is tft display easier to see in the sun free sample

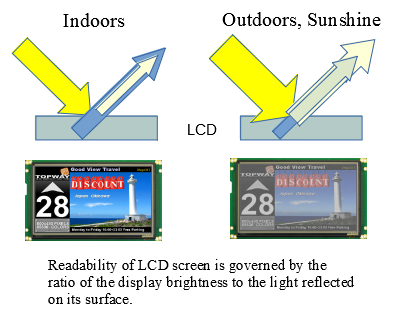

When display devices are brought outside, oftentimes they face the brightness of sunlight or any other form of high ambient light sources reflecting off of and overwhelming the LED backlight’s image.

With the growth of the LCD panel industry as a whole, it has become more important than ever to prevent the sun’s wash out of displays used outdoors, such as automobile displays, digital signage, and public kiosks. Hence, the sunlight readable display was invented.

One solution would be to increase the luminance of the TFT LCD monitor’s LED backlight to overpower the bright sunlight and eliminate glare. On average, TFT LCD screens have a brightness of about 250 to 450 Nits, but when this is increased to about 800 to 1000 (1000 is the most common) Nits, the device becomes a high bright LCDand a sunlight readable display.

Doing this is an affordable option for enhancement of image quality in the outdoors, including features like contrast ratio and viewing angle, in a common use setting like with phones.

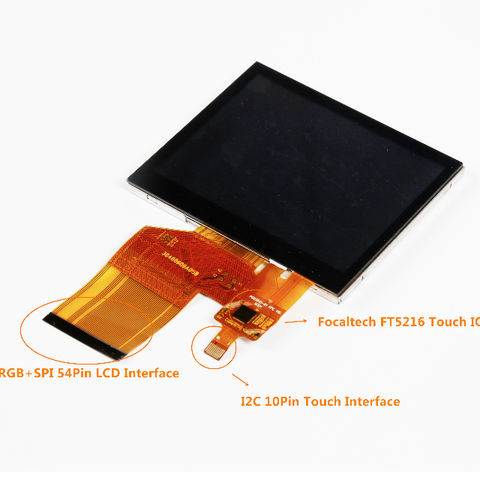

Since many of today’s TFT LCD display devices have shifted to touchscreens, the touch panels on the surface of LCD screens already block a small percentage of backlighting, decreasing the surface brightness and making it so that the sunlight can even more easily wash out the display. Resistive touch panels use two transparent layers above the glass substrate, but the transparent layers can still block up to 5% of the light.

In order to optimize the high brightness of the backlight, a different type of touchscreen can be used: the capacitive touchscreen. Though it is more expensive than the resistive touch screen, this technology is more ideal for sunlight readable displays than the resistive due to its usage of a thinner film or even in-cell technologies rather than two layers above the glass of the display, and therefore, light can pass more efficiently.

However, with this method comes a list of potential problems. Firstly, high brightness displays result in much greater power consumption and shorter battery life. In order to shed more light, more power will be needed which can also consequently result in device overheating which can also shorten battery life. If the backlight’s power is increased, the LED’s half-life may also be reduced.

While in bright exterior light settings, these devices reduce eye strain as the user attempts to view the image on screen, the brightness of the display itself can also cause eye strain, seen as the brightness may overwhelm your eyes. Many devices allow the user to adjust brightness, so this concern is oftentimes not too severe.

A recent technology falling into the sunlight readable display category is the transflective TFT LCD, coming from a combination of the word transmissive and reflective. By using a transflective polarizer, a significant percentage of sunlight is reflected away from the screen to aid in the reduction of wash out. This optical layer is known as the transflector.

In transflective TFT LCDs, sunlight can reflect off the display but can also pass through the TFT cell layer and be reflected back out off a somewhat transparent rear reflector in front of the backlight, illuminating the display without as much demand and power usage from the transmissive nature of the backlight. This addresses both the issues of wash out and the disadvantages of high brightness TFT LCDs in high ambient light environments. Because of its transmissive and reflective modes, this type of device is very useful for devices that will be used outdoors but also indoors.

While it does greatly reduce power consumption, transflective LCDs are much more expensive than high brightness LCDs. In recent years, the cost has decreased, but transflective LCDs continue to be more costly.

In addition to adjustments to the internal mechanics of LCDs, it is possible to make devices more sunlight-readable using surface treatments. The most common are anti-reflective (A/R) films/coatings and anti-glare processing.

Anti-reflective focuses on depositing multiple transparent thin film layers. With the thicknesses, structures, and properties of each individual layer composing the film, reflecting light wavelengths are changed, and thus less light is reflected.

When anti-glare is used, reflected light is fragmented. Using a rough surface as opposed to a smooth one, anti-glare treatments can reduce the reflection’s disruption of the actual image of the display.

Often paired with other methods of creating sunlight readable displays is optical bonding. By gluing the glass of a display to the TFT LCD cells beneath it, optical bonding eliminates the air gap that traditional LCD displays have in them using an optical grade adhesive.

This adhesive reduces the amount of reflection between the glass and LCD cell as well as the reflection of external ambient light. Doing this helps provide a clearer image with an increased contrast ratio, or the difference in the light intensity of the brightest white pixel color and darkest black pixel color.

With this contrast ratio improvement, optical bonding addresses the root issue with unreadable outdoor displays: the contrast. Though an increase in brightness can improve contrast, by fixing the contrast itself, LCD display images in outdoor environments will not be as washed out and will require less power consumption.

Besides the visual display advantages that optical bonding provides, this adhesive improves the display in many other ways. The first being durability, optical bonding eliminates the air gap within the device and replaces it with a hardened adhesive that can act as a shock absorber.

Touch screens with optical bonding gain, accuracy in where the point of contact is between the touch and screen. What is known as parallax, the refraction angle of light, can make it seem that the point of contact and the actual point on the display are different. When the adhesive is used, this refraction is minimized, if not reduced.

The optical bonding adhesive’s elimination of the air gap also protects the LCD from moisture/fogging and dust, as there is no space for impurities to penetrate and remain under the glass layer. This especially helps with maintaining the state of LCDs in transport, storage, and humid environments.

Compiling the various methods of improving LCD screens for sunlight readability, these devices can be optimized in high ambient light settings. An anti-glare coating is applied to the surface of the glass and anti-reflective coatings are applied to both the front and back. The transflector is also used in front of the backlight. These features can result in 1000 Nit or more display lighting, without the excessive power consumption and heat production through a high brightness backlight, consequently allowing for a longer lasting and better performing LCD

Unfortunately, the process of building a reflector inside TFT LCD is complicated and transflective TFT LCD is normally several times higher cost compared with normal transmissive TFT LCD.

To further improve and enhance the qualities of the LCD, LED and cold cathode fluorescent lamp (CCFL) backlights are used. Both these create bright displays, but the LED specifically can do so without as much power consumption and heat generation as compared to the CCFL option. Optical bonding is also applied in order to improve display contrast, leading to a more efficient and better quality sunlight readable display.

TFT (Thin Film Transistor) LCD (Liquid Crystal Display) we are talking here is TN (Twisted Nematic) type TFT displays which is align with the term in the TV and computer market. Now, TFT displays have taken over the majority of low-end color display market. They have wide applications in TV, computer monitors, medical, appliance, automotive, kiosk, POS terminals, low end mobile phones, marine, aerospace, industrial meters, smart homes, consumer electronic products etc. For more information about TFT displays, please visit our knowledge base.

Talking about Pros and Cons of TFT displays, we need to clarify which display they are compared to. To some displays, TFT displays might have advantages, but compared with another display, the same character might become the disadvantages of TFT displays. We will try our best to make clear as below.

Less Energy Consumption: Compared with CRT(Cathode-Ray Tube) VFD ( Vacuum Fluorescent Display) and LED (Light Emitting Diode) display, which made laptop possible.

Excellent physical design. TFT displays are very easy to design and integrated with other components, such as resistive and capacitive touch panels (RTP, CTP, PCAP) etc.

Minimum Eye Strain: Because TFT panel itself doesn’t emit light itself like CRT, LED, VFD. The light source is LED backlight which is filtered well with the TFT glass in front for the blue light.

More Energy Consumption: Compared with monochrome displays and OLED (PMOLED and AMOLED) display, which makes TFT displays less attractive in wearable device.

Poor response time and viewing angle: Compared with IPS LCD displays, AMOLED displays and recent micro-LED display. TFT displays still need to note viewing angle of 6 o’clock or 12 o’clock in the datasheet and still have the gray scale inversion issue.

High tooling cost: Depending on which generation production line to produce and also depending on its size. Building a TFT display fab normally need billions of dollars. For a big size display which needs high generation production line to produce. The NRE cost can be millions dollars.

Sunlight Readability: Because it is very expensive to produce transflective TFT LCD displays, in order to be readable under the sunlight, very bright LED backlight (> 1,000 nits) has to be used. The power needed is high and also need to deal with heat management. If used together with touch panel, expensive optical bonding (OCA or OCR) and surface treatment (AR, AF) technologies have to be used.

Let us start with the basics first; refresh the knowledge about TN and LCD displays in general, later we will talk about TFTs (Thin Film Transistors), how they differ from regular monochrome LCD displays. Then we will go on to the ghosting effect, so we will not only discuss the technology behind the construction of the TFT, but also some phenomena, like the ghosting effect, or grayscale inversion, that are important to understand when using an LCD TFT display.

Next, we will look at different technologies of the TFT LCD displays like TN, IPS, VA, and of course about transmissive and transflective LCD displays, because TFT displays also can be transmissive and transflective. In the last part we will talk about backlight.

Let us start with a short review of the most basic liquid crystal cell, which is the TN (twisted nematic) display. On the picture above, we can see that the light can be transmit through the cell or blocked by the liquid crystal cell using voltage. If you want to learn more about monochrome LCD displays and the basics of LCD displays, follow this link.

What is a TFT LCD display and how it is different from a monochrome LCD display? TFT is called an active display. Active, means we have one or more transistors in every cell, in every pixel and in every subpixel. TFT stands for Thin Film Transistor, transistors that are very small and very thin and are built into the pixel, so they are not somewhere outside in a controller, but they are in the pixel itself. For example, in a 55-inch TV set, the TFT display contains millions of transistors in the pixels. We do not see them, because they are very small and hidden, if we zoom in, however, we can see them in every corner of each pixel, like on the picture below.

On the picture above we can see subpixels, that are basic RGB (Red, Green, Blue) colors and a black part, with the transistors and electronic circuits. We just need to know that we have pixels, and subpixels, and each subpixel has transistors. This makes the display active, and thus is called the TFT display. TFT displays are usually color displays, but there are also monochrome TFT displays, that are active, and have transistors, but have no colors. The colors in the TFT LCD display are typically added by color filters on each subpixel. Usually the filters are RGB, but we also have RGBW (Red, Green, Blue, White) LCD displays with added subpixels without the filter (White) to make the display brighter.

What is interesting, the white part of the RGB and RGBW screen will look exactly the same from a distance, because the lights are mixed and generate white light, but when we come closer to the screen, we will not see white light at all.

Going a little bit deeper, into the TFT cell, there is a part inside well known to us from the monochrome LCD display Riverdi University lecture. We have a cell, liquid crystal, polarizers, an ITO (Indium Tin Oxide) layer for the electrodes, and additionally an electronic circuit. Usually, the electronic circuit consists of one transistor and some capacitors to sustain the pixel state when we switch the pixel OFF and ON. In a TFT LCD display the pixels are much more complicated because apart from building the liquid crystal part, we also need to build an electronic part.

That is why TFT LCD display technologies are very expensive to manufacture. If you are familiar with electronics, you know that the transistor is a kind of switch, and it allows us to switch the pixel ON and OFF. Because it is built into the pixel itself, it can be done very quickly and be very well controlled. We can control the exact state of every pixel not only the ON and OFF states, but also all the states in between. We can switch the light of the cells ON and OFF in several steps. Usually for TFT LCD displays it will be 8-bit steps per color, so we have 256 steps of brightness for every color, and every subpixel. Because we have three subpixels, we have a 24-bit color range, that means over 16 million combinations, we can, at least theoretically, show on our TFT LCD display over 16 million distinct colors using RGB pixels.

Now that we know how the TFT LCD display works, we can now learn some practical things one of which is LCD TFT ghosting. We know how the image is created, but what happens when we have the image on the screen for a prolonged time, and how to prevent it. In LCD displays we have something called LCD ghosting. We do not see it very often, but in some displays this phenomenon still exists.

If some elements of the picture i.e., your company logo is in the same place of the screen for a long period of time, for couple of weeks, months or a year, the crystals will memorize the state and later, when we change the image, we may see some ghosting of those elements. It really depends on many conditions like temperature and even the screen image that we display on the screen for longer periods of time. When you build your application, you can use some techniques to avoid it, like very rapid contrast change and of course to avoid the positioning the same image in the same position for a longer time.

You may have seen this phenomenon already as it is common in every display technology, and even companies like Apple put information on their websites, that users may encounter this phenomenon and how to fix it. It is called image ghosting or image persistence, and even Retina displays are not free of it.

Another issue present in TFT displays, especially TN LCD displays, is grayscale inversion. This is a phenomenon that changes the colors of the screen according to the viewing angle, and it is only one-sided. When buying a TFT LCD display, first we need to check what kind of technology it is. If it is an IPS display, like the Riverdi IPS display line, then we do not need to worry about the grayscale inversion because all the viewing angles will be the same and all of them will be very high, like 80, 85, or 89 degrees. But if you buy a more common or older display technology type, like the TN (twisted nematic) display, you need to think where it will be used, because one viewing angle will be out. It may be sometimes confusing, and you need to be careful as most factories define viewing direction of the screen and mistake this with the greyscale inversion side.

On the picture above, you can see further explanation of the grayscale inversion from Wikipedia. It says that some early panels and also nowadays TN displays, have grayscale inversion not necessary up-down, but it can be any angle, you need to check in the datasheet. The reason technologies like IPS (In-Plane Switching), used in the latest Riverdi displays, or VA, were developed, was to avoid this phenomenon. Also, we do not want to brag, but the Wikipedia definition references our website.

We know already that TN (twisted nematic) displays, suffer from grayscale inversion, which means the display has one viewing side, where the image color suddenly changes. It is tricky, and you need to be careful. On the picture above there is a part of the LCD TFT specification of a TN (twisted nematic) display, that has grayscale inversion, and if we go to this table, we can see the viewing angles. They are defined at 70, 70, 60 and 70 degrees, that is the maximum viewing angle, at which the user can see the image. Normally we may think that 70 degrees is better, so we will choose left and right side to be 70 degrees, and then up and down, and if we do not know the grayscale inversion phenomena, we may put our user on the bottom side which is also 70 degrees. The viewing direction will be then like a 6 o’clock direction, so we call it a 6 o’clock display. But you need to be careful! Looking at the specification, we can see that this display was defined as a 12 o’clock display, so it is best for it to be seen from a 12 o’clock direction. But we can find that the 12 o’clock has a lower viewing angle – 60 degrees. What does it mean? It means that on this side there will be no grayscale inversion. If we go to 40, 50, 60 degrees and even a little bit more, probably we will still see the image properly. Maybe with lower contrast, but the colors will not change. If we go from the bottom, from a 6 o’clock direction where we have the grayscale inversion, after 70 degrees or lower we will see a sudden color change, and of course this is something we want to avoid.

To summarize, when you buy older technology like TN and displays, which are still very popular, and Riverdi is selling them as well, you need to be careful where you put your display. If it is a handheld device, you will see the display from the bottom, but if you put it on a wall, you will see the display from the top, so you need to define it during the design phase, because later it is usually impossible or expensive to change the direction.

We will talk now about the other TFT technologies, that allow us to have wider viewing angles and more vivid colors. The most basic technology for monochrome and TFT LCD displays is twisted nematic (TN). As we already know, this kind of displays have a problem with grayscale inversion. On one side we have a higher retardation and will not get a clear image. That is why we have other technologies like VA (Vertical Alignment), where the liquid crystal is differently organized, and another variation of the TFT technology – IPS which is In-Plane Switching. The VA and IPS LCD displays do not have a problem with the viewing angles, you can see a clear image from all sides.

Nowadays all TV sets, tablets and of course mobile phones are IPS or VA. You can turn them around and see the image clear from all sides. But, for monitor applications the TN technology is still widely used, because the monitor usually is in front of you and most of the time you look directly at it, from top, left or right side, but very rarely from the bottom, so the grayscale inversion viewing angle can be placed there. This technology still is very practical because it is affordable and has some advantages for gamers because it is very fast.

Apart from the different organization of the liquid crystals, we also organize subpixels a little bit differently in a VA and IPS LCD displays. When we look closer at the TN display, we will just see the subpixels with color filters. If we look at the VA or IPS display they will have subpixels of subpixels. The subpixels are divided into smaller parts. In this way we can achieve even wider viewing angles and better colors for the user, but of course, it is more complicated and more expensive to do.

The picture above presents the TN display and grayscale inversion. For IPS or VA technology there is no such effect. The picture will be the same from all the sides we look so these technologies are popular where we need wide viewing angles, and TN is popular where we don’t need that, like in monitors. Other advantages of IPS LCD displays are they give accurate colors, and wide viewing angles. What is also important in practice, in our projects, is that the IPS LCD displays are less susceptible to mechanical force. When we apply mechanical force to the screen, and have an optically bonded touch screen, we push the display as well as squeeze the cells. When we have a TN display, every push on the cell changes the image suddenly, with the IPS LCD displays with in-plane switching, different liquid crystals organization, this effect is lesser. It is not completely removed but it is much less distinct. That is another reason IPS displays are very popular for smartphones, tablets, when we have the touchscreens usually optically bonded.

If we wanted to talk about disadvantages, there is a question mark over it, as some of them may be true, some of them do not rely on real cases, what kind of display, what kind of technology is it. Sometimes the IPS displays can have higher power consumption than others, in many cases however, not. They can be more expensive, but not necessarily. The new IPS panels can cost like TN panels, but IPS panels definitely have a longer response time. Again, it is not a rule, you can make IPS panels that are very fast, faster than TN panels, but if you want the fastest possible display, probably the TN panel will be the fastest. That is why the TN technology is still popular on the gaming market. Of course, you can find a lot of discussions on the internet, which technology is better, but it really depends on what you want to achieve.

Now, let us look at the backlight types. As we see here, on the picture above, we have four distinct types of backlight possible. The most common, 95 or 99 per cent of the TFT LCD displays on the market are the transmissive LCD display type, where we need the backlight from the back. If you remember from our Monochrome LCD Displays lecture, for transmissive LCD displays you need the backlight to be always on. If you switch the backlight off, you will not see anything. The same as for monochrome LCD displays, but less popular for TFT displays, we have the transflective LCD display type. They are not popular because usually for transflective TFT displays, the colors lack in brightness, and the displays are not very practical to use. You can see the screen, but the application is limited. Some transflective LCD displays are used by military, in applications where power consumption is paramount; where you can switch the backlight off and you agree to have lower image quality but still see the image. Power consumption and saving energy is most important in some kind of applications and you can use transflective LCD displays there. The reflective type of LCD displays are almost never used in TFT. There is one technology called Low Power Reflective Displays (LPRD) that is used in TFT but it is not popular. Lastly, we have a variation of reflective displays with frontlight, where we add frontlight to the reflective display and have the image even without external light.

Just a few words about Low Power Reflective Displays (LPRD). This kind of display uses environmental light, ambient light to reflect, and produce some colors. The colors are not perfect, not perfectly clear, but this technology is becoming increasingly popular because it allows to have color displays in battery powered applications. For example, a smartwatch would be a case for that technology, or an electrical bike or scooter, where we can not only have a standard monochrome LCD display but also a TFT LCD color display without the backlight; we can see the image even in

You have app. 15% of the article left. That content is exclusive for our Riverdi University members only. Please fill out the Riverdi University Membership form below and join our community!

strong sunlight and not need backlight at all. So, this kind of TFL LCD display technology is getting more and more popular when we have outdoor LCD displays and need a low power consumption.

On the picture above, we have some examples of how transmissive and reflective LCD displays work in the sunlight. If we have a simple image, like a black and white pattern, then on a transmissive LCD display, even with 1000 candela brightness, the image probably will be lower quality than for a reflective LCD display; if we have sunlight, we have very strong light reflections on the surface of the screen. We have talked about contrast in more detail in the lecture Sunlight Readable Displays. So, reflective LCD displays are a better solution for outdoor applications than transmissive LCD displays, where you need a really strong backlight, 1000 candela or more, to be really seen outdoors.

To show you how the backlight of LCD displays is built, we took the picture above. You can see the edge backlight there, where we have LEDs here on the small PCB on the edge, and we have a diffuser that distributes the light to the whole surface of LCD screen.

In addition to the backlight, we have something that is called a frontlight. It is similar to backlight, it also uses the LEDs to put the light into it, but the frontlight needs to be transparent as we have the display behind. On the example on the picture above we can see an e-paper display. The e-paper display is also a TFT display variation, but it is not LCD (liquid crystal), it is a different technology, but the back of the display is the same and it is reflective. The example you see is the Kindle 4 eBook reader. It uses an e-paper display and a frontlight as well, so you can read eBooks even during the night.

Please remember to SUBSCRIBE to our YouTube channel and fill out the MEMBERSHIP FORM, to be informed about our Riverdi University materials and live events!

I agree to the Riverdi Sp. z o.o Terms & Conditions and Privacy Policy. I also agree to receive emails from Riverdi Sp. z o.o and I understand that I may opt out of Riverdi Sp. z o.o subscriptions at any time.

There are more and more TFT displays used in outdoor applications, such as automobile display, digital signage and kiosks. High ambient light in outdoor environment often causes wash-out image and renders the screen not readable. Readability & sustainability of TFT display under direct sunlight is becoming vital. Topway Display has been developing sunlight readable LCD display solution for years. The company understands the ins and outs of sunlight readable TFT LCD.

Visibility is the ease with which a viewer can detect an object, or in more scientific term: the relationship between luminance contrast and human eye’s threshold. Therefore, the higher an object’s contrast is, the better is its visibility.

For an LCD to be readable in outdoor environment with very bright ambient light, the LCD screen’s brightness needs to exceed the intensity of light that is reflected from the display surface. To be comfortably viewed by human eyes, the LCD’s brightness needs to exceed its reflected light by a factor of 2.5 at minimum. Naturally, to make an LCD sunlight readable, we can work on two areas, increasing brightness or reducing reflectance.

On a clear day in direct sunlight, the ambient brightness is about 6000 cd/m2. And a typical TFT LCD with touch screen reflects about 14% of ambient light, which is around 840 cd/m2. These days, most LCD displays use LED backlight as light source. It is not too difficult to increase an LCD’s brightness to 800 ~ 1000 Nits, to overpower the bright reflected sunlight. Thus, you have a sunlight readable TFT LCD.

However, this method requires more backlight LEDs and/or higher driving current. The drawbacks are high power consumption, more heat dissipation, increased product size and shorter LED backlight lifespan. Apparently, increasing backlight to make TFT LCD sunlight-readable is not a very good solution.

Transflective TFT LCD is a TFT LCD with both transmissive and reflective characteristics. A partially reflective mirror layer is added between LCD and backlight. This change turns part of the reflected ambient light into LCD’s light source, increasing the TFT display’s brightness. However, transflective TFT LCD is more expensive than transmissive one. At the same time, the partially reflective mirror layer will block some of the backlight, making it not ideal in indoor or low ambient light environment.

What causes light reflection? When light traveling in one transparent medium encounters a boundary with another transparent medium, a portion of the light bounces off the border. Through the simplest version of Fresnel’s equation, we can calculate the amount of reflected light.

The total reflectance on a TFT LCD with touch panel is the sum of reflected light on any interface where two materials meet. As an example, between polarizer and display glass, the difference in index of refractions for the two materials is very small, around 0.1. So the reflected light on this interface is only 0.1%. As Fresnel’s equation points out, we should focus reflection reduction on air interfaces. For air, its index of refraction is 1; for glass, it is 1.5. And that results in a reflectance of 4.5%. Therefore, the three air interfaces contribute majority of TFT LCD’s reflectance, at about 13%.

The quick and easiest thing we can do to reduce air-glass interface reflectance is to use an Anti-Reflection and Anti-Glare film or apply AR coating. An external film with AR properties not only reduces reflected light, but also brings other benefits.

For food industry application, shattered glass is a serious problem. An LCD screen with external film solves this issue nicely. As for automotive applications, in an accident, broken LCD with top AR film won’t produce sharp edge glass that could harms auto occupant. Nevertheless, a top film always reduces TFT LCD’s surface hardness. And it is susceptible to scratches. On the other hand, AR coating retains LCD’s hardness and touch performance. But it comes with a bigger price tag.

Another quick and easy way to tackle reflectance is to affix a linear polarizer on the top of TFT screen. When ambient light gets to the top polarizer, only half of the light passes through. Which results in reflection light cutting to half. This is a very low cost way to increase TFT LCD’s contrast, such that making it more sunlight readable.

Laminating a circular polarizer in TFT LCD will get rid of a lot of reflectance. That is because when ambient light passes through circular polarizer it gets circularly polarized. And when it is reflected, the polarization direction flips by 180 degrees. So when reflected light comes back to the circular polarizer, nothing goes through to viewer’s eyes.

This method is very effective for an LCD display with resistive touch panel. We know resistive touch LCD has two air gaps: air gap between two ITO layers and air gap between touch panel and LCD display. Reflectance caused by the two air gaps is very high. Applying circular polarizer blocks off most of the reflected light, and makes the LCD display sunlight readable.

The disadvantage of such solution is its cost. Since we need not only a circular polarizer, but also a retarder film on the top of LCD display, making sure light originates from within LCD is not blocked by external circular polarizer.

Add AR films on both interfaces of internal air gap. The add-ons can reduce this area’s reflection from 8.5% to 2%. And since the AR films are not outside facing, they are much cheaper than the one used outside. Keeping the air gap also retains the ease of service, in case either touch panel or LCD display needs to be repaired.

The most effective way is to eliminate air gap totally, by using optical bonding. In plain language, we fill air gap with special optical adhesive, to smooth out the area’s refraction index differences. Such that reflectance caused by internal air gap drops from 8.5% to 0.5%. Optical bonding is expensive but effective way to improve TFT LCD sunlight readability. It enhances durability and resistance to impact. Moreover, no air gap means no moisture condensation and fogging.

There are many ways to make TFT LCDsunlight readable. They all have their own pros and cons. With 20+ years" LCD design and manufacturing experience, Topway knows how to create the best sunlight readable TFT LCD for challenging environments. Leave us a message and let"s start the conversation of creating suitable sunlight readable TFT LCD for your project.

Focus Displays offers a wide range of standard full color TFT displays. 64 million unique colors, high brightness, sharp contrast, -30C operating temperature, and fast response time are all good descriptions of a TFT display. This is why TFT technology is one of the most popular choices for a new product.

Thin Film Transistor (TFT) display technology can be seen in products such as laptop computers, cell phones, tablets, digital cameras, and many other products that require color. TFT’s are active matrix displays which offers exceptional viewing experiences especially when compared to other passive matrix technologies. The clarity on TFT displays is outstanding; and they possess a longer half-life than some types of OLEDs and range in sizes from less than an inch to over 15 inches.

Cold-Cathode Fluorescent Lamp (CCFL) is an AC driven backlight that requires an inverter to convert DC to AC. The AC signal and inverter may generate EMI (Electromagnetic interference) and arcing; Arcing must be eliminated for Intrinsically Safe products.

CCFL’s are still available, but are becoming a legacy (obsolete) component. TFT displays equipped with a CCFL require higher MOQs (Minimum Order Quantities) than displays with LED backlights.

Red, Green and Blue (RGB) backlights are built with either a single LED that produces red, green and blue colors or with three separate Red, Green or Blue LEDs.

RGB backlights require a controller to regulate the different intensities of each color. The controller’s function is to combine unique levels of Red, Green and Blue to produce any of 64M different colors.

Backlight brightness (Luminance) is measured in nits. A nit being the amount of light that one candle delivers in a 1 square meter box. The intensity of the LED backlight can be critical when operating in low light or in direct sun light and is usually controlled by adjusting the DC voltage. In many applications this is accomplished through pulse-width modulation (PWM)

The majority of TFT displays contain a touch panel, or touch screen. The touch panel is a touch-sensitive transparent overlay mounted on the front of the display glass. Allowing for interaction between the user and the LCD display.

Some touch panels require an independent driver IC; which can be included in the TFT display module or placed on the customer’s Printed Circuit Board (PCB). Touch screens make use of coordinate systems to locate where the user touched the screen.

Resistive touch panels are the lowest cost option and are standard equipment on many TFT modules. They are more common on smaller TFT displays, but can still be incorporated on larger modules.

Resistive touch panels are constructed using flexible materials with an air gap between and are coated with a resistive layer. When an object applies pressure to the top layer, it makes contact with microdots located on the bottom layer. This allows the touch screen to find the location of the touch using X and Y coordinates.

Custom resistive touch screens are an option if the customer requires a seal or gasket to be in contact with the glass and not in contact with the touch panel.

Resistive touch panels allow a single touch, although advances in new resistive technology will allow multi-touch operation in the near future. One main advantage of a resistive touch screen is the ability to be activated by the touch of any material. This includes a range of items from a bare finger, to a pencil, to even the edge of a credit card; regardless of its composition.

They also have the added advantage of operating in a wide temperature range and environments, including anything from the arctic cold of Alaska to the extreme heat of Death Valley.

Capacitive touch panels have become popular with such software as Windows 8®, Android® and Apple®. Additionally it is used in products such as cell phones and tablets, where multi-touch and zoom capabilities are important.

Current capacitive touch technology is limited to a conductive stylus such as a finger. The touch screen operates on capacitive sensing, based on capacitive coupling. A capacitive touch screen detects any material that is conductive or has a different dielectric then the air around it.

Contrast ratio, or static contrast ratio, is one way to measure the sharpness of the TFT LCD display. This ratio is the difference between the darkest black and the brightest white the display is able to produce. The higher the number on the left, the sharper the image. A typical contrast ratio for TFT may be 300:1. This number ratio means that the white is 300 times brighter than the black.

TFT LCD displays are measured in inches; this is the measurement of the diagonal distance across the glass. Common TFT sizes include: 1.77”, 2.4”, 2.8”, 3”, 4.3”, 5”, 5.7”, 5.8”, 7”, 10.2”, 12.1 and 15”.

As a general rule, the larger the size of the glass the higher the cost of the display, but there are exceptions to this rule. A larger display may be less expensive than a smaller display if the manufacture produces higher quantities of the larger displays. When selecting your color display, be sure to ask what the cost is for one size smaller and one size larger. It may be worth modifying your design requirements.

TFT resolution is the number of dots or pixels the display contains. It is measured by the number of dots along the horizontal (X axis) and the dots along the vertical (Y axis).

The higher the resolution, the more dots per square inch (DPI), the sharper the display will look. A higher resolution results in a higher cost. One reason for the increase in cost is that more driver chips are necessary to drive each segment.

Certain combinations of width and height are standardized and typically given a name and a letter representation that is descriptive of its dimensions. Popular names given to the TFT LCD displays resolution include:

Transmissive displays must have the backlight on at all times to read the display, but are not the best option in direct sunlight unless the backlight is 750 Nits or higher. A majority of TFT displays are Transmissive, but they will require more power to operate with a brighter backlight.

Transflective displays are readable with the backlight off provided there is enough ambient light. Transflective displays are more expensive than Transmissive also there may be a larger MOQ for Transflective. However, Transflective displays are the best option for direct sunlight.

Drivers update and refresh the pixels (Picture Elements) of a display. Each driver is assigned a set number of pixels. If there are more pixels than a single driver can handle, then an additional drivers are added.

A primary job of the driver is to refresh each pixel. In passive TFT displays, the pixel is refreshed and then allowed to slowly fade (aka decay) until refreshed again. The higher the refresh frequency, the sharper the displays contrast.

The controller does just what its name suggest. It controls the drivers. There is only one controller per display no matter how many drivers. A complex graphic display with several thousand pixels will contain one controller and several drivers.

The TFT display (minus touch screen/backlight) alone will contain one controller/driver combination. These are built into the display so the design engineer does not need to locate the correct hardware.

Response Time is the measurement of time it takes for a pixel/segment to change from black (OFF state) to white (ON state) and then back to black again. In other words, how fast the picture can be changed. A slow response time can result in the blurring of the picture in games, movies and even cad type programs.

If you do not see a Thin Film Transistor (TFT) Display module that meets your specifications, or you need a replacement TFT, we can build a custom TFT displays to meet your requirements. Custom TFTs require a one-time tooling fee and may require higher MOQs.

Ready to order samples for your TFT design? Contact one of our US-based technical support people today concerning your design requirements. Note: We can provide smaller quantities for samples and prototyping.

In order to keep this display in production over the long term, we are revising it to the CFA240320E0-024SN. Any backorders placed now will be fulfilled with the new part when it becomes available. Please contact support@crystalfontz.com with any questions.

This TFT EVE module simplifies development with this 2.4" Full-Color TFT Display. The EVE FT811 chip controls the display using a display list to easily display complex graphics. The display is sunlight readable, full color, and has a wide viewing angle, so it"s a great choice for inside or outside.

The PCB handles the TFT display backlight voltage, making this display module perfect for hand-held applications. Read more about how the EVE chip can help your product development on our blog.

For more detailed information on EVE, see the FTDI FT81x Datasheet. Further information including programming examples, interface design software, and more can be found on FTDI’s website here:https://www.ftdichip.com/Support/Utilities.htm.

The board is being revised to support a different NXP processor as the helper processor on the board. This will not affect the functionality of the module and is a drop-in replacement.

Due to the ongoing worldwide component shortage, we are unable to source the current processor until 2023. Instead of having a year-long lead time for our product, we are designing in a readily available processor.

Have you ever been at the car wash in the late afternoon, struggling to read the instructions on the display at the pay kiosk? That may be because it was not a sunlight-readable LCD display.

Any character or graphic LCD (not TFT, we will get to that in a bit) that is “positive mode” will be sunlight readable. Positive mode displays will have dark letters on a light background.

However, where regular (transmissive) TFT modules wash out in direct sunlight, a transflective TFT will use the sun to be more visible in brighter conditions.

For any questions about Crystalfontz LCD product lines, what LCD is the best choice for your application, or any other questions (technical or availability), please contact our knowledgeable and friendly support staff via email, phone, or chat.

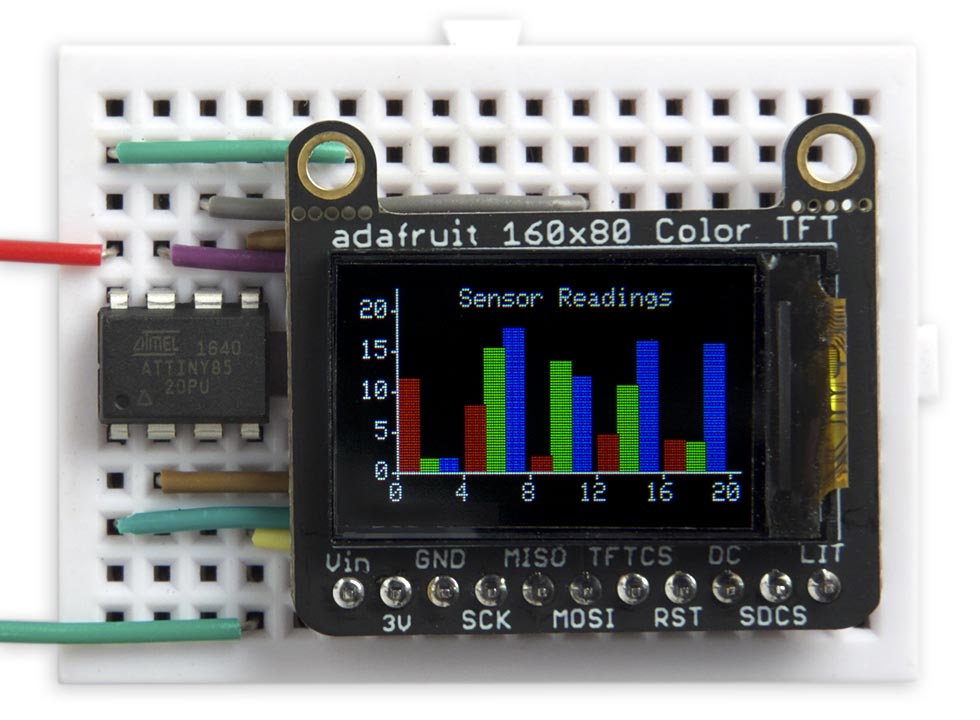

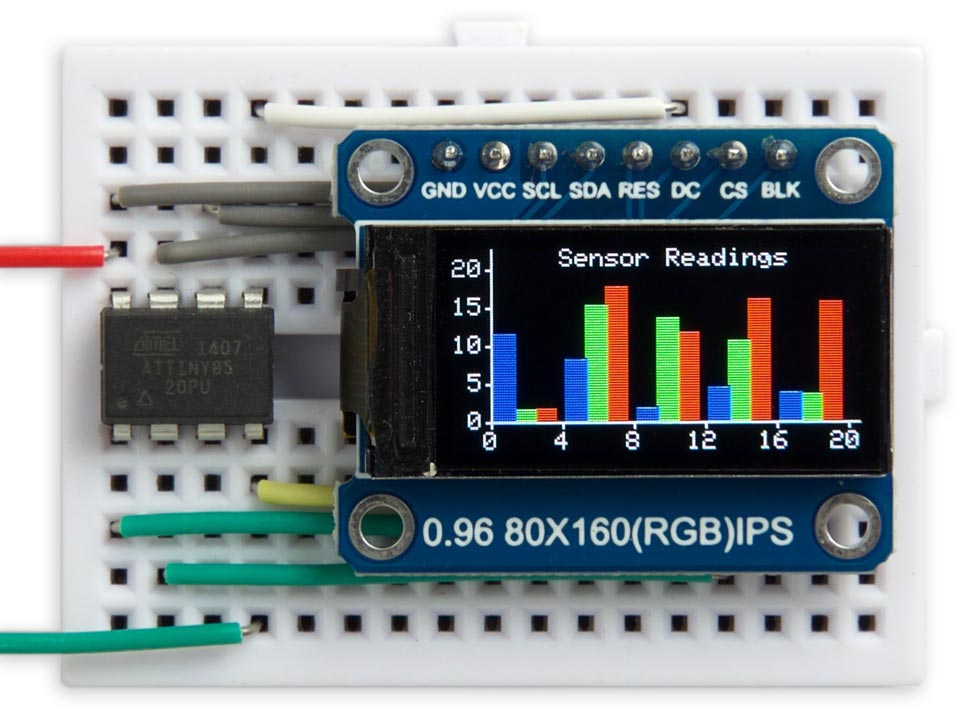

This is a graphics library for the family of small colour TFT displays based on the ST7735 and ST7789 driver chips. These are really nice displays; bright, colourful, available in a variety of useful sizes, and available at low cost from suppliers like Adafruit, AliExpress, or Banggood:

This library allows you to plot points, draw lines, draw filled rectangles, and plot text with an optional scale factor. I"ve included a demo histogram-plotting program that adjusts itself to fit each of the displays I"ve supported.

Unlike most other TFT display libraries this one doesn"t require a memory buffer, allowing it to be run on any processor down to an ATtiny85. The displays are SPI and require four pins to drive the display, leaving one pin free on an ATtiny85 to interface to another device, such as a temperature sensor. If you need more pins choose a larger chip, such as the ATtiny84; see Using the library with other AVR chips at the end of the article for information about how to convert the code for different chips.

I started developing this library for another project that I hope to write about at a later date; in the meantime I thought it would be useful to write it up as a stand-alone article.

I"ve published a library for a colour OLED display in a previous article: Colour Graphics Library. The main difference between the colour TFT displays and the colour OLED displays is that the TFT displays are not self-illuminating, and so need a backlight; they therefore have a slightly higher power consumption. However, they are exceedingly cheap, and they are available in larger sizes than the colour OLED displays.

I wrote an initial version of this library in uLisp, my Lisp interpreter for microcontrollers, which made it easy to experiment with different approaches. I then converted it to C to run on an ATtiny85. I can publish the uLisp version if anyone"s interested.

This library will work with displays based on the ST7735 which supports a maximum display size of 132 (H) x 162 (V), or the similar ST7789 which supports a maximum display size of 240 (H) x 320 (V).

The display driver interfaces to the displays with the longer side as the vertical dimension, which is why the rectangular displays are usually listed with the longer dimension second. My library allows you to rotate the image for any desired orientation.

All the Adafruit breakout boards for these displays include level-shifting circuitry, so they will work with either 5V or 3.3V microcontroller boards. They also include an SD card socket, if that"s of interest to you. The Adafruit boards have pullups on the backlight and reset pins, so the display will work if you leave these pins unconnected.

The boards available from AliExpress or Banggood are generally 3.3V only. If you"re using them with a 5V microcontroller you need to include a regulator and level-shifting circuitry.

The pullup resistor from the display"s CS pin is optional; it holds the chip select high to prevent the display from being affected by the ISP signals while programming the ATtiny85.

The different displays are catered for by six constants which specify the size of the display, the offsets relative to the area supported by the display driver, whether the display is inverted, and the rotation value; for example:

Note that on some displays you may also have to change the xoff or yoff value when rotating the display. For example, to rotate the image on the 240x240 displays by 180° use the settings:

To check or adjust the values for each display I ran this program, which draws a one-pixel border around the display area, and plots an "F" to show the orientation:

The ATtiny85 and other AVR processors supports toggling of one or more bits in a port, so provided you set all the pins to their disabled state at startup, for speed the display access routines can simply toggle the appropriate pins to enable or disable them.

The InitDisplay() routine first defines the four display pins as outputs, and takes the SCK, DC, and CS pins high (inactive). It then sends the essential configuration commands to the display.

Most published ST7735 libraries have a long list of initialisation parameters, but I found that most of these aren"t necessary, as the default settings work fine, and I"ve whittled the list down to just five commands:

The display memory stores 18 bits per pixel: 6 bits per colour. However, you can write to the display in three alternative modes, with 12, 16, or 18 bits per pixel. I chose the 16 bit mode, which assigns 5 bits to red, 6 bits to green, and 5 bits blue. It"s the most convenient one to work with as you simply send two bytes to define the colour of each pixel.

The foreground and background colours are defined by the two global variables fore and back. Initially these are set to 0xFFFF, white, and 0, black, respectively:

To clear the display the ClearDisplay() routine sends the appropriate number of zero bytes. The routine temporarily switches to 12-bit colour mode, which reduces the time to clear the display by 25%:

The library includes basic graphics routines for plotting points and drawing lines. These work on a conventional coordinate system with the origin at lower left. For example, on the 80x160 display:

The DrawTo()line-drawing routine uses Bresenham"s line algorithm to draw the best line between two points without needing any divisions or multiplications

My first version of PlotChar() plotted characters by calling PlotPoint() for each pixel. However, I then tried the following alternative approach which defines an area of the display using the CASET (Column Address Set) and RASET (Row Address Set) commands, and then sends a stream of the appropriate bytes to define the character. This turned out to be over three times faster!

The default value of scale is 1, but you can change it to plot larger characters. After plotting a character PlotChar() moves the plot position to the start of the next character to make it easy to plot several characters in a row without needing to callMoveTo().

I compiled the program using Spence Konde"s ATTiny Core ATtiny25/45/85 option under the ATTinyCore heading on the Board menu. Then check that the subsequent options are set as follows (ignore any other options):

By default the ATtiny85 runs at 1MHz. Choose Burn Bootloader to set the fuses for 8MHz operation, or your graphics will run rather slowly, then upload the program using ISP (in-system programming).

14th January 2020: Tested the program with the Adafruit 1.3" 240x240 TFT display, and updated the program to correct a problem when rotating the image on that display.

The wide range of conditions over which LCD monitors are used means that it is desirable to produce displays whose luminance (brightness) can be altered to match both bright and dim environments. This allows a user to set the screen to a comfortable level of brightness depending on their working conditions and ambient lighting. Manufacturers will normally quote a maximum brightness figure in their display specification, but it is also important to consider the lower range of adjustments possible from the screen as you would probably never want to use it at its highest setting. Indeed with specs often ranging up to 500 cd/m2, you will certainly need to use the screen at something a little less harsh on the eyes. As a reminder, we test the full range of backlight adjustments and the corresponding brightness values during each of our reviews. During our calibration process as well we try to adjust the screen to a setting of 120 cd/m2 which is considered the recommended luminance for an LCD monitor in normal lighting conditions. This process helps to give you an idea of what adjustments you need to make to the screen in order to return a luminance which you might actually want to use day to day.

Changing the display luminance is achieved by reducing the total light output for both CCFL- and LED-based backlights. By far the most prevalent technique for dimming the backlight is called Pulse Width Modulation (PWM), which has been in use for many years in desktop and laptop displays. However, this technique is not without some issues and the introduction of displays with high brightness levels and the popularisation of LED backlights has made the side-effects of PWM more visible than before, and in some cases may be a source of visible flicker, eyestrain, eye fatigue, headaches and other associated issues for people sensitive to it. This article is not intended to alarm, but is intended to show how PWM works and why it is used, as well as how to test a display to see its effects more clearly. We will also take a look at the methods some manufacturers are now adopting to address these concerns and provide flicker-free backlights instead. As awareness grows, more and more manufacturers are focusing on eye health with their monitor ranges.

Pulse Width Modulation (PWM) is one method of reducing the perceived luminance in displays, which it achieves by cycling the backlight on and off very rapidly, at a frequency you can’t necessary detect with the naked eye, but which could lead to eye issues, headaches etc. This method generally means that at 100% brightness a constant voltage is applied to the backlight and it is continuously lit. As you lower the brightness control the perceived luminance for the user reduces due to a number of possible controlling factors:

1) Frequency –The backlight is cycled on and off very rapidly, and this cycling typically occurs at a fixed frequency (in Hz). How fast this cycling occurs can impact whether flicker is visible or perceivable to the user, with higher frequencies being potentially less problematic. PWM has been known to operate at low frequencies of 180 – 240Hz for example which are likely to be more problematic than higher frequencies ranging up in to the Kilohertz range (e.g. 18,000Hz).

2) Modulation –The modulation of the cycling has an impact on the perceived brightness, and this describes the difference between the luminance in an “on” and in an “off” state. In some examples the backlight is completely turned off during the cycle so it is literally being turned on/off rapidly across the full brightness adjustment range. In those examples the luminance output is controlled really by the duty cycle only (see point 3). In other examples the backlight is not always being completely turned off but rather the voltage applied to the backlight is being rapidly alternated, resulting in less extreme differences between the on and off states. Often this modulation will be narrow in the high brightness range of the display, but as you reduce further, the modulation becomes wider until it reaches a point where the backlight is being switched completely off. From there, the change in the duty cycle (point 3) controls the further changes in the luminance output.

3) Duty Cycle – The fraction of each cycle for which the backlight is in an “on” state is called the duty cycle. By altering this duty cycle the total light output of the backlight can be changed. As you reduce the brightness to reach a lower luminance, the duty cycle becomes progressively shorter, and the time for which the backlight is on becomes shorter, while the time for which it is off is longer. This technique works visually since cycling the backlight on and off sufficiently fast means the user cannot see this flickering, because it lies above their flicker-fusion threshold (more on this later).

Above we can see graphs of a backlight’s output using “ideal” PWM for several cycles. The maximum output of this backlight in the example is 100 cd/m2, and the perceived luminance for the 90%, 50% and 10% cases are: 90, 50 and 10 cd/m2 respectively. The modulation percentage is the ratio between the minimum and maximum luminance during the cycle, and is 100% here, so it is being completely turned on and off. Note that during the duty cycle the backlight is at its maximum luminance.

The analogue (non-PWM) graphs corresponding to these perceived luminance levels would appear as shown below. In this case there is no modulation. This is the method used for flicker-free backlights which we will discuss more a little later.

The main reasons for the use of PWM is that it is simple to implement, requiring only that the backlight can be switched on and off rapidly, and also gives a large range of possible luminance.

CCFL backlights can be dimmed by reducing the current through the bulb, but only by about a factor of 2 because of their strict current and voltage requirements. This leaves PWM as the only simple method of achieving a large range of luminance. A CCFL bulb is in fact normally driven by the inverter to cycle on and off at a rate in the 10’s of kilohertz and well outside the range of flicker visible to humans. However, the PWM cycling typically occurs at a much lower frequency, around 175Hz, which can produce artefacts visible to humans.

The luminance of LED backlights can be adjusted greatly by altering the current passing through them, though this has the effect of altering the colour temperature slightly. This analogue approach to LED luminance is also undesirable since the accompanying circuits must take into account the heat generated by the LED’s. LED’s heat up when on, which reduces their resistance and further increases the current flowing through them. This can quickly lead to runaway current use in very high-brightness LED’s and cause them to burn out. Using PWM the current can be forced to hold a constant value during the duty cycle, meaning the colour temperature is always the same and current overloads are not a problem.

While PWM is attractive to hardware makers for the reasons outlined above, it can also introduce distracting visual effects if not used carefully. Flicker from LED backlights is typically much more visible than for older CCFL backlights at the same duty cycle because the LED’s are able to switch on and off much faster, and do not continue to “glow” after the power is cut off. This means that where the CCFL backlight showed rather smooth luminance variation, the LED version shows sharper transitions between on and off states. This is why more recently the subject of PWM has cropped up online and in reviews, since more and more displays are moving to W-LED backlighting units now.

Where the effect of flicker can really come into play is any time the user’s eyes are moving. Under constant illumination with no flickering (e.g. sunlight) the image is smoothly blurred and is how we normally perceive motion. However, when combined with a light source using PWM several discrete afterimages of the screen may be perceived simultaneously and reduce readability and the ability of the eyes to lock onto objects. From the earlier analysis of the CCFL backlighting we know that false colour may be introduced as well, even when the original image is monochromatic. Below are shown examples of how text might appear while the eyes are moving horizontally under different backlights.

It is important to remember that this is entirely due to the backlight, and the display itself is showing a static image. Often it is said that humans cannot see more than 24 frames per second (fps), which is not true and actually corresponds to the approximate frame rate needed to perceive continuous motion. In fact, while the eyes are moving (such as when reading) it is possible to see the effects of flicker at several hundred hertz. The ability to observe flicker varies greatly between individuals, and even depends on where a user is looking since peripheral vision is most sensitive.

So how fast is PWM cycling backlights on and off? This seems to depend on the backlight type used, with CCFL-based backlights nearly all cycling at 175Hz or 175 times per second. LED backlights have been reported typically running from 180 – 420Hz, with those at the lower end flickering much more visibly. Some have even faster frequencies of >2000Hz so it really can vary. While this might seem too fast to be visible, keep in mind that 175Hz is not much faster than the 100-120Hz flicker observed in lights connected directly to the mains power.

100-120Hz flickering of fluorescent lights has in fact been linked to symptoms such as severe eye strain and headaches in a portion of the population, which is why high-frequency ballast circuits were developed that provide almost continuous output. Using PWM at low frequencies negates the advantages of using these better ballasts in backlights because it turns an almost constant light source back into one that flickers. An additional consideration is that poor quality or defective ballasts in fluorescent backlights can produce audible noise. In many cases this is exacerbated when PWM is introduced since the electronics are now dealing with an additional frequency at which power usage is changing.

It is also important to distinguish the difference between flicker in CRT displays and CCFL and LED backlit TFT displays. While a CRT may flicker as low as 60Hz, only a small strip is illuminated at any time as the electron gun scans from top to bottom. With CCFL and LED backlit TFT displays the entire screen surface illuminates at once, meaning much more light is emitted over a short time. This can be more distracting than in CRTs in some cases, especially if short duty cycles are used.

The flicker itself in display backlights may be subtle and not easily perceptible for some people, but the natural variation in human vision seems to make it clearly visible to others. With the use of high-brightness LED’s on the rise it is becoming increasingly necessary to use short PWM duty cycles to control brightness, making flicker more of a problem. With users spending many hours every day looking at their monitors, shouldn’t we consider the long term effects of both perceptible and imperceptible flicker?

If you find PWM backlight flickering distracting or just want to see if reducing it makes reading on a monitor easier, I’d encourage you to try the following: Turn the brightness of your monitor up to maximum and disable any automatic brightness adjustments. Now use the colour correction available in your video card drivers or calibration device to reduce the brightness to normal levels (usually by adjusting the contrast slider). This will reduce the luminance and contrast of your monitor while leaving the backlight on as much as possible during PWM cycles. While not a long-term solution for most due to the decreased contrast, this technique can help to discover if a reduction in PWM usage is helpful.

A much better method of course would be to purchase a display not relying on PWM for dimming, or at least one which uses a much higher cycling frequency. Few manufacturers seem to have implemented PWM at frequencies that would limit visible artefacts (well above 500Hz for CCFL and above 2000 Hz for LED). Additionally, some displays using PWM do not use a 100% duty cycle even at full brightness, meaning they will always produce flicker. Several LED-based displays may in fact be currently available which do not use PWM, but until backlight freq

Ms.Josey

Ms.Josey

Ms.Josey

Ms.Josey