arduino tft lcd temperature manufacturer

In this Arduino touch screen tutorial we will learn how to use TFT LCD Touch Screen with Arduino. You can watch the following video or read the written tutorial below.

As an example I am using a 3.2” TFT Touch Screen in a combination with a TFT LCD Arduino Mega Shield. We need a shield because the TFT Touch screen works at 3.3V and the Arduino Mega outputs are 5 V. For the first example I have the HC-SR04 ultrasonic sensor, then for the second example an RGB LED with three resistors and a push button for the game example. Also I had to make a custom made pin header like this, by soldering pin headers and bend on of them so I could insert them in between the Arduino Board and the TFT Shield.

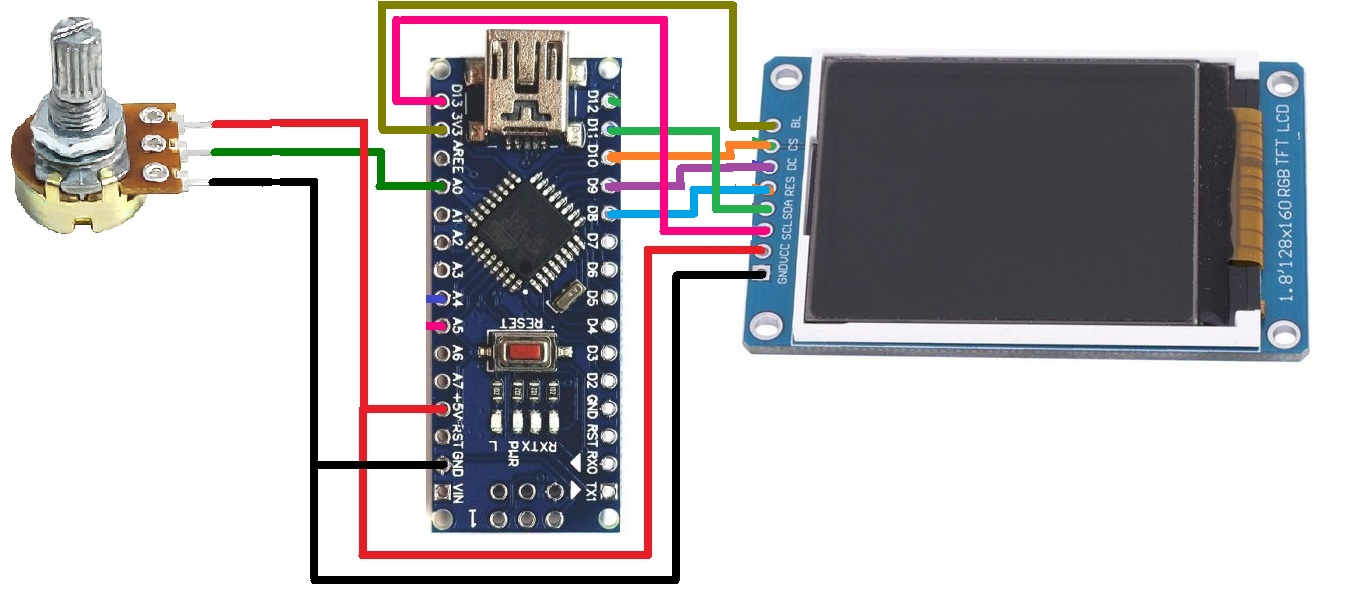

Here’s the circuit schematic. We will use the GND pin, the digital pins from 8 to 13, as well as the pin number 14. As the 5V pins are already used by the TFT Screen I will use the pin number 13 as VCC, by setting it right away high in the setup section of code.

I will use the UTFT and URTouch libraries made by Henning Karlsen. Here I would like to say thanks to him for the incredible work he has done. The libraries enable really easy use of the TFT Screens, and they work with many different TFT screens sizes, shields and controllers. You can download these libraries from his website, RinkyDinkElectronics.com and also find a lot of demo examples and detailed documentation of how to use them.

After we include the libraries we need to create UTFT and URTouch objects. The parameters of these objects depends on the model of the TFT Screen and Shield and these details can be also found in the documentation of the libraries.

So now I will explain how we can make the home screen of the program. With the setBackColor() function we need to set the background color of the text, black one in our case. Then we need to set the color to white, set the big font and using the print() function, we will print the string “Arduino TFT Tutorial” at the center of the screen and 10 pixels down the Y – Axis of the screen. Next we will set the color to red and draw the red line below the text. After that we need to set the color back to white, and print the two other strings, “by HowToMechatronics.com” using the small font and “Select Example” using the big font.

In order the code to work and compile you will have to include an addition “.c” file in the same directory with the Arduino sketch. This file is for the third game example and it’s a bitmap of the bird. For more details how this part of the code work you can check my particular tutorial. Here you can download that file:

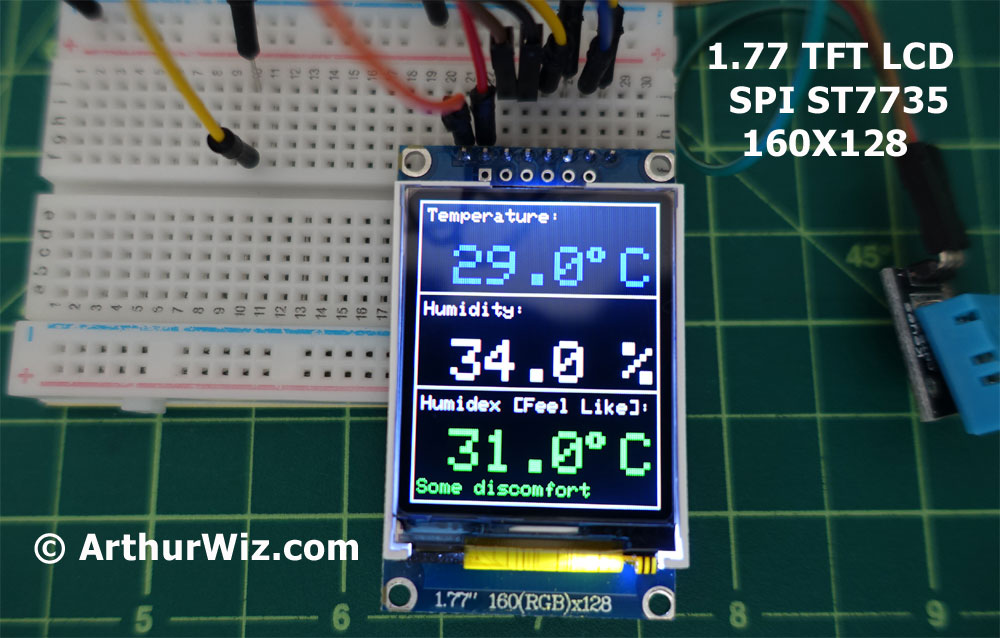

But i don"t know how to combine the lcd and dht22 so i can watch temperature and humidity on lcd instead monitor. If i had some code or schematic help i would do it easy, but i"m very bad at code.

The DHT11 is an all-in-one temperature and humidity digital sensor that includes an internal resistive moisture measurement element and an NTC temperature measurement element and is connected to a high performance 8-bit micro-controller.

A simple external circuit connection is all that is needed to collect local temperature and humidity in real time. the DHT11 communicates with controllers such as micro-controllers using a simple single bus, requiring only one I/O port.

The sensor internal temperature and humidity data 40Bit is transmitted to the micro-controller at once, and the data is checked by means of checksum, which effectively ensures the accuracy of data transmission.

The Arduino Uno is an ATmega328P based micro-controller board. It has 14 digital input/output pins (6 of which can be used as PWM outputs), 6 analog inputs, a 16MHz ceramic resonator (CSTCE16M0V53-R0), a USB connection, a power socket, an ICSP header, and a reset button.

To develop based on our STONE TFT LCD, you first need to use to an upper computer development software STONE designer, in this upper computer, all screen-related settings are carried out in this upper computer, so how to download it, click the link below to go to the official website:https://www.stoneitech.com/support/download

First add a button control to the temperature, select “button” control, and draw the corresponding area; then in the right feature settings, set the button effect, here select page 2, that is, when the button is pressed, the corresponding area to display the effect of page 2; then select the page switch function, here select the No. 4 page, that is, when this button is pressed, the page will immediately switch to page 4, that is, the temperature display interface.

Under the temperature display interface, a text display control is needed to display the real-time temperature data passed by the Arduino, so it is necessary to add a data variable control, as shown in the following figure.

The STONE TFT LCD sometimes needs to control the micro-controller to achieve a two-way interaction, which is also the case here, and needs to implement the start and stop acquisition function, using the START button as an example.

In this article, you will learn how to use TFT LCDs by Arduino boards. From basic commands to professional designs and technics are all explained here.

There are several components to achieve this. LEDs, 7-segments, Character and Graphic displays, and full-color TFT LCDs. The right component for your projects depends on the amount of data to be displayed, type of user interaction, and processor capacity.

TFT LCD is a variant of a liquid-crystal display (LCD) that uses thin-film-transistor (TFT) technology to improve image qualities such as addressability and contrast. A TFT LCD is an active matrix LCD, in contrast to passive matrix LCDs or simple, direct-driven LCDs with a few segments.

In Arduino-based projects, the processor frequency is low. So it is not possible to display complex, high definition images and high-speed motions. Therefore, full-color TFT LCDs can only be used to display simple data and commands.

There are several components to achieve this. LEDs, 7-segments, Character and Graphic displays, and full-color TFT LCDs. The right component for your projects depends on the amount of data to be displayed, type of user interaction, and processor capacity.

TFT LCD is a variant of a liquid-crystal display (LCD) that uses thin-film-transistor (TFT) technology to improve image qualities such as addressability and contrast. A TFT LCD is an active matrix LCD, in contrast to passive matrix LCDs or simple, direct-driven LCDs with a few segments.

In Arduino-based projects, the processor frequency is low. So it is not possible to display complex, high definition images and high-speed motions. Therefore, full-color TFT LCDs can only be used to display simple data and commands.

After choosing the right display, It’s time to choose the right controller. If you want to display characters, tests, numbers and static images and the speed of display is not important, the Atmega328 Arduino boards (such as Arduino UNO) are a proper choice. If the size of your code is big, The UNO board may not be enough. You can use Arduino Mega2560 instead. And if you want to show high resolution images and motions with high speed, you should use the ARM core Arduino boards such as Arduino DUE.

In electronics/computer hardware a display driver is usually a semiconductor integrated circuit (but may alternatively comprise a state machine made of discrete logic and other components) which provides an interface function between a microprocessor, microcontroller, ASIC or general-purpose peripheral interface and a particular type of display device, e.g. LCD, LED, OLED, ePaper, CRT, Vacuum fluorescent or Nixie.

The LCDs manufacturers use different drivers in their products. Some of them are more popular and some of them are very unknown. To run your display easily, you should use Arduino LCDs libraries and add them to your code. Otherwise running the display may be very difficult. There are many free libraries you can find on the internet but the important point about the libraries is their compatibility with the LCD’s driver. The driver of your LCD must be known by your library. In this article, we use the Adafruit GFX library and MCUFRIEND KBV library and example codes. You can download them from the following links.

You must add the library and then upload the code. If it is the first time you run an Arduino board, don’t worry. Just follow these steps:Go to www.arduino.cc/en/Main/Software and download the software of your OS. Install the IDE software as instructed.

First you should convert your image to hex code. Download the software from the following link. if you don’t want to change the settings of the software, you must invert the color of the image and make the image horizontally mirrored and rotate it 90 degrees counterclockwise. Now add it to the software and convert it. Open the exported file and copy the hex code to Arduino IDE. x and y are locations of the image. sx and sy are sizes of image. you can change the color of the image in the last input.

Upload your image and download the converted file that the UTFT libraries can process. Now copy the hex code to Arduino IDE. x and y are locations of the image. sx and sy are size of the image.

In this template, We converted a .jpg image to .c file and added to the code, wrote a string and used the fade code to display. Then we used scroll code to move the screen left. Download the .h file and add it to the folder of the Arduino sketch.

In this template, We used sin(); and cos(); functions to draw Arcs with our desired thickness and displayed number by text printing function. Then we converted an image to hex code and added them to the code and displayed the image by bitmap function. Then we used draw lines function to change the style of the image. Download the .h file and add it to the folder of the Arduino sketch.

In this template, We added a converted image to code and then used two black and white arcs to create the pointer of volumes. Download the .h file and add it to the folder of the Arduino sketch.

In this template, We added a converted image and use the arc and print function to create this gauge. Download the .h file and add it to folder of the Arduino sketch.

while (a < b) { Serial.println(a); j = 80 * (sin(PI * a / 2000)); i = 80 * (cos(PI * a / 2000)); j2 = 50 * (sin(PI * a / 2000)); i2 = 50 * (cos(PI * a / 2000)); tft.drawLine(i2 + 235, j2 + 169, i + 235, j + 169, tft.color565(0, 255, 255)); tft.fillRect(200, 153, 75, 33, 0x0000); tft.setTextSize(3); tft.setTextColor(0xffff); if ((a/20)>99)

while (b < a) { j = 80 * (sin(PI * a / 2000)); i = 80 * (cos(PI * a / 2000)); j2 = 50 * (sin(PI * a / 2000)); i2 = 50 * (cos(PI * a / 2000)); tft.drawLine(i2 + 235, j2 + 169, i + 235, j + 169, tft.color565(0, 0, 0)); tft.fillRect(200, 153, 75, 33, 0x0000); tft.setTextSize(3); tft.setTextColor(0xffff); if ((a/20)>99)

In this template, We display simple images one after each other very fast by bitmap function. So you can make your animation by this trick. Download the .h file and add it to folder of the Arduino sketch.

In this template, We just display some images by RGBbitmap and bitmap functions. Just make a code for touchscreen and use this template. Download the .h file and add it to folder of the Arduino sketch.

WF43WTYBEDSG0 is a 4.3-inch IPS TFT-LCD display with a Capacitive Touch screen, made of resolution 480x272 pixels. This module is built-in with BT815 controller IC, and it supports SPI and QSPI interfaces. The QSPI interface can achieve four times data rate compared with the current SPI interface and make a smoother display accordingly. The series of BT815/6 controller IC with EVE (Embedded Video Engine) technology simplifies the system architecture, Eve technology is a revolutionary concept that utilizes an object-oriented approach to creating high-quality human-machine interfaces (HMI). This new technology supports display, audio and touch, enabling engineers to quickly and efficiently design HMI and provide a powerful solution for high-resolution displays that reduce material costs.

We offer the TFT module WF43WTYBEDSG0#000 designed to support the Arduino board. The control signal for WF43WTYBEDSG0 is 3.3V; it has a built-in storage device (FLASH 32M). The control signal of WF43WTYBEDSG0#000 is 5V; without a built-in storage device (FLASH); but with a MicroSD Socket, pins CON1~CON4 are designed for SPI control (such as for Arduino Uno Rev3). WF43W model can be operating at temperatures from -20℃ to+ 70℃ and storage temperatures from -30℃ to +80℃.

STONE intelligent TFT LCD display module manufacturer focuses on the research and development of HMI display module products, which are widely used in the fields of medical equipment LCD, industrial terminal TFT LCD, civil terminal display screen, and intelligent home control panel.(Click here to see the Display Heart Rate on the LCD with Arduino development case: https://www.stoneitech.com/arduino-lcd-display-project

low voltage application, low drive voltage, solid use safety, and reliability improvement; Flat, light, and thin, saving a lot of raw materials and space; Low power consumption, its power consumption is about one-tenth of the CRT display, reflective TFT-LCD is only about one percent of the CRT, saving a lot of energy; TFT LCD products also have specifications, models, size series, variety, convenient and flexible use, maintenance, update, upgrade easy, long service life and many other characteristics.

no radiation, no flicker, no harm to users’ health. In particular, the appearance of TFT-LCD electronic books and periodicals will bring mankind into the era of a paperless office and paperless printing, and trigger the revolution of human learning, communication, and recording civilization.

From -20℃ to +50℃ temperature range can be used normally, after temperature reinforcement TFT-LCD low temperature working temperature can reach minus 80℃. It can be used as a mobile terminal display, desktop terminal display, and large screen projection TV. It is a full-size video display terminal with excellent performance.

It is a perfect combination of large-scale semiconductor integrated circuit technology and light source technology and has great potential for further development. There are amorphous, polycrystalline, and monocrystalline TFT-LCDs, and there will be TFTs of other materials, both glass, and plastic.

The first generation of large-area glass substrate (300mm×400mm) TFT-LCD production line was put into production in the early 1990s. By the first half of 2000, the area of glass substrate has been expanded to 680mm×880mm.

TFT was first used as a matrix location circuit to improve the characteristics of liquid crystal optical valves. For high-resolution display screens, the accurate control of object elements is achieved through voltage adjustment in the range of 0-6v (its typical value is 0.2 to 4V), thus making it possible for LCD to achieve a high-quality high-resolution display.

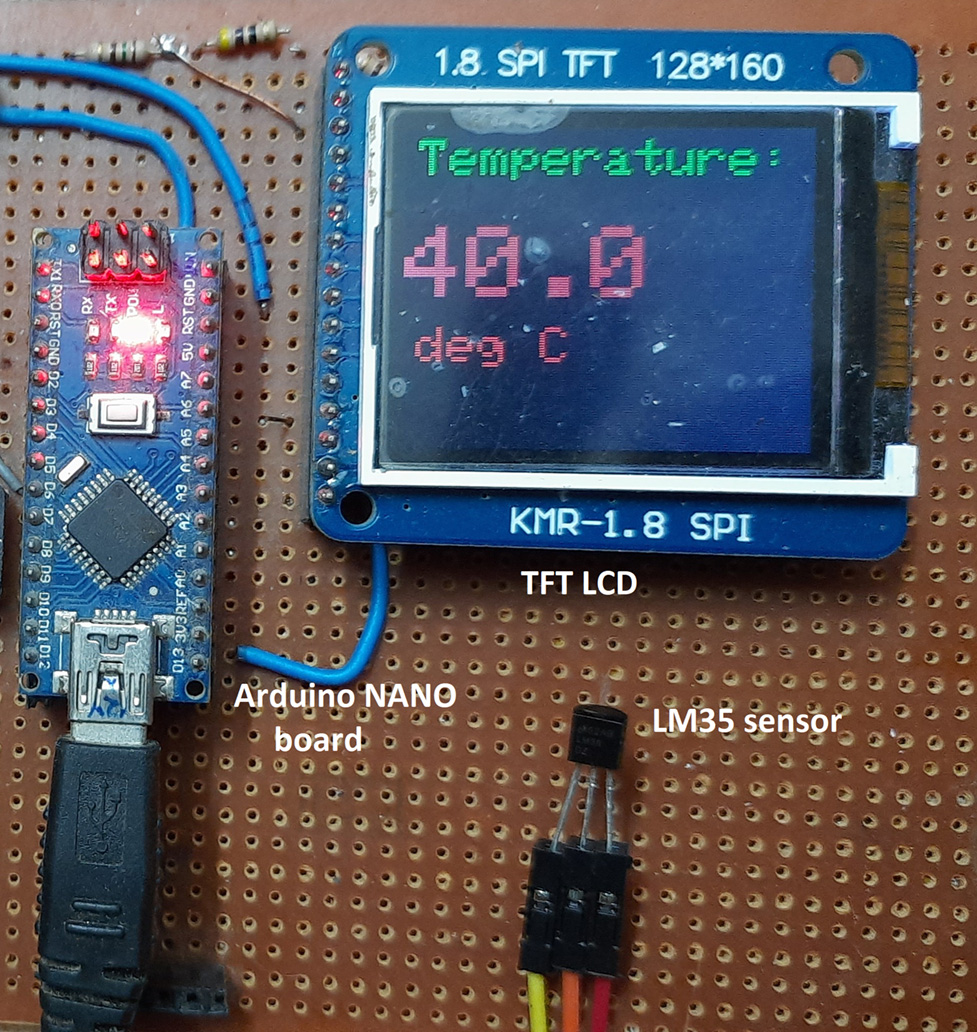

This paper describes data acquisition with an Arduino Nano from eight DS18B20 temperature sensors and four DHT11 relative humidity sensors. The data are displayed on a 3.5″ 320×480 pixel color TFT screen.

As a home owner living in a country with a moderate, often moist climate I am interested in the continuously changing relative humidity conditions and in the daily change in temperatures inside and outside my home. Monitoring various temperatures became more interesting when I acquired a solar thermal water heater together with several solar panels that each have their (micro)inverter. The temperature of a solar device is directly related to how successful it is running. Think about hot ‘solar’ water for your shower! Failure of such a device reveals itself by a flat temperature or a temperature that stays close to the ambient room temperature. Keeping an eye on temperatures may thus save energy.

Recently I started an attempt to reduce central heating energy use through playing with the unit’s hot water circulating water thermostat. For this I needed multiple temperature sensors at various strategic positions. An additional condition was that data should be displayed neatly arranged and immediately visible in an aesthetic manner.

With an Arduino microcontroller board equipped with temperature and relative humidity sensors my aim should be attainable. The condition to display all data permanently and visible at a single glance is better provided by a 320×480 pixel color TFT display than with a 16×2 or 20×4 character monochrome LCD display. This was a decisive factor to go for a TFT display.

The ‘Arduino’ marketplace supplies us with many cheap temperature and humidity sensors. For the relative humidity data acquisition I selected the DHT11 sensor and I decided to use this device in pairs to cope with their inaccuracy. While a DHT11 measures also temperature next to humidity they do so with a miserable accuracy range of two degrees Celsius. A much more accurate temperature sensor (tenth of degrees Celsius) is Maxim’s Dallas DS18B20. Its clever design allows multiple sensors running on a single bus. This is a very valuable feature given the fact that a TFT screen ‘consumes’ many digital pins on an Arduino board.

As TFT displays are typically marketed as shields, the Arduino Uno Mega would be the typical platform of choice. However, for the purpose of building an ultra compact monitoring device and also to challenge myself I started a project aiming at the creation of a multi-temperature- and humidity display with a 320×480 color TFT screen using the Arduino Nano as its microcontroller platform. The Nano’s attractiveness lies in its reduced dimensions which makes it a microcontroller board that can be hidden behind a big TFT display in a small assembly mounted in a modest, attractive casing.

I bought a nameless 3.5 inch color TFT LCD shield for the Arduino UNO (figure 3). Doing so is risky because there is no uniformity in TFT controllers, and nameless displays usually arrive without any documentation or software drivers. This particular display had two advantages: 1) it appeared compatible with the mcufriend.kbv library, 2) background lighting is very uniform, which makes this screen particularly attractive. Note that ordering this screen was a gamble. If gambling and experimenting are is not your favorite occupations an Adafruit 3.5″ 320×480 pixel color TFT touchscreen breakout with its lavish documentation and company support is recommended.

The TFT shield plugs nicely into an Arduino Uno but then covers non-connected pins that are necessary for getting sensor data. Wire connectivity between the microcontroller board and the TFT screen uses 16 wires, and an additional four wires are necessary for the SD slot to function. The total amounts to 20 wires capturing almost all available pins on an Arduino Nano! In my configuration I needed next to TFT connectivity another four pins on the microcontroller board to connect the four DHT11s, plus one pin for the one-wire DS18B20 connectivity. To free pins I sacrificed the SD connectivity. Pin connectivity between TFT display shield and the Nano is shown in figure 3.

Gear whose operating temperatures I wanted to monitor is mostly located in the loft, approximately 10 meters away from my tiny hobby office. The loft currently hosts five DS18B20 probes at various locations. An 8-wire twisted pair cable (cable #1) obtained from a computer store (plain network cable without connectors) was drawn from my office to the loft. Of the 8 available wires, only three were used: one 5V line (orange wire), one GND line (blue wire) and one wire for the DS18B20 data bus (white-blue striped wire). One advantage for the DS18B20 one-wire concept is that considerable cable distances are supported. I assume that twisted-pair cable favors signal separation as it does in fast computer networks.

A wiring diagram is shown in figure 4. ‘Attic’ temperature probes were taped onto the hot water and return pipes of the central heating (CH) unit (probes 01 and 02), on casings of solar energy grid tie inverters (probes 03 and 08), one sensor was left hanging loose (probe 04, ambient loft air temperature), and one was taped onto the hot tap water pipe coming out of the storage tank of the solar water heating system (probe 06) (as close as possible to the hot interior of the tank).

In addition I ran a twisted pair cable (cable #2) in my office to a distribution box from which wires run via a drilled hole in a window frame to a DHT11 pod mounted outside. This pod (fIgure 1) holds a pair of DHT 11s and it is mounted in a weather-shielded, shady spot. Immediately next to this ‘outside’ pod I installed one DS18B20 temperature sensor to measure the temperature outside the home. Of the eight available wires in the connecting cable I used five: orange (5V), blue (GND), white-brown striped (DHT11-1-DATA), white-orange striped (DHT11-2-DATA), and white-blue striped (DS18B20 data).

Both cables were connected to a junction box on the wall in my office and from here a common final cable (#3) runs to the Arduino Nano. Because I wanted to measure the relative humidity and air temperature in my office, the junction box was decorated with an add ional DHT11 ‘pod’ and apart from that with a DS18B20 probe (probe 07). The data pin of probe 07 was connected to the white-blue-striped wires whilst the two DATA wires from the pair of DHT11’s inside the pod were connected to the wires green and the white-green-striped wires of cable #3. In summary the color codes wires in the common final cable #3 that leads to the Nano correspond with the following sensors:

Pin connectivity between the Arduino Nano and the sensors and display are illustrated in figure 5A. The pin layout is mostly standard TFT shield connectivity (i.e., as if placed on an Arduino UNO). The only difference here is that the wires belonging to the SD part of the shield are not connected since I needed five pins to connect sensors to. The tradeoff of assigning these pins to the humidity and temperature sensors is that the SD functionality of the TFT shield is not available.

The result of the entire project is shown in figure 5B. The seven temperature sensors and four humidity sensors provide a clean and continuous data stream concerning temperatures and relative humidities on various spots inside and outside the home. The 3.5 inch TFT display has even space to accommodate more readings. It is tempting to add more DS18B20 sensors to the one-wire bus to measure temperatures of more solar inverters. keeping an eye on casing temperatures of solar tie grid inverters is very convenient because an inverter produces heat and, conversely, if an inverter malfunctions its temperature goes down to the ambient temperature. The sensor can be considered a good ‘health’ indicator for solar inverters!

The next challenge is to log the acquired data. One way to do so could be via data transfer to another Arduino equipped with a logging shield. Another option is to send data via the home computer network to a network storage unit for later analysis. However, the sketch controlling the TFT display and the data acquisition contains code that draws heavily on the Nano’s ATmega328 storage space and the available dynamic memory. The sketch consumes 74% of available program storage space (23k out of 30k) while global variables take 1,364 bytes of 2,048 available bytes of dynamic memory. The most urgent action for the moment may be compression of the sketch to reduce the use of memory storage in the Nano as much as possible.

We thinks what prospects think, the urgency of urgency to act from the interests of a client position of theory, allowing for greater high-quality, reduced processing costs, rates are much more reasonable, won the new and previous consumers the support and affirmation for Arduino Uno Tft Display, Lcd And Touch Screen, Scratch On Monitor, Small Tft Lcd Display,Front Panel Lcd. Our mission is to help you create long-lasting relationships with your clients through the power of promotional products. The product will supply to all over the world, such as Europe, America, Australia,Sacramento, Roman,Czech, Dubai.We can meet the various needs of customers at home and abroad. We welcome new and old customers to come to consult & negotiate with us. Your satisfaction is our motivation! Allow us to work together to write a brilliant new chapter!

The main algoritm is taking the recent temperature and humidity values from related environment which the sensor has located, we see the results on the display. Since the display is multicolored, I add colored response when it is hot or cold. These are:if (DHT.temperature > 30){

In this guide we’re going to show you how you can use the 1.8 TFT display with the Arduino. You’ll learn how to wire the display, write text, draw shapes and display images on the screen.

The 1.8 TFT is a colorful display with 128 x 160 color pixels. The display can load images from an SD card – it has an SD card slot at the back. The following figure shows the screen front and back view.

This module uses SPI communication – see the wiring below . To control the display we’ll use the TFT library, which is already included with Arduino IDE 1.0.5 and later.

The TFT display communicates with the Arduino via SPI communication, so you need to include the SPI library on your code. We also use the TFT library to write and draw on the display.

The 1.8 TFT display can load images from the SD card. To read from the SD card you use the SD library, already included in the Arduino IDE software. Follow the next steps to display an image on the display:

In this guide we’ve shown you how to use the 1.8 TFT display with the Arduino: display text, draw shapes and display images. You can easily add a nice visual interface to your projects using this display.

TFT (Thin Film Transistor) LCD (Liquid Crystal Display) dominates the world flat panel display market now. Thanks for its low cost, sharp colors, acceptable view angles, low power consumption, manufacturing friendly design, slim physical structure etc., it has driven CRT(Cathode-Ray Tube) VFD ( Vacuum Fluorescent Display) out of market, squeezed LED (Light Emitting Diode) displays only to large size display area. TFT LCD displays find wide applications in TV, computer monitors, medical, appliance, automotive, kiosk, POS terminals, low end mobile phones, marine, aerospace, industrial meters, smart homes, handheld devices, video game systems, projectors, consumer electronic products, advertisement etc. For more information about TFT displays, please visit our knowledge base.

There a lot of considerations for how to choose a most suitable TFT LCD display module for your application. Please find the check list below to see if you can find a right fit.

Resolution will decide the clearance. Nobody likes to see a display showing pixel clearly. That is the reason for better resolution, going from QVGA, VGA to HD, FHD, 4K, 8K. But higher resolution means higher cost, power consumption, memory size, data transfer speed etc. Orient Display offers low resolution of 128×128 to HD, FHD, we are working on providing 4K for our customers. For full list of resolution available, please see Introduction: LCD Resolution

TFT screen brightness selection is very important. You don’t want to be frustrated by LCD image washout under bright light or you drain the battery too fast by selecting a super brightness LCD but will be used indoor only. There are general guidance listed in the table below.

Orient Display offers standard brightness, medium brightness , high brightness, and high end sunlight readable IPS TFT LCD display products for our customers to choose from.

If the budget is tight, TN type TFT LCD can be chosen but there is viewing angle selection of either 6 o’clock or 12 o’clock. Gray scale inversion needs to be taken of carefully. If a high-end product is designed, you can pay premium to select IPS TFT LCD which doesn’t have the viewing angle issue.

It is similar to viewing angle selection, TN type TFT LCD has lower contrast but lower cost, while IPS TFT LCD has much high contrast but normally with higher cost. Orient Display provides both selections.

Normal TFT LCD displays provide wide enoughtemperature range for most of the applications. -20 to 70oC. But there are some (always) outdoor applications like -30 to 80oC or even wider, special liquid crystal fluid has to be used. Heater is needed for operating temperature requirement of -40oC. Normally, storage temperature is not an issue, many of Orient Display standard TFT display can handle -40 to 85oC, if you have any questions, feel free to contact our engineers for details.

Power consideration can be critical in some hand-held devices. For a TFT LCD display module, backlight normally consumes more power than other part of the display. Dimming or totally shutdown backlight technology has to be used when not in use. For some extreme power sensitive application, sleep mode or even using memory on controller consideration has to be in design. Feel free to contact our engineers for details.

High Level Interfaces: Orient Display has technologies to make more advanced interfaces which are more convenient to non-display engineers, such as RS232, RS485, USB, VGA, HDMI etc. more information can be found in our serious products. TFT modules, Arduino TFT display, Raspberry Pi TFT display, Control Board.

If you can’t find a very suitable TFT LCD Display in our product line, don’t be discouraged. The products listed on our website is only small part of standard products. We have thousands of standard products in our database, feel free to contact our engineers for details.

If you like to have a special display, Orient Display is always flexible to do partial custom solution. For example, to modify the FPC to different length or shape, or use as fewer pinouts as possible, or design an ultra-bright LCD display, or a cover lens with your company logo on it, or design an extreme low power or low cost TFT display etc. our engineers will help you to achieve the goals. The NER cost can start from hundreds of dollars to Thousands. In rare case, it can be tens of thousands of dollars.

A fully custom TFT LCD panel can have very high NRE cost. Depending on the size of the display, quantity and which generation production line to be used. The tooling cost can start from $100,000 to over $1M.

This is the 2.4 inch touch screen for Arduino UNO and MEGA. It use 8-bit parallel bus, faster than serial SPI refresh , support 16-bit RGB 65K color display, display rich colors , easy to expand the experiment with SD card slot.

Ms.Josey

Ms.Josey

Ms.Josey

Ms.Josey