any more square shaped lcd displays supplier

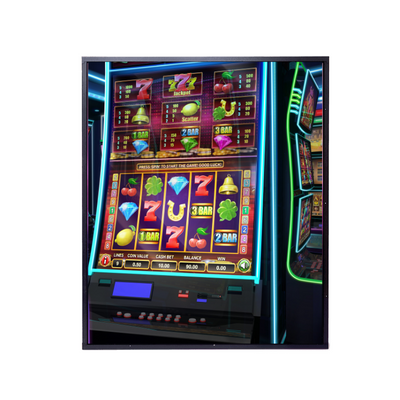

CDS Square LCD displays, square screens, square monitors, and professional square monitors for commercial use are increasingly popular in retail, museum, digital art, amusement and Gaming design installs where a niche and unique display is required. Particularly popular in Museum displays and display designs as well as art installs.

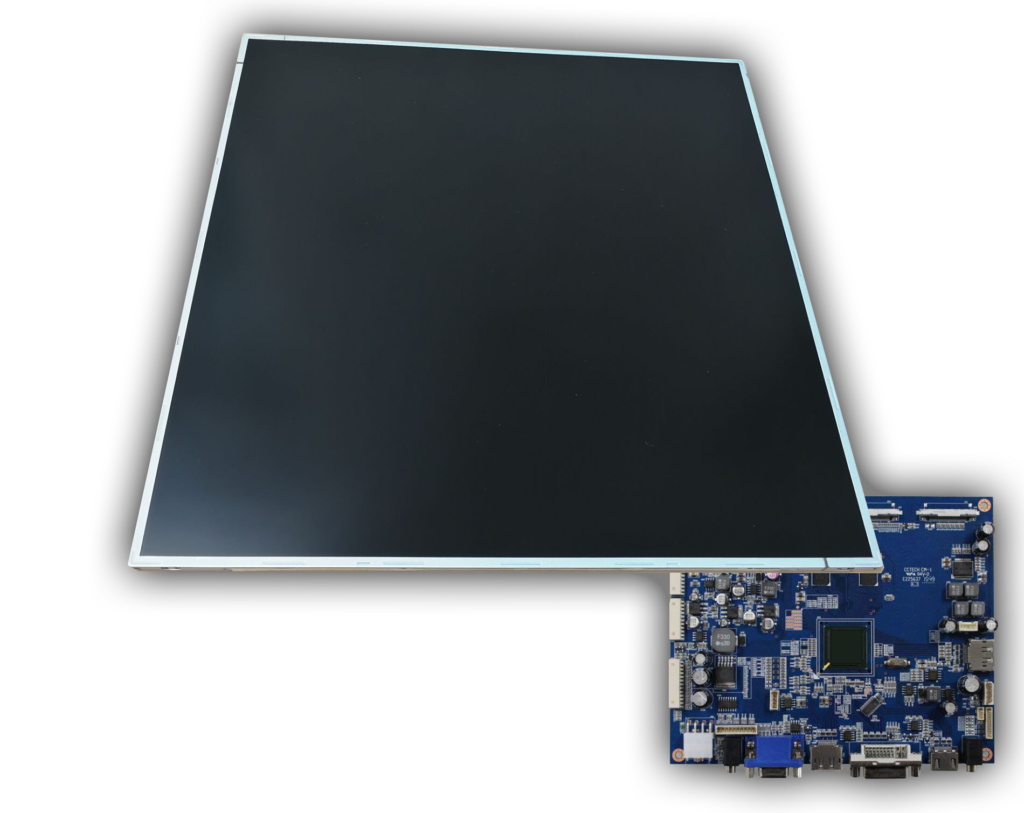

Multiple options available including square panel, panel & kit as well as enclosed square LCD monitor (square monitor), and square chassis monitors. Interactive touch screen options are also available as well as fully customised solutions to specifically meet your project requirements whether that be high brightness, ruggedization, extra thick touchscreens, or various input options such as HDMI, VGA, DP, DVI etc.

Square lcd displays usually, Nasher-sensitive (DIY), and on the other hand. There are no other lcd displays, NativelyID, and able to display the specific functions of a screen. In the case of a lcd display, NasherIDs are available. In the type of lcd display, Nasherid is available as well.@@@@@

Square lcd displays are available in the form of square-sized lcd displays, such as square-light lcd screens, square-light lcd displays, and lcd display in bulk are the most popular choices. For one of the type of lcd display, the 12-pin lcd display is the most popular type. For instance, the type of lcd display in bulk is one of the most popular choices.@@@@@

A wide variety of square lcd display with ips options are available to you, such as original manufacturer, odm and agency.You can also choose from tft, ips and standard square lcd display with ips,

With the rapid growth of smart homes, lots of customers are looking for square displays to be applied in the temperature control device and intelligent switch. Leadtek has developed three options of 4.0" LCD square displays with resolution at 480x480 and 720x720. In our range, one of the 4.0" square displays is designed with PCAP.

Through the square LCD panel display, messages, device status, and percentage information can all be displayed; This enables a user to find the key system information effortlessly. The fascia color, material, and appearance can also be customized allowing a user to tailor the panel to their personal requirements.

A square LCD screen monitor is a type of display device that uses liquid crystal display (LCD) technology to display images on a screen. LCD monitors are known for their thin, lightweight design and low power consumption, which makes them a popular choice for computer displays, televisions, and other electronic devices. Leadtek square tft display wholesale are you great option.

LCD, a short form for Liquid Crystal Display, is an electronically modulated optical device that makes use of liquid crystals in its primary form of operation. LCD doesn’t emit light directly, rather make use of a backlight or reflector to display images in colors.Types of LCD Displays

There are three major types of LCD displays. They are Twisted Nematic (TN), In-Plane Switching (IPS), and Vertical Alignment (VA).Twisted Nematic (TN): This is the most popular LCD display type. The technology consists of nematic liquid crystals compressed between two glass plates. When power is applied to the electrodes, the LCD will twist by 90⁰. It’s cost-effective, has a high refresh rate but limited brightness.In-Plane Switching (IPS): This LCD technology enhances image quality by acting on the liquid crystal in the display screen. When power is applied, the liquid crystals rotate parallel instead of upright to allow light to go through. This action results in high image quality. With IPS, you will get better contrast, brightness, color representation, and viewing angles than TN. No matter the angle you’re viewing from, the images won’t be distorted.Vertical Alignment (VA): Also called Multi-Domain Vertical Alignment. It displays both TN and IPS screens features. When power is applied, the pixels align vertically to the glass, allowing light to pass through. VA LCD provides wide angle, high contrast, and good color reproduction images.Sourcing from a Reliable LCD Screen Supplier

Zhsunyco® is a LCD screen manufacturer and supplier you can count on to deliver LCD screen display solutions and electronic price tags in supermarkets with the highest quality, functionality, and durability. Starting from the conversation stage, we help take your requirements from the concept level to a feasible design level. After production is completed, we continue to provide you with professional assistance and support.Customer Communication and Consultation: We talk with you, discussing your LCD screen requirements and concerns.Quotation: We will send you a price quote based on your LCD order.Samples: Within 3 days, we will make small-scale samples for you to assess.Customer Confirmation: You will thoroughly assess and evaluate the LCD screens to know if they comply with your requirements.Mass production: Following the approval of the samples, we begin full production of your order.Delivery: Within 7 days, your order production will be completed and shipped to you via your preferred means.

DS042BOE40N-001 is a 4.2inch normally black display mode,it applies to 4.2” color TFT-LCD panel.The 4.2inch color TFT-LCD panel is designed for electronic label,white house,smart home,intercome device,industrial equipment device and other electronic products which require high quality flat panel displays,excellent visual effect.This module follows RoHS.

6.Special share LCD can be customized,such as bar,square and round LCD display can be customized or any other special shaped display is available to custom.

Thinking of incorporating small LCDs or specialty shaped custom static LCD displays? There is an element you need to be aware of. Using a nonstandard shape or implementing a smaller display may increase the production cost of your custom LCD display module.

Small custom LCD Modules in this article are represented by having dimensions with an area [Width times Height] smaller than 400 millimeters squared. The reason for the higher cost of these units is taken from the fact that only a portion of the LCD production process is automated. The cutting of the glass is mechanized and can easily be repeated for smaller sized cuts; however, the polarizer, which is applied to the back of the LCD, must be applied by hand and requires delicate, labor intensive skill. This makes for higher labor costs and decreased production line efficiency for each small custom LCD display. Smaller displays are still available, but customers should be prepared to pay a higher price for the production of their unique design.

Likewise, if you need specialty shape cuts, expect slightly increased costs. Manufacturing uses an original sheet of glass, approximately 396mm by 345mm, to cut out the smaller ITO glass pieces for each individual LCD. The increased cost arises from the amount of glass wasted in between cuts. For example, the waste generated from cutting a circle out of an original square shape. The corners left over by this cut are unusable in the creation of additional circle displays.

Increased costs are a given when you are looking to design and build small custom LCD displays. With changing technology and greater specializations of technology, the factories efficiency for customized LCDs will continue to improve. Slowly the prices for today’s smaller LCDs and specialty cut displays should decrease as customers continue to look for smaller and more flexible custom LCDs to distinguish their products from their competitors.

The custom LCD displays have tremendous benefits to offer. It has become more popular because of its excellent use. The major benefit of the custom LCD is that you can choose the display size you need. It indicates that you are not required to engage with the preset size anymore.

You can use custom LCD displays whenever you want to stand out from the crowd. It suits all industries and minimizes the hassles involved in your task. Since LCD screens are not expensive to buy and maintain, you can invest in them and enjoy huge flexibility.

LCD displays are designed to be highly efficient and access less energy. So, you can incorporate it into your industry easily and grab huge benefits. With the customization LCD, you can enjoy different features such as industrial-grade material, long backlight lifetime, wide temperature range, and much more.

Upon joining hands with the reliable LCD manufacturer, you can easily choose the custom LCD displays. We are the leading LCD manufacturer and supplier in the market. With years of experience and the accessibility of an expert team, we listen to your needs and work to provide the best solution. We render the best quality lcd display panel at an affordable rate.

LCD display panelsare required in different industries for various uses like to design POS systems, IOT, use as screen in medical devices and for different other purposes. We offer you the best range of TFT displays – available in a variety of sizes. Choose the best one from:

They are offered with precise information about features and technical specifications so that you can choose the best one according to your choice. Our displays are commonly used in smart home, POS systems, to display information, in automotive industry and different others. Our prices are competitive; while we ensure customs clearance and documentation – required for display. We have a world-class large manufacturing unit in Shenzhen China, where a pool of engineers has been working dedicatedly to fulfill your requirement to get the best models of custom lcd, lcd display panel, tft display in different sizes and designs.

For monitor and display system manufacturers there is now significant choice available regarding size and brightness. 4:3 and 16:9 aspect ratios are no longer limitations as there are many models that can be described as ultra-wide or banner panels. Similarly LCD panels are available with brightness ratings from 250nit to over 2,000nit enabling displays for indoor an outdoor sunlight readable installations.

There are over 400 panel models (with backlight) over 30″ listed as in production. For a long time displays were 4:3 aspect ratio then with the advent of HD in the 1990’s we got 16:9 and these two remain the mainstream shapes. However as anyone in the display industry will know, super wide aspect ratio panels (often referred to as stretch, banner or bar type) have been available for some time and are getting considerably more common. Many of these are cut from larger panels to achieve custom sizes but there are an increasing number of standard models, especially with high bright backlights.

Not as mainstream but getting more visibility are other shapes such as square panels, I know of two sizes, 26.5″ and 40″, and these are eye catching. We have done a number of projects using square panels as part of a mosaic type wall arrangement mixing, square, 16:9, and super wide panels.

Curved panels made it to consumer TV’s and OLED has helped with that. But for commercial applications the big market has been gaming machines and I was interested to learn recently of J shaped panels, these are just curved in the lower half of a portrait oriented panel. This gives rise to the description of C shaped (evenly curved) and J shaped panels.

Today’s vivid, immersive displays rely on layers of Corning glass to provide a stunning viewing experience. Wherever you look for news and entertainment, chances are Corning glass is there, too.

We are the science and engineering powerhouse behind revolutionary display inventions, including glass cathode-ray tubes for the first televisions and the LCD glass that made smartphones and laptop computers commonplace. We set the standard for the industry with Corning® EAGLE XG® Slim Glass substrates, manufacturing over 25 billion square feet while eliminating more than the equivalent of 6,000 truckloads of heavy metals from entering the environment.

Corning’s latest glass innovation and product is enabling brighter, faster, and more lifelike images. Award winning Corning® Astra™ Glass is a precisely engineered, balanced glass substrate that enables high-performance displays for a variety of applications, including the tablets, notebooks, and 8K TVs.

Corning"s display portfolio is finding new opportunities in emerging technologies, including Quantum Dot, Micro LED and Mini LED. With our proven track record of navigating the display technology roadmap, our proprietary fusion manufacturing platform and reliable supply network, our commitment to our customers and innovation, and our innovative portfolio, we are excited to support the next generation of displays.

Take your design to the next level with our range of TFT Displays including latest IPS TFT, circular and bar shape as well as large size TFT. With or without touch, these are fully customisable to your system requirements.

TFT-LCD technology is now fairly mature. As a result, manufacturing processes are efficient and production yields are high, leading to very competitive unit prices. Upgrading from a monochrome display to a TFT is now an affordable way to give your product an uplift.

It is now possible to transform from a monochrome display to a colour display in space constrained systemsby using a letterbox shaped display. These ultra-wide displays are ideal for applications with restricted build height such as rack mount systems or landscape format front panels.

Large TFT display systems are increasingly being used for transportation information, retail signage and vending machines and kiosks. We can supply a large range of TFT solutions up to 65" diameter and in bar-style, square or rectangular configurations.

We are now offering increasing cover lens customisation options and processes to make your TFT LCD user interface truly stand out! Anders’ experienced marketers and engineers work with our manufacturing partners around the world to keep informed of the latest innovations, including mirrored glass,tinted glass, spot-facing, three dimension glass, and many more!

See below our range of TFT Displayswith sizes ranging from0.96" to 64.5" and including circular and bar type shape. All our displays can be tailored to suit your application antimicrobial coating technology,

There are many display technologies, but do you know which one would be better for your application? Particularly when considering optimum viewing angle and contrast. We discuss 2 of the best options.

Compare IPS vs TFT displays - the TFT display is the display of choice for industrial designs, but it can have its limitations. A newer technology called IPS (in plane switching) offers better viewing angles and colours, but is it really the best choice - we discuss benefits and negatives of both types of TFT display.

Pixel, also called Picture Element, A pixel is the smallest unit of a digital image or graphic that can be displayed and represented on a digital display device. A pixel is the basic logical unit in digital graphics. Pixels are combined to form a complete image, video, text, or any visible thing on a computer display

LCD display doesn’t operate the same way as CRT displays , which fires electrons at a glass screen, a LCD display has individual pixels arranged in a rectangular grid. Each pixel has RGB(Red, Green, Blue) sub-pixel that can be turned on or off. When all of a pixel’s sub-pixels are turned off, it appears black. When all the sub-pixels are turned on 100%, it appears white. By adjusting the individual levels of red, green, and blue light, millions of color combinations are possible

The pixels of the LCD screen were made by circuitry and electrodes of the backplane. Each sub-pixel contains a TFT (Thin Film Transistor) element. These structures are formed by depositing various materials (metals and silicon) on to the glass substrate that will become one part of the complete display “stack,” and then making them through photolithography. For more information about TFT LCDs, please refer to “

The etched pixels by photolith process are the Native Resolution. Actually, all the flat panel displays, LCD, OLED, Plasma etc.) have native resolution which are different from CRT monitors

Although we can define a LCD display with resolution, a Full HD resolution on screen size of a 15” monitor or a 27” monitor will show different. The screen “fineness” is very important for some application, like medical, or even our cell phone. If the display “fineness” is not enough, the display will look “pixelized” which is unable to show details.

But you see other lower resolution available, that is because video cards are doing the trick. A video card can display a lower LCD screen resolution than the LCD’s built-in native resolution. The video cards can combine the pixels and turn a higher resolution into lower resolution, or just use part of the full screen. But video cards can’t do the magic to exceed the native resolution.

![]()

LCD displays in cars have been flat, rectangular and low resolution since the beginning. However, as the cockpit becomes a smart mobile digital assistant, there is increased need for bigger, higher-resolution, more immersive displays. Next-generation cockpit displays are curved and offer high resolution at much larger sizes than current displays. Visteon is one of the largest suppliers of automotive displays to the industry and has multiple years of experience in critical aspects of automotive use cases, such as head impact safety, long life, extreme temperatures, vibrations and reflectivity.

Many Apple products use liquid crystal displays (LCD). LCD technology uses rows and columns of addressable points (pixels) that render text and images on the screen. Each pixel has three separate subpixels—red, green and blue—that allow an image to render in full color. Each subpixel has a corresponding transistor responsible for turning that subpixel on and off.

Depending on the display size, there can be thousands or millions of subpixels on the LCD panel. For example, the LCD panel used in the iMac (Retina 5K, 27-inch, 2019) has a display resolution of 5120 x 2880, which means there are over 14.7 million pixels. Each pixel is made up of a red, a green, and a blue subpixel, resulting in over 44 million individual picture elements on the 27-inch display. Occasionally, a transistor may not work perfectly, which results in the affected subpixel remaining off (dark) or on (bright). With the millions of subpixels on a display, it is possible to have a low number of such transistors on an LCD. In some cases a small piece of dust or other foreign material may appear to be a pixel anomaly. Apple strives to use the highest quality LCD panels in its products, however pixel anomalies can occur in a small percentage of panels.

In many cases pixel anomalies are caused by a piece of foreign material that is trapped somewhere in the display or on the front surface of the glass panel. Foreign material is typically irregular in shape and is usually most noticeable when viewed against a white background. Foreign material that is on the front surface of the glass panel can be easily removed using a lint free cloth. Foreign material that is trapped within the screen must be removed by an Apple Authorized Service Provider or Apple Retail Store.

One of today’s modern technological wonders is the flat-panel liquid crystal display (LCD) screen, which is the key component we find inside televisions, computer monitors, smartphones, and an ever-proliferating range of gadgets that display information electronically.What most people don’t realize is how complex and sophisticated the manufacturing process is. The entire world’s supply is made within two time zones in East Asia. Unless, of course, the factory proposed by Foxconn for Wisconsin actually gets built.

Liquid crystal display (LCD) screens are manufactured by assembling a sandwich of two thin sheets of glass.On one of the sheets are transistor “cells” formed by first depositing a layer of indium tin oxide (ITO), an unusual metal alloy that you can actually see through.That’s how you can get electrical signals to the middle of a screen.Then you deposit a layer of silicon, followed by a process that builds millions of precisely shaped transistor parts.This patterning step is repeated to build up tiny little cells, one for each dot (known as a pixel) on the screen.Each step has to be precisely aligned to the previous one within a few microns.Remember, the average human hair is 40 microns in diameter.

On the other sheet of glass, you make an array of millions of red, green, and blue dots in a black matrix, called a color filter array (CFA).This is how you produce the colors when you shine light through it.Then you drop tiny amounts of liquid crystal material into the cells on the first sheet and glue the two sheets together.You have to align the two sheets so the colored dots sit right on top of the cells, and you can’t be off by more than a few microns in each direction anywhere on the sheet.The sandwich is next covered with special sheets of polarizing film, and the sheets are cut into individual “panels” – a term that is used to describe the subassembly that actually goes into a TV.

For the sake of efficiency, you would like to make as many panels on a sheet as possible, within the practical limitations of how big a sheet you can handle at a time.The first modern LCD Fabs built in the early 1990s made sheets the size of a single notebook computer screen, and the size grew over time. A Gen 5 sheet, from around 2003, is 1100 x 1300 mm, while a Gen 10.5 sheet is 2940 x 3370 mm (9.6 x 11 ft).The sheets of glass are only 0.5 - 0.7 mm thick or sometimes even thinner, so as you can imagine they are extremely fragile and can really only be handled by robots.The Hefei Gen 10.5 fab is designed to produce the panels for either eight 65 inch or six 75 inch TVs on a single mother glass.If you wanted to make 110 inch TVs, you could make two of them at a time.

The fab is enormous, 1.3 km from one end to the other, divided into three large buildings connected by bridges.LCD fabs are multi-story affairs.The main equipment floor is sandwiched between a ground floor that is filled with chemical pipelines, power distribution, and air handling equipment, and a third floor that also has a lot of air handling and other mechanical equipment.The main equipment floor has to provide a very stable environment with no vibrations, so an LCD fab typically uses far more structural steel in its construction than a typical skyscraper.I visited a Gen 5 fab in Taiwan in 2003, and the plant manager there told me they used three times as much structural steel as Taipei 101, which was the world’s tallest building from 2004- 2010.Since the equipment floor is usually one or two stories up, there are large loading docks on the outside of the building.When they bring the manufacturing equipment in, they load it onto a platform and hoist it with a crane on the outside of the building.That’s one way to recognize an LCD fab from the outside – loading docks on high floors that just open to the outdoors.

LCD fabs have to maintain strict standards of cleanliness inside.Any dust particles in the air could cause defects in the finished displays – tiny dark spots or uneven intensities on your screen.That means the air is passed through elaborate filtration systems and pushed downwards from the ceiling constantly.Workers have to wear special clean room protective clothing and scrub before entering to minimize dust particles or other contamination.People are the largest source of particles, from shedding dead skin cells, dust from cosmetic powders, or smoke particles exhaled from the lungs of workers who smoke.Clean rooms are rated by the number of particles per cubic meter of air.A class 100 cleanroom has less than 100 particles less than 0.3 microns in diameter per cubic meter of air, Class 10 has less than 10 particles, and so on. Fab 9 has hundeds of thousands of square meters of Class 100 cleanroom, and many critical areas like photolithography are Class 10.In comparison, the air in Harvard Square in Cambridge, MA is roughly Class 8,000,000, and probably gets substantially worse when an MBTA bus passes through.

Since most display manufacturing has to be done in a cleanroom and handling the glass requires such precision, the factory is heavily automated.As you watch the glass come in, it is placed into giant cassettes by robot handlers, and the cassettes are moved around throughout the factory.At each step, robots lift a piece of glass out of the cassette, and position it for the processing machines.Some of the machines, like the ones that deposit silicon or ITO, orient the glass vertically, and put them inside an enormous vacuum chamber where all the air is first pumped out before they can go to work.And then they somehow manage to deposit micrometer thin layers that are extremely uniform.It is a miracle that any of this stuff actually works.

The Hefei Gen 10.5 is one of the most sophisticated manufacturing plants in the world.On opening day for the fab, BOE shipped panels to Sony, Samsung Electronics, LG Electronics, Vizio, and Haier.So if you have a new 65 or 75-inch TV, there is some chance the LCD panel came from here.

Ms.Josey

Ms.Josey

Ms.Josey

Ms.Josey