flexible transparent lcd screen free sample

Free sample for Flexible Display Programmable Transparent Led Curtain Wall. #transparentledcurtaindisplay #transparentledpanel #transparentledposter #transparentledvideoscreen #leddisplaytransparent #glasswindowleddisplay #transparentleddisplayglass #transparentledfilmdisplay #transparentledtv, www.szradiant.com , email:info@szradiant.com skype:radiant-led , wechat:+86-13902918225

TheTOUCH DEMO 1-5 P FOX is a bundle of TASEL® display panel (Lumineq Touch TASEL display), flexible printed circuit (FPC) cables and driving electronics. With the product, Lumineq customers can experiment with integrated touch technology.

Alibaba.com offers 45 8 inch flexible transparent lcd display products. About 35% % of these are lcd modules, 28%% are digital signage and displays, and 11%% are oled/e-paper modules.

A wide variety of 8 inch flexible transparent lcd display options are available to you, such as advertising publish, shopping mall and exhibition hall.You can also choose from touch screen, kiosk 8 inch flexible transparent lcd display,As well as from sdk, {2}, and {3}. and whether 8 inch flexible transparent lcd display is original manufacturer, oem, or odm.

Awesome little transparent OLED display. Its a 128x56 pixels and 1.51 inch diagonal. Super-bright, monochrome (light blue). We powered it up with a Seeeduino for this demonstration.

Instead of a few hundred thousand thermostats, gas pumps and credit card terminals that use monochrome character or graphic LCDs being the driving market for small displays, we now have giant companies turning out hundreds of millions of cell phones, each with an incredible display that was barely thinkable only 20 years ago.

We are happy to say that we are adding both flexible and transparent displays to the Crystalfontz lineup. Please see the top of this post for the latest additions.

At Crystalfontz, we strive to keep each of our displays available indefinitely. The first CFA-634 LCDs first shipped in 1999 and the CFA-634 is still available today — keeping backward compatibility even as we upgrade technology and add features.

TransPrint is a method for fabricating flexible, transparent free-form displays based on electrochromism. Using screen-printing or inkjet printing of electrochromic ink, plus a straightforward assembly process, TransPrint enables rapid prototyping of displays by nonexperts. The displays are nonlight-emissive and only require power to switch state and support the integration of capacitive touch sensing for interactivity. We present instructions and best practices on how to design and assemble the displays and discuss the benefits and shortcomings of the TransPrint approach. To demonstrate the broad applicability of the approach, we present six application prototypes.

Recently, the field of printed electronics has developed to the point at which thin and deformable interactive prototypes can be created at low cost, e.g., as design prototypes [1–3]. Prior work has focused on extending printing methods to create interactive materials such as flexible touch sensors, thin film displays, and even haptic feedback [4–7]. Especially, printed electronics displays have the potential to overcome the limitations of current digital display technologies, enabling more interactivity and new form-factors. Moving away from the square pixel-based architecture, which is dominant in today’s display technologies, has been highlighted as a key factor to deliver truly ubiquitous technologies [8].

In this paper, we present TransPrint, an adaptable method that enables the production of flexible, transparent displays in highly customizable shapes by the maker community and other nonexperts (see Figure 1). TransPrint is based on electrochromism (EC), i.e., the property of materials to reversibly switch their optical properties, e.g., colour, through electrochemical oxidization. For TransPrint, this switch is between near-transparency and a dark blue opaque colour.

While EC-based displays have been well established and most characteristics of the different materials have been well investigated in the past, constructing these displays usually required laboratory settings [11]. With TransPrint we present a method that allows nonexperts to produce EC-based displays with commercially available materials. We present two ways of printing such displays using either screen-printing or inkjet printing. Both methods are rapid and inexpensive and only require a limited amount of hardware and technical knowledge. We show how to integrate these printed displays with static printed elements as well as new application scenarios stemming from the unique traits of TransPrint displays. Furthermore, we discuss how support for capacitive touch input can be easily incorporated. With this we hope to enable the community to adapt such displays and embed them in future research, e.g., in the realm of printed electronics for interaction.

In this paper, we firstly discuss related work in the fields of printed electronics and displays, focusing on electrochromic systems and transparent displays. We then provide background on the operation of electrochromic displays in general and describe the TransPrint approach to design, print, and assemble displays. Following this, we present an analysis of the key characteristics of the created displays. Finally, we present a set of application cases that demonstrate the possibilities of TransPrint displays.

A variety of different approaches to print these new materials have been presented, the most common being inkjet printing and screen-printing. Recently hydroprinting—printing via water transfer—has been employed to print touch screens on highly curved organic geometries [24]. Kuznetsov et al. analysed the potential of screen-printing as a DIY fabrication technique for embedding interactive behaviour onto a range of substrates [25]. They conducted workshops in Science, Technology, Engineering, Arts, and Mathematics (STEAM) contexts and found that it has a relatively low barrier to entry for smart material fabrication and supports collaboration and creative engagement.

Building on these previous approaches, TransPrint employs inkjet and screen-printing in the creation of our displays and aims to enable the combination of printed EC displays with other printed electronics prototyping techniques, hence, enabling easy integration into wider printed electronics prototyping pipeline.

A major distinction when it comes to thin film display technologies is whether the display is pixel-addressable such as OLED and E-Ink, or a graphical segment-based display in which only predefined shapes can be switched. Although the second category offers less visual dynamicity, it provides advantage in other areas, such as ease of fabrication and possibility of creating displays in a variety of shapes and forms. Common technologies to realize thin film displays are, e.g., ultraviolet [26], thermochromism [27, 28], electroluminescence (EL) [4, 6, 29], and electrochromism (EC) [4, 30, 31], each having relative advantages and disadvantages. Ultraviolet-based displays require an additional light source and can suffer from low visibility in daylight conditions. Thermochromism is hard to control, due to the need for exact temperature control and the potential influence of ambient temperature. EC and EL displays are easy to fabricate at low cost and are flexible, robust, and low-power consuming. EL displays have a relatively long lifetime of up to 50,000 hours and, in comparison to EC, have faster switching times [6], making EL suitable for lighting applications [6, 32]. (Switching time here refers to the time it takes to switch from on state, e.g., an off state where nothing is shown to another state where something else is shown.) Different techniques have been proposed for the production of EL displays, such as cutting segments from a larger EC film [33], and screen- and inkjet printing the substrate layers [6]. Olberding et al. demonstrated the possibilities of such displays with a design space that included different materials as well as a variety of application cases [6]. Additionally, screen-printed EL displays can be integrated with textiles [34]. Klamka and Dachselt extended the EL design space with their exploration into the possibilities of added pen interaction [4]. EC-based displays have several promising properties; for example, they can hold their display content for an amount of time without a battery, like e-ink displays. As with e-ink displays, they do not emit any light themselves and they have a comparably slow switching time between states. Previous work on EC displays investigated the capabilities for mass-manufacturing [35], manual manufacturing processes [30], and even developed multilayered colour displays [31]. One of the main application cases for electrochromism so far is smart windows [36–38], while, more recently, other HCI applications have been explored. Klamka and Dachselt used an EC-based 8-segment display in their IllumiPaper prototype and Vyas et al. used an EC-based display that changed opacity with the increasing dust level of a vacuum cleaner [4, 39]. With TransPrint, we extend this line of work by presenting a fabrication process that enables nonexperts to produce such displays and demonstrating the capabilities of EC-based displays for a wider range of mobile and wearable UbiComp and HCI prototypes. Compared to previous work, we specifically provide detailed instruction on the design, printing, and assembly processes for transparent EC displays, which are based on commercially available materials and can be fabricated in nonlaboratory settings with simple prototyping equipment.

Electrochromism is the capability of some materials to reversibly change colour stimulated by redox reactions. This means that EC materials can change their optical absorption characteristics or colour when an electrical voltage is applied. A variety of different materials exist that can switch between different colour combinations and intensities. For TransPrint we are using the PEDOT:PSS (the chemical name poly(3,4-ethylenedioxythiophene) polystyrene sulfonate) mixture for printing, which can change its colour from nearly transparent to a darker blue. The PEDOT:PSS mixture exhibits EC properties because it is electrochemically active which makes it suitable as electrodes in EC displays and operates at low voltages (1-5 volt). Additionally it takes few seconds (< 3s) and requires low current draws (< 3mA) to switch a 5x5cm display fabricated with PEDOT:PSS. However, one thing to note is switch time and current draw heavily depends on size and graphics design (amount of PEDOT:PSS used).

A functioning EC display is composed of the following components: two conductors (electrodes) each connected to a field of EC material or ‘ink’, and electrolyte which separates the two fields of EC material (see Figure 3). The conductors create an electrical circuit by allowing electrons and ions to move when an electrical current is applied through the EC material. The electrolyte is a gel substance with electrically conductive properties and is responsible for the ion exchange between the two fields of EC ink when a voltage is applied at the conductors. Insertion or extraction of ions into the EC ink changes the optical characteristics through reduction and oxidization, and as little as 1V is sufficient for this change to occur. An EC system needs two fields of EC ink that are connected to two different conductors so that an exchange of ions from one field to the other can happen when a voltage is applied. One field will be oxidized while the other is reduced, and vice versa when the polarity of the voltage is reversed. Visually, this redox causes one EC field to become transparent while the other gains colour. Alternatively, one of the EC ink fields can also be replaced by any other ion storage material that does not exhibit colour change on redox, as shown in Figure 3.

While theoretically not needed for functionality, the display components need to be contained by elements that will insulate and protect them. Thus, top and bottom substrates are required. To be able to observe the visual change, at least the upper substrate should be transparent. Typically, glass has been used, but more recently, polymer-based plastics, e.g., polyethylene terephthalate (PET) and polycarbonate (PC), have been employed as well. In some implementations, the lower substrates can even be replaced with paper [42].

In this section, we present the design and fabrication process of TransPrint displays, which are transparent, flexible EC displays. This includes two alternative structures or stack designs, vertical and coplanar (see Figure 4), a detailed description of the fabrication process using screen-printing and inkjet printing as well as design considerations.

For TransPrint we selected to use transparent PET film as the substrates onto which displays are constructed. In the vertical stack configuration, one EC ink field is printed on both substrate layers, whereas in the coplanar stack, both EC ink fields are printed on a single substrate. In both cases the two EC ink fields each have their own conductor and are connected only by the electrolyte layer. The EC ink used in TransPrint displays is itself conductive; thus it is only required to configure the conductors to connect to the edges of the EC ink fields. However, to reduce potential design limitations and ensure consistent switching performance, in TransPrint we utilize substrates coated with a conductive Indium Tin Oxide (ITO) layer which is one of the most commonly used transparent conductors and is also used as the conductor on smartphone touch panels.

Thus, TransPrint utilizes PET film precoated with ITO (PET-ITO) as substrates. For the vertical stack, both base and top layer are PET-ITO whereas for the coplanar structure PET-ITO is used for the base layer and noncoated PET for the upper layer. When using precoated PET-ITO where the whole piece is one conductor (e.g., the Adafruit ITO Coated PET (https://www.adafruit.com/product/1309) with a thickness of 175μm) for the coplanar stack, electrical separation of the two ink fields must be ensured, e.g., by scratching away the ITO coating from the PET to create a gap. Graphical display designs can be printed directly onto the ITO side of the PET-ITO using either screen- or inkjet printing. The PET-ITO material used is a thin film, which can easily be cut to different shapes, increasing the options for customization and flexibility of the displays. To prevent electrical short circuits between the top and bottom layers and to provide a container for the electrolyte, the PET-ITO substrate layers must be held apart.

Either inkjet or screen-printing can be used to transfer the graphical design onto the PET-ITO substrates. For rapid and precise prints inkjet is optimal; however, it allows for less control over the amount of EC ink deposited during the printing process which can potentially lead to lower quality prints. For both, inkjet and screen-printing we used PEDOT:PSS based EC inks supplied by Ynvisible Interactive Inc. (https://www.ynvisible.com/ec-kit). While not completely identical, we expect comparable results from PEDOT:PSS based inks supplied, e.g., by Sigma-Aldrich (https://www.sigmaaldrich.com/catalog/product/aldrich/483095). Screen-printing utilizes a stencil of the graphic design on a frame-mounted mesh to transfer the ink onto the substrate [25]. Screen-printing meshes have different thread densities, depending on how much detail is required, or how much ink has to pass through it. Additionally, the type of emulsion used to create the stencil affects the print detail. As an alternative to using emulsion, stencils may be cut out from vinyl.

If screen-printing is used, the frame count and emulsion determine the minimum size of both trace width and detail size; however there is no limitation for how big a trace or feature can be. The same applies when vinyl cutting is used to create a stencil; the accuracy of the vinyl cutter used must be sufficient for the level of detail in the design. Once the graphics have been developed, the design has to be finalized for print which requires adding registration lines for the spacer material (double-sided tape) and connections for the electrodes (see Figure 5). This step is especially important when designing for the vertical stack structure, as the conductive leads should be offset to avoid shorting the electrical circuit. If a vertical stack design uses superimposed graphics between the two layers, one side of the design should be mirrored to ensure it would be correctly oriented when assembled. The switching time of the display can be affected by altering the balance of the amount of ink between the paired EC fields, e.g., if both top and bottom layer have an equal amount of ink for insertion and extraction of ions the switching time will be equal for both polarities. Altering this equilibrium allows designers to create interesting and alternative transitions in their designs.

The process of screen-printing EC displays follows the normal screen-printing procedure and does not require any specific changes to the process (compare Figure 6). In Section 5.1 we discuss in detail the effect of different stencils and mesh counts. Most screen-printing equipment should be suitable for printing of TransPrint displays and, besides the graphical design of the fields, there are no limitations that affect the screen-printing of EC ink compared to any other ink. When using inkjet printing some details should be considered. Firstly, we recommend using a piezo-driven printer rather than a thermally driven one. As the EC ink is water based there is a risk that the heat of the thermal-driven printing alters the structure of the EC ink. Considering the amount of ink discharged, prior work recommends using the Brother brand of printers, as they have been shown to dispense larger amount of ink [2]. For our tests, we utilized a Brother MFC-J480DW with corresponding refillable cartridges, which provided excellent print quality. The Ynvisible inkjet EC ink has to be filtered before use, to avoid particles clogging the print head. Overall, inkjet printed displays have shown lower contrast ratios compared to screen-printed ones. However, inkjet printing provides the possibility of easily changing and adjusting the graphical design without the need to manufacture a stencil first. Therefore, it is very well suited for making rapid proof-of-concept prototypes. After the silkscreen or inkjet printing process the ink, coated PET-ITO must be heat-cured for 2m-3m at 120°. This is because the EC ink is water based which should evaporate before the display is assembled. For this either a small oven or a heat gun with temperature control is recommendable.

After the EC ink has been printed on the PET-ITO, the first step in the assembly is to cut the PET-ITO and spacer to size (Figure 7(1)). If the cut lines did not get through the mesh during the screen-printing process, the negative mask can be used to mark where to cut. Afterwards the spacer material—double-sided tape—should be applied (Figure 7(2)). To help aligning the layers, the base and top layers should align and taped to the cutting board at one side, i.e., creating a hinge. This way the top layer can then be flipped over while maintaining alignment with base layer while the spacer is added to the base layer (Figure 7(3-4)). The cubic volume of the spacer cut-out should be calculated to identify the amount of electrolyte required. Using a syringe, the liquid electrolyte is then applied as a blob in the middle of the cut-out in the spacer, and the top substrate layer is flipped back over to cover it (Figure 7(5)). The electrolyte should then be gently dispersed to fill the spacer area using light pressure in a circular motion while at the same time removing the spacer protection as it is dispersed. Firstly, the electrolyte will disperse towards the spacer wall midpoints. However, before the electrolyte reaches the spacer walls midpoint, the top substrate layer should be pressed to the spacer ensuring it adheres and preventing the electrolyte from being squeezed out. The electrolyte should then be eased into the corners of the space, ensuring it is evenly dispersed (Figure 7(6-8)). Finally, copper tape is applied to the conductive leads to improve conductivity (Figure 7(9)). Once the display is assembled, it should be cured under UV light for 25-30 minutes using a commercial 500W halogen spotlight. But basically, any lightbulb that emits UV can be used but will require different times [43]. The UV curing process solidifies the electrolyte to film instead of a liquid, making the display more robust. While this step is not needed, it is recommended to ensure a longer lifetime as well as prevent short circuits. A video overview of how to assemble the display can be found here: https://youtu.be/mi0p2VBo41s.

One of the advantages of EC-based displays is their relatively low need for power. Once the display has been switched (either oxidized or reduced) into one of its states, it will stay in this state for a certain amount of time, while slowly fading to the neutral state. To investigate this fading contrast, we switched a TransPrint display into one of its states and captured pictures with constant illumination every ten minutes. We used a Canon EOS600D camera connected to a Raspberry Pi to capture the pictures. To quantify the temporal change we used the contrast ratio as a measure. The contrast ratio is defined as the ratio of the brightest colour compared to the darkest colour that the display can produce [49]. Usually it is measured between white and black, but as we used blue EC ink, we measure the contrast between an area of the display placed on a white background and the darkest blue tone on the display. As no standardized method existed, we employed an approach similar to Gentile et al. [50], the W3C defined method from the Web Content Accessibility Guidelines (WCAG) [51]. The WCAG uses the following definition of contrast ratio () between the text and background colours:where L1 is the relative luminance of the brightest colour, L2 is the relative luminance of the darkest colour for which 1 ≥ L1 ≥ L2 ≥ 0. The definition of relative luminance L corresponds to the Y component of the colour in the CIE 1931 XYZ colour space [49]. Given the above formula the maximum is 21 and the minimum 1. The WCAG suggest a minimum of 3 for websites to be easily readable [49, 50]. We repeated the fade test for 10 displays printed with screen-printing using 80T frames and High Resolution-Diazo-Photoemulsion and calculated the for these displays at 10-minute periods. The averaged fading can be seen in Figure 8. Directly after the displays have been switched into one of their states, the is very high at around 4.5 but after the first 20mins on average it already loses a significant amount of contrast, but nevertheless it stays above the minimum recommended of 3 for over 2 hours. This demonstrates that TransPrint displays can retain an adequate contrast ratio for 2 hours before they need to be stimulated again. While this is not as lengthy as the retention time of e-ink displays [44], the possibility of fabricating them in a DIY manner and the ability to be transparent provides advantages that are unmatched by e-ink.

EC-based displays have a low-power consumption and only require to be powered when switching between the different states of the display. However, the exact amount of energy consumed by an EC display to switch depends on a variety of different factors. The main factors are the size of the displays as well as the amount of ink that has been used. In addition, the amount used electrolyte and the quality of the ITO coating on the PET potentially affects the energy consumption. To give an estimate of the power consumption, we measured the consumption of a set of displays. We used an Agilent 34450A Multimeter and the corresponding software for it. We tested three different displays; 5x5cm Evaluation Design printed using inkjet printing, 5x5cm Evaluation Design printed using an 80T frame with high-resolution emulsion, and a 10x10cm honeycomb design (compare Figure 10 printed using an 80T frame with high-resolution emulsion). For each of these displays we used a switching time that was just long enough to fully complete the visual transition. We then calculated the average power requirements over five switches for each display. For the inkjet display, the switching time was 1.1s, with an average current draw of 2.72mA, resulting in a power consumption of 4.3mW per switch. The screen-printed 5x5cm display took 2.4s to switch and had an average current draw of 2.6mA, which resulted in a power consumption of 3.8mW. Lastly the screen-printed 10x10cm display had a switching time of 5.1s and an average current draw of 4.9mA, resulting in a power consumption of 7.8mW. These values well demonstrate the low-power consumption of TransPrint displays.

As the amount of EC ink applied to the PET-ITO affects the maximum levels transparency and colourization of the final display, here we provide an overview of the influence of mesh count and vinyl stencil placement in terms of ink dispersion. For detailed prints it is important to ensure that high details are retained from the original digital design through to the final print. As the emulsion type dictates the amount of detail retained during the exposure, we investigated two different types of emulsion. Furthermore, we also give an overview of results that can be achieved of vinyl stencils, which are a viable option for screen-printing. For emulsion-based prints, the digital test design was printed to fill an A4 exposure film. An example of the digital design for test and assembled display in balanced and powered state can be seen in Figure 9. Photographs of the displays were taken before and after applying power (1.5v and -1.5v). To keep to the off-the-shelf viability of fabricating EC displays we bought a screen-printing starter kit that contained a 55T frame, hybrid photoemulsion, and press. A starter kit of this kind is the fastest way to get into screen-printing as it contains all the materials required to get started. Additional 80T and 120T frames and a high-resolution emulsion were bought for testing. All prints were made using 125μm PET-ITO (40-60 Ω), 230μm double-sided tape sheet spacer, and Ynvisible EC-SC ink and electrolyte.

Left: digital design used for evaluating different parameters during screen-printing.Right: difference between displays printed using a 80T frame with high-resolution emulsion and inkjet printing.

There is a difference in the preparation time between using vinyl stencils or emulsion stencils. While emulsion requires several hours of drying and washing out, as well as exact exposure when the prints are transferred from the negative, preparing the cut-out vinyl requires a lot of manual labour depending on the amount of details that have been cut out. Depending on ones’ knowledge of these techniques, times can vary. Nevertheless, both approaches will take longer compared to inkjet printing. However, as the inkjet ink needs to be more liquid than the screen-printing ink to be properly dispensed, inkjet prints generally result in lower maximum colourization. Therefore, inkjet printing is recommended for proof-of-concept prototypes, while screen-printed displays present a quality ehich are suited for longer-term usage.

Many factors affect the quality of the assembled display, including scratches and fingerprints created during the assembly process. However, here we disregard these production defects and specifically focus on the quality of the print regarding transparency, colour, and detail. The following factors were noted as affecting the display print quality:(i)The thread count of the frame has a very eminent effect on the maximum transparency and colourization of the displays, see Figure 10. A lower thread count will allow for a higher ink dispersion onto the PET-ITO.(ii)The FLX screen emulsion produced consistently good results. The high-resolution emulsion resulted in similar results in terms of the amount of inks dispersed but with slightly higher details. Using 80T or 120T with high-resolution emulsion produced the best results in terms of details and transparency.(iii)When the vinyl stencil was mounted on the top of the mesh, the results are comparable to the FLX screen emulsion print. However, due to the limits of a vinyl cutter, fewer details are possible. For a vinyl stencil placed below the mesh, only a thread count of 55T produced prints of viable detail. However, the amount of ink dispersed was so high that the ink in its reduced transparent state was still strongly visible. The other two thread-counts consistently produced unusable results.A general challenge with the vinyl stencil was that during the transfer of the vinyl to the frames small standalone details can easily fall off.

An important characteristic of TransPrint displays is their transparency, and we experienced different levels depending on the printing process and materials used. One of the main influencing factors is the used PET-ITO. While the aforementioned Adafruit PET-ITO only has a very thin layer of ITO and is therefore highly transparent, other PET-ITO supplies we tested created a visible yellowing of the displays. The electrolyte [43] on the other hand has very little influence. Thinner layers of EC ink result in higher transparency when the ink is in a reduced state, but consequently result in a lower opacity when excited. Depending on the application case for the printed display, different approaches to printing will be optimal. For example, in a case where only limited transparency is needed but high colourization is required, a lower thread count and perhaps a vinyl stencil should be used to print the display. If the display requires a high transparency, a higher thread count with using screen print emulsion or even inkjet printing should be favoured. Being able to vary the thickness of the layer by utilizing different mesh counts in the screen-printing process allows for more diversity in the design. The usage of vinyl as a stencil material is possible; however it should be placed on the top of the frame and a frame with a higher thread count should be used to get more usable results. Moreover, vinyl stencils only work acceptably with low detailed graphic designs. The high amount of ink dispersed when vinyl is placed on the bottom of the screen is most likely due to the thickness of the vinyl allowing a larger amount of ink to be deposited.5.2.2. Ease of Design and Fabrication

In this section, we present different application scenarios and ways to utilize TransPrint displays. We present six examples: a switchable logo, a context-adaptive timetable, touch sensitive transparent buttons, an interactive paper map overlay, a wireless powered game card, and interactive art. All the displays were printed using screen-printing with the following materials: 175μm PET-ITO, 130μm 3M spacer, Ynvisible EC-SC ink, and Ynvisible electrolyte. As a limitation of the ITO, the maximum voltage for these displays is 1.5V unless otherwise stated. Higher voltages will degrade the ITO layer and eventually render the displays nonfunctional.

The first application case is a switchable logo for a glass. It demonstrates several of the unique capabilities of EC displays. It is a transparent and nonrectangular display—here in form of a circle—that is bent around a glass; see Figure 12 (left). The display is fabricated as a vertical stack and demonstrates a switch between two different graphics that, for example, can highlight different properties of a product, here the fact that the beer is Natural and Premium Quality.

Several previous attempts have explored how transparent displays can support colocated work on a shared visual workspace [52–54]. However, these approaches often required complex display technologies such as LCD [54]. We believe that EC ink displays can be used for fast and cheap prototypes in this area as well. We printed a set of touchable buttons, e.g., to control a media player (compare Figure 13), that can be attached to a variety of surfaces. For touch sensing we use an MPR-121 breakout board, as described above. User interface elements that only express minimal change such as the here shown music player controls or simple switches are perfect examples how TransPrint displays can be used as interactive graphics that allow to be fitted on a variety of existing objects without altering their aesthetics significantly. However, if needed they can be used to alter the experience. For example, the different levels of transparency that EC displays offer can alter the appearance, e.g., similar to the work of Lindlbauer et al. [55].

The last three application cases make all use of the same principle, they take advantage of the fact that TransPrint displays are transparent and can therefore be combined with already existing static printed materials. To demonstrate these retrofitting capabilities we created three examples: an interactive paper map overlay (see Figure 15), a wireless powered game card, and interactive art (see Figure 14).

TransPrint is a method to print custom flexible transparent free-form electrochromic (EC) displays, which allows nonexperts to easily create displays for use in HCI applications. The created displays are nonlight-emissive, making them suitable for seamless integration into a variety of environments, without the disruptive light output of other display technologies. We have detailed the process to design and construct TransPrint displays, highlighting best practices and the benefits of alternative approaches. TransPrint displays are created using common screen-printing or inkjet printing methods, together with a lightweight assembly process. Capacitive touch sensing can be seamlessly integrated into the displays without the need for additional sensor wiring. The example TransPrint displays created maintain their display state without power for 2 hours and have low-power consumption, requiring less than 4mW to switch state. The potential application space for TransPrint displays has been demonstrated by the construction of five prototypes. Our contribution extends the tool set available for the maker community enabling designers and creators to rapidly functional devices with a minimal overhead. For future work, we want to develop a software stack that will enable designers to simulate the visual qualities of the display before the display is printed. In addition, plugins that will support the designer while designing these displays, e.g., by showing the area of the different EC ink fields would be beneficial. Furthermore, we want to explore more prototyping techniques.

OLED technology enables thin, efficient and bright displays and lighting panels. OLEDs are currently used in many mobile devices, some TVs and lighting fixtures. OLED displays offer a better image quality compared to LCD or Plasma displays - and can also be made flexible and transparent.

Several companies develop transparent OLED (also referred to as T-OLED) technologies. While there"s no inherent technology barrier towards transparent OLED displays, finding actual applications for such displays is not easy.

As of 2021, LG Display is producing 55-inch transparent OLED panels (used mostly in signage and commercial settings) while other companies produce small (around 1-2 inch in size) transparent PMOLED display. In April 2013 we posted a review of Futaba"s 2" 160x128 transparent PMOLED panel - which could be an interesting read even if this specific display is no longer in production.

OLED technology can be used to make lighting panels - these are thin, area-lit and efficient lighting panels, that can be made transparent. Unlike displays, transparent OLED lighting panels have more immediate applications (embedded in windows, for example). In April 2012 we posted our hands-on review with a transparent Tabola OLED lighting panel sample. As the OLED lighting market in general is still at an early stage, we do not see actual adoption and production of transparent OLED lighting.

The report package also provides a complete list of transparent OLED developers and makers and their current (and future) products, and a lot more. Read more here!

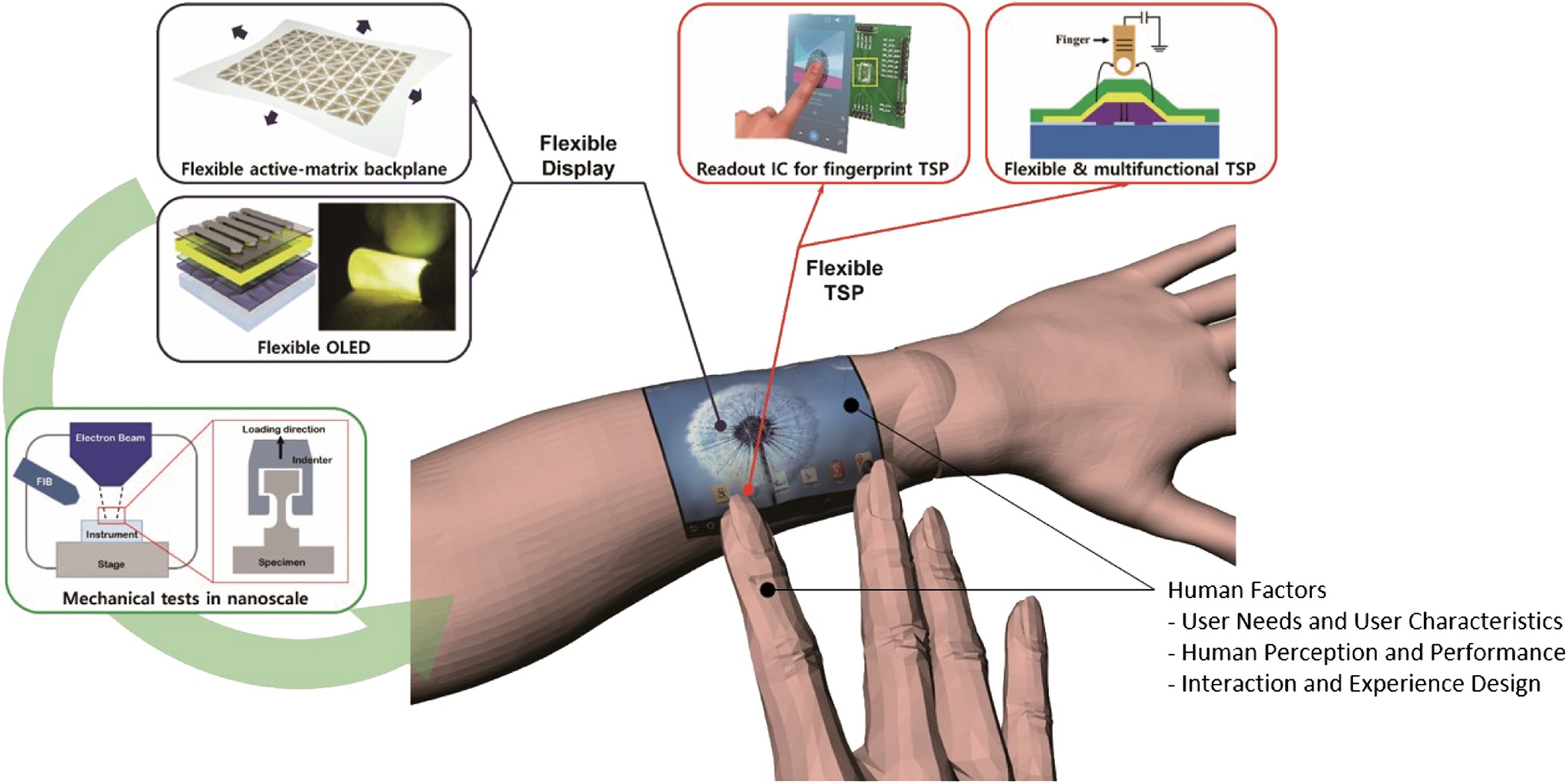

Flexible displays open up new dimension of design opportunities that aren’t possible with rigid glass-based displays. Nowadays, users have come to expect touch capability from almost any display-enabled device, but, many devices still need certain buttons or knobs – for example in cars. This becomes a limitation when using rigid glass displays - designers need to allow for additional space for knobs or buttons outside the display area. This can waste space, compromise aesthetics and result in a bulky non-optimised design.

Recently, some display makers have introduced glass displays with through-holes for the camera in smartphone screens. For example, Tianma has recently announced a 6.4” LCD with a through-hole that will be used in Huawei’s nova 4 device. It becomes more challenging and more expensive if the holes or the displays are larger, or if there are multiple holes required, when the displays are made from glass

In order to make displays flexible, the transistor backplane technology used needs to be flexible. This is currently made possible using conventional silicon technology or metal oxides on bespoke polyimide substrates. Flexible displays need to be mounted onto glass in order to keep them flat during fabrication. At the end of the process the flexible displays need to be demounted from the glass carrier by using a laser de-bonding process. Holes can be cut through the displays before or after the de-bonding process. If the demounting process is aggressive, like in the case of laser de-bonding for the polyimide-based displays, it can generate unwanted stresses which will cause the edges of the holes to be concentrated stress relief areas and hence impact yield and cost.

FlexEnable has developed a different approach for flexible displays. By using low temperature processing of organic thin-film transistors (OTFTs) on low cost plastics like triacetyl cellulose (TAC), no laser de-bonding processes are required. Instead a mild heat or UV treatment is used to separate the flexible displays from the glass. Holes through the displays are laser profiled while the displays are still mounted onto the glass. Unlike polyimide-based displays, OTFT displays have a simple high yielding demounting process.

As the landscape for flexible displays evolves with new use cases, the ability to cut holes through the displays unlocks even more design freedom and enables bolder product designs to meet growing consumer expectations.

A large transparent liquid crystal display (LCD) prototype with ultrahigh transmittance and good see-through property is demonstrated in this paper. The transmittance reaches more than 20% by introducing the RGBW pixel arrangement, a thin color filter process, a large aperture ratio design, as well as antireflective polarizer film. The see-through image quality is also greatly improved by suppressing the blurring by using domain reduction pixel design. All these approaches are applicable for large LCD panel products, and we expect broad applications of large transparent LCDs in the near future.

A:We are professional manufactory, which specializes in TN, HTN, FSTN, STN monochrome LCD, LED backlights, LCD modules more than 6 years in Dongguan ! Our advanced full set equipments make sure good quality and competitive price!

Our Main products including a Small LCD screen 0.96inch to 13.3inch, TFT LCD display modules, AMOLED displays, OLED with capacitive touchscreen display. We also expanding our product range to flexible OLED screens as well as Transparent LCD displays. We have to say, you can find a variety of different displays in our company. Most of our products are widely used in smartwatch wearable device, automotive industry, Smart Home device, industrial control machine, Portable POS System, Gaming console, Smart home robot, Handheld devices, Household appliances like Sweeping robot, other communication devices like IP phone, Smart Security equipment, And other fields. All developed products have passed CE, ROHS, and other certifications.

Our team through qualified training. Skilled professional knowledge, powerful sense of support, to satisfy the support desires of consumers for Flexible Transparent Led Screen, Flex Led Display , Led See Through Screen , Mall Led Screen ,Indoor Led Display Video . For high quality gas welding & cutting equipment supplied on time and at the right price, you can count on company name. The product will supply to all over the world, such as Europe, America, Australia,UK, Naples,Turkey, Bogota.Each product is carefully made, it will make you satisfied. Our products in the production process have got strictly monitored, because it is only to provide you the best quality, we will feel confident. High production costs but low prices for our long-term cooperation. You can have a variety choices and the value of all types are same reliable. If you have any question, do not hesitate to ask us.

LG takes pride as the leading provider of innovative, flexible and feature-packed Commercial Display Products in the market. Boasting the cutting-edge features and modern design, LG Commercial Displays redefines a whole new way of delivering an ultimate viewing experience to enhance engagement with the audience. From Ultra UD OLED monitors for a digital signage network to hospitality TVs for in-room entertainment solutions, LG Commercial Displays offer a variety of display products to meet the demands of every business environment including:

Digital Signage: Raise your sales with LG Digital Signage and discover our collection of LED Backlit Displays, DS Media Players, Stretch and Touch Screen Displays. Our digital signage displays are available in different sizes and specifications to match the requirements of your business.

Ms.Josey

Ms.Josey

Ms.Josey

Ms.Josey