready, you will have to spend a minimum of Rs. 10,000 and the price will go up with an increase in screen size and technology. Smart TVs, for instance, come with a higher price tag.

The best part about an LED TV is that it can perfectly fit your space, however limited or expansive it may be, courtesy its versatile size and thickness. You can buy LCDs ranging between 13 and 57 inches in size and LEDs of up to 90 inches, based on the available space.

The most common type of LCD TVs today is the flat screen; however, you can also get front projection LCDs that project an image onto a flat screen. When it comes to LEDs, the most common type is the Edge LED TV that spreads the light uniformly behind the screen. You can also find Dynamic RGB LEDs, which offer dimmer or brighter projections on certain areas, and Full-array LEDs that do not offer dimming or brightening of an individual area.

With this comparison, you must have realised that LED TVs are better than LCDs. However, when choosing a TV, understand your viewing requirement first, then choose what suits you the best. If playing games or watching films in high definition is your passion, then choose LED TVs over LCDs.

The distance at which you sit to view the TV and the number of people viewing the TV at once determines the ideal size of a TV. Simply divide the viewing distance by 1.6 to get the ideal TV size for your room!

In the time to come, OLED technology is going to dominate the LED TV market. While some brands like Sony have already launched exceptional OLED TVs, more is yet to come. Unfortunately, LCD TVs will slowly vanish from the market owing to their cumbersome make and limited features.

Ms.Josey

Ms.Josey

Ms.Josey

Ms.Josey