tft lcd material factory

Actually, the monitors 20 year ago were CRT (Cathode Ray Tube) displays, which requires a large space to run the inner component. And now the screen here in your presence is the LCD(Liquid Crystal Display) screen.

As mentioned above, LCD is the abbreviation of Liquid Crystal Display. It’s a new display technology making use of the optical-electrical characteristic of liquid crystal.

STN LCD: STN is for Super-twisted Nematic. The liquid crystal in STN LCD rotate more angles than that in TN LCD, and have a different electrical feature, allowing STN LCD to display more information. There are many improved version of STN LCD like DSTN LCD (double layer) and CSTN LCD (color). This LCD is used in many early phones, computers and outdoor devices.

TFT LCD: TFT is for Thin Film Transistor. It’s the latest generation of LCD technology and has been applied in all the displaying scenario including electronic devices, motor cars, industrial machines, etc. When you see the word ‘transistor’, you may realize there’s integrated circuits in TFT LCD. That’s correct and the secret that TFT LCD has the advantage of high resolution and full color display.

In a simple way, we can divide TFT LCD into three parts, from bottom to top they are: light system, circuit system and light and color control system.In manufacturing process, we’ll start from inner light and color control system and then stretch out to whole module.

It’s accustomed to divide TFT LCD manufacturing process into three main part: array, cell and module. The former two steps are about the production of light and color control system, which contains TFT, CF (color filter) and LC (liquid crystal), named a cell. And the last step is the assembly of cell, circuit and light system.

First, let me introduce a crucial material, ITO, to you. ITO, abbreviation of Indium tin oxide, has the characteristic of electrical conductivity and optical transparency, as well as can be easily deposited as a thin film. Thus it’s widely used to create circuit on glass.

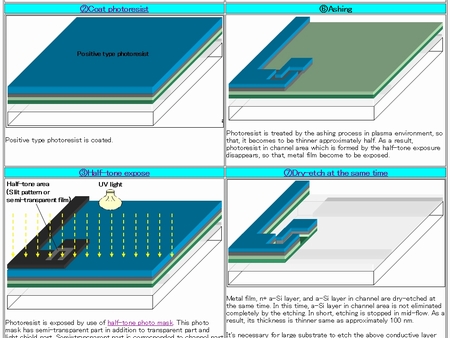

Now let’s turn to the production of TFT and CF. Here is a common method called PR (photoresist) method. The whole process of PR method will be demonstrated in TFT production.

This marks the end of this post. If you find it useful or want to know more about TFT LCD, just leave your comment below or contact us. We’re hearing!

Asia has long dominated the display module TFT LCD manufacturers’ scene. After all, most major display module manufacturers can be found in countries like China, South Korea, Japan, and India.

In this post, we’ll list down 7 best display module TFT LCD manufacturers in the USA. We’ll see why these companies deserve recognition as top players in the American display module industry.

STONE Technologies is a leading display module TFT LCD manufacturer in the world. The company is based in Beijing, China, and has been in operations since 2010. STONE quickly grew to become one of the most trusted display module manufacturers in 14 years.

Now, let’s move on to the list of the best display module manufacturers in the USA. These companies are your best picks if you need to find a display module TFT LCD manufacturer based in the United States:

Planar Systems is a digital display company headquartered in Hillsboro, Oregon. It specializes in providing digital display solutions such as LCD video walls and large format LCD displays.

Microtips Technology is a global electronics manufacturer based in Orlando, Florida. The company was established in 1990 and has grown into a strong fixture in the LCD industry.

Taiwan and Mainland China are two Asian countries where Microtips set up their manufacturing plants. The factories boast of modern equipment, high-quality raw materials, and stringent quality control measures. Microtips even earned ISO9001 and ISO14001 certifications for excellent quality management.

What makes Microtips a great display module TFT LCD manufacturer in the USA lies in its close ties with all its customers. It does so by establishing a good rapport with its clients starting from the initial product discussions. Microtips manages to keep this exceptional rapport throughout the entire client relationship by:

Displaytech is an American display module TFT LCD manufacturer headquartered in Carlsbad, California. It was founded in 1989 and is part of several companies under the Seacomp group. The company specializes in manufacturing small to medium-sized LCD modules for various devices across all possible industries.

The company also manufactures embedded TFT devices, interface boards, and LCD development boards. Also, Displaytech offers design services for embedded products, display-based PCB assemblies, and turnkey products.

Displaytech makes it easy for clients to create their own customized LCD modules. There is a feature called Design Your Custom LCD Panel found on their site. Clients simply need to input their specifications such as their desired dimensions, LCD configuration, attributes, connector type, operating and storage temperature, and other pertinent information. Clients can then submit this form to Displaytech to get feedback, suggestions, and quotes.

A vast product range, good customization options, and responsive customer service – all these factors make Displaytech among the leading LCD manufacturers in the USA.

Products that Phoenix Display offers include standard, semi-custom, and fully-customized LCD modules. Specifically, these products comprise Phoenix Display’s offerings:

Clients flock to Phoenix Display because of their decades-long experience in the display manufacturing field. The company also combines its technical expertise with its competitive manufacturing capabilities to produce the best possible LCD products for its clients.

True Vision Displays is an American display module TFT LCD manufacturing company located at Cerritos, California. It specializes in LCD display solutions for special applications in modern industries. Most of their clients come from highly-demanding fields such as aerospace, defense, medical, and financial industries.

The company produces several types of TFT LCD products. Most of them are industrial-grade and comes in various resolution types such as VGA, QVGA, XGA, and SXGA. Clients may also select product enclosures for these modules.

All products feature high-bright LCD systems that come from the company’s proprietary low-power LED backlight technology. The modules and screens also come in ruggedized forms perfect for highly-demanding outdoor industrial use.

LXD Incorporated is among the earliest LCD manufacturers in the world. The company was founded in 1968 by James Fergason under the name International Liquid Xtal Company (ILIXCO). Its first headquarters was in Kent, Ohio. At present, LXD is based in Raleigh, North Carolina.

We’ve listed the top 7 display module TFT LCD manufacturers in the USA. All these companies may not be as well-known as other Asian manufacturers are, but they are equally competent and can deliver high-quality display products according to the client’s specifications. Contact any of them if you need a US-based manufacturer to service your display solutions needs.

We also briefly touched on STONE Technologies, another excellent LCD module manufacturer based in China. Consider partnering with STONE if you want top-of-the-line smart LCD products and you’re not necessarily looking for a US-based manufacturer. STONE will surely provide the right display solution for your needs anywhere you are on the globe.

TFT displays are full color LCDs providing bright, vivid colors with the ability to show quick animations, complex graphics, and custom fonts with different touchscreen options. Available in industry standard sizes and resolutions. These displays come as standard, premium MVA, sunlight readable, or IPS display types with a variety of interface options including HDMI, SPI and LVDS. Our line of TFT modules include a custom PCB that support HDMI interface, audio support or HMI solutions with on-board FTDI Embedded Video Engine (EVE2).

A thin-film-transistor liquid-crystal display (TFT LCD) is a variant of a liquid-crystal display that uses thin-film-transistor technologyactive matrix LCD, in contrast to passive matrix LCDs or simple, direct-driven (i.e. with segments directly connected to electronics outside the LCD) LCDs with a few segments.

In February 1957, John Wallmark of RCA filed a patent for a thin film MOSFET. Paul K. Weimer, also of RCA implemented Wallmark"s ideas and developed the thin-film transistor (TFT) in 1962, a type of MOSFET distinct from the standard bulk MOSFET. It was made with thin films of cadmium selenide and cadmium sulfide. The idea of a TFT-based liquid-crystal display (LCD) was conceived by Bernard Lechner of RCA Laboratories in 1968. In 1971, Lechner, F. J. Marlowe, E. O. Nester and J. Tults demonstrated a 2-by-18 matrix display driven by a hybrid circuit using the dynamic scattering mode of LCDs.T. Peter Brody, J. A. Asars and G. D. Dixon at Westinghouse Research Laboratories developed a CdSe (cadmium selenide) TFT, which they used to demonstrate the first CdSe thin-film-transistor liquid-crystal display (TFT LCD).active-matrix liquid-crystal display (AM LCD) using CdSe TFTs in 1974, and then Brody coined the term "active matrix" in 1975.high-resolution and high-quality electronic visual display devices use TFT-based active matrix displays.

The circuit layout process of a TFT-LCD is very similar to that of semiconductor products. However, rather than fabricating the transistors from silicon, that is formed into a crystalline silicon wafer, they are made from a thin film of amorphous silicon that is deposited on a glass panel. The silicon layer for TFT-LCDs is typically deposited using the PECVD process.

Polycrystalline silicon is sometimes used in displays requiring higher TFT performance. Examples include small high-resolution displays such as those found in projectors or viewfinders. Amorphous silicon-based TFTs are by far the most common, due to their lower production cost, whereas polycrystalline silicon TFTs are more costly and much more difficult to produce.

The twisted nematic display is one of the oldest and frequently cheapest kind of LCD display technologies available. TN displays benefit from fast pixel response times and less smearing than other LCD display technology, but suffer from poor color reproduction and limited viewing angles, especially in the vertical direction. Colors will shift, potentially to the point of completely inverting, when viewed at an angle that is not perpendicular to the display. Modern, high end consumer products have developed methods to overcome the technology"s shortcomings, such as RTC (Response Time Compensation / Overdrive) technologies. Modern TN displays can look significantly better than older TN displays from decades earlier, but overall TN has inferior viewing angles and poor color in comparison to other technology.

The transmittance of a pixel of an LCD panel typically does not change linearly with the applied voltage,sRGB standard for computer monitors requires a specific nonlinear dependence of the amount of emitted light as a function of the RGB value.

Less expensive PVA panels often use dithering and FRC, whereas super-PVA (S-PVA) panels all use at least 8 bits per color component and do not use color simulation methods.BRAVIA LCD TVs offer 10-bit and xvYCC color support, for example, the Bravia X4500 series. S-PVA also offers fast response times using modern RTC technologies.

TFT dual-transistor pixel or cell technology is a reflective-display technology for use in very-low-power-consumption applications such as electronic shelf labels (ESL), digital watches, or metering. DTP involves adding a secondary transistor gate in the single TFT cell to maintain the display of a pixel during a period of 1s without loss of image or without degrading the TFT transistors over time. By slowing the refresh rate of the standard frequency from 60 Hz to 1 Hz, DTP claims to increase the power efficiency by multiple orders of magnitude.

Due to the very high cost of building TFT factories, there are few major OEM panel vendors for large display panels. The glass panel suppliers are as follows:

External consumer display devices like a TFT LCD feature one or more analog VGA, DVI, HDMI, or DisplayPort interface, with many featuring a selection of these interfaces. Inside external display devices there is a controller board that will convert the video signal using color mapping and image scaling usually employing the discrete cosine transform (DCT) in order to convert any video source like CVBS, VGA, DVI, HDMI, etc. into digital RGB at the native resolution of the display panel. In a laptop the graphics chip will directly produce a signal suitable for connection to the built-in TFT display. A control mechanism for the backlight is usually included on the same controller board.

The low level interface of STN, DSTN, or TFT display panels use either single ended TTL 5 V signal for older displays or TTL 3.3 V for slightly newer displays that transmits the pixel clock, horizontal sync, vertical sync, digital red, digital green, digital blue in parallel. Some models (for example the AT070TN92) also feature input/display enable, horizontal scan direction and vertical scan direction signals.

New and large (>15") TFT displays often use LVDS signaling that transmits the same contents as the parallel interface (Hsync, Vsync, RGB) but will put control and RGB bits into a number of serial transmission lines synchronized to a clock whose rate is equal to the pixel rate. LVDS transmits seven bits per clock per data line, with six bits being data and one bit used to signal if the other six bits need to be inverted in order to maintain DC balance. Low-cost TFT displays often have three data lines and therefore only directly support 18 bits per pixel. Upscale displays have four or five data lines to support 24 bits per pixel (truecolor) or 30 bits per pixel respectively. Panel manufacturers are slowly replacing LVDS with Internal DisplayPort and Embedded DisplayPort, which allow sixfold reduction of the number of differential pairs.

Kawamoto, H. (2012). "The Inventors of TFT Active-Matrix LCD Receive the 2011 IEEE Nishizawa Medal". Journal of Display Technology. 8 (1): 3–4. Bibcode:2012JDisT...8....3K. doi:10.1109/JDT.2011.2177740. ISSN 1551-319X.

K. H. Lee; H. Y. Kim; K. H. Park; S. J. Jang; I. C. Park & J. Y. Lee (June 2006). "A Novel Outdoor Readability of Portable TFT-LCD with AFFS Technology". SID Symposium Digest of Technical Papers. AIP. 37 (1): 1079–82. doi:10.1889/1.2433159. S2CID 129569963.

Kim, Sae-Bom; Kim, Woong-Ki; Chounlamany, Vanseng; Seo, Jaehwan; Yoo, Jisu; Jo, Hun-Je; Jung, Jinho (15 August 2012). "Identification of multi-level toxicity of liquid crystal display wastewater toward Daphnia magna and Moina macrocopa". Journal of Hazardous Materials. Seoul, Korea; Laos, Lao. 227–228: 327–333. doi:10.1016/j.jhazmat.2012.05.059. PMID 22677053.

![]()

Reliable good quality and very good credit standing are our principles, which will help us at a top-ranking position. Adhering to your tenet of "quality 1st, purchaser supreme" for Industrial Tft-Lcd Panel, Vehicle Touch Displays, Tft Monitor Screen, Round Tft Lcd Display Module,Lcd Display With Tn Panel. Let"s cooperate hand in hand to jointly make a beautiful future. We sincerely welcome you to visit our company or contact us for cooperation! The product will supply to all over the world, such as Europe, America, Australia,Spain, Muscat,Italy, Finland.Our factory insists on the principle of "Quality First, Sustainable Development", and takes "Honest Business, Mutual Benefits" as our developable goal. All members sincerely thanks for all old and new customers" support. We will keep working hard and offering you the highest-quality products and service.Thanks.

Since its initial communalization in the 1990s, active matrix thin-film-transistor (TFT) displays have become an essential and indispensable part of modern living. They are much more than just televisions and smartphones; they are the primary communication and information portals for our day-to- day life: watches (wearables), appliances, advertising, signage, automobiles and more.

There are many similarities in the display TFT manufacturing and semiconductor device manufacturing such as the process steps (deposition, etch, cleaning, and doping), the type of gases used in these steps, and the fact that both display and semiconductor manufacturing both heavily use gases.

In general, there are two types of displays in the market today: active matrix liquid crystal display (AMLCD) and AMOLED. In its simplicity, the fundamental components required to make up the display are the same for AMLCD and AMOLED. There are four layers of a display device (FIGURE 1): a light source, switches that are the thin-film-transistor and where the gases are mainly used, a shutter to control the color selection, and the RGB (red, green, blue) color filter.

Technology trends TFT-LCD (thin-film-transistor liquid-crystal display) is the baseline technology. MO / White OLED (organic light emitting diode) is used for larger screens. LTPS / AMOLED is used for small / medium screens. The challenges for OLED are the effect of < 1 micron particles on yield, much higher cost compared to a-Si due to increased mask steps, and moisture impact to yield for the OLED step.

Although AMLCD displays are still dominant in the market today, AMOLED displays are growing quickly. Currently about 25% of smartphones are made with AMOLED displays and this is expected to grow to ~40% by 2021. OLED televisions are also growing rapidly, enjoying double digit growth rate year over year. Based on IHS data, the revenue for display panels with AMOLED technol- ogies is expected to have a CAGR of 18.9% in the next five years while the AMLCD display revenue will have a -2.8% CAGR for the same period with the total display panel revenue CAGR of 2.5%. With the rapid growth of AMOLED display panels, the panel makers have accel- erated their investment in the equipment to produce AMOLED panels.

There are three types of thin-film-transistor devices for display: amorphous silicon (a-Si), low temperature polysilicon (LTPS), and metal oxide (MO), also known as transparent amorphous oxide semiconductor (TAOS). AMLCD panels typically use a-Si for lower-resolution displays and TVs while high-resolution displays use LTPS transistors, but this use is mainly limited to small and medium displays due to its higher costs and scalability limitations. AMOLED panels use LTPS and MO transistors where MO devices are typically used for TV and large displays (FIGURE 3).

This shift in technology also requires a change in the gases used in production of AMOLED panels as compared with the AMLCD panels. As shown in FIGURE 4, display manufacturing today uses a wide variety of gases.

Nitrogen trifluoride: NF3 is the single largest electronic material from spend and volume standpoint for a-Si and LTPS display production while being surpassed by N2O for MO production. NF3 is used for cleaning the PECVD chambers. This gas requires scalability to get the cost advantage necessary for the highly competitive market.

Nitrous oxide: Used in both LTPS and MO display production, N2O has surpassed NF3 to become the largest electronic material from spend and volume standpoint for MO production. N2O is a regional and localized product due to its low cost, making long supply chains with high logistic costs unfeasible. Averaging approximately 2 kg per 5.5 m2 of mother glass area, it requires around 240 tons per month for a typical 120K per month capacity generation 8.5 MO display production. The largest N2O compressed gas trailer can only deliver six tons of N2O each time and thus it becomes both costly and risky

Individual packages: Specialty gases are supplied in individual packages. For higher volume materials like silane and nitrogen trifluoride, these can be supplied in large ISO packages holding up to 10 tons. Materials with smaller requirements are packaged in standard gas cylinders.

In-fab distribution: Gas supply does not end with the delivery or production of the material of the fab. Rather, the materials are further regulated with additional filtration, purification, and on-line analysis before delivery to individual production tools.

To facilitate these increasing demands, display manufacturers must partner with gas suppliers to identify which can meet their technology needs, globally source electronic materials to provide customers with stable and cost- effective gas solutions, develop local sources of electronic materials, improve productivity, reduce carbon footprint, and increase energy efficiency through on-site gas plants. This is particularly true for the burgeoning China display manufacturing market, which will benefit from investing in on-site bulk gas plants and collaboration with global materials suppliers with local production facilities for high-purity gas and chemical manufacturing.

We have thousands of standard products that are in stock and available from our Seattle, WA and Hong Kong warehouses to support fast product development and preproduction without MOQ. The stock covers TN, STN LCD display panels, COB, COG character LCD display, graphic LCD display, PMOLED, AMOLED display, TFT display, IPS display, high brightness and transflective, blanview sunlight readable display, super high contrast ratio display, lightning fast response displays, efficient low power consumption display, extreme temperature range display, HMI display, HDMI display, Raspberry Pi Display, Arduino display, embedded display, capacitive touch screen, LED backlight etc. Customers can easily purchase samples directly from our website to avoid time delays with setting up accounts and credit terms and shipping within 24 hours.

Many of our customers require customized OEM display solutions. With over two decades of experience, we apply our understanding of available display solutions to meet our customer’s requirements and assist from project concept to mass production. Using your ideas and requirements as a foundation, we work side by side with you to develop ideas/concepts into drawings, build prototypes and to final production seamlessly. In order to meet the fast changing world, we can provide the fastest turnaround in the industry, it takes only 3-4 weeks to produce LCD panels samples and 4-6 weeks for LCD display module, TFT LCD, IPS LCD display, and touch screen samples. The production time is only 4-5 weeks for LCD panels and 5-8 weeks for LCD display module, TFT LCD, IPS LCD display, and touch screen.

Generally, LCDs are filled with a liquid crystal layer with a thickness of about 3~4um between the upper and lower transparent electrodes, and the electric field of the liquid crystal interlayer is controlled by the method of filling the pixel electrode voltage, and then the intensity of the transmitted light is adjusted to produce a full brightness. Gray level between and full darkness. At present, LCD is mainly composed of three parts: color filter (CF), TFT array (TFT Array) substrate and backlight module (Backlight) as shown in Figure 1 (a). Each Pixel of TFT-LCD has a set of TFTs to control its voltage value, and to make the light generated by the backlight module and transmitted through the LC have different colors, red, blue, and green (R/B/G) are needed. Three colors of color resist are formed on the CF glass, and the gray scales are used to produce a full-color effect; after the TFT array and the CF substrate are respectively completed, then the CF upper plate and the TFT lower plate are filled with LC and bonded together. Finally, attach the polarizer. This process is called the "LCD process"; and the final "LCM process" is the connection between the driver IC and the control circuit board (PCBA) and the glass substrate (JI Process). Assemble with the backlight module (MA Process), and finally the lighting detection of the module... and so on as shown in Figure 1 (b).

AU Optronics (hereinafter referred to as AU Optronics) has developed a process above the 8.5 generation factory to produce large-size LCD TV panels (see Figure 2). In December 2008, AUO successfully lighted the first 46-inch LCD TV panel produced in the G8.5 plant in China. The process technology once again led the whole Taiwan, marking a new page in the milestone of the new generation of TFT-LCD plant. Also established a new model of TFT-LCD green plant. The size of the G8.5 glass substrate is equivalent to the size of a pool table, but the thickness of the glass is less than 1mm. Therefore, the new-generation plant requires higher process technology; as the technology of large-size panels gradually matures, AUO will still Continue to focus on the development of new-generation plants, and continue to advance with the goal of increasing production capacity, improving process quality, and targeting customer service.

The development direction of next-generation process technology is nothing more than simplifying the process and selecting optimized raw materials and components to increase process yield and productivity, and reduce production costs. The capital investment of the front-end TFT Array and CF process equipment accounts for more than 60% of the total TFT-LCD expenditure. Therefore, the front-end process research and development first focuses on simplifying the process and improving the utilization of raw materials: for example, the four-pass mask technology that simplifies the mask process ( See Figure 3 (a)) and the pattern forming method without exposure and etching. In addition, the use of thinned glass substrates not only reduces the consumption of glass raw materials, but also has the advantages of lighter weight and thinner products; at the same time, it can achieve the goals of energy saving and waste reduction such as reducing packaging materials and improving transportation efficiency. As for LCM, with the rapid development of gate drive circuit substrate technology (Gate on Array, GOA) and HSD (Half source driving) technology in Figure 3 (b), it has not only simplified the material dependence of traditional panels on a large number of driver ICs. , Also contributes to the increase of LCM production capacity. In terms of module backlights, replacing traditional cold cathode tubes with light-emitting diodes (Light Emitting Diode, LED) not only avoids the harm of mercury (Hg) vapor in the tubes to the environment; the better luminous efficiency of LEDs also makes the products more efficient Energy saving.

A liquid crystal display (LCD) has liquid crystal material sandwiched between two sheets of glass. Without any voltage applied between transparent electrodes, liquid crystal molecules are aligned in parallel with the glass surface. When voltage is applied, they change their direction and they turn vertical to the glass surface. They vary in optical characteristics, depending on their orientation. Therefore, the quantity of light transmission can be controlled by combining the motion of liquid crystal molecules and the direction of polarization of two polarizing plates attached to the both outer sides of the glass sheets. LCDs utilize these characteristics to display images.

An LCD consists of many pixels. A pixel consists of three sub-pixels (Red/Green/Blue, RGB). In the case of Full-HD resolution, which is widely used for smartphones, there are more than six million (1,080 x 1,920 x 3 = 6,220,800) sub-pixels. To activate these millions of sub-pixels a TFT is required in each sub-pixel. TFT is an abbreviation for "Thin Film Transistor". A TFT is a kind of semiconductor device. It serves as a control valve to provide an appropriate voltage onto liquid crystals for individual sub-pixels. A TFT LCD has a liquid crystal layer between a glass substrate formed with TFTs and transparent pixel electrodes and another glass substrate with a color filter (RGB) and transparent counter electrodes. In addition, polarizers are placed on the outer side of each glass substrate and a backlight source on the back side. A change in voltage applied to liquid crystals changes the transmittance of the panel including the two polarizing plates, and thus changes the quantity of light that passes from the backlight to the front surface of the display. This principle allows the TFT LCD to produce full-color images.

Many people know what the characteristics of TFT LCD screens are, but do you know what are the characteristics of TFT LCD screen material? Today, we will tell you about the knowledge of the characteristics of TFT LCD screen materials.

With the rapid development of TFT array-driven liquid crystal display technology, in recent years, TFT LCD not only occupied the high-end display market such as portable notebook computers but also challenged the desktop display with the improvement of the manufacturing process and cost reduction. Because the TFT array directly drives the liquid crystal molecules, the cross-distortion effect is eliminated, and the display information capacity is large; the use of low-viscosity liquid crystal materials greatly improves the response speed, which can meet the needs of video image display. Therefore, compared with TFT display, TN type, and STN type liquid crystal display have made a qualitative leap and become one of the most promising display technologies in the 21st century.

TFT also adopts the principle of TN type electro-optic effect, but the TFT LCD material is different from the traditional liquid crystal material. In addition to good physical and chemical stability and a wide operating temperature range, TFT LCD materials must also have the following characteristics:

(4) The optical anisotropy (Δn) is matched to the TFT to eliminate the rainbow effect for greater contrast and wide-angle field of view. The range of △n value should be between 0.07~0.11.

At present, among the TFT LCD screen materials, TN type LCD screen has gradually entered a recession period, the market demand is gradually shrinking, the production capacity is excessive, the price competition is fierce, and there is no investment value. STN-type LCD will gradually enter a mature stage, the market demand will grow steadily, and the production technology will be fully mature. The TFT-type LCD is entering a new round of rapid growth, and the market demand will increase sharply, and it is expected to become one of the most promising display materials in the 21st century.

Although liquid crystal materials whose end groups are cyano groups, such as biphenyl and phenylcyclohexane liquid crystals, have been widely used in TN and STN LCDs, their viscosity is higher than that of fluorine-containing liquid crystals with the same molecular structure. These unfavorable factors limit the application of this type of compounds in TFT LCDs. The ester liquid crystal has the characteristics of simple synthesis method, wide variety, and wide phase transition range, but its high viscosity greatly reduces the dosage in TFT formulation. Therefore, the development of new liquid crystal compounds that meet the above requirements has become the focus of liquid crystal chemistry research.

The liquid crystal materials have developed rapidly with the development of liquid crystal devices, from biphenyl nitrile, esters, oxygen-containing heterocyclic benzenes, and pyrimidine ring liquid crystal compounds to cyclohexyl (bi) benzene, diphenylacetylene, ethyl bridge bonds and various fluorine-containing aromatic ring liquid crystal compounds. Japan has synthesized difluoroethylene liquid crystal compounds with stable structure, and its molecular structure is more and more stable, and it continuously meets the performance requirements of STN and TFT LCDs.

The 7 inch tft lcd panel is a vertical screen design with a resolution of 800*1280,with MIPI interface.We can provide the driver board to use with HDMI and USB interface. It realizes the drive-free function, plug and play. At present, it is mainly used in medical electronics, face recognition and other fields.

A: The phenomenon of water ripples is also related to the structural design and the panel material of the display itself. The following is mainly analyzed from two aspects:

2)Panel material: If the capacitive screen module adopts the display withTN panel, the strength of the tempered glass(cover lens) should be sufficient, otherwise the surface pressing will cause water ripple when the deformation contacts the glass of the display panel; If it is the IPS panel display, only the backlight part on the back of the display screen should not be locally squeezed by external force and no water ripple will occur;

A: The reason for air bonding screen module generating Newton"s ring is that the surface of capacitive touch screen and the LCD screen are not parallel enough, and the issue is generally caused by the collapse when the capacitive touch screen being pressed.

The most common semiconducting layer is made of amorphous silicon (a-Si). a-Si thin film transistor - liquid crystal display (TFT-LCD) has been the dominant technology for the manufacturing of active matrix TFT-LCD for over 20 years. a-Si is a low cost material in abundant supply.

a-Si is a low cost material in abundant supply. However, the electron mobility of a-Si is very low (around 1cm2/Vs) and can’t physically support high refresh rates such as the 240Hz needed for HDTV. Due to their high electron mobility, new materials such as metal oxide (MO) and low temperature polysilicon (LTPS) are now replacing a-Si to manufacture the industry’s two main types of screens: LCD and organic light-emitting diode (OLED) displays.

Ms.Josey

Ms.Josey

Ms.Josey

Ms.Josey