chip on glass lcd module manufacturer

You don"t know which module is right for you? Contact us, we will be happy to advise you more about our products and will surely find the right product together with you.

QS-9000, ISO-9001 & ISO-14001 certified manufacturer of chip-on-glass (COG) displays. Chip-on-glass displays are available in various models with specifications including character pattern ranging from 2 lines x 16 characters to 160 lines x 100 characters, module size ranging from 34 mm W x 28 mm H to 102 mm W x 70 mm H, viewing area ranging from 31 mm W x 19 mm H to 87 mm W x 43 mm H. Display available in white, yellow & gray LED colors with or without backlight. COG displays are suitable for a variety of markets including handhelds, industrial, irrigation, medical & scales. RoHS compliant.

This method of packaging cuts the amount of layers on the PCB and therefore reduces the board complexity and size.COG reduces the overall system cost but requires close co-ordination between LCD design and IC module manufacturer.

OKAYA is a worldwide company that designs, manufactures and markets LCD, TFT, and OLED displays and Electrical Noise and Surge Suppression Components for use in many industries.

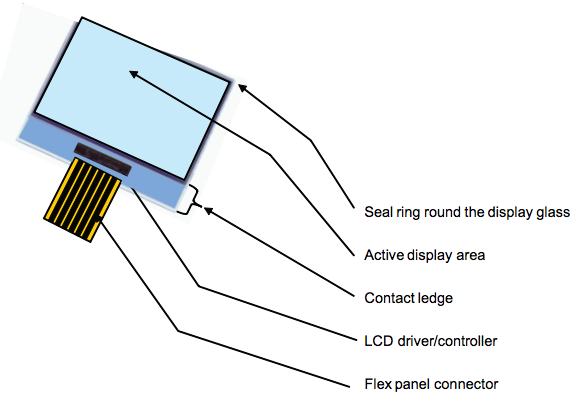

Available in character and graphic formats, COG (Chip-On-Glass) LCD Displays are designed without a PCB. The LCD driver/controller is bonded directly to the glass of the display. This allows COG displays to be smaller in size, more cost effective and a highly customizable display solution compared to typical LCD modules with a board.

Chip-On-Glass (COG) is a flip chip bonding method which is used for connect assembly of bare integrated circuits (ICs) on glass substrate directly by using Anisotropic Conductive Film (ACF). The pitch of the IC bumps (footprint) can be scaled down according to customers" requirements (contact pitch of glass substrate). This method reduces the assembly area to the highest possible packing density, which especially important to those applications that space saving is crucial. It allows a cost-effective mounting of driver chips because integrating flex PCB is no longer required. The IC is bonded directly onto the glass substrate and is suitable for handling high-speed or high-frequency signals.

COG technology is one of the high-tech mounting methods which use Gold Bump or Flip Chip IC"s, and implemented in most compact applications. Chip-On-Glass integrated circuits were first introduced by Epson. In flip-chip mounting, the IC chip is not packaged but is mounted directly onto the PCB as a bare chip. Because there is no package, the mounted footprint of the IC can be minimized, along with the required size of the PCB. This technology reduces the mounting area and is better suited to handling high-speed or high frequency signals.

COG is primarily used for source driver ICs within TFT display technologies where they are used for LCD, plasma, e-ink, OLED or 3D technologies. This is essential for consumer electronic products such as notebooks, tablets, cameras or mobile phones with the need for small size and light-weight components.

COG can only be used at a certain resolution level where the lines are not too fine. At very fine pitches COG becomes difficult to test, and TAB would be the preferred approach.

COG is an advanced technology to adhere IC chips onto glass(LCD). By Flip Chip technology, a gold bumped IC chip is connected to the ITO of LCD panels with ACF as a media. When this technology is applied to LCD panels due to the circuit board being glass, it is so-called Chip on Glass (COG), and bonding of the flexible printed circuit(FPC) and glass(LCD) is called FOG(Film On Glass). COG would be produced by means of wafer to tray. After LCD panel module factory acquires IC, the gold bump of the IC is bonded to the circuit board of LCD panels with ACF, then use ACF bonding with FPC, this production is called FOG process.

Not EXACTLY what you need? We specialize in custom and semi-custom display solutions. Contact us about creating something that fits your exact specifications.

Asia has long dominated the display module TFT LCD manufacturers’ scene. After all, most major display module manufacturers can be found in countries like China, South Korea, Japan, and India.

However, the United States doesn’t fall short of its display module manufacturers. Most American module companies may not be as well-known as their Asian counterparts, but they still produce high-quality display products for both consumers and industrial clients.

In this post, we’ll list down 7 best display module TFT LCD manufacturers in the USA. We’ll see why these companies deserve recognition as top players in the American display module industry.

STONE Technologies is a leading display module TFT LCD manufacturer in the world. The company is based in Beijing, China, and has been in operations since 2010. STONE quickly grew to become one of the most trusted display module manufacturers in 14 years.

Now, let’s move on to the list of the best display module manufacturers in the USA. These companies are your best picks if you need to find a display module TFT LCD manufacturer based in the United States:

Planar Systems is a digital display company headquartered in Hillsboro, Oregon. It specializes in providing digital display solutions such as LCD video walls and large format LCD displays.

The company started in 1983 as a corporate spin-off from the American oscilloscope company Tektronix. In 2015, Planar Systems became a subsidiary of the Chinese manufacturer Leyard Optoelectronics.

Another thing that makes Planar successful is its relentless focus on its customers. The company listens to what each customer requires so that they can come up with effective display solutions to address these needs.

Microtips Technology is a global electronics manufacturer based in Orlando, Florida. The company was established in 1990 and has grown into a strong fixture in the LCD industry.

Microtips also provides value-added services to all its clients. The company’s Electronic Manufacturing Services team gives product suggestions and shares insights on how clients can successfully manage their projects.

Taiwan and Mainland China are two Asian countries where Microtips set up their manufacturing plants. The factories boast of modern equipment, high-quality raw materials, and stringent quality control measures. Microtips even earned ISO9001 and ISO14001 certifications for excellent quality management.

What makes Microtips a great display module TFT LCD manufacturer in the USA lies in its close ties with all its customers. It does so by establishing a good rapport with its clients starting from the initial product discussions. Microtips manages to keep this exceptional rapport throughout the entire client relationship by:

Displaytech is an American display module TFT LCD manufacturer headquartered in Carlsbad, California. It was founded in 1989 and is part of several companies under the Seacomp group. The company specializes in manufacturing small to medium-sized LCD modules for various devices across all possible industries.

The company also manufactures embedded TFT devices, interface boards, and LCD development boards. Also, Displaytech offers design services for embedded products, display-based PCB assemblies, and turnkey products.

Displaytech makes it easy for clients to create their own customized LCD modules. There is a feature called Design Your Custom LCD Panel found on their site. Clients simply need to input their specifications such as their desired dimensions, LCD configuration, attributes, connector type, operating and storage temperature, and other pertinent information. Clients can then submit this form to Displaytech to get feedback, suggestions, and quotes.

Clients are assured of high-quality products from Displaytech. This is because of the numerous ISO certifications that the company holds for medical devices, automotive, and quality management. Displaytech also holds RoHS and REACH certifications.

A vast product range, good customization options, and responsive customer service – all these factors make Displaytech among the leading LCD manufacturers in the USA.

Products that Phoenix Display offers include standard, semi-custom, and fully-customized LCD modules. Specifically, these products comprise Phoenix Display’s offerings:

Phoenix Display also integrates the display design to all existing peripheral components, thereby lowering manufacturing costs, improving overall system reliability, and removes unnecessary interconnects.

Clients flock to Phoenix Display because of their decades-long experience in the display manufacturing field. The company also combines its technical expertise with its competitive manufacturing capabilities to produce the best possible LCD products for its clients.

True Vision Displays is an American display module TFT LCD manufacturing company located at Cerritos, California. It specializes in LCD display solutions for special applications in modern industries. Most of their clients come from highly-demanding fields such as aerospace, defense, medical, and financial industries.

The company produces several types of TFT LCD products. Most of them are industrial-grade and comes in various resolution types such as VGA, QVGA, XGA, and SXGA. Clients may also select product enclosures for these modules.

All products feature high-bright LCD systems that come from the company’s proprietary low-power LED backlight technology. The modules and screens also come in ruggedized forms perfect for highly-demanding outdoor industrial use.

Slow but steady growth has always been True Vision Display’s business strategy. And the company continues to be known globally through its excellent quality display products, robust research and development team, top-of-the-line manufacturing facilities, and straightforward client communication.

LXD Incorporated is among the earliest LCD manufacturers in the world. The company was founded in 1968 by James Fergason under the name International Liquid Xtal Company (ILIXCO). Its first headquarters was in Kent, Ohio. At present, LXD is based in Raleigh, North Carolina.

All of their display modules can be customized to fit any kind of specifications their clients may require. Display modules also pass through a series of reliability tests before leaving the manufacturing line. As such, LXD’s products can withstand extreme outdoor environments and operates on a wide range of temperature conditions.

LXD has research centers and factories in both the United States and China. The US-based headquarters feature a massive 30,000 square feet of manufacturing and research development centers. Meanwhile, LXD’s Chinese facilities feature a large 5,000 square meters of cleanrooms for manufacturing modular and glass products.

Cystalfontz America is a leading supplier and manufacturer of HMI display solutions. The company is located in Spokane Valley, Washington. It has been in the display solutions business since 1998.

Crystalfontz takes pride in its ISO 9001 certification, meaning the company has effective quality control measures in place for all of its products. After all, providing high-quality products to all customers remains the company’s topmost priority. Hence, many clients from small hobbyists to large top-tier American companies partner with Crystalfontz for their display solution needs.

We’ve listed the top 7 display module TFT LCD manufacturers in the USA. All these companies may not be as well-known as other Asian manufacturers are, but they are equally competent and can deliver high-quality display products according to the client’s specifications. Contact any of them if you need a US-based manufacturer to service your display solutions needs.

We also briefly touched on STONE Technologies, another excellent LCD module manufacturer based in China. Consider partnering with STONE if you want top-of-the-line smart LCD products and you’re not necessarily looking for a US-based manufacturer. STONE will surely provide the right display solution for your needs anywhere you are on the globe.

The Displaytech 162GCOG series is a lineup of 16x2 character chip-on-glass LCD modules. These modules have an 65x27.7 mm outer dimension with 61x15.7 mm viewing area on the display. The 162GCOG 16x2 LCD display series has the controller mounted directly onto the LCD glass. The chip-on-glass (COG) technology allows for a cost-effective system build since the display does not require a PCB. Get a quote directly from Displaytech for the 16x2 COG character LCD display from the 162GCOG series.

Established in 1998, Winstar Display Co., Ltd. is a reliable LCD Display Module Manufacturer and LCD Panel Supplier. Winstar has development of high-quality display module products. We operate worldwide, configure, service products, and also provide logistics support to deliver products and services competitively. We provide LCM Modules including monochrome TN/STN/FSTN LCM, COG LCD, TFT LCM / TFT panels, FSC-LCD, graphic LCM, character LCD displays, OLED display modules (PMOLED), custom LCD displays, OLED and LCD panel.

RX12864K1 is a dot matrix 128x64 COG Graphic LCD module (Chip-on-Glass LCD Module) with LED backlight. The module dimension is 89.7x49.8mm with active area size 63.98x31.98 mm. This module using ST7565V IC supports 8080, 6800 and SPI interface.

RX12864K1 is a perfect drop-in replacement for certain discontinued display modules on the market. Four screw holes allow for quick & easy mounting. Raystar changed the IC to ST7565P (positive voltage). ST7565P serves as a replacement for IC NT7534.

Supply voltage for logic of this 128x64 COG LCD Module ranges from 2.8V-3.2V, the typical value is 3V. The module works within temperature from -20 to +70°C; storage temperature covers from-30 to +80℃.

LCD displays are commonly supplied as a module with a built-in driver circuitry usually mounted on a PCB at the rear of the module. While this strengthen the module mechanically, it has some drawbacks such as it increases the thickness of the display module and raises the manufacturing cost. NXP semiconductors describes the

Dr Pan: Hello, Greg. COG is the abbreviation for chip on glass. It is a technology, which IC is bonded directly onto ITO glass. COG technology is usually used in small size dot matrix monochrome LCD module and TFT LCD module.

NO.1, it can greatly reduce the size of the LCD module because it doesn’t have PCB and it can be as thin as 2.0mm (maybe thinner). The thinner the more expensive.

NO.3, it is cost effective over COB LCD and can totally replace COB LCD in function, especially in graphic LCD modules, because it reduces the number of IC.

NO.4, for some dot matrix LCD modules, it is not possible to apply COB LCD technology because it is too crowded to place so many points on the view area. COG LCD is an economical and feasible solution because the pitch is smaller .

We have thousands of standard products that are in stock and available from our Seattle, WA and Hong Kong warehouses to support fast product development and preproduction without MOQ. The stock covers TN, STN LCD display panels, COB, COG character LCD display, graphic LCD display, PMOLED, AMOLED display, TFT display, IPS display, high brightness and transflective, blanview sunlight readable display, super high contrast ratio display, lightning fast response displays, efficient low power consumption display, extreme temperature range display, HMI display, HDMI display, Raspberry Pi Display, Arduino display, embedded display, capacitive touch screen, LED backlight etc. Customers can easily purchase samples directly from our website to avoid time delays with setting up accounts and credit terms and shipping within 24 hours.

Many of our customers require customized OEM display solutions. With over two decades of experience, we apply our understanding of available display solutions to meet our customer’s requirements and assist from project concept to mass production. Using your ideas and requirements as a foundation, we work side by side with you to develop ideas/concepts into drawings, build prototypes and to final production seamlessly. In order to meet the fast changing world, we can provide the fastest turnaround in the industry, it takes only 3-4 weeks to produce LCD panels samples and 4-6 weeks for LCD display module, TFT LCD, IPS LCD display, and touch screen samples. The production time is only 4-5 weeks for LCD panels and 5-8 weeks for LCD display module, TFT LCD, IPS LCD display, and touch screen.

Ms.Josey

Ms.Josey

Ms.Josey

Ms.Josey