tft lcd film made in china

In recent time, China domestic companies like BOE have overtaken LCD manufacturers from Korea and Japan. For the first three quarters of 2020, China LCD companies shipped 97.01 million square meters TFT LCD. And China"s LCD display manufacturers expect to grab 70% global LCD panel shipments very soon.

BOE started LCD manufacturing in 1994, and has grown into the largest LCD manufacturers in the world. Who has the 1st generation 10.5 TFT LCD production line. BOE"s LCD products are widely used in areas like TV, monitor, mobile phone, laptop computer etc.

TianMa Microelectronics is a professional LCD and LCM manufacturer. The company owns generation 4.5 TFT LCD production lines, mainly focuses on making medium to small size LCD product. TianMa works on consult, design and manufacturing of LCD display. Its LCDs are used in medical, instrument, telecommunication and auto industries.

TCL CSOT (TCL China Star Optoelectronics Technology Co., Ltd), established in November, 2009. TCL has six LCD panel production lines commissioned, providing panels and modules for TV and mobile products. The products range from large, small & medium display panel and touch modules.

Established in 1996, Topway is a high-tech enterprise specializing in the design and manufacturing of industrial LCD module. Topway"s TFT LCD displays are known worldwide for their flexible use, reliable quality and reliable support. More than 20 years expertise coupled with longevity of LCD modules make Topway a trustworthy partner for decades. CMRC (market research institution belonged to Statistics China before) named Topway one of the top 10 LCD manufactures in China.

Founded in 2006, K&D Technology makes TFT-LCM, touch screen, finger print recognition and backlight. Its products are used in smart phone, tablet computer, laptop computer and so on.

The Company engages in the R&D, manufacturing, and sale of LCD panels. It offers LCD panels for notebook computers, desktop computer monitors, LCD TV sets, vehicle-mounted IPC, consumer electronics products, mobile devices, tablet PCs, desktop PCs, and industrial displays.

LCD manufacturers are mainly located in China, Taiwan, Korea, Japan. Almost all the lcd or TFT manufacturers have built or moved their lcd plants to China on the past decades. Top TFT lcd and oled display manufactuers including BOE, COST, Tianma, IVO from China mainland, and Innolux, AUO from Tianwan, but they have established factories in China mainland as well, and other small-middium sizes lcd manufacturers in China.

China flat display revenue has reached to Sixty billion US Dollars from 2020. there are 35 tft lcd lines (higher than 6 generation lines) in China,China is the best place for seeking the lcd manufacturers.

The first half of 2021, BOE revenue has been reached to twenty billion US dollars, increased more than 90% than thesame time of 2020, the main revenue is from TFT LCD, AMoled. BOE flexible amoled screens" output have been reach to 25KK pcs at the first half of 2021.the new display group Micro LED revenue has been increased to 0.25% of the total revenue as well.

Established in 1993 BOE Technology Group Co. Ltd. is the top1 tft lcd manufacturers in China, headquarter in Beijing, China, BOE has 4 lines of G6 AMOLED production lines that can make flexible OLED, BOE is the authorized screen supplier of Apple, Huawei, Xiaomi, etc,the first G10.5 TFT line is made in BOE.BOE main products is in large sizes of tft lcd panel,the maximum lcd sizes what BOE made is up to 110 inch tft panel, 8k resolution. BOE is the bigger supplier for flexible AM OLED in China.

Technology Co., Ltd), established in 2009. CSOT is the company from TCL, CSOT has eight tft LCD panel plants, four tft lcd modules plants in Shenzhen, Wuhan, Huizhou, Suzhou, Guangzhou and in India. CSOTproviding panels and modules for TV and mobile

three decades.Tianma is the leader of small to medium size displays in technologyin China. Tianma have the tft panel factories in Shenzhen, Shanhai, Chendu, Xiamen city, Tianma"s Shenzhen factory could make the monochrome lcd panel and LCD module, TFT LCD module, TFT touch screen module. Tianma is top 1 manufactures in Automotive display screen and LTPS TFT panel.

Tianma and BOE are the top grade lcd manufacturers in China, because they are big lcd manufacturers, their minimum order quantity would be reached 30k pcs MOQ for small sizes lcd panel. price is also top grade, it might be more expensive 50%~80% than the market price.

Panda electronics is established in 1936, located in Nanjing, Jiangshu, China. Panda has a G6 and G8.6 TFT panel lines (bought from Sharp). The TFT panel technologies are mainly from Sharp, but its technology is not compliance to the other tft panels from other tft manufactures, it lead to the capacity efficiency is lower than other tft panel manufacturers. the latest news in 2022, Panda might be bougt to BOE in this year.

Established in 2005, IVO is located in Kunsan,Jiangshu province, China, IVO have more than 3000 employee, 400 R&D employee, IVO have a G-5 tft panel production line, IVO products are including tft panel for notebook, automotive display, smart phone screen. 60% of IVO tft panel is for notebook application (TOP 6 in the worldwide), 23% for smart phone, 11% for automotive.

Besides the lcd manufacturers from China mainland,inGreater China region,there are other lcd manufacturers in Taiwan,even they started from Taiwan, they all have built the lcd plants in China mainland as well,let"s see the lcd manufacturers in Taiwan:

Innolux"s 14 plants in Taiwan possess a complete range of 3.5G, 4G, 4.5G, 5G, 6G, 7.5G, and 8.5G-8.6G production line in Taiwan and China mainland, offering a full range of large/medium/small LCD panels and touch-control screens.including 4K2K ultra-high resolution, 3D naked eye, IGZO, LTPS, AMOLED, OLED, and touch-control solutions,full range of TFT LCD panel modules and touch panels, including TV panels, desktop monitors, notebook computer panels, small and medium-sized panels, and medical and automotive panels.

AUO is the tft lcd panel manufacturers in Taiwan,AUO has the lcd factories in Tianma and China mainland,AUOOffer the full range of display products with industry-leading display technology,such as 8K4K resolution TFT lcd panel, wide color gamut, high dynamic range, mini LED backlight, ultra high refresh rate, ultra high brightness and low power consumption. AUO is also actively developing curved, super slim, bezel-less, extreme narrow bezel and free-form technologies that boast aesthetic beauty in terms of design.Micro LED, flexible and foldable AMOLED, and fingerprint sensing technologies were also developed for people to enjoy a new smart living experience.

Hannstar was found in 1998 in Taiwan, Hannstar display hasG5.3 TFT-LCD factory in Tainan and the Nanjing LCM/Touch factories, providing various products and focus on the vertical integration of industrial resources, creating new products for future applications and business models.

driver, backlight etc ,then make it to tft lcd module. so its price is also more expensive than many other lcd module manufacturers in China mainland.

Maclight is a China based display company, located in Shenzhen, China. ISO9001 certified, as a company that more than 10 years working experiences in display, Maclight has the good relationship with top tft panel manufacturers, it guarantee that we could provide a long term stable supply in our products, we commit our products with reliable quality and competitive prices.

Maclight products included monochrome lcd, TFT lcd module and OLED display, touch screen module, Maclight is special in custom lcd display, Sunlight readable tft lcd module, tft lcd with capacitive touch screen. Maclight is the leader of round lcd display. Maclight is also the long term supplier for many lcd companies in USA and Europe.

If you want tobuy lcd moduleorbuy tft screenfrom China with good quality and competitive price, Maclight would be a best choice for your glowing business.

China"s first 8.5-generation TFT-LCD production line was launched in Bengbu, East China"s Anhui province, on June 18, 2019, representing a breakthrough in the production of high-definition LCD screen, Science and Technology Daily reported.

TFT-LCD, or Thin Film Transistor Liquid Crystal Display, is key strategic material of the electronic information display industry. The Gen 8.5 TFT-LCD production line, launched by the Bengbu Glass Industry Design and Research Institute of the China National Building Material Group, will produce high-definition LCD screens of 55 inches, the report said.

According to the Liquid Crystal Branch of the China Optics and Optoelectronics Manufactures Association, the demand for TFT-LCD in the Chinese mainland was about 260 million square meters in 2018, including 233 million square meters" Gen 8.5 TFT-LCD. However, the annual supply of domestically made TFT-LCD is less than 40 million square meters, with all of them Gen 6 or below, which cannot meet the demand in scale and quantity.

The association predicted that China"s market demand for Gen 8.5 TFT-LCD or above will exceed 300 million square meters by 2020, accounting for 49.6 percent of the total global demand.

The production and control precision of Gen 8.5 TFT-LCD is comparable to that of the semiconductor industry, representing a higher level of large-scale manufacturing of modern glass industry.

The institute in Bengbu, with 60 years of expertise in glass, has finally made a breakthrough in the production of Gen 8.5 TFT-LCD, and will provide key raw material guarantee for China"s LCD panel industry after it goes into mass production in September, the report said.

(Yicai Global) June 19 -- China National Building Material has built the country"s first production line capable of producing 8.5th-generation TFT-LCD glass substrates, making China one of few nations to master the technology.

TFT-LCD, or thin-film-transistor liquid-crystal displays, are classified by the size of their glass substrate. Sixth-generation displays are now widely considered out-dated while 8.5th-gen tech is the most advanced. The newer technologies use larger substrates, which are more efficient to make and can be used in larger screens.

In recent years, with the rapid development of China"s high generation LCD panel industry, related industry chain development is also in full swing, Polaroid flat panel display as one of the most important supporting materials industry, also ushered in a rare development opportunity, and gradually localization, in this process, Shenzhen City three tiptop photoelectric Polytron Technologies Inc (hereinafter abbreviation: Sanli plays the role of forerunner spectrum), the future will continue to enjoy the huge growth space localization alternative polarizer.

As everyone knows, the polarizing film of high technical threshold, before the market dominated by several major manufacturers of LG chemistry, chemistry, etc. Sumitomo ensequence foreign monopoly. But with the transfer of the global panel business to the domestic market, the trend of polarizing industry transfer to the mainland has also been formed. For the growing domestic panel capacity, the urgent demand for the polarizing film localization is increasing.

As a domestic Polaroid pioneer, three physical encountered in the field of polarizer challenges and difficulties in other enterprises are difficult to understand, but to persevere through the development and continuous input, support of the government and the industry in addition to the final completion of the competition with foreign enterprises in the growth and transformation, and the first to break the domestic medium and large size TFT polarizing film all the history of dependence on imports.

At present, three physical has numerous applications to meet the downstream demand of Polaroid production capacity. The product types include TN polarizer, STN polarizer, TFT polarizer, OLED polarizer and 3D glasses polarizer. The effective thickness of the product is the thinnest that has reached 90m, and can provide 120m, 130m, 150m, 210m and other different thickness products. At the same time, the company can provide different types and thickness matching products to support customers" product design according to customer needs, and jointly develop special polarized products with customers.

Polarizer, as one of the key raw materials of LCD panel, has been strongly supported by the national industrial policy. In recent years, the state has continuously increased its support for the flat panel display industry, especially the LCD panel industry.

At present, the domestic LCD panel production capacity has been ranked first in the world, while domestic panel makers still further accelerated the high generation panel production line construction progress, and promote domestic Polaroid demand growth, although foreign investment increase in domestic production capacity construction, but there are still a large gap between supply and demand.

According to statistics, the current domestic Polaroid accounted for less than 40% of domestic demand, to 2019 self-sufficiency rate is expected to increase to 65%, is expected to 2019 domestic demand for TFT-LCD panel factory Polaroid polarizer of about 185 million square meters, OLED needs about 9 million 580 thousand square meters, and almost all are increasing demand for capacity planning; to 2019 domestic manufacturers look at the supply of only 120 million square meters, there is a big gap between supply and demand, as one of the polarizer panel core material, the panel cost accounted for about 10%, to accelerate the localization of materials is one of the important starting point for the downstream panel manufacturers in the future to further improve the cost competitiveness, in line with industry rules - the rise of downstream upstream material substitution accelerate domestic drive. With the rapid growth of demand and the rise of domestic panel manufacturers, domestic polarizer will usher in the best opportunity for development. Three physical will take this wind, become a polarizing film industry rise directly to a high position, the leading solutions provider with international competitiveness.

LG.Philips LCD began production of seventh-generation TFT LCDs (thin-film transistor liquid crystal displays) at its facility in Paju (Korea) at the beginning of 2006. The ramp up was over six months earlier than previously planned, prompted by increasing demand for LCD TVs and PCs. The expansion made it the world’s largest LCD production facility. Philips made a pilot production run at the end of November 2005, and has started production of 42in panels from its 1,950mm x 2,250mm glass substrates.

The company is investing $10 billion and expects annual sales close to $3 billion, more than 90% of which will be from exports. The 1,650,000m² complex takes the LG.Philips LCD industrial cluster to 3,300,000m², housing next-generation LCD production and R&D facilities. Preparatory work was completed by March 2004.

The fab is located in Paju, Kyonggi Province, north of Seoul. LG.Philips LCD and the Kyonggi provincial government has provided infrastructure including industrial water systems, electricity utilities and roads. The investment has created around 5,000 new jobs.

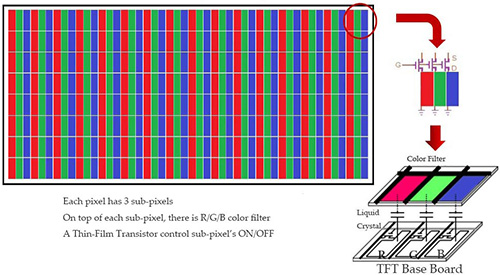

TFT LCDs have three layers. A glass plate substrate with TFT transistors is at the bottom, a glass plate colour filter on top and the liquid crystal is injected between the two. Although LCDs are fluid, they show long-range order like solids. The molecules are roughly bar shaped but with anisotropic values of reflective index, dielectric constant, conductivity and viscosity: all have different values along different axes.

The transistors apply voltages to the liquid crystals to control the vibration direction of polarized light passing through them. This affects the light permeability of the individual LCD pixels to form images.

TFT-LCD screens are flatter and lighter than CRTs, consume less power and generate lower electromagnetic emissions. Besides going into TV sets for the home, TFT LCDs will be used in monitors for mini notebook PCs and hand-held computers, medical equipment, car navigation and entertainment systems and avionics instrumentation.

Philips has been improving the technical limitations of TFT-LCDs, particularly angle, brightness response time. The company now has 20.1in UXGA, 23in WUXGA and 30in WQXGA+ TFT-LCD panels for large-scale, wide monitor-specific TFT-LCDs for desktop monitors.

Photolithography first coats the substrate with a very thin liquid film of photosensitive ‘resist’. Exposing the photoresist to light through a mask transfers the pattern onto the substrate. This is followed by cleaning. Another layer of the photoresist is then deposited to the substrate, exposed, cleaned, and so on, until all the layers have been printed or imaged onto the surface.

LG.Philips LCD is a 50:50 joint venture between LG Electronics and Philips Electronics. The company produces TFT-LCDs for notebook PCs, desktop monitors, LCD TVs and special applications including car navigation systems, avionics, miniature notebook PCs, hand-held PCs and medical diagnostic machines. Higher value 18in-and-above screens make up more than 20% of LG.Philips LCD’s total TV LCD production.

The company has also invested a total of 3.3 trillion won (just under $2 billion) to build a new sixth-generation TFT-LCD plant in Gumi, south of Seoul. In addition to its Korean facilities, where the core panels are made, LG.Philips LCD has expanded its Nanjing, China, fifth-generation module plant, where it has produced more than one million TFT-LCDs for desktop monitors (module yield is more than 99%). In Nanjing, panels are equipped with other components before being sold to monitor and TV set manufacturers.

The global TFT-LCD industry has entered its mature stage. In the past 5 years, the overall output value of TFT-LCD is relatively stable and fluctuates around $130 billion. Among which, China has become the world’s largest TFT-LCD producer.

TFT-LCD (thin film transistor liquid crystal display) is an outcome of microelectronics technology and liquid crystal display technology, a kind of LCD, belonging to the active matrix LCD. TFT-LCD has a three-layer structure, among them, the upper glass substrate is a color filter, the lower glass substrate contains a transistor, and the liquid crystal is located between them. TFT-LCD has the following advantages: High resolution, strong interference immunity, low working voltage, low power consumption, long lifetime and wide application range.

TFT-LCD is widely used in TV, PC, laptops, tablets, projectors, car monitors, smart phones, wearable devices, smart homes and many other fields. The large global shipments of smart phones and computers as well as rapid development of wearable devices and smart home market, have brought robust demand for TFT-LCD.

Compared with the overseas market, China"s TFT-LCD production capacity has expanded rapidly in the past five years, and the output value has continued to grow. According to the "China Thin-Film Transistor Liquid Crystal Display Device (TFT-LCD) Industry Market Research Report in 2022-2026" released by the Newsijie Industry Research Center, China"s TFT-LCD production capacity accounted for more than 50% of the total global production capacity for the first time in 2020; China’s TFT-LCD production capacity accounted for 57% of the total global production capacity and its output value reached about 74 billion dollars in 2021. In 2021, Chinese enterprises including BOE, CSOT, Innolux Display Group, AUO and HKC had high shares in the global TFT-LCD market, among which, BOE is the world"s largest TFT-LCD manufacturer with strong competitiveness in the field of large-size TFT-LCDs.

With the continuous improvement in global display panel technologies as well as the incremental iteration and update of products, CRT has been eliminated and LCD has become the mainstream, meanwhile, OLED is squeezing the LCD market due to its lighter, thinner, flexible and transparent display and other advantages. The global TFT-LCD production capacity is concentrated in Chinese mainland, Taiwan and South Korea. In South Korean market, the panel makers such as Samsung and LG are phasing out LCD production lines to expand OLED production capacity. Although TFT-LCD is the current mainstream LCD product, only LG still has some large-size TFT-LCD production lines. TFT-LCD production capacity in overseas market is shrinking, therefore, although China"s TFT-LCD production capacity is expanding rapidly, the output value of global TFT-LCD is still stable.

The experts of Newsijie expressed that the shipment of TFT-LCD still accounted for 65% in the global display panel industry in 2021, far ahead of OLED"s 20%. In comparison, TFT-LCD shipment is relatively stable, and OLED has become the upgrade target of display panel with rapid growth in shipment. In the short term, TFT-LCD will still be the mainstream product in the display panel market, but in the future, its demand will gradually decline under the pressure of OLED; in the long term, the development space of TFT-LCD will shrink. China has become the world"s largest TFT-LCD producer with enterprises developed in scales and products with cost-effective advantages; China will further squeeze the development space of the TFT-LCD manufacturers in South Korea and Taiwan. In the future, Chinese TFT-LCD manufacturers are expected to lead the global TFT-LCD market.

In ruling NY N320557 (August 4, 2021), Customs and Border Protection (CBP) discussed the country of origin of five Thin Film Transistor – Liquid Crystal Display (TFT-LCD) modules. All five modules are virtually identical in composition, as they are all composed of a TFT-LCD cell, polarizers, a backlight, a driver and control printed circuit board (PCB), and a flexible PCB for connection. TFT display technology allows for the construction of high-resolution LCD displays, and the modules – once completed – can be incorporated into a variety of consumers display applications.

The manufacturing process for the five modules is also identical. The process begins in Japan where the TFT-LCD cell is manufactured. The TFT is created by depositing transistors onto a substrate through chemical vapor deposition, while the color filter is manufactured by building a color matrix on a glass substrate. The creation process of the cells is then completed when a layer of liquid crystal is deposited between the color filter and TFT as the two part are bonded together, creating a sheet of TFT-LCD cells. As next steps, the sheet of cells is delivered to China to be cut into individual cells. The cut-up cells are then bonded to the printed circuit board assembly (PCBA) – which contains the driver and control circuity – before the polarizers, backlight, and flexible connection PCBA are attached.

CBP also established that “substantial transformation” takes place when a particular product “emerges from a process with a new name, character or use different from that possessed by the article prior to processing.” The agency explained that the completed TFT-LCD cell is what imparts the essential function of the module and that the manufacturing process in Japan is what renders the end-use of the product. Despite the assembly that took place in China, the process did not substantially transform the cell into a new and different article. As such, CBP determined that the country of origin of the five modules is Japan.

One of the industry’s leading oxide panel makers selected Astra Glass as its backplane glass substrate because it has the inherent fidelity to thrive in high-temperature oxide-TFT glass fabrication for immersive high-performance displays.

One of the industry’s leading oxide panel makers selected Astra Glass as its backplane glass substrate because it has the inherent fidelity to thrive in high-temperature oxide-TFT glass fabrication for immersive high-performance displays.

2.0TFT sunlight visible half penetration half anti RGB/color screen 240*320 Thin film transistor displays are a full color modules that can display graphics, characters and video and are great for adding an interesting user interface to any product. Thin Film Transistor Advantages: Since there is no fluid, thin film...

2.2 Visible semi-transparent semi-reflection color screen 240*320 under TFT sunlight Thin film transistor displays are a full color modules that can display graphics, characters and video and are great for adding an interesting user interface to any product. Thin Film Transistor Advantages: Since there is no fluid,...

A liquid crystal display or LCD draws its definition from its name itself. It is a combination of two states of matter, the solid and the liquid. LCD uses a liquid crystal to produce a visible image. Liquid crystal displays are super-thin technology display screens that are generally used in laptop computer screens,...

A liquid-crystal display (LCD) is a flat-panel display or other electronically modulated optical device that uses the light-modulating properties of liquid crystals combined with polarizers. Liquid crystals do not emit light directly, instead using a backlight or reflector to produce images in color or monochrome....

A thin-film-transistor liquid-crystal display (TFT LCD) is a variant of a liquid-crystal display (LCD) that uses thin-film-transistor (TFT) technology to improve image qualities such as addressability and contrast. A TFT LCD is an active matrix LCD, in contrast to passive matrix LCDs or simple,...

Standard small to mid-size color TFT displays Increase your product’s appeal with a TFT LCD display from YeTai! TFT displays are liquid-crystal display modules with thin-film transistor technology. This TFT technology offers full RGB showcasing a range of colors and hues. Get rich colors, detailed images, and bright...

A liquid crystal display or LCD draws its definition from its name itself. It is a combination of two states of matter, the solid and the liquid. LCD uses a liquid crystal to produce a visible image. Liquid crystal displays are super-thin technology display screens that are generally used in laptop computer screens,...

TFT stands for "thin-film transistor." LCD stands for "liquid crystal display." Both terms refer to the flat-panel display, or screen, of a computer monitor or television set. TFT displays are made using large sheets of transistors, each one of which is controlled independently. A TFT screen is an "active-matrix"...

A thin-film-transistor liquid-crystal display (TFT LCD) is a variant of a liquid-crystal display (LCD) that uses thin-film-transistor (TFT) technology to improve image qualities such as addressability and contrast. A TFT LCD is an active matrix LCD, in contrast to passive matrix LCDs or simple,...

A thin-film-transistor liquid-crystal display (TFT LCD) is a variant of a liquid-crystal display (LCD) that uses thin-film transistor (TFT) technology to improve image qualities such as addressability and contrast. A TFT LCD is an active-matrix LCD, in contrast to passive-matrix LCDs or simple, direct-driven LCDs with...

A thin-film-transistor liquid-crystal display (TFT LCD) is a variant of a liquid-crystal display (LCD) that uses thin-film transistor (TFT) technology. A TFT LCD is an active-matrix LCD, in contrast to passive-matrix LCDs or simple, direct-driven LCDs with a few segments.TFT LCDs are used in appliances including...

A thin-film-transistor liquid-crystal-display (TFT-LCD) is another form of LCD which uses TFT technology to improve image quality like contrast and addressability. thin film transistor-liquid crystal display are used widely in computer monitors, mobile phones, television screens, handheld video game systems,...

A thin-film-transistor liquid-crystal-display (TFT-LCD) is another form of LCD which uses TFT technology to improve image quality like contrast and addressability. The emergence of high performance Thin Film Transistor Liquid Crystal Display (TFT LCD) technology over the last decade heralds a new era in desktop...

Thin Film Transistor Liquid Crystal Displays or TFT LCD is an active matrix LCD as opposed to the non TFT variant which is passive. LCD came on the scene in the late sixties further to developments by RCA. Optel Corporation provided the first application of LCD in commercial/consumer items such as calculators and...

Stands for "Thin Film Transistor." These transistors are used in high-quality flat panel liquid-crystal displays (LCDs). TFT-based displays have a transistor for each pixel on the screen. This allows the electrical current that illuminates the display to be turned on and off at a faster rate, which makes the display...

The development of a thin-film transistor (TFT) technology for use with plastic substrates is still in its infancy. There is significant room for improvement in ultra-low temperature fabricated poly-Si TFTs. High mobilities, low leakage currents and threshold voltages are desirable for high-performance active-matrix...

LCD’s became most popular in consumer devices. As the technology developed and progressed, TFT’s improved the LCD technology and the realm of possibility of uses grew. This became an active matrix technology allowing for the ability to address and electronically maintain the state of each pixel. Developments such as...

A TFT display is a form of Liquid Crystal Display with thin film transistors for controlling the image formation. The technology works by controlling brightness in red, green and blue sub-pixels through transistors for each pixel on the screen.The liquid-crystal behaviour is similar to that of a TN display, relying on...

An LCD consists of many pixels. A pixel consists of three sub-pixels (Red/Green/Blue, RGB). In the case of Full-HD resolution, which is widely used for smartphones, there are more than six million (1,080 x 1,920 x 3 = 6,220,800) sub-pixels. To activate these millions of sub-pixels a TFT is required in each sub-pixel....

A thin film transistor liquid crystal display (TFT-LCD) is a technology which is used in LCD monitor and television displays. TFT technology can be used to give one of the clearest pictures of any flat screen display and it uses much less electricity than older screens. Positive aspects of TFT displays: easy to...

Thin film transistor displays are a full color modules that can display graphics, characters and video and are great for adding an interesting user interface to any product. Thin Film Transistor Advantages: Can display up to 64 million colors Operates down to -30C Available sizes from 1.7” to 15” Larger and smaller...

Thin film transistor displays are a full color modules that can display graphics, characters and video and are great for adding an interesting user interface to any product. Thin Film Transistor Advantages: Can display up to 64 million colors Operates down to -30C Available sizes from 1.7” to 15” Larger and smaller...

STONE Technologies is a proud manufacturer of superior quality TFT LCD modules and LCD screens. The company also provides intelligent HMI solutions that perfectly fit in with its excellent hardware offerings.

STONE TFT LCD modules come with a microcontroller unit that has a 1GHz Cortex-A8 CPU. Such a module can easily be transformed into an HMI screen. Simple hexadecimal instructions can be used to control the module through the UART port. Furthermore, you can seamlessly develop STONE TFT LCD color user interface modules and add touch control, features to them.

Becoming a reputable TFT LCD manufacturer is no piece of cake. It requires a company to pay attention to detail, have excellent manufacturing processes, the right TFT display technology, and have a consumer mindset.

Now, we list down 10 of the best famous LCD manufacturers globally. We’ll also explore why they became among the top 10 LCD display Manufacturers in the world.

LG Display is a leading manufacturer of thin-film transistor liquid crystal displays (TFT-LCD) panels, OLED, and flexible displays.LG Display began developing TFT-LCD in 1987 and currently offers Display panels in a variety of sizes and specifications using different cutting-edge technologies (IPS, OLED, and flexible technology).

With innovative and differentiated technologies, QINNOOptoelectronics provides advanced display integration solutions, including 4K2K ultra-high resolution, 3D naked eye, IGZO, LTPS, AMOLED, OLED, and touch solutions. Qinnooptoelectronics sets specifications and leads the market. A wide range of product line is across all kinds of TFT LCD panel modules, touch modules, for example, TV panel, desktop and laptop computer monitor with panels, small and medium scale “panels, medical, automotive, etc., the supply of cutting-edge information and consumer electronics customers around the world, for the world TFT – LCD (thin-film transistor liquid crystal display) leading manufacturers.

AU Optronics Co., LTD., formerly AU Optronics Corporation, was founded in August 1996. It changed its name to AU Optronics after its merger with UNIOPtronics in 2001. Through two mergers, AU has been able to have a full range of generations of production lines for panels of all sizes.Au Optronics is a TFT-LCD design, manufacturing, and r&d company. Since 2008, au Optronics has entered the green energy industry, providing customers with high-efficiency solar energy solutions.

Sharp has been called the “father of LCD panels”.Since its founding in 1912, Sharp developed the world’s first calculator and LIQUID crystal display, represented by the living pencil, which was invented as the company name. At the same time, Sharp is actively expanding into new areas to improve people’s living standards and social progress. Made a contribution.

BYD IT products and businesses mainly include rechargeable batteries, plastic mechanism parts, metal parts, hardware electronic products, cell phone keys, microelectronics products, LCD modules, optoelectronics products, flexible circuit boards, chargers, connectors, uninterruptible power supplies, DC power supplies, solar products, cell phone decoration, cell phone ODM, cell phone testing, cell phone assembly business, notebook computer ODM, testing and manufacturing and assembly business, etc.

Tianma microelectronics co., LTD., founded in 1983, the company focus on smartphones, tablets, represented by high order laptop display market of consumer goods and automotive, medical, POS, HMI, etc., represented by professional display market, and actively layout smart home, intelligent wear, AR/VR, unmanned aerial vehicles (UAVs) and other emerging markets, to provide customers with the best product experience.IN terms of technology, the company has independently mastered leading technologies such as LTPS-TFT, AMOLED, flexible display, Oxide-TFT, 3D display, transparent display, and in-cell/on-cell integrated touch control. TFT-LCD key Materials and Technologies National Engineering Laboratory, national enterprise Technology Center, post-doctoral mobile workstation, and undertake national Development and Reform Commission, The Ministry of Science and Technology, the Ministry of Industry and Information Technology, and other major national thematic projects. The company’s long-term accumulation and continuous investment in advanced technology lay the foundation for innovation and development in the field of application.

Ms.Josey

Ms.Josey

Ms.Josey

Ms.Josey