is an lcd panel with a broken ribbon cable unfixable made in china

If that"s the case it should be fairly straight-forward. I"m guessing you already have the screen off; otherwise it wouldn"t have broken, so you probably know how to do that part.

Once the screen is off, you just have to remove the rear cover to get to where the LCD is plugged into the motherboard. Basically just take out a zillion screws, take off the back and flip it over. That whole procedure is shown in this video teardown; all you have to do is follow it up to about the 13:43 mark.

And of course you"ll need a replacement flex cable; you can find those all over the place; eBay, Amazon, AliExpress, etc. Here"s one of the first ones that came up on a search.

This instructable came about from a broken LCD control module out of a modern VW Camper Van. The LCD module is part of a control unit which was virtually unreadable and a replacement for a new unit was £400+. It really was a no lose option, either have a go at fixing it or end up buying a new unit.

The fault of the LCD was that it only displayed a couple lines of output on the LCD. The symptoms are caused by poor location of the LCD ribbon in manufacture and also the poor position of the whole module in the vehicle which exposes it to heat and is subject to vibration within the vehicle. This causes the ribbon to fail eventually and is a known common fault.

The ribbon in this display actually controls the Rows of the LCD matrix and the Columns were handled by a rubber standoff connection on the longest side of the LCD. There were no problems with the rubberized connection.

Some re-work on the LCD ribbon had already been tried with a little improvement but the poor registration of the ribbon pushed me to try a new attachment.

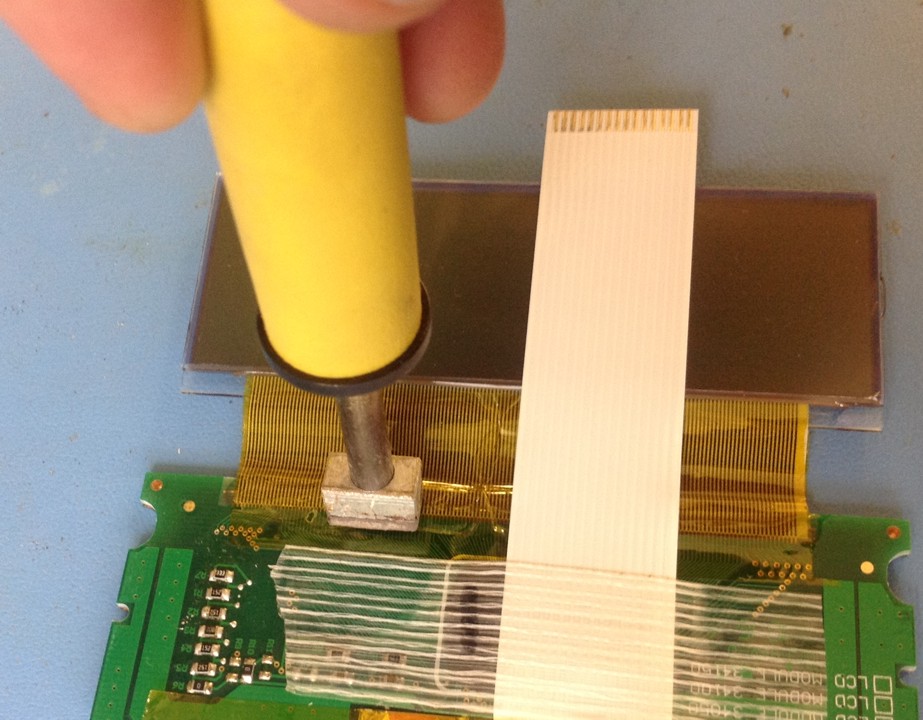

From the photos below you can see the LCD control unit and the state of the LCD ribbon before repair. You can just make out the offset placement and poor registration of the ribbon before repair.

Do not under estimate the patience required for this repair as some delicate and nimble work is required and i cannot stress how important it is to take your time and not rush. You may only get one chance with this sort of repair.

The registrations of the LCD ribbon in this repair was difficult. It took me and my friend 20 minutes just to line up the ribbon for re-attachment. The ribbon in this case is sub 1mm pitch OR less than 25.4 thousands of an inch. You may want to try a simpler ribbon repair on an old LCD clock for example before jumping in head first with fine pitch.

Also the removal of the LCD ribbon is a delicate process as you do not want to tear what is a good ribbon or damage the carbon printed lines. Also the PCB must be respected to avoid introducing other faults and the the re-attachment may need an extra pair of hands.

You may also want to review the last step for results and lessons learned from this instructable before jumping in head first but i believe this will give a you a good insight to some important factors of LCD ribbons and possible success.

Other favorites of reworking the LCD connection that i have read here are the tinfoil on a heat gun. This has good temperature management but not so good in tight spaces. The solder iron with flat blade and tin foil is more precise but a 25 Watt iron can be too brutal on the ribbon.

1. Do you have enough spare ribbon to detach and re-attach? The more ribbon you have the more goes you may get but watch out for the mechanical caveat below.

2. Will you be mechanically constrained if you cut the ribbon. This is a tough one as some shortening of the ribbon may make it impossible to re-assemble the device!!

3. Is the Ribbon continuity visibly good, by that i mean the carbon connection lines are continuous and unbroken - Do check otherwise you may be wasting your time.

In the photos below you can see the available ribbon length was generous enough but do watch for mechanical constraints. In some cases you could find yourself not being able to lay down the LCD back down as it is too tight a radius to sit down.

The ribbon removal needs careful thought depending on your device. It would be difficult to write a complete panacea solution for every device so please use some careful judgement on your device.

You do not want to pull at the ribbon as you will most likely damage what you already have. In my instance it was best to cut the ribbon free as close to the PCB pads as possible.I used a scalpel to slice parallel to the PCB board to remove the ribbon. Do make a good job of this as you may need to preserve as much extra ribbon to re-attach the LCD module.

The LCD assembly was lifted off and put in safe place to avoid damage. The ribbon was then gently lifted and peeled back with tweezers to remove the bulk. You must not use force to remove the remainder ribbon especially if your PCB is off a cheap quality OR single sided cardboard type variety. The PCB pads can come off with the ribbon! If you have a double sided PCB of FR4

If you have a half decent PCB the connecting pads may be gold flashed (actually called Electroless Plated gold). This gold flashing is good as it provides a very good flatness to the PCB pads but they are not as mechanically strong as gold edge connectors (like you see on old PC adapter cards) which is a hard gold . The gold plate here is soft and also micrometer thin on the surface.

For either connection style you need to remove any old glue from the ribbon and remaining carbon debris from the pads. I used isopropanol on a cotton wool bud. Do not flood the PCB with cleaning fluidas you may effect electro-mechanical elements in close proximity such as switches and other items on the PCB which are not sealed against cleaning!

The PCB pads must be thoroughly cleaned and no debris must exist. Use you X10 OR x20 eyepiece here to check how clean the pads are. The PCB pads need to be pristine and nothing less.

From the photos you can see the PCB pads before cleaning through the eyepiece and the final photo shows the clean PCB pads with leftover cotton wool buds.

From the photos you can see that ribbon was trimmed with a rounded scalpel blade. The ribbon also had extra green tape which adhered to the original heel of the PCB pad connection. This gave extra mechanical stability for the ribbon but has to be peeled off to allow for re-connection. Later in this instructable i will mention about putting back extra mechanical stability for ribbon support.

If you have a fine pitch ribbon like i had this will cause you the most trouble. I needed an extra steady pair of hands to help and some patience before i got the the ribbon aligned. It took twenty minutes of nudging the PCB and ribbon to get a precise alignment. Our alignment was actually better than the original which was slightly skewed to one side.

If you do not have an extra pair of hands then i did think of using a large ball of Blu-tak to hold things in place but a second pair of hands is much better!

The trick to get good alignment is to allow some the gold pad fingers toes of the PCB to be visible just beyond the carbon lines of the ribbon. You then get the pads toes to line up with the carbon lines of the LCD ribbon.

Do not continue until you have excellent alignment of the black carbon lines of the ribbon to the PCB pads. The finer the pitch of the ribbon the better registration is required.

The photos below show how i handled the PCB and LCD and clamped the ribbon in place. The LCD display is being held by a plastic clamp above the PCB assembly. The PCB below which has components both sides is laying on some foam (try polystyrene). This allowed me to nudge the PCB under the ribbon into position. The plastic ruler acts as a LCD ribbon clamp. When you have got the registration get a steady handed friend to hold the ruler as a ribbon clamp in place so you can then apply the heat to stick the ribbon back down.

Check out the third photo and you can see what fine pitch means. There are two carbons tracks with a gap in every 1mm (25.4 thou). Now you see why it took twenty minutes to align!

You may want to skip forward to the next step to see the re-attached picture of the ribbon and to see how the alignment was achieved. You should see the gold PCB pad finger toes in line with the carbon of the ribbon

1. Do not apply so much heat you obliterate the ribbon. Yes it sounds stupid but i over cooked one side of my ribbon and got away with it. You may want to test on the bit you trimmed off elsewhere to get correct amount of heat.

2. Only tack the ribbon down my pressing the heated tip down vertically and stroking from the heel to the toe. That is to say in the same line that the carbon lines flows.

Tools for apply heating are up to you but i used a 25W Soldering iron with a wide flat tip covered in tin foil. Warning, the solder iron is too hot with tin foil so i cool it a little by dipping it into a wet sponge just before applying the heat. I used the solder iron tip method because i have more fine control but it did not have a regulated heat. If you have a good soldering iron with temperature control start low and work up to get the right heat.

Again Do not apply heat to the ribbon in one broad stroke. Work from the heel of the ribbon to the toe Or work by dabbing. By dabbing I mean hitting one spot on the ribbon with the heated tip and then lifted vertically again cooling the tip with the wet sponge before each dab.

The second photo in this step is the actual ribbon re-attached. You can see that the left hand side of the ribbon has not worked out as well as the right. I had too much heat in the solder iron. This is how i ended up cooling the solder iron with the wet sponge before applying heat.

In our case the LCD ribbon was not only glued to the PCB pads but there was some additional tape at the heel of the ribbon to hold the ribbon in place. By holding at the heel the ribbon you get some good extra mechanical support.

I did not go further with more re-work as the VW LCD module was considered a good enough result and some other time pressures intervened. It was concluded that we could read the display well enough and operate items from the controller. It was also considered as one of those quit while your ahead things!

For some people this may not be good enough but i hope that some of the steps i have listed will get people going in the correct direction when considering this. I do believe with a little more time a 100% is achievable. I took two hours to dismantle and remove the ribbon, Most of this was thinking things through... and another two hours to re-register and re-attach ribbon.

The technique for LCD ribbon removal and re-attachment are achievable certainly on simpler ribbons and fine pitch ribbons with careful preparation and thought. I hope this instructable is comprehensive enough for people to get some good results.

The ribbon is know as a "Heat Seal Connection" OR "HSC". In the industry heat and pressure are used to make this type of connection. The material comes from a family of "Anisotropic Conductive Films" OR "ACF".

The material bonds at 180 DegreeC. Direct Ribbon connection is used for economy (i.e. no fancy connectors) and for the number of connections its offers in a small footprint which would not be possible through traditional connectors.

The other end of the ribbon that joins to the LCD is terminated on the glass on Indium tin oxide (ITO) which is one of the most widely used transparent conducting oxides.

If you want more information there are many different types of LCM assemby (LCD Display plus it driving chips) to look at but these are the main ones (increasing in density):

In manufacture of these modules a machine is used for assembly which would compress HSC to the LCD Or the PCB and then apply the correct amount of heat.

very nice and complicated work but...my question is, where can I find a ribbon cable like this? I have a keyboard Technics KN2000 with a display not working because the cable was disconnected from both the glass display and the circuit board. Thank You!

I am attempting to fix a TV with vertical lines in it. Actually it was showing a black screen. I cleaned the ribbon connections and now I get an image with some multicolored vertical lines. ( good progress) . When I looked at the ends of the cable some of them were "missing" the last 1 - 2 mm of gold plating? do you think the method you used of slicing the ribbon to even the pads up is a good method? Or is there a way of replating/tinning the missing portions?

These graphite ribbon cables appear to have a layer of clear tape on either side of the graphite paths. To expose a new area of graphite paths for reconnection should the original path be damaged, the tape on one side needs to be peeled back. In my case, when I attempted to peel back the tape some of the paths fragmented and went with the peeled back tape. I suspect that in the case at hand, the peel back was not necessary and heat was used to reattach the previously exposed paths.0

My flat ribbon seems to have a plastic covering on both sides but looks just like your pictures. Must I remove the plastic covering on the attachment side before applying heat to make the connection or does the plastic stay in place and somehow act as a glue when hot?0

Attached is a picture of a screen from a Brookstone clock. I think it may be an LCD. The black pads show where a ribbon cable was connected and I see not transmission paths from the pads into the screen. How does this work? Is it really an LCD?

Are the paths in this ribbon cable covered on both sides as mine is and can you adhere the ribbon without removing any covering by applying heat? And what do I do on the LCD side where there appears to be no pads on the LCD but the ribbon cable was apparently applied in this manner?0

If this was a VW from when I use to drive them back in the 80"s, I would insert a comment here regarding "European automotive electrical systems, a love hate relationship". But since you posted "Modern" VW camper van, I"m assuming the electrical parts have little to do with "Where" the vehicle was manufactured. But back in the day (yeah, I said "Back in the day". I"m old...lol) I was having to fix something electrical on my VW"s once or twice a year on average...lol. But I loved my VW camper vans and continued to buy them. :-)0

I have two items to add, kapton tape and sil-pads used to isolate heat-sinks from semiconductor devices. With kapton tape it brings the means to secure the ribbon to the board, place the tape over the whole connection area, and kapton resists heat very well, ( try and melt it with your soldering iron). This means an average soldering iron turned down will allow heat to be applied to each joint. With experience a rework can be done in a few minutes. The bond can also be renewed on the LCD glass as well, kapton also works here. Sil-pads allow heat to be passed to the joint with some pressure applied at the same time. The sil-pad can be dragged up and down all the ribbon connections allowing uniform heating. Once the bond is resurrected the sil-pad is discarded. http://goo.gl/mpZNkm0

It"s pretty cheap and easier to solder, then you just have to clamp the cable into the connector. Maybe you are interested in reworking that to get all lines back.

Sorry, the connector on the link doesn"t match the board design... you must search for FFC, FPC connectors with the number of vias of your cable and look for the real dimensions on the datasheet.

I just thought the same way, adding aLCD flat connector... then you can swap chinese or VDO oem screens. Seems the VDO LCD(as for Audi A3-Vw golf/jetta4) have 50 pins and the ribbons is 48mm width. Then you have to look to modify the metal bracket to avoid pressure on ribbon.

i would not rule out a connector fix totally but its nice if you can fix for zero cost if possible. Also you then have to manage the mechanical constraints as well as choosing a suitable connector. Usually only the semi flexi PCB circuits ribbons go into connectors not the carbon screen printed sort so may not be so desirable.0

I think........you are a good electronics engineer ...........but I am not as you ......rather I have damaged my 3 calculator by this action.....................!..........................................but you have written very good............!0

I simply lifted the clear tape off from the top of the ribbon, then slowly stroked the ribbon contacts in turn a couple of times with the hot glue gun tip. Not hot enough to cause any damage.

My recommendation is to use a T-iron (see eBay .. about $35USD) which has the added advantage of having a heat shield that protects the insulation leading up to the solder pads.

In the photo i am only using a soldering iron covered in tin foil to heat the plastic ribbon. There is no solder used in this setup. The tin foil is there only to provide a better surface to apply heat to the ribbon (does not stick to the ribbon!!).

Actual Electrical connectivity is provided by carbon lines which are printed in the ribbon. The carbon lines only make contact via the adhesion of the ribbon.

The solder iron method technique is actually too hot and so i dip the solder iron in a sponge to cool it down before pressing down on the ribbon. If you have a temperature controlled soldering iron it would be much better.

i have an alarm clock which doesn"t have a ribbon, but instead some sort of rubbery contact strip against which the display should be pressed. You can find pics of it on google images for "lcd rubber contact strip", it seems to be called a zebra rubber. Any idea on how to glue/solder the display to that rubbery contact strip?More CommentsPost Comment

This website is using a security service to protect itself from online attacks. The action you just performed triggered the security solution. There are several actions that could trigger this block including submitting a certain word or phrase, a SQL command or malformed data.

Afghanistan, Africa, American Samoa, Anguilla, Antigua and Barbuda, Armenia, Aruba, Bahamas, Bahrain, Bangladesh, Barbados, Belize, British Virgin Islands, Brunei Darussalam, Cambodia, Cayman Islands, China, Cook Islands, Costa Rica, Dominica, Dominican Republic, El Salvador, Fiji, French Polynesia, Georgia, Grenada, Guadeloupe, Guam, Guatemala, Haiti, Honduras, Hong Kong, Iceland, India, Indonesia, Iraq, Israel, Italy, Jamaica, Jordan, Kiribati, Kuwait, Laos, Lebanon, Liechtenstein, Macau, Malaysia, Malta, Marshall Islands, Martinique, Micronesia, Montserrat, Nauru, Netherlands Antilles, New Caledonia, Nicaragua, Niue, North America, Norway, Oman, Palau, Panama, Papua New Guinea, Philippines, Qatar, Russian Federation, Saint Kitts-Nevis, Saint Lucia, Saint Vincent and the Grenadines, San Marino, Saudi Arabia, Solomon Islands, South America, Svalbard and Jan Mayen, Taiwan, Tonga, Trinidad and Tobago, Turks and Caicos Islands, Tuvalu, Ukraine, United Arab Emirates, Vanuatu, Virgin Islands (U.S.), Wallis and Futuna, Western Samoa, Yemen

- If the bulbs are out behind the display, then all the rows and colunms do work on the SAAB SID display, but the background light of the SID display is uneven, or some cases the display is completely dark. This case no need to repair the pixels, you do not need a silver ribbon cable, nor a new SID display. This case you just need to buy the lightbulbs that provide light behind the SAAB SID display.

- If the SAAB SID display has really pixel problems, then typically lines or colunms of the display are missing. Several cases the characters are broken, numbers and letters shown on the SAAB SID LCD display are unreadable - the backlight is even. In case of a real pixel problem, when one or more pixels are missing from the SAAB LCD display, you need to buy a silver ribbon cable, a carbon ribbon cable, or some cases a complete SAAB LCD display. It really depends on that if it is a BMW, a Mercedes and Audi, VW, Saab or other make, and of course if it a MID display, a speedometer, a board computer or other LCD dipslay. Most cases, when you have a pixel failure, and you decide to repair it, it"s really worth to buy a set of bulbs too, as bulbs tend to go out during repair - this is due to the massive mechanical shocks experienced during the pixel repair procedure.

Well, most of the SAAB SID LCD display pixel repair kits we sell are designed to be simple and easy to use. The word easy should now be the subject of further discussion. An average SAAB SID pixel repair is far more difficult then replacing a lightbulb. You definitely have to have good mechnical skills, and some household tools, too, such as nippers, screewdrivers, household tape, and other goodies to fix things around the house.

If you have to ask one of these questions, then you definitly should NOT do a SAAB SID LCD display pixel repair at home (we were asked these questions before, this is not a joke):

Well, Pixelfix is an internationally registered trademark. Pixelfix only sells the highest quality SAAB SID cables, that are capable of lifetime operation. We sell most of our repairs with lifetime warranty, and you will find the exact same SAAB SID displays, cables, and other spare parts that we use for professional repairs. Them SAAB SID cables we use for LCD display pixel repair are real silver, which is a very expensive base material, that is why the price is much higher compared to carbon SID cables.

You may keep an eye on your package, if you ordered the SAAB SID cables with postal delivery on you may check the status on your local post office"s website, or if you ordered next day deliver then you need to see TNT / FedEx or DHL tracking site for status.

All SAAB SID displays, SAAB SID cables, speedometer spare parts bought in the webshop will come with an invoice. All invoices are issued electronically, so you will receive an e-mail with the printable invoice in it. This invoce can be printed and filed to the accounts.

No worries, we do provide technical support, and help repairing your SAAB SID display. However there is an advice you ought to consider before starting the work. If you have not done this before, this is mandatory. PLEASE read the manual, and if available watch the video BEFORE starting the work on your SAAB SID display. This will definitely save a lot of time and will help to do a hassle free work.

No worries, this symptom can be due to a bagatel problem which is easy to fix. If there are no pixels on the SAAB SID display at all, that MUST be due to one of the followings:

- the contacts of the SAAB SID display or the SID panel are not perfectly clean - this case there is no contact between the SAAB SID display and the panel

- the alignment of the silver ribbon cable is no good, so the pads of the silver ribbon cable do not match the pads of the SAAB SID LCD display or the SID panel.

Let"s talk about the worst case scenario, you started the repair, but you do not seem to deal with the repair of the SAAB SID display. This case we have a backup solution. We always stand behind our customers, so you may send the SAAB SID LCD display unit to us for repair, and no matter what the condition of the unit is, we can help. More precisely, up to this point we always succeeded, meaning none of our customers managed to do such a damage in the unit that we could not fix. The repair does not cost a fortune, in a lucky case it is 20-30 Euro plus return delivery cost only.

Like anything using proprietary parts that are NLA, it depends on the impact to the system operation. Many of the pre-built desktops from the big names (Dell included) now use mainboards that won"t fit into other than the chassis they ship in -- and use proprietary wiring, power supplies, etc. So it"s either expensive parts replacement (it takes a long time for refurbished parts to completely disappear from the marketplace) or a complete system replacement.

It"s not an issue unique to computers - it"s becoming common with automobiles. Once a module becomes NLA, if it"s critical to vehicle operation, the car becomes a total loss. Just look at any one of the cars these days having a completely LCD display system in the dashboard -- what are the chances that in 10-20 years, these parts will still be available?

Building custom cables is one thing -- designing a complete aftermarket dash display is quite another. Yes, repair is possible - but with highly integrated displays depending on hundreds or more discrete, under-$1.00 components not available to the repair industry, we"ve likely reached a point where in 20-30 years, today"s cars will not be tomorrow"s classics -- they will have been long recycled into something else.

![]()

We know that it may be so if homoeopathic practitioners will but use their influence among medical men and medical students to secure a well filled class-room. HAHNEMANN PUBLISHING SOCIETY. THE annual meeting of this Society will be held at the " Royal Hotel," Matlock, Bath, at 8 o"clock in the evening of Wednesday, September 12th ; and, if necessary, by adjournment, at 9 am on Thursday the 18th.

THE melancholy days are come, the saddest of the year, Of wailing winds, and naked woods, and meadows brown and sere. Heaped in the hollows of the grove, the autumn leaves lie dead ; They rustle to the eddying gust, and to the rabbit"s tread ; The robin and the wren are flown, and from the shrubs the jay, And from the wood-top calls the crow through all the gloomy day. Where are the flowers, the fair...

Ordinance 1908." 2. The Governor in Council may from time to time make such orders as may to the Governor in Council appear expedient for preventing the introduction into the Colony of any insect, fungus or other pest...

Abies balsamea, from which it is distinguished by its sharp-pointed leaves. The flowers are unknown. The branches are used for adorning the churches in Mexico. According to Mr. Lambert, the cones are like those of the cedar of Lebanon, but...

This storm shows some very curious and interesting features, in the remarkable violence of the wind, rain and hail, within a small area, and the suddenness with which it burst. There was an area of thunderstorms over the whole of the south of England on the evening of that day. The most violent storm, however, burst over Grayshott on Hindhead at 8.20, and pursued a narrow track through Godalming and Guildford to Ripley, б miles north-east of Guildford.

Garden at Wisley, conforming to the general rules laid down there for Students. In the second year of the Scholarship he may, if he like, continue his studies at some other place at home or abroad which is approved by the Council of the Royal Horticultural Society. In case of two or more eligible students being adjudged equal, the Council reserve to themselves the right to decide which of them shall be presented to the Scholarship.

It is told with freshness and pathos, and should bo one of the most popular as it is one of the most helpful of children"s books. The Cruise of the "Petrel:

England or elsewhere, such offender and any person aiding him shall be guilty of felony and be punished by transportation for seven years, or by imprisonment (with or without hard labour) for a term not exceeding two years.Less

Ms.Josey

Ms.Josey

Ms.Josey

Ms.Josey