msp430 lcd display manufacturer

Our 16-bit MSP430™ microcontrollers (MCUs) provide affordable solutions for all applications. Our leadership in integrated precision analog enables designers to enhance system performance and lower system costs. Designers can find a cost-effective MCU within the broad MSP430 portfolio of over 2000 devices for virtually any need. Get started quickly and reduce time to market with our simplified tools, software, and best-in-class support.

The MSP-EXP430FR2355 LaunchPad™ Development Kit is an easy-to-use evaluation module (EVM) based on the MSP430FR2355 Value Line microcontroller (MCU). It contains everything needed to start developing on the ultra-low-power MSP430FR2x Value Line MCU platform, including on-board debug probe for (...)

MSP430Ware is a collection of resources that help users to effectively create and build MSP430 code. These resources support ALL MSP430 microcontrollers (MCUs). As one user mentioned, “It’s essentially everything developers need to become MSP430 microcontroller experts!”

Our family of MSP430 MCUs offers a broad and affordable portfolio of products to solve today’s increasing and diverse MCU design challenges. This includes flexible, integrated analog components, such as ADCs, DACs, and Op-amps; Integrated LCD controllers for displaying information; and devices with integrated USB2.0 for communicating with a PC or application updates.

The Energy Measurement Design Center is a rapid development tool that uses MSP430i20xx and MSP430F67xx flash-based microcontrollers (MCUs). It includes a graphical user interface (GUI), documentation, software library and examples that can simplify development and accelerate in smart grid and building automation applications. Using the Design Center you can configure, calibrate, and view results without writing a single line of code.

Your one stop resource to develop ultrasonic sensing applications using MSP430TM microcontrollers (MCUs) that includes tools, a graphical user interface (GUI), documentation, software libraries and application examples.

The MSP430FR604x and MSP430FR504x SoC microcontroller families, offer a low-cost, single-chip solution with integrated ultrasonic sensing analog front end which is easy to use and flexible for developing various applications. Its unique waveform capturing technology with high speed ADC and cross correlation method enables high accuracy measurements with low power.

Your one stop resource to develop ultrasonic sensing applications using MSP430TM microcontrollers (MCUs) that includes tools, a graphical user interface (GUI), documentation, software libraries and application examples.

MSP430™ capacitive touch sensing MCUs feature CapTIvate™ technology offering the lowest power capacitive touch solutions. With support from 1 to 64 buttons, sliders, wheels and proximity with reliable performance in wet, dirty and greasy conditions as well as through metal, glass, plastic and other overlays, we have a capacitive touch solution for your MCU-based design.

This training series details the key features of MSP430 MCUs featuring CapTIvate technology, enabling you to get started on your next capacitive touch design.

The CapTIvate™ Design Center GUI is a one-stop resource for everything related to CapTIvate capacitive sensing technology integrated on TI MSP430™ microcontrollers.

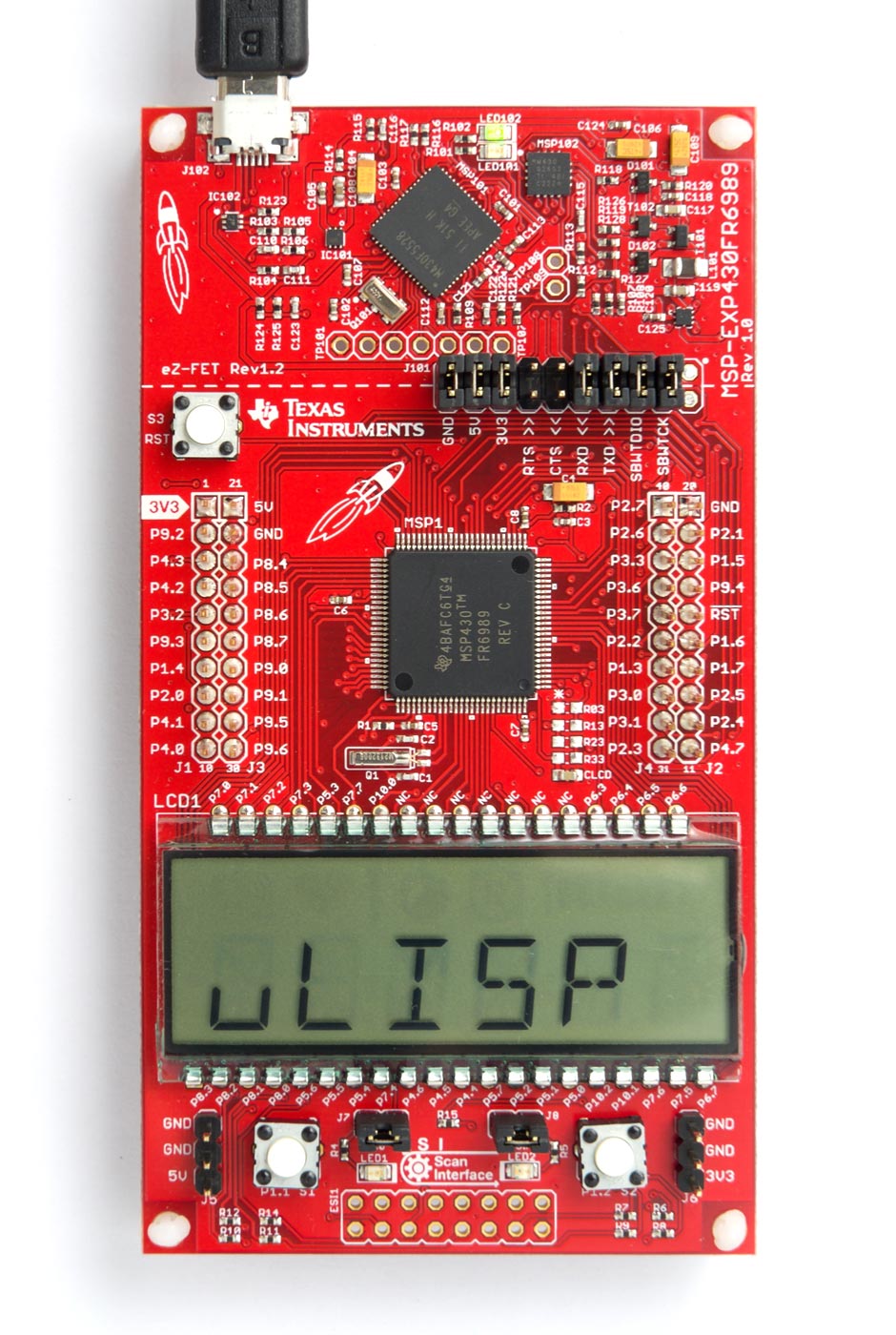

Photo of two experimenter boards for the MSP430 chipset by Texas Instruments. On the left the larger chip version, on the right a small version in USB format.

The MSP430 is a mixed-signal microcontroller family from Texas Instruments, first introduced on 14 February 1992.CPU, the MSP430 is designed for low cost and, specifically, low power consumption

The MSP430 can be used for low powered embedded devices. The current drawn in idle mode can be less than 1 µA. The top CPU speed is 25 MHz. It can be throttled back for lower power consumption. The MSP430 also uses six different low-power modes, which can disable unneeded clocks and CPU. Further, the MSP430 can wake-up in times under 1 microsecond, allowing the controller to stay in sleep mode longer, minimizing average current use.

Some less usual peripheral options include comparators (that can be used with the timers to do simple ADC), on-chip operational amplifiers (op-amp) for signal conditioning, 12-bit digital-to-analog converter (DAC), liquid crystal display (LCD) driver, hardware multiplier, USB, and direct memory access (DMA) for ADC results. Apart from some older erasable programmable read-only memory (EPROM, such as MSP430E3xx) and high volume mask ROM (MSP430Cxxx) versions, all of the devices are in-system programming enabled via Joint Test Action Group (JTAG), full four-wire or Spy-Bi-Wire), a built in bootstrapping loader (BSL) using UART such as RS-232, or USB on devices with USB support. No BSL is included in F20xx, G2xx0, G2xx1, G2xx2, or I20xx family devices.

There are, however, limits that preclude its use in more complex embedded systems. The MSP430 does not have an external memory bus, so it is limited to on-chip memory, up to 512 KB flash memory and 66 KB random-access memory (RAM), which may be too small for applications needing large buffers or data tables. Also, although it has a DMA controller, it is very difficult to use it to move data off the chip due to a lack of a DMA output strobe.

Six general generations of MSP430 processors exist. In order of development, they are: "3xx generation, "1xx generation, "4xx generation, "2xx generation, "5xx generation, and "6xx generation. The digit after the generation identifies the model (generally higher model numbers are larger and more capable), the third digit identifies the amount of memory included, and the fourth, if present, identifies a minor model variant. The most common variation is a different on-chip analog-to-digital converter.

The MSP430x1xx Series is the basic generation without an embedded LCD controller. They are generally smaller than the "3xx generation. These flash- or ROM-based ultra-low-power MCUs offer 8 MIPS, 1.8–3.6 V operation, up to 60 KB flash, and a wide range of analog and digital peripherals.

The MSP430F2xx Series are similar to the "1xx generation, but operate at even lower power, support up to 16 MHz operation, and have a more accurate (±2%) on-chip clock that makes it easier to operate without an external crystal. These flash-based ultra-low power devices offer 1.8–3.6 V operation. Includes the very-low power oscillator (VLO), internal pull-up/pull-down resistors, and low-pin count options.

The MSP430G2xx Value Series features flash-based Ultra-Low Power MCUs up to 16 MIPS with 1.8–3.6 V operation. Includes the Very-Low power Oscillator (VLO), internal pull-up/pull-down resistors, and low-pin count options, at lower prices than the MSP430F2xx series.

The MSP430x3xx Series is the oldest generation, designed for portable instrumentation with an embedded LCD controller. This also includes a frequency-locked loop oscillator that can automatically synchronize to a low-speed (32 kHz) crystal. This generation does not support EEPROM memory, only mask ROM and UV-eraseable and one-time programmable EPROM. Later generations provide only flash memory and mask ROM options. These devices offer 2.5–5.5 V operation, up to 32 KB ROM.

The MSP430x4xx Series are similar to the "3xx generation, but include an integrated LCD controller, and are larger and more capable. These flash or ROM based devices offers 8–16 MIPS at 1.8–3.6 V operation, with FLL, and SVS. Ideal for low power metering and medical applications.

Other integrated peripherals: SCAN_IF, ESP430, 12-bit DAC, Op Amps, RTC, up to 2 16-bit timers, watchdog timer, basic timer, brown-out reset, SVS, USART module (UART, SPI), USCI module, LCD Controller, DMA, 16×16 & 32x32 multiplier, Comparator_A, temperature sensor, 8 MIPS CPU Speed

The MSP430x5xx Series are able to run up to 25 MHz, have up to 512 KB flash memory and up to 66 KB RAM. This flash-based family features low active power consumption with up to 25 MIPS at 1.8–3.6 V operation (165 uA/MIPS). Includes an innovative power management module for optimal power consumption and integrated USB.

The MSP430x6xx Series are able to run up to 25 MHz, have up to 512 KB flash memory and up to 66 KB RAM. This flash-based family features low active power consumption with up to 25 MIPS at 1.8–3.6 V operation (165 uA/MIPS). Includes an innovative power management module for optimal power consumption and integrated USB.

Other integrated peripherals: USB, LCD, DAC, Comparator_B, DMA, 32x32 multiplier, power management module (BOR, SVS, SVM, LDO), watchdog timer, RTC, Temp sensor

Other integrated peripherals: LCD Controller, up to 2 16-bit timers, watchdog timer, RTC, power management module (BOR, SVS, SVM, LDO), USCI module, DMA, 32x32 multiplier, Comp B, temperature sensor

Other possible integrated peripherals: MPU, up to 6 16-bit timers, watchdog timer, RTC, power management module (BOR, SVS, SVM, LDO), USCI module, DMA, multiplier, Comp B, temperature sensor, LCD driver, I2C and UART BSL, Extended Scan Interface, 32 bit multiplier, AES, CRC, signal processing acceleration, capacitive touch, IR modulation

The Low Voltage Series include the MSP430C09x and MSP430L092 parts, capable of running at 0.9 V. These 2 series of low voltage 16-bit microcontrollers have configurations with two 16-bit timers, an 8-bit analog-to-digital (A/D) converter, an 8-bit digital-to-analog (D/A) converter, and up to 11 I/O pins.

The MSP430BQ1010 16-bit microcontroller is an advanced fixed-function device that forms the control and communications unit on the receiver side for wireless power transfer in portable applications. MSP430BQ1010 complies with the Wireless Power Consortium (WPC) specification. For more information, see Contactless Power

Automotive MSP430 microcontrollers (MCUs) from Texas Instruments (TI) are 16-bit, RISC-based, mixed-signal processors that are AEC-Q100 qualified and suitable for automotive applications in environments up to 105 °C ambient temperature. LIN compliant drivers for the MSP430 MCU provided by IHR GmbH.

MSP430 devices are very popular in harsh environments such as industrial sensing for their low power consumption and innovative analog integration. Some harsh environment applications include transportation/automotive, renewable energy, military/space/avionics, mineral exploration, industrial, and safety & security.

The MSP430 peripherals are generally easy to use, with (mostly) consistent addresses between models, and no write-only registers (except for the hardware multiplier).

The MSP430 family defines 11 I/O ports, P0 through P10, although no chip implements more than 10 of them. P0 is only implemented on the "3xx family. P7 through P10 are only implemented on the largest members (and highest pin count versions) of the "4xx and "2xx families. The newest "5xx and "6xx families has P1 through P11, and the control registers are reassigned to provide more port pairs.

The MSP430 line offers two types of analog-to-digital conversion (ADC). 10- and 12-bit successive approximation converters, as well as a 16-bit sigma-delta converter. Data transfer controllers and a 16-word conversion-and-control buffer allow the MSP430 to convert and store samples without CPU intervention, minimizing power consumption.

The MSP430"s comparator module provides precision slope analog-to-digital conversions. Monitors external analog signals and provides voltage and resistor value measurement. Capable of selectable power modes.

The BOR circuit detects low supply voltages and resets the device by triggering a power-on reset (POR) signal when power is applied or removed. The MSP430 MCU’s zero-power BOR circuit is continuously turned on, including in all low-power modes.

Although the MSP430"s DMA subsystem is very capable it has several flaws, the most significant of which is the lack of an external transfer strobe. Although a DMA transfer can be triggered externally, there is no external indication of completion of a transfer. Consequently DMA to and from external sources is limited to external trigger per byte transfers, rather than full blocks automatically via DMA. This can lead to significant complexity (as in requiring extensive hand tweaking of code) when implementing processor to processor or processor to USB communications.

The EEM provides different levels of debug features such as 2-8 hardware breakpoints, complex breakpoints, break when read/write occurs at specified address, and more. Embedded into all flash-based MSP430 devices.

Some MSP430 models include a memory-mapped hardware multiplier peripheral which performs various 16×16+32→33-bit multiply-accumulate operations. Unusually for the MSP430, this peripheral does include an implicit 2-bit write-only register, which makes it effectively impossible to context switch. This peripheral does not interfere with CPU activities and can be accessed by the DMA. The MPY on all MSP430F5xx and some MSP430F4xx devices feature up to 32-bit x 32-bit.

MSP430 devices have up to 12 digital I/O ports implemented. Each port has eight I/O pins. Every I/O pin can be configured as either input or output, and can be individually read or written to. Ports P1 and P2 have interrupt capability. MSP430F2xx, F5xx and some F4xx devices feature built-in, individually configurable pull-up or pull-down resistors.

The universal synchronous/asychrnous receive/transmit (USART) peripheral interface supports asynchronous RS-232 and synchronous SPI communication with one hardware module. The MSP430F15x/16x USART modules also support I²C, programmable baud rate, and independent interrupt capability for receive and transmit.

Available on the MSP430FR4xxx and MSP430FR2xxx series chips, this feature is configured via the SYSCFG register set. This peripheral ties into other peripherals (Timers, eUSCI_A) to generate an IR modulated signal on an output pin.

The LCD/LCD_A controller directly drives LCDs for up to 196 segments. Supports static, 2-mux, 3-mux, and 4-mux LCDs. LCD_A module has integrated charge pump for contrast control. LCD_B enables blinking of individual segments with separate blinking memory.

The LCD_E controller comes with the newer MSP430FR4xxx series microcontrollers and directly drives LCDs up to 448 segments. Supports static, 2-mux, 3-mux, 4-mux, 5-mux, 6-mux, 7-mux, 8-mux (1/3 bias) LCDs. Segment and Common pins may be reprogrammed to available LCD drive pins. This peripheral may be driven in LPM3.5 (RTC running+Main CPU core shutdown low-power mode).

Texas Instruments provides various hardware experimenter boards that support large (approximately two centimeters square) and small (approximately one millimeter square) MSP430 chips. TI also provides software development tools, both directly, and in conjunction with partners (see the full list of compilers, assemblers, and IDEs). One such toolchain is the IAR C/C++ compiler and debugger (assembly language programs of any size can be developed and debugged with this free toolchain).

For those who are more comfortable with the Arduino, there is also another software Energia, an open source electronics prototyping platform with the goal to bring the Wiring and Arduino framework to the Texas Instruments MSP430 based LaunchPad where Arduino code can be exported for programming MSP430 chips. The latest release of Energia supports the MSP-EXP430G2xxx, MSP-EXP430FR5739, MSP-EXP430FR5969, MSP-EXP430FR5994, MSP-EXP430F5529LP, Stellaris EK-LM4F120XL, Tiva-C EK-TM4C123GXL, Tiva-C EK-TM4C1294XL, CC3200 WiFi LaunchPad.

TI consulted with RedHat to provide official support for the MSP430 architecture to the GNU Compiler Collection C/C++ compiler. This msp430-elf-gcc compiler is supported by TI"s Code Composer Studio version 6.0 and higher.

The MSP430F2013 and its siblings are set apart by the fact that (except for the MSP430G2 Value Line) it is the only MSP430 part that is available in a dual in-line package (DIP). Other variants in this family are only available in various surface-mount packages. TI has gone to some trouble to support the eZ430 development platform by making the raw chips easy for hobbyists to use in prototypes.

TI has tackled the low-budget problem by offering a very small experimenter board, the eZ430-F2013, on a USB stick (now obsolete). This made it easy for designers to choose the MSP430 chip for inexpensive development platforms that can be used with a computer. The eZ430-F2013 contains an MSP430F2013 microcontroller on a detachable prototyping board, and accompanying CD with development software. It is helpful

Texas Instruments released the MSP430 LaunchPad in July 2010. The MSP430 LaunchPad has an onboard flash emulator, USB, 2 programmable LEDs, and 1 programmable push button.shield board is available.

In common with other microcontroller vendors, TI has developed a two-wire debugging interface found on some of their MSP430 parts that can replace the larger JTAG interface. The eZ430 Development Tool contains a full USB-connected flash emulation tool (FET) for this new two-wire protocol, named

The advantage of the Spy-Bi-Wire protocol is that it uses only two communication lines, one of which is the dedicated _RESET line. The JTAG interface on the lower pin count MSP430 parts is multiplexed with general purpose I/O lines. This makes it relatively difficult to debug circuits built around the small, low-I/O-budget chips, since the full 4-pin JTAG hardware will conflict with anything else connected to those I/O lines. This problem is alleviated with the Spy-Bi-Wire-capable chips, which are still compatible with the normal JTAG interface for backwards compatibility with the old development tools.

JTAG debugging and flash programming tools based on OpenOCD and widely used in the ARM architecture community are not available for the MSP430. Programming tools specially designed for the MSP430 are marginally less expensive than JTAG interfaces that use OpenOCD. However, should it be discovered mid-project that more MIPS, more memory, and more I/O peripherals are needed, those tools will not transfer to a processor from another vendor.

The MSP430 CPU uses a von Neumann architecture, with a single address space for instructions and data. Memory is byte-addressed, and pairs of bytes are combined little-endian to make 16-bit words.

The MSP430X extension with 20-bit addressing adds added instructions that can require up to 10 clock cycles. Setting or clearing a peripheral bit takes two clocks. A jump, taken or not takes two clocks. With the 2xx series 2 MCLKs is 125 ns at 16 MHz.

The basic MSP430 cannot support more memory (ROM + RAM + peripherals) than its 64K address space. In order to support this, an extended form of the MSP430 uses 20-bit registers and a 20-bit address space, allowing up to 1 MB of memory. This uses the same instruction set as the basic form, but with two extensions:

There is a new extended version of the architecture (named MSP430X) which allows a 20-bit address space. It allows added program ROM beginning at 0x10000.

The size bit is named A/L, where L (long) is used by other processors to indicate 32-bit operands. Also the description of the SXTX instruction (MSP430F5xx Family User"s Guide alau208f page 237) describes the effect of the instruction in register bits 20–31.

Beijing STONE Technology co., ltd was established in 2010 and devoted itself to manufacturing and developing high-quality intelligent TFT LCD display modules.

Our vision is to become one of the world"s top display manufacturers in the industrial intelligent field. And providing top-quality products and professional technical services to customers all over the world.

The modules come with a UART TFT serial interface that can be controlled by any MCU through simple but powerful instruction set like the 8051 series, AVR series, MSP430 Series, STM32 series, MC9S12, and Arduino series, among others.

Each TFT display LCD module has a wide range of applications, such as automated system control, vending machine functionality, intelligent lockers, electricity equipment (oiling machine, EV charger), elevators, smart home and office, precision instruments, and much more.

To date, we have delivered custom display solutions to over 3000 customers around the world. Our TFT LCD modules have been widely praised for their quality and performance and that is in large part thanks to our partners, including NI, Siemens, ThyssenKrupp, and many others. These long-term cooperative relationships have been mutually beneficial and we hope to continue a long history of success.

In this post will you find some basic tests with 16×2 LCD display using the MSP430. It is a widely used display controlled by the Hitachi HD44780. This display is able to show 2 lines of 16 alphanumeric characters.

Character LCDs use a 16 contact interface, commonly using pins or card edge connections on 0.1 inch (2.54 mm) centers. Those without backlights may have only 14 pins, omitting the two pins powering the light. The pinout is as follows:

The hardware assembly of this project is very simple. The commication with display is done using 8-bits or 4-bits, to save I/O pins is commonly used the 4-bit operation mode. In this case the data is send in two parts: first the upper nibble is sent and after the lower nibble is sent. The connection between LCD and MSP430 is as follow:

Communicating with LCD controller requires to follow a specific initialization sequence. The commands and timings must be respected in order to achieve a proper work in desired mode. The following diagram shows the initialization sequence for the JHD162A (The device that I utilized, some variations in timings can happens depending on lcd display manufacturer).

The full project can be downloaded in the GitHub. At this step you might set the development environment like shown in previous article. More things can be done to improve this code, specially removing the delays. As the LCD is a ‘slow device’, the microcontroller usually hangs much on delays during commands, this time could be used to make other tasks.

Ultra-low-power MSP430 microcontroller featuring CapTIvate touch technology and FRAMMutual capacitance HMI with 17 buttons: 2 sliders: 1 wheel: a proximity/guard channel and hapticsMSP432 MCU: a low-power: high-performance 32-bit ARM® Cortex®-M4F host 320 x 240 pixel SPI controlled TFT QVGA display CapTIvate Design Center support

I am using a 16x2 LCD with an MSP430 and am unable to figure out how to print a value from my AtoD. My LCD is using the ST7066U driver, and the setup code for my LCD is this:

In my main code, I read an AtoD value, but I am not too sure how to display it. The AtoD works fine, I can use debug mode in Crossworks and see the AtoD value is what I am expecting. I can display text on the LCD with something like this:

I am a complete novice at this, and the code for setting up the LCD was taken from HERE and edited slightly to fit my MSP and setup. Essentially, I just want to do something like

I get an error saying too many arguments to lcd_print. I assume this means in my setup, I need to change something to the way lcd_print works, but not sure how to do this. Can someone please let me know how to edit this so I can do something along the lines of

This is the third tutorial in the sequence of tutorials in which we are learning to program the MSP430G2 LaunchPad using the Energia IDE. In our previous tutorial, we learned how to control the Digital Input and Output pins on our MSP board. In this tutorial, we will learn how to interface an LCD with the board so that we can display useful information.

The LCD that we are using in this project is the most commonly used 16×2 Dot matrix LCD display a.k.an Alphanumeric Displays. Most of us would have come across this either through public PCOs or other electronics projects. A display like this will come in very handy for our future tutorials to display data and other debugging information. Interfacing this LCD with MSP430 is very easy, thanks to the library available. So let’s dive in!!

As told earlier the Energia IDE provides a beautiful library which makes the interfacing a piece of cake and hence it’s not mandatory to know anything about the display module. But, would didn’t it be interesting to show what we are using!!

The name 16×2 implies that the display has 16 Columns and 2 Rows, which together (16*2) forms 32 boxes. One single box would look something like this in the picture below

A single box has 40 pixels (dots) with a matrix order of 5 Rows and 8 columns, these 40 pixels together forms one character. Similarly, 32 characters can be displayed using all the boxes. Now lets take a look at the pinouts.

Out of all these 16 pins, only 10 pins are to be used mandatory for the proper working of the LCD if you want to know more about these LCD display jump to this LCD article.

One major constraint while interfacing these two is their operating voltages. The LCD display has an operating voltage of +5V while the MSP operates only with 3.6V. Lucky for us the data pin of LCD interface IC (HD44780U) has a wide operating voltage of 2.7V to 5.5V. So we have to worry only about the Vdd (pin 2) of the LCD while the data pins can work even with 3.6V.

The MSP430G2 board by default does not give you a +5V pin, but by we can do a smallhack to get +5V from MSP430 using the USB port. If you take a close look near the USB port you can find a terminal called TP1, this terminal will give us +5v. All we have to do is to solder a small male header pin as shown below so that we can connect it to our LCD display.

If you are not interested in soldering simply use any +5V regulated supply and power the LCD, in that case, make sure you connect the ground of your power supply to the ground of the MSP board.

The complete program to interface an MSP430G2553 with LCD display is given at the end of this page. The code can be compiled, uploaded and used as such. In the following paragraphs, I will explain how the program works.

Before we proceed with explanation, we have to make a note of the pins that we are using. If you take a look the circuit diagram above and the MSP430 pin-out diagram below

With this in mind let’s start defining the LCD pins used in our program. We will name each pin with a more meaningful name so that we can use it easily later.

The next step would be to include the LCD library. This library would have been installed automatically when you installed the Energia IDE. So just add it by using the following line

The next step is to mention the pins to which the LCD is connected to, as we have already named it using the #define we can now simply mention the names of the LCD pins. Make sure the same order is followed.

Now let us move into the void setup() function. There are so many types of LCD displays varying in size and nature, the one that we are using is 16*2 so let’s specify that in our program

To print something on the LCD we have to mention two things in the program. One is the position of the text which can be mentioned using the line lcd.setCursor() and other is the content to print which can be mentioned by lcd.print().In this line we are setting the cursor to 1st row and 1st column.

Just like erasing a whiteboard after writing on it, an LCD should also be erased once something is written on it. This can be done by using the below line

Next, inside our void loop() function, let’s keep incrementing a number for every 500ms and display the number in the LCD. This number tests and is initialized to 1 as shown below

Once your hardware and code is ready, simply connect your board the computer and upload the code as we did in tutorial one. Once the code is uploaded you should see the display showing the following.

After two seconds, the display screen will change from setup to loop and start incrementing the variable and display on the screen as shown the below picture.

The complete working can be found in the video below. Go ahead and try changing what’s being displayed on the LCD and play with it. Hope you understood the tutorial and learned something useful form it. If you have any doubts leave them in the comment section below or use the forums. Let’s meet in another tutorial.

I"ve been trying to get my LCD initialized for about a week now, and am quite embarrassed to say that I"ve been unsuccessful thus far. I"ve done this in the past, and I remember it being a little tricky getting the initialization sequence just right, but at this point I think I"ve fully vetted the implementation and it"s just not working.

The manufacturer has verified that there is a bug in the NT7605 where the busy bit isn"t asserted properly. So I have been using fixed delays (fine with me), but wanted to use the busy flag to see if the driver is even responding to commands. Is there another way for me to do a low-level diagnostic to see what the LCD is thinking as I send initialization commands?

Has anyone else here used the same LCD? All other standard LCDs I"ve used (2x20 character types) darken noticeably when I turn the contrast adjustment, and IIRC they do this even when not initialized properly. However, when I turn the pot on mine, the LCD doesn"t darken at all. Perhaps this is because it"s not initialized, but I"m not sure.

The only thing I can say is that the LCD looks like it flickers when I step over SendLcdByte and am sending it character data. When I scope everything, it sure looks like I"m flipping bits properly...

EDIT -- I soldered up a new LCD, and this time I tried leaving the unused data pins (D0-D3) disconnected (i.e. floating). There was no difference. The LCD still flickers when I initialize. I am now waiting 100ms for all delays, including a delay when strobing E. I have also disconnected Vcc coming from the Launchpad FET section and am now just powering the MSP430 and LCD from my lab power supply.

EDIT #2 -- I went to a 3.3V LCD and everything magically started working. Thanks to ToyBuilder for catching a stupid code bug when I was debugging with the 5V LCD. After the swap the LCD initialized properly. I"m currently displaying garbage instead of "Hello", but that"s unrelated to this question.

Ms.Josey

Ms.Josey

Ms.Josey

Ms.Josey