msp430 lcd display quotation

DALLAS, Jan. 24, 2012 /PRNewswire/ -- Offering developers more flexibility in electricity metering and energy monitoring applications, Texas Instruments Incorporated (TI) (NASDAQ: TXN) today announced the MSP430F673x/F672x family of ultra-low-power 16-bit microcontrollers. TI"s new devices guarantee no interruption of operation through a backup capable microcontroller supporting real-time clock (RTC) operation and power management from the main power supply and up to two separate auxiliary supplies. The 24 new F673x/F672x devices also achieve more precise measurements through an increased sampling rate and superior linearity over multiple operating conditions, such as current range and time, resulting in a stable system solution. These devices are TI"s first 6xx series microcontrollers with integrated 24-bit sigma-deltas and a 320-segment LCD controller. Compared to the previous 160-segment solution, developers can leverage enhanced segmented LCDs with more programmability and enable more characters on displays, especially with Asian languages. As part of the MSP430(TM) microcontroller portfolio, the F673x/F672x devices are designed for ultra-low-power modes, ensuring the LCD display is consuming as little power as possible during operation. For more information, visit www.ti.com/msp430f673x-430metering-pr-lp.

TI"s free MSP430 Energy Library is available to support metrology software on the new F673x/F672x devices, providing an easy startup for customers developing a utility meter product. Developers can test and experience accuracy results with the MSP430F6736 EVM, a single-phase electricity meter as well as program and debug F673x/F672x devices with the MSP-TS430PZ100B target board and MSP-FET430U100B flash emulation tool.

Stop by booth 4735 to see the MSP430F6736 EVM as well as other TI demos and solutions. Be sure to follow @TXInstruments on Twitter for exclusive show updates and giveaways.

The MSP430F673x/F672x microcontrollers are immediately available, starting at $2.00 for 1K-units. The MSP-TS430PZ100B target board is available for $75 and the MSP-FET430U100B flash emulation tool is available for $149. Both can be ordered at TI"s eStore. Please contact local sales representatives for additional details regarding the MSP430F6736 EVM.

From general purpose, ultra-low power MSP430(TM) MCUs, to Stellaris® Cortex(TM)-M MCUs to real-time control C2000(TM) MCUs, and Hercules(TM) safety MCUs, TI offers the broadest range of microcontroller solutions. Designers can accelerate time to market by tapping into TI"s complete software and hardware tools, extensive third-party offerings and technical support.

MSP430, C2000, Hercules are trademarks and Stellaris is a registered trademark of Texas Instruments. All registered trademarks and other trademarks belong to their respective owners.

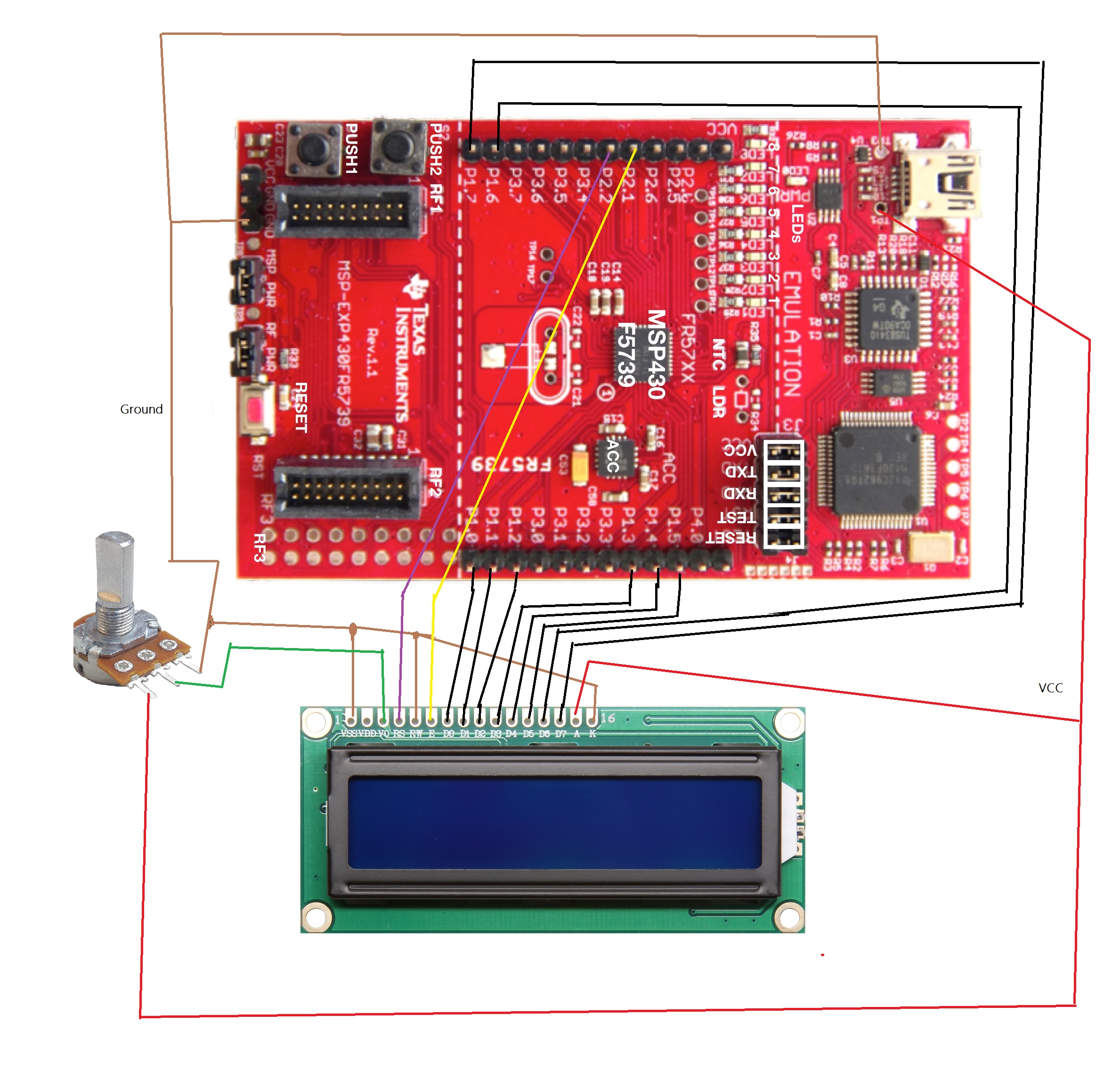

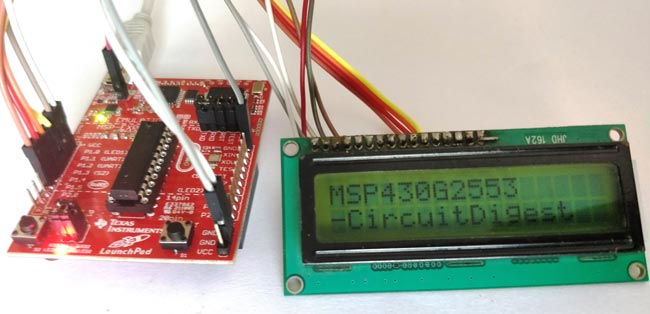

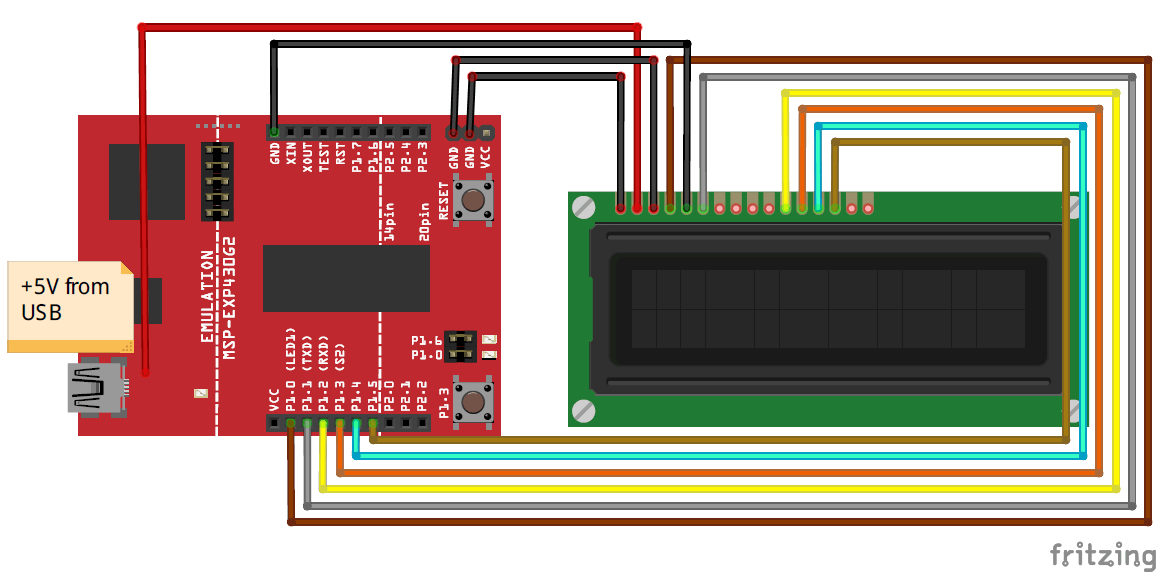

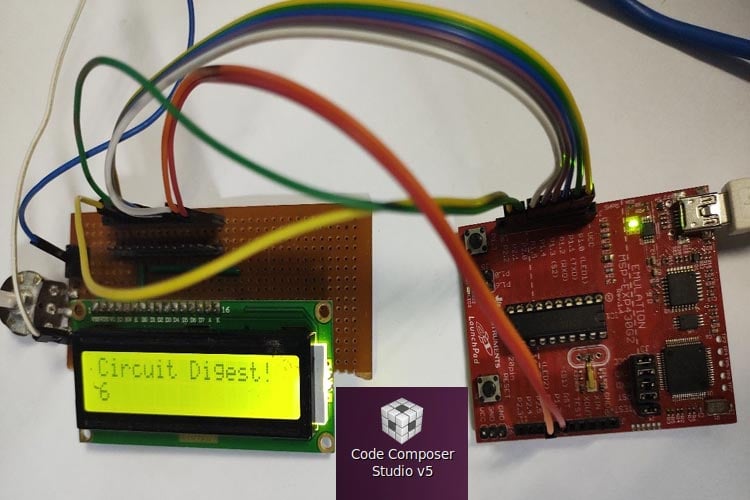

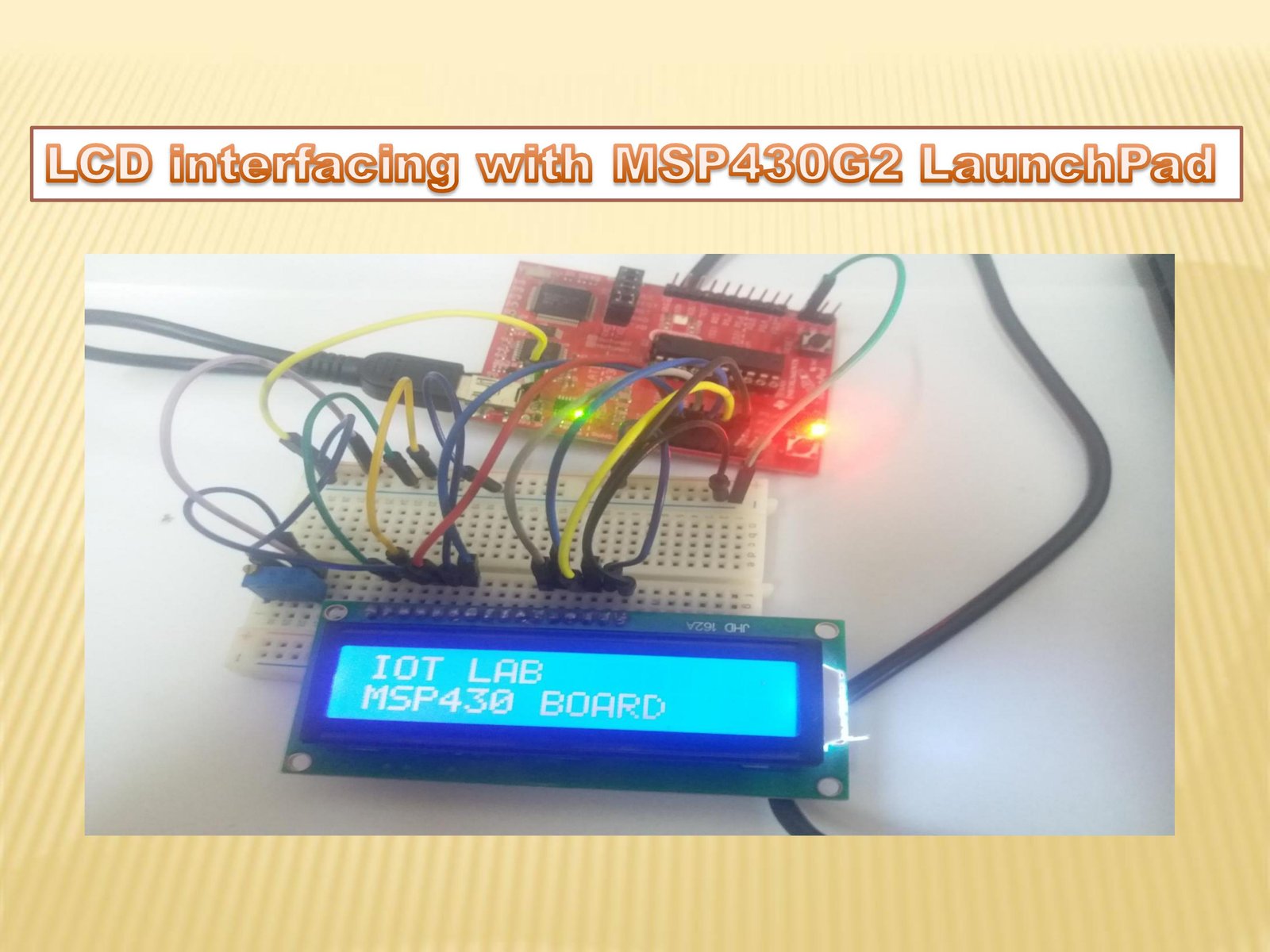

This article is the continuation of our tutorial series on programming MSP430 using Code Composer Studio. Last tutorial was based on GPIO pins. This tutorial is about interfacing a display with MSP430, when it comes to display the 16*2 LCD Display,it is the first choice for any electronic hobbyist. Previously we have also interfaced LCD with MSP430 using Arduino IDE, in this tutorial, we will use the native Code Composer studio platform instead of using the Arduino IDE, this way as a designer, we get more flexibility.

It has an in-built IC hd44780 that can store the command and data passed to it. The LCD Module has about 16 pins. 8 of which are data pins, 4 of them are supply pins for backlight LED and the whole LCD module, 3 for controlling the operation, and 1 pin for contrast adjustment. The tutorial is based on the library created by Dennis Eichmann. It is very easy to use a library with separate functions to print different data types. It also has provisions to display the data in different forms with leading, blanked, and deleted zeroes. It is a pretty expansive and comprehensive library and is configurable to the different connections. Here, the header file is modified to accommodate an 8-pin parallel configuration for data communication.

A generic 16x2 Display has an inbuilt hd44780 IC(circled in red below), that can store the command and data passed to it. The LCD Module has about 16 pins. 8 of which are data pins, 4 of them are supply pins for backlight LED and the whole LCD module, 3 for controlling the operation, and 1 pin for contrast adjustment.

This LCD module is shown above versatile and uses minimum pins compared to other segmented LCDs. If you are curious to know how exactly all this works, you should check out the working of the 16x2 LCD display where we have already discussed how the LCD works in detail.

RS Pin: RS=1 will enable the data register in the LCD, which is used to write the values to the data register in LCD. RS=0 will enable the Instruction register of the LCD.

Enable pin: Negative edge-triggered; when the pin is changed from the HIGH state to LOW state, LCD is prompted to write to the data pins. Positive edge-triggered; when the pin is changed from the LOW state to HIGH state, LCD is prompted to read from the data pins.

The tutorial is based on the library created by Dennis Eichmann. It is very easy to use a library with separate functions to print different data types. It also has provisions to display the data in different forms with leading, blanked, and deleted zeroes. It is a pretty expansive and comprehensive library and is configurable to the different connections. Here, the header file is modified to accommodate an 8-pin parallel configuration for data communication. The library can be download from the below link, after downloading you follow the below steps to add the library to CCS.

In the properties dialog box of the hd44780 project and inside the include options for the MSP430 compiler, add the include folder in file the search path.

In the properties dialog box for the CCS_LCD project and in the file search path of MSP430 Linker tab, include the hd44780.lib located inside the debug folder of the hd44780 project. The debug folder is also included in the file search path.

void hd44780_timer_isr( void ):This is periodically called in the ISR of the Timer A. The Timer A is used to periodically do the LCD functions like clearing the screen, setting the cursor, and displaying the data. The function is to be used in the ISR. It returns nothing.

char * ch__string:The string to be written to the data buffer (inside the hd44780_timer_isrfunction). The data will be copied to the data register and instruction register of the LCD IC when the hd44780_timer_isris periodically called.

uint8_t hd44780_output_unsigned_16bit_value( uint16_t u16__value, uint8_t u8__leading_zero_handling, uint8_t u8__row, uint8_t u8__column, uint8_t u8__cr_lf ):The function will display the unsigned 16-bit value on the desired location of the LCD.

The anode of the LED backlight cannot be connected directly to a 5V supply. It should be connected to a resistance to minimize the current flow through the LCD Module. I have made my connections using a perf board to solder the LCD and then used jumper wires to connect the LCD with the MSP430 board, my set-up looks like this below but you can also simply use a breadboard to make your connections.

Inbuilt timer is being used to display values periodically. Timer A is selected with SMCLK (1MHZ) as the clock source and continuous mode being the mode of operation.

Once you have your code compiled, you can upload it to the MSP430 board, as explained in the getting started with the MSP430 tutorial. If everything goes as expected, you should see your LCD display some contrast as shown below.

Liquid Crystal Displays or more commonly known as LCDs are one of the most common electronic components which help us interact with an equipment or a device. Most personal portable equipment and even gigantic industrial equipment utilize a custom segment display to display data. For many portable consumer electronics, a segment LCD display is one of the biggest contributors to the overall cost of the device, hence designing a custom segment display can drive the cost down while also utilizing the display area in the most optimum manner. These displays have the lowest cost per piece, low power requirements, and a low tooling fee too.

At first thought, designing a custom segment LCD might look like a Herculean task, but trust me that it is easier than it seems. In this article, we have summarised and compared the display types and available technologies which are required to construct a custom segment LCD. We have also provided a flowchart that can act as a step-by-step guide while you design your own custom LCD. We have also provided the process we followed, a require gathering sheet we used for communicating our needs to the manufacturer, and a few other data and the quotation we received from the manufacturer.

Icons: A silhouette of any shape can be placed on the glass which enhances the ability to display data. For example, a symbol of a heart can be made to denote heart rate or an icon for a low battery to show that the battery needs to be charged. Icons are counted as a single pixel or segment and can give a lot more details than similar-sized text.

LCD Bias– It denotes the number of different voltage levels used in driving the segments, static drives (explained later in this article) only have 2 voltage levels or 2 bias voltage while multiplex drives have multiple voltage levels. For example, 1/3 will have 4 bias voltages.

LCDs utilizes the light modulating properties of liquid crystals which can be observed by using polarizing filters. Polarizing filters are special materials that have their molecules aligned in the same direction. If the light waves passing through polarisers have the same orientation as the filter, then the molecules of lights are absorbed by the filter, hence reducing the intensity of light passing through it, making it visible.

A custom LCD is important for maximizing the efficiency of the display area by adding custom symbols and characters. It also helps in reducing the cost and improving energy efficiency of the product. A higher number of custom symbols and specified placement of numerical and alphanumerical characters make the display more informative and readable for the user. This makes it look better than the plain old boring displays we get in the market. Furthermore, we can specify the viewing angle, contrast, and other specifications which can increase durability or give a better value for money for our intended usage. A typical Custom Segment display is shown below, we will also show you how to design and fabricate the same further in the article.

The LCD display doesn’t emit any light of its own, therefore it requires an external source of illumination or reflector to be readable in dark environments.

While designing a custom segment LCD display, we have the leverage of choosing a lot of parameters that affect the final product. From the color of the display to the illumination technique and color of illumination as well as the type of input pins. Some important considerations we need to take while designing a custom 7 segment display are - the type of display, i.e. positive or negative, illumination method, driving technique, polarising type, and connection method. All these design criteria are explained below:

Positive and negative displays can be easily distinguished by the colour of the background and characters. Some common differences between the positive and negative displays are:

So, which one should you choose? When the displays are to be used in areas with higher ambient light, we should select positive segment LCD display as it has better visibility than negative segment LCD displays without using a backlight.

As we know that LED displays don’t emit any light, hence to illuminate it and make it visible in a dark environment, we can use different methods of illumination. The most common LCD Illumination methods are compared below:

For displays that need to be used for budget-friendly devices that should be small and rugged, LED lights are preferred for the displays due to the high durability and low cost of operations. For high brightness, CCFL and Incandescent lights can be used.

A polarizer film is the most important component of an LCD display, which makes it possible to display characters by controlling the light. There are 3 types of polarizers that can be used in the LCD display, the properties and difference are given below:

Displays can be categorized into two types, passive displays, and active display, passive displays are simpler to construct as they have 2 connections at each segment, the conductors comprise of an Indium Tin Oxide to create an image, whereas the active displays use thin-film transistors (TFT) arranged in a grid. The name is due to its ability to control each pixel individually.

If your displays have fewer segments, then static LCD drive is preferred as it is easier to control and cheaper to construct, and has a better contrast ratio. But let’s say that if the number of segments in the display are more than 30-40 then a multiplex LCD drive should be preferred as it has multiple common pins, hence reducing the total number of pins required to drive the display.

Choosing a connector type!!! For the prototyping phase or if you need to connect your LCD display on a Microcontroller directly, a pin type connector is the best and most economical option you have. If you need to connect your LCD display in a final product with a high volume of production which also requires to be extremely durable, but at the same time should not take up a lot of space, a Flex type LCD Connector will work best for you

LCDs have limited viewing angles and when seen from an angle they lose contrast and are difficult to be observed. The viewing angle is defined by the angles perpendicular to the center of the display towards its right, left, up, and down which are denoted by the notations 3:00, 9:00, 12:00, and 6:00 respectively. The viewing angle of LCD can be defined as the angle w.r.t. to the bias angle at which the contrast of segments is legible.

To improve the viewing angle in an LCD, a Bias is incorporated in the design which shifts the nominal viewing angle with an offset. Another technique is to increase the Voltage, it affects the bias angle, making the display crisper when viewed from a direction.

For example, the viewing angle of a TN type TFT LCD is 45-65 degrees. Extra-wide polarising film (EWP) can increase the viewing angle by 10 degrees, using an O film polariser can make the viewing angles 75 degrees but these come at a cost of reduced contrast.

LCD Control chip or LCD driver chips can be mounted on the flex cable, display, or externally on a PCB. The placement of LCD control chip can affect the cost and size of the display. The 2 most common methods of chip placement are-Chip of Board (COB)and Chip on Glass(COG) which are described below:

We planned to design an air quality monitoring system for which we needed a custom segment LCD panel for an air quality monitoring device. Our product needs to display the following data: 2.5-micron and 10-micron particulate matter (PM) suspended in the air; the units should be in parts per million (PPM). CO2 in the air in PPM along with total volatile organic compounds present in the air in parts per billion (PPB). To make the product more usable, we included time in 24-hour format, Temperature in ºC, Battery status, loudspeaker status, Bluetooth status, and Wi-Fi status. And for some personal touch, we also added how good the air quality in the room is by using 3 different smileys.

We realized that it was impossible to provide all these data in a generic LCD available in the market, thus decided to build a custom LCD for our project.

A step-by-step flowchart is shown below to walk you through each and every step of selecting components and getting your custom segment LCD manufactured.

We started by listing down our requirements and drew a mock-up of the display on paper. After finalizing the placement of all the segments and icons on the prototype sketch of the display, we then decided which all icons and segments have to be kept on for the whole time and which needs to be driven. Realizing that there are too many segments, characters and icons, hence we selected a multiplex drive with 8 common pins which helped us bring down the total pins from an estimated 180 pins to less than 40 pins.

Since the device was meant to be used inside houses and offices, which are more often than not well lit and protected from environmental conditions, we opted for a positive mode display. For superior contrast ratio and better viewing angle, we chose a Film Super Twisted Nematic Display (FSTN) with a drive condition of 1/8 Duty and bias of 1/4.

Usually, the displays are mounted at a height of 4.5 feet from the ground, thus the viewing direction was selected to be 12"O clock with an operating frequency of 64Hz. We selected a Transmissive polarizer for the front glass and a reflective polarizer for the rear glass so that the natural light can pass through the front panel and the display can achieve the maximum contrast without the need for backlighting and we opted for the pin type connectors as they are easy for prototyping and are suitable for harsh environment with a lot of vibrations and shocks which best suited our purpose.

In the above image of a custom display design, we sent to the manufacturer, the red lines over multiple characters indicate that all these are considered as a single segment. For the sake of simplicity, we added test like T, S, U, B to denote Text, Symbols, Units, and Battery respectively. These characters were followed by numbers to simplify communication between us and the manufacturer. For example, if we needed any particular text or symbol to remain on, we can easily specify that to the manufacturer by using the corresponding text for that segment.

We mailed our requirements to multiple LCD manufacturers, (you will find a lot of LCD manufacturers on the Internet). Most LCD manufacturers have competitive pricing, and reply within a week. A sample requirement sheet is shown above which a customer needs to fill to specify all the details to the manufacturer.

This is a sample Custom Segment LCD quotation we got from one of the manufacturers. As you can see, the cost is based on the quantity. Higher the quantity, lower the cost. Apart from the cost per quantity, there is one more component called tooling fees. Tooling fee is a one-time fee charged by the manufacturer. It is for the technical design, support, and customization of the product. Customization of PCB or tooling of LCD can drive the tooling price higher or lower.

A custom segment LCD can help you personalize your product while also saving the overall cost of your product. The whole process will take you around 2-3 months, which will include the designing phase, prototyping phase, and getting your custom segment LCDs delivered to your doorstep. Higher ordering quantity will reduce the cost per piece of each unit, thus driving down the cost of your final product.

This is the simple one: Look for an LCD display that supports 3.3 Volt logic. To minimize pin usage on the microcontroller, I2C or SPI support would be ideal.

A character LCD display, e.g. a 16 character x 2 row LCD, is easiest to handle. This example from eBay supports both I2C and 4-wire SPI serial interfaces. The seller provides links to documentation as well, something few eBay sellers seem to do.

A graphic (dot matrix) LCD display is somewhat more complicated to deal with, as the required display buffer for building up an image for display will tax the rather limited FLASH memory on the MSP430G2553. However, again a search for options reveals several options, including this 3.3V compatible, 240 x 320 pixel, 2.2 inch, SPI controlled LCD display. Unfortunately no documentation links on that page.

The MSP430g2553 is quite capable of driving both these LCD display modules. For wiring them up, you need to understand how to interface any I2C or SPI device with the MSP430, for which there are tutorials and discussions available, such as on 43oh.

Again, there are enough tutorials on wiring up a matrix keypad with the GPIO pins of a microcontroller: Mapping this to the MSP430G2553 specifically is a simple enough task.

If, however, the requirement mandates the use of a USB keyboard, the MSP430 by itself is not an option: While many MSP430 microcontrollers do have USB device mode support, this one does not (and, as Lior Bilia points out, none of the MSP430 MCUs support USB host mode or OTG mode).

However, "not recommended" does not mean "can never be done": See this forum discussion for an upcoming bit-banged, low speed USB device mode implementation using the MSP430G2 family. It is not ready for prime time yet, nor does it offer USB host mode or OTG mode (which will be needed for interfacing with a USB keyboard), but is just an illustration of what can be done with sufficient persistence.

Using a PS/2 keyboard might work if you can source one: There is at least one project that claims to interface both a PS/2 keyboard, and a 1602 LCD display, with an MSP430.

I have found a very simple LCD display "DfRobot LCD for Arduino with rgb backlight". It seems like a good way to have a display with projects but the problem is that for some reason Energia cannot process the code. No matter how I try, i just get an error message: Error compiling for board MSP-EXP430G2ET w/ MSP430G2553. Is there any way to use such displays with Energia?

This example demonstrates writing to a 20x4 character LCD module based on the HD44780 display controller using the 4-bit parallel interface mode. The example uses a blocking delay to set the update speed of an 8-bit up-counter which is displayed in decimal, hexadecimal, and binary formats on the LCD. This example can be used to explore display characteristics such as refresh rate.

This example requires the MSP430F5529LP development board and a 20x4 character LCD display based on the Hitachi HD44780 LCD Display controller. In order to use the 4-bit parallel interface, it is best to purchase a bare display, such as the Cofufu 20x4 Black on Green LCD module from Amazon. This particular display comes with male and female headers and a 10k potentiometer to implement the contrast adjustment. This will require soldering to connect the headers to the display, and to create the display cable.

The example code provided requires the following connections to be made. For more information on how to make these connections, see the section for building the display cable.

The example code is provided as a main.c file that is available on GitHub at (LCD_Display_4Bit_Counting_Example), or if preferred, it can be cut-pasted from the window below.

After the hardware initialization, the LCD library is initialized, which includes passing it the GPIO pin numbers for RS, RW, EN, D4, D5, D6, and D7. Although the example code was written to use these connections, the code can be modified to use other connections. In that case, the initialization would also need to be modified to identify the GPIO pins used.

The main function consists of a simple "forever loop" that performs a blocking delay of 250 ms, increments the up-counter, and updates the LCD display. This is a very simple program, but it can be useful to investigate the LCD display behavior (such as refresh rate, or "ghosting"), and the behavior of the LCD display library (such as execution time to write a character).

IMPORTANT: It is important to note is that there is an extra initialization step that is performed after the standard initialization function and before entering the forever loop. Updating the LCD display as part of initialization ensures that the display provides a known value to the user on start-up. This ensures that the display does not continue to display old data (or uninitialized data) to the user until the first time it is updated. Without this the display would not be updated until after the first 250 ms delay.

The reason that updating the LCD is done after initialization is that the LCD library uses the TIMERA2 module delay functions and global interrupts must be enabled for them to work properly. As with most things in software programming, there are several ways to do everything. An alternative for this specific example could be to re-arrange the order of operations in the forever loop to update the LCD display first, however I would strongly discourage this approach. This results in the desired behavior, however it makes it less obvious that the intention is to initialize the LCD immediately upon start-up.

A better alternative approach would be to add a 4th section to the standard initialization called "program specific initialization that requires interrupts", and move updating the LCD for the first time back into the initialization function. This would make it obvious that updating the LCD is intended to be part of initialization, and that interrupts are required for it to work properly.

The Update_LCD_Display function writes the text to be displayed to the LCD. In this example, the cursor position is set to the beginning of each row, and the text for the entire row is written to the display. Note that even for the first row spaces are included in the quotes after the word "Example" to fill in the rest of the row. This provides a robust solution that re-writes the entire row every time. That way if old data exist, or if noise or a poor connection causes erroneous characters to appear, they are corrected the next time the display updates.

The LCD_Print function works just like the C library function printf. The format string contains embedded format tags, like %3d and %3X, which are replaced by the value specified in s_count_u8 using the formatting specified. %3d reserves 3 spaces to display a decimal number, and %3X reserves 3 spaces to display capitalized hexadecimal values.

The C library doesn"t have functions to display binary values, so the macros BYTETOBINARYPATTERN, and BYTETOBINARY() are used to create the binary format and values. BYTETOBINARYPATTERN is replaced by the format specifier "%d%d%d%d%d%d%d%d", which says to place 8 decimal values one right after the other with no spaces in between. The macro BYTETOBINARY() is passed the count value s_count_u8, and creates a list of 8 comma separated short-hand IF/THEN statements like (byte & 0x80 ? 1 : 0) that says if the eighth bit is non-zero return a 1, else return a 0. For a count value of s_count_u8 = 53 decimal, the string of IF/THEN statements would evaluate to be the string of values: 0,0,1,1,0,1,0,1.

One other thing being done within this LCD Update function is the setting and clearing of the P1.0 LED using the statements P1OUT_bits.P1OUT0 = X, where X = 0 or 1. By asserting the LED during display processing it is possible to use an oscilloscope to measure how long it takes to update the LCD display.

In the example code, the entire display is being updated each time, even though large sections of text like "Decimal:", and "Hexadecimal:" don"t change. This was done intentionally to capture "worst-case" processing times, and to make the example robust so that it recovers if there are connection issues. Processing time can be reduced a little by only updating the values that are changing, but it does reduce the robustness of the design to interference.

In the example, there are 84 commands being sent ot the display for each LCD update: 4 set position commands, and 80 write character commands. The measured time for the entire update process was 11.8 ms, which results in per command processing time of 0.14 ms/command.

Once the example code is built and executed, the end result should be an up-counter that is displayed in decimal, hexadecimal and binary formats, as shown below. (The video snippet only counts from 15 to 28 decimal, but the actual example will count from 0 through 255)

Change the blocking delay value to something very small like delay(1). This will make the display update as fast as possible. Are the digits even readable at this speed?

Before running the example code, the LCD display needs to be connected to the development board. To do this I started with a 20 cm (approx. 8 inch) Female to Female jumper wire ribbon cable and several pieces of 2.5 mm x 30 mm pre-cut heat shrink tubing. I selected 8 different colors to connect to the 4 control and data lines, and then selected 2 sets of the same 2 color combinations to connect to pwr/gnd for the LCD controller and pwr/gnd for the LCD backlight. When the cable was completed it looked like the image below.

The HD44780 LCD Display Controller has a minimum high level input voltage of 2.2V, so all signals output from the MSP430 will be acceptable to the LCD, however when the MSP430 reads from the LCD, the signals on D4-D7 will be driven to 5V, and that is not acceptable, as the MSP430 is not 5V tolerant! Based on measurements that I made on one of my displays, it appears that the HD44780 is limited to driving approx. 1 mA max, which is below the absolute maximum current allowed into the MSP430 protection diodes of 2 mA. This means that if the D4-D7 data lines were connected directly to the MSP430 it would probably be fine. However, it is never a good idea to rely on undocumented features. I added 1 kOhm resistors in series with the four D4-D7 connections. This ensures that the current will always be within a safe level. Any value greater than 1 kOhm would work, but I would recommend staying between 1 kOhm to 2.2 kOhm.

On the V0 signal line I added the 10 kOhm potentiometer that came with the Cofufu display. The potentiometer is a 3-pin device that is intended to be soldered to a PC board. I bent the 3 pins flat, cut the wire for the V0 signal at about 4 inches, and soldered the center-tap pin to the red V0 wire. On the other side of the potentiometer I added two 4 inch wires (white and black) with female receptacles. By connecting the two wires between ground and either the 3V3 or 5V supply, it is possible to adjust the contrast properly.

Not all displays have the pins marked. The pin ordering is as follows when viewed from the front side. It is recommended that this be confirmed using the manufacturer"s datasheet, if one is available.

After soldering the female receptacle (provided with the Cofufu) to the backside of the display, I soldered the wires directly pins on the male header (also provided with the Cofufu). The end result when viewed from the backside of the display is shown below. Keep in mind that the pin names shown above, run in the opposite direction when viewed from the backside. The pin color combinations, running from left to right are: (Pin K - Purple) (Pin A - Blue) (Pin D7 - Grey) (Pin D6 - White) (Pin D5 - Black) (Pin D4 - Brown) (Pin E - Green) (Pin RW - Yellow) (Pin RS - Orange) (Pin V0 - Red) (Pin VDD - Blue) (Pin VSS - Purple).

I connected the backlight anode (Pin A) to the 3V3 supply pin. The LCD backlight connections are intended to be connected to a +5V source (A=+5V, K=GND), however the backlight will function at +3.3V. I think this provides a less harsh and glaring look when using the Yellow/Green displays.

I have a MSP chip and a LCD screen - throughout my code I output messages to my LCD screen. 80% of the time it works but if I do a power cycle the screen will get stuck on "UART Baud: 9600". ...

I am doing the project by using the serial jpeg camera on the MSP430F5529 and below is the snapshot"s hex data. I have no idea why the catching data can not be transferred to the JPEG image.

I got the issue when I was doing project on the Launchpad MSP430F5529 using Energia IDE and my environment is Ubuntu 18.04. The attachment picture is the issue"s screenshot. Could anyone tell me how ...

Using MSP430F6736A embedded programming. Code written in Code Composer Studio. I have a problem in my code, but i have no idea what i can do to fix it.

I have used MSP430 to write a custom blinking code with adjustable frequency. I use an ADC to adjust the frequency but I have been having issues with the ADC portion of the code being stuck while I ...

I am in the middle of a project where two ADS1220 are needed to configure in order to measure three bridge circuits with differential modes. I am using the MSP430f5529 launch pad to configure ADS1220. ...

I working on a project where i need measurement of a bridge circuit(strain gauge) through MCU. For that I am using a MSP430F2013 MCu with 16 bit ADC. I dont have data logging hardware for this Mcu so ...

I"m working with the MSP430Ware Sample Code for a basic ADC on the MSP-EXP430FR5994 development board. On the code, it uses MEM0 and the supporting infrastructure such as flag 0 to convert. The one ...

I am currently having an issue with trying to use the -mlarge flag with the MSPGCC compiler on an MSP430, its throwing the following error for all the generated objects in my code:

I am trying to run "Hello world", the most simple and basic code there is, on an MSP430 Launchpad (specifically, the MSP430FR5994 Launchpad). I want to run this and have it be displayed on ...

Here is the problem: I am trying to initialize the 12-bit built-in ADC on MSP430FR2476, but no matter what I do it seems to work at 10 bits. I change the resolution bits in a control register and alas,...

I am working on a SPI-UART bridge connection with an MSP430F5133 to RHD2132. The code was compiled using Code Compose Studio. This is the current code I have but I am still having issues

I am using the hardware multiplier in the MSP430 to multiply a constant (5) to each element of an array that I have initialized as arrX: .int 8, 16, 32

I have the MSP430 configured as an i2c master device and it is talking with two slave devices: a battery fuel gauge (LTC2943) and a battery charger (LT8491 evaluation board). I noticed that when ...

I have been trying out my first assembly level program on MSP4302355 microcontroller. All i am doing is just moving values from one register to another. But whenever I compile the code i am getting a ...

I"m trying to port a FunkOS RTOS from MSP430F2xxx to MSP430F5529. I"m using CCS 10.4 with TI v20.2.5 LTS compiler. I ported most of the code but I have problem with the RTOS taking over the control. ...

I am trying to emulate a USB-HID gamepad/controller using the MSP430 with 7-14 analog inputs but I had trouble getting the descriptors right for my custom USB-HID device.

I am trying to create a UART bridge using MSP430. I have a sensor sending strings to the MSP430 which I intend to send to my PC. Additionally, the sensor responds to commands which I intend to send ...

I"m trying to read temperature values from the TMP117 sensor [1] connected to an MSP430FR5969 MCU [2] through the I2C protocol. The data in the result register of the sensor is in two"s complement ...

Each LCD Pin Software Configurable as SEG or COM Contrast Control From by 0.06-V Steps Clock System (CS) � On-Chip 32-kHz RC Oscillator (REFO) � On-Chip 16-MHz Digitally Controlled Oscillator (DCO) With Frequency Locked Loop (FLL) �1% Accuracy With On-Chip Reference at Room Temperature � On-Chip Very Low-Frequency 10-kHz Oscillator (VLO) � On-Chip High-Frequency Modulation Oscillator (MODOSC) � External 32-kHz Crystal Oscillator (XT1) � Programmable MCLK Prescalar 128 � SMCLK Derived From MCLK With Programmable Prescalar or 8 General Input/Output and Pin Functionality � Total 60 I/Os on 64-Pin Package � 16 Interrupt Pins (P1 and P2) Can Wake Up MCU From LPMs � All I/Os are Capacitive Touch I/O Development Tools and Software � Free Professional Development Environments � Development Kit (MSP-TS430PM64D) Family Members (Also See Section 15KB of Program FRAM 512B of Information FRAM 2KB of RAM 8KB of Program FRAM 512B of Information FRAM 1KB of RAM 4KB of Program FRAM 512B of Information FRAM 512B of RAM Package Options � 64-Pin: LQFP (PM) � 56-Pin: TSSOP � 48-Pin: TSSOP (G48) For Complete Module Descriptions, See the MSP430FR4xx and MSP430FR2xx Family User"s Guide (SLAU445)

Embedded Microcontroller � 16-Bit RISC Architecture to 16 MHz � Wide Supply Voltage Range From 3.6 V Optimized Low-Power Modes (at V) � Active Mode: 126 �A/MHz � Standby Mode: 770 nA With Real-Time Clock (RTC) Counter and Liquid Crystal Display (LCD) � Shutdown (LPM4.5): 15 nA Low-Power Ferroelectric RAM (FRAM) 15.5KB of Nonvolatile Memory � Built-In Error Correction Code (ECC) � Configurable Write Protection � Unified Memory of Program, Constants, and Storage � 1015 Write Cycle Endurance � Radiation Resistant and Nonmagnetic Intelligent Digital Peripherals � IR Modulation Logic � Two 16-Bit Timers With Three Capture/Compare Registers Each (Timer_A3) � One 16-Bit Counter-Only Real-Time Clock counter (RTC) � 16-Bit Cyclic Redundancy Checker (CRC) Enhanced Serial Communications � Enhanced USCI A (eUSCI_A) Supports UART, IrDA, and SPI � Enhanced USCI B (eUSCI_B) Supports SPI and I2C High-Performance Analog 10-Channel 10-Bit Analog-to-Digital Converter (ADC) Internal 1.5-V Reference Sample-and-Hold 200 ksps � Low-Power Liquid Crystal Display (LCD) Supports or 8x32-Segment LCD Configuration On-Chip Charge Pump to Keep LCD Active in Standby Mode (LPM3.5)

The Texas Instruments MSP430TM family of low-power microcontrollers consists of several devices that feature different sets of peripherals targeted for various applications. The architecture, combined with extensive low-power modes, is optimized to achieve extended battery life in portable measurement applications. The device features a powerful 16-bit RISC CPU, 16-bit registers, and constant generators that contribute to maximum code efficiency. The digitally controlled oscillator (DCO) allows the device to wake up from low-power modes to active mode in less than 10 �s. Device Information (1)

Figure 1-1. Functional Block Diagram The device has one main power pair of DVCC and DVSS that supplies both digital and analog modules. Recommended bypass and decouple capacitors are 10 �F and 0.1 �F, respectively, with �5% accuracy. P1 and P2 feature the pin-interrupt function and can wake the MCU from LPM3.5. Each Timer_A3 has three CC registers, but only the CCR1 and CCR2 are externally connected. CCR0 registers can only be used for internal period timing and interrupt generation. In LPM3.5, the RTC counter and the LCD can be functional while the rest of peripherals are off. All I/Os can be configured as Capacitive Touch I/Os.

Ms.Josey

Ms.Josey

Ms.Josey

Ms.Josey