tft lcd to display picture id manufacturer

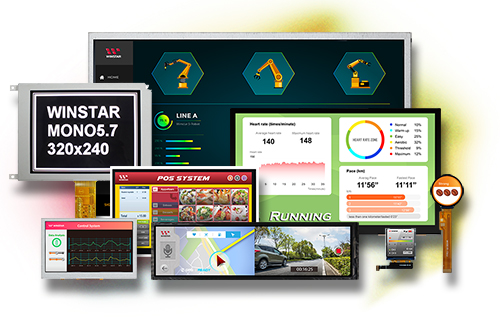

AZ Displays offers a range of Digital TFT Panels from 1.77″ to 15.4″ with an emphasis 4.3” , 5 “, and 7.0” displays. Featured below is AZ Display"s standard, popular offerings. However, AZ Displays has many more customized options and special sizes available.

SUNLIKE DISPLAY has developed a UI Editing Tool for the user to design their User Interface easily- just connect the PC and the UART TFT-LCD module through the UART port, and create everything with our software! For more details, feel free to contact us and we will soon respond to your request.

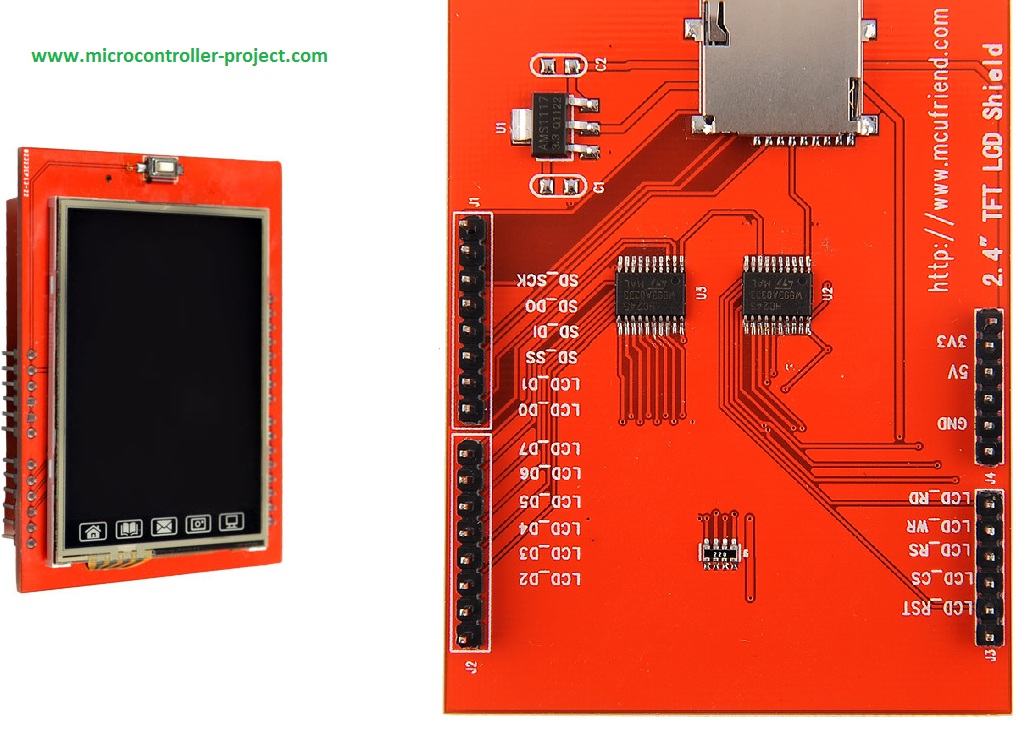

I bought four MCU Friend 3.5″ TFT shields. And, unfortunately, they have spiraled me into a deep, dark place trying to figure out how to use them. The the documentation consists of a sticker on the antistatic bag, a picture of the shield with a list of 5 different possible LCD drivers, a pinout, and a block of code that supposedly represents the startup code. The unfortunate part is that none of these have been exactly right – they all have errors. This article is a description of the journey to figuring out how to use them.

Here is a picture of the bag. (the QR code is a number “181024202132” which I thought might be a phone number but isn’t. It also doesn’t match anything in google, so i’m not sure what it is.

It also has a picture which says the LCD has one of several different controllers (and after digging in I know for a fact that two of mine were made by Raydium and are not on the list)

The first thing I did was try to use the MCUFRIEND_kbv library to see if the screens worked. The first board identified as ID=0x9403 and did not work. Apparently, the tool just spits out the ID if it doesn’t know it, which it did not.

One of the boards identified as ID=0x6814 worked perfectly, and one had a blue cast to all of the screens. The crazy part is the two boards that identified as ID=0x6814 had different PCBs. According to the comments in the MCUFRIEND_kbv.cpp ID=0x6814 is an RM68140 and ID=9403 is unknown.

Next, I started down the path of trying to figure out what the controllers were by using register reads. David Prentice (the guy who wrote/maintains the MCU Friend_kbv Arduino library) has an absolute ton of responses on the Arduino forum trying to help people figure out what their shield is. He asks them to post the register report from his example program LCD_ID_readnew which is included as an example in the library.

When you look at these LCD controllers they all have some variant of “Read ID” which responds with 1-6 bytes. The basic idea of this program is to look at what bytes are returned to try to identify the controller. Here is an example of what I got when I ran the LCD_ID_readnew program on my shields:

The key thing to see in this output is the register 0x04 which says 54,80,66 which identifies this as a Raydium RM68140 LCD controller. Here is a snapshot from the data sheet.

Unfortunately, the next thing to notice is that Register 0xBF has reg(0x00BF) FF FF 68 14 00 FF. The unfortunate part is that this register is not documented in the data sheet beyond this one reference:

Presumably the “68 14” corresponds to a Raydium 68140, but who knows? When I posted this on the Arduino forum, David Prentice responded (David does yeoman’s labor helping people and should be Thanked for all of his pro-bono work and putting up with a bunch of really bad questions)

After digging some more, I decided that it is super ugly out there, as you find that there are a significant number of LCD controllers that are clones, copies, pirated etc… and that they all present themselves differently. And, in hindsight I think that this is the reason that my ILI9341 from the previous article doesnt quite work correctly.

The next thing that I did was create a PSoC Program to read registers from the controllers to try to figure out what they were. My original plan was to write a complete identification program, but I have largely decided that this is a waste of time (more on this later). Here is the beginning of the project, it is called “Identify” in the workspace.

First, a function to reset the screen by toggling the reset line on the controller, then sending a command “0x01” which is commonly a software reset. It turns out that I spent a bunch of time trying to figure out what was going on because I was not getting any responses from the controllers. This was caused by not sending the software reset, which at least in two of the cases makes them unresponsive.

And all of this is insane because most of these companies don’t appear to have coherent websites or generally available datasheets. I suppose that it would help if I spoke and read Chinese.

The next thing that I did was try out the startup code that MCUFriend_kbv generates. I used the same technique from PSoC 6 + Segger EmWin + MCUFriend 2.4″ Part 1 and spit out the startup bytes. Here they are:

Well, things still aren’t quite right, so for some strange reason, I keep going and try to use the startup code from the web. In order to make it work I translate

Earlier I told you that I much preferred to use the more compact startup code. In order to match this, I decided to add a new code “0xDD” which means delay. (I hope that there are no controllers out there that use 0XDD). Here is the updated function:

Notice that my comments on the commands show that there are a bunch of them I dont know what they mean. Moreover, the MIPI spec says that all of the commands after 0xAF are reserved for the manufacturer… so I am pretty sure that they don’t do anything, or maybe should’nt be used?. The last thing that I decide to do is edit out the stuff that does not seem to make sense. Here is the new sequence:

At this point I have spent a frightening amount of time figuring out how these screens work. Although it has been a good learning experience, I have generally decided that using unknown displays from China with LCD drivers of questionable origin is not worth the pain of trying to sort out the interface. Beyond that:

Antigua and Barbuda, Aruba, Australia, Austria, Bahamas, Bahrain, Bangladesh, Barbados, Belgium, Belize, Bermuda, Bolivia, Brazil, Brunei Darussalam, Bulgaria, Cambodia, Canada, Cayman Islands, Chile, Colombia, Costa Rica, Cyprus, Czech Republic, Denmark, Dominica, Dominican Republic, Ecuador, Egypt, El Salvador, Estonia, Finland, France, French Guiana, Germany, Gibraltar, Greece, Grenada, Guadeloupe, Guatemala, Guernsey, Honduras, Hungary, Iceland, Indonesia, Ireland, Israel, Italy, Jamaica, Japan, Jersey, Jordan, Kuwait, Latvia, Liechtenstein, Lithuania, Luxembourg, Macau, Malaysia, Maldives, Malta, Martinique, Mexico, Monaco, Montserrat, Netherlands, New Zealand, Nicaragua, Norway, Oman, Pakistan, Panama, Paraguay, Peru, Philippines, Poland, Portugal, Qatar, Republic of Croatia, Reunion, Romania, Saint Kitts-Nevis, Saint Lucia, Saudi Arabia, Singapore, Slovakia, Slovenia, South Africa, South Korea, Spain, Sri Lanka, Sweden, Switzerland, Taiwan, Thailand, Trinidad and Tobago, Turks and Caicos Islands, United Arab Emirates, United Kingdom, United States, Vietnam

-Select-AlbaniaAlgeriaAmerican SamoaAndorraAngolaArgentinaArmeniaAustraliaAustriaAzerbaijan RepublicBahrainBarbadosBelarusBelgiumBelizeBeninBoliviaBosnia and HerzegovinaBotswanaBrazilBritish Virgin IslandsBrunei DarussalamBulgariaBurkina FasoBurundiCambodiaCameroonCanadaCape Verde IslandsCayman IslandsCentral African RepublicChadChileColombiaComorosCook IslandsCosta RicaCyprusCzech RepublicCôte d"Ivoire (Ivory Coast)Democratic Republic of the CongoDenmarkDjiboutiDominicaDominican RepublicEcuadorEgyptEl SalvadorEstoniaEthiopiaFalkland Islands (Islas Malvinas)FijiFinlandFranceFrench GuianaFrench PolynesiaGabon RepublicGambiaGeorgiaGermanyGhanaGibraltarGreeceGrenadaGuadeloupeGuamGuatemalaGuernseyGuineaGuyanaHaitiHondurasHungaryIcelandIndonesiaIrelandIsraelItalyJamaicaJapanJerseyJordanKazakhstanKenyaKiribatiKuwaitKyrgyzstanLaosLatviaLiberiaLibyaLiechtensteinLithuaniaLuxembourgMacedoniaMadagascarMalawiMalaysiaMaldivesMaliMaltaMarshall IslandsMartiniqueMauritaniaMauritiusMayotteMexicoMicronesiaMoldovaMonacoMongoliaMontenegroMontserratMoroccoMozambiqueNamibiaNauruNepalNetherlandsNetherlands AntillesNew CaledoniaNew ZealandNicaraguaNigerNigeriaNiueNorwayOmanPakistanPalauPanamaPapua New GuineaParaguayPeruPhilippinesPolandPortugalPuerto RicoQatarRepublic of CroatiaRepublic of the CongoReunionRomaniaRwandaSaint HelenaSaint Kitts-NevisSaint LuciaSaint Pierre and MiquelonSaint Vincent and the GrenadinesSan MarinoSaudi ArabiaSenegalSerbiaSeychellesSierra LeoneSingaporeSlovakiaSloveniaSolomon IslandsSomaliaSouth AfricaSouth KoreaSpainSri LankaSwazilandSwedenSwitzerlandTajikistanTanzaniaThailandTogoTongaTrinidad and TobagoTunisiaTurkeyTurkmenistanTuvaluUgandaUnited Arab EmiratesUnited KingdomUnited StatesUruguayUzbekistanVanuatuVatican City StateVenezuelaVietnamVirgin Islands (U.S.)Wallis and FutunaWestern SaharaWestern SamoaYemenZambiaZimbabwe

I found the TFT screen and Uno on Banggood.com about a month ago and over the weekend I was messing with the pair and found the tftbmp draw code in the demo.. I extended it with the ability to read any bmp file on the SD card.. so all you do is put your bitmaps on the SD and plug it in.. Having to add/edit/recompile/reload the Uno everytime is BS... Here is my code:

About: White House Maker Faire // 20 years old // U.C. Berkeley Junior in M.E.T. program. CEO of Qtechknow, maker and electronics enthusiast, I teach Arduino classes, and put making into schools! My successful Qduino…

Have you ever heard of TFT LCD screens? They are great ways to display information from your Arduino, or display pictures. The Arduino team just released an official TFT LCD screen with their new Robot at Maker Faire 2013. It"s very easy to get started with!! This tutorial will show you how to get the LCD up and running, load information from the SD card, and make a few simple projects.

The TFT LCD screen is a great way to detach your computer, and have the Arduino relay information that you need to know onto the LCD. A great part of the LCD is that it has a built in microSD card socket. You can store images on the microSD card socket, and even some text!

TFT LCD Screens (Thin-film-transistor liquid crystal display) are great graphical displays to display information. They are a variant of a liquid crystal display (LCD) which uses TFT technology to improve image qualities such as addressability and contrast. They are used often in video games, smartphones, cell phones, and sometimes even TV"s. Now, with the technology and accessibility today, you can use one with your Arduino!

LCDs, or liquid crystal displays, are easy to use with your Arduino. They are a very simple ways of telling the user data from the Arduino. Standard 16x2 character LCDs are found in grocery stores, when the display tells you what you bought as the cashier scans each item, and how much it costs.

For the first example, let"s put the Instructables Logo on our TFT display! Download the zip file below, and put it onto a microSD Card (2GB). You will probably a microSD to SD Card adapter. There is no special software needed, just copy and paste it onto the card.

Let"s try another example. This time, we"ll be mimicking the Serial Monitor on our TFT LCD. Keep the same circuit, and then upload the new code below.

This sketch will gather the reading from the ArduSensor Pot, and then relay it onto the TFT LCD screen 10 times per second. This is a great way to display data without a computer.

Open up the CardInfo sketch from the Arduino program; File>Examples>SD>CardInfo. Upload this to your Arduino, and then open the serial monitor in the Arduino program.

This looks like a fantastic tutorial, but could you please help: is there a cheaper alternative to the official arduino TFT screen but will still work with the tft library? Help and multiple suggestions are much appreciated!0

Without a storage medium you would need to convert the image data into an array representing each pixel and make it part of your sketch. So you would be limited by the on-board memory of the Arduino.0

I am also trying to play a video using Arduino. If I use images after split from a video as a slideshow using higher speed. will Arduino able to process it ?0

In this article, you will learn how to use TFT LCDs by Arduino boards. From basic commands to professional designs and technics are all explained here.

In electronic’s projects, creating an interface between user and system is very important. This interface could be created by displaying useful data, a menu, and ease of access. A beautiful design is also very important.

There are several components to achieve this. LEDs, 7-segments, Character and Graphic displays, and full-color TFT LCDs. The right component for your projects depends on the amount of data to be displayed, type of user interaction, and processor capacity.

TFT LCD is a variant of a liquid-crystal display (LCD) that uses thin-film-transistor (TFT) technology to improve image qualities such as addressability and contrast. A TFT LCD is an active matrix LCD, in contrast to passive matrix LCDs or simple, direct-driven LCDs with a few segments.

In Arduino-based projects, the processor frequency is low. So it is not possible to display complex, high definition images and high-speed motions. Therefore, full-color TFT LCDs can only be used to display simple data and commands.

In this article, we have used libraries and advanced technics to display data, charts, menu, etc. with a professional design. This can move your project presentation to a higher level.

In electronic’s projects, creating an interface between user and system is very important. This interface could be created by displaying useful data, a menu, and ease of access. A beautiful design is also very important.

There are several components to achieve this. LEDs, 7-segments, Character and Graphic displays, and full-color TFT LCDs. The right component for your projects depends on the amount of data to be displayed, type of user interaction, and processor capacity.

TFT LCD is a variant of a liquid-crystal display (LCD) that uses thin-film-transistor (TFT) technology to improve image qualities such as addressability and contrast. A TFT LCD is an active matrix LCD, in contrast to passive matrix LCDs or simple, direct-driven LCDs with a few segments.

In Arduino-based projects, the processor frequency is low. So it is not possible to display complex, high definition images and high-speed motions. Therefore, full-color TFT LCDs can only be used to display simple data and commands.

In this article, we have used libraries and advanced technics to display data, charts, menu, etc. with a professional design. This can move your project presentation to a higher level.

Size of displays affects your project parameters. Bigger Display is not always better. if you want to display high-resolution images and signs, you should choose a big size display with higher resolution. But it decreases the speed of your processing, needs more space and also needs more current to run.

After choosing the right display, It’s time to choose the right controller. If you want to display characters, tests, numbers and static images and the speed of display is not important, the Atmega328 Arduino boards (such as Arduino UNO) are a proper choice. If the size of your code is big, The UNO board may not be enough. You can use Arduino Mega2560 instead. And if you want to show high resolution images and motions with high speed, you should use the ARM core Arduino boards such as Arduino DUE.

In electronics/computer hardware a display driver is usually a semiconductor integrated circuit (but may alternatively comprise a state machine made of discrete logic and other components) which provides an interface function between a microprocessor, microcontroller, ASIC or general-purpose peripheral interface and a particular type of display device, e.g. LCD, LED, OLED, ePaper, CRT, Vacuum fluorescent or Nixie.

The display driver will typically accept commands and data using an industry-standard general-purpose serial or parallel interface, such as TTL, CMOS, RS232, SPI, I2C, etc. and generate signals with suitable voltage, current, timing and demultiplexing to make the display show the desired text or image.

The LCDs manufacturers use different drivers in their products. Some of them are more popular and some of them are very unknown. To run your display easily, you should use Arduino LCDs libraries and add them to your code. Otherwise running the display may be very difficult. There are many free libraries you can find on the internet but the important point about the libraries is their compatibility with the LCD’s driver. The driver of your LCD must be known by your library. In this article, we use the Adafruit GFX library and MCUFRIEND KBV library and example codes. You can download them from the following links.

You must add the library and then upload the code. If it is the first time you run an Arduino board, don’t worry. Just follow these steps:Go to www.arduino.cc/en/Main/Software and download the software of your OS. Install the IDE software as instructed.

By these two functions, You can find out the resolution of the display. Just add them to the code and put the outputs in a uint16_t variable. Then read it from the Serial port by Serial.println(); . First add Serial.begin(9600); in setup().

First you should convert your image to hex code. Download the software from the following link. if you don’t want to change the settings of the software, you must invert the color of the image and make the image horizontally mirrored and rotate it 90 degrees counterclockwise. Now add it to the software and convert it. Open the exported file and copy the hex code to Arduino IDE. x and y are locations of the image. sx and sy are sizes of image. you can change the color of the image in the last input.

Upload your image and download the converted file that the UTFT libraries can process. Now copy the hex code to Arduino IDE. x and y are locations of the image. sx and sy are size of the image.

In this template, We just used a string and 8 filled circles that change their colors in order. To draw circles around a static point ,You can use sin(); and cos(); functions. you should define the PI number . To change colors, you can use color565(); function and replace your RGB code.

In this template, We converted a .jpg image to .c file and added to the code, wrote a string and used the fade code to display. Then we used scroll code to move the screen left. Download the .h file and add it to the folder of the Arduino sketch.

In this template, We used sin(); and cos(); functions to draw Arcs with our desired thickness and displayed number by text printing function. Then we converted an image to hex code and added them to the code and displayed the image by bitmap function. Then we used draw lines function to change the style of the image. Download the .h file and add it to the folder of the Arduino sketch.

In this template, We created a function which accepts numbers as input and displays them as a pie chart. We just use draw arc and filled circle functions.

In this template, We added a converted image to code and then used two black and white arcs to create the pointer of volumes. Download the .h file and add it to the folder of the Arduino sketch.

In this template, We added a converted image and use the arc and print function to create this gauge. Download the .h file and add it to folder of the Arduino sketch.

while (a < b) { Serial.println(a); j = 80 * (sin(PI * a / 2000)); i = 80 * (cos(PI * a / 2000)); j2 = 50 * (sin(PI * a / 2000)); i2 = 50 * (cos(PI * a / 2000)); tft.drawLine(i2 + 235, j2 + 169, i + 235, j + 169, tft.color565(0, 255, 255)); tft.fillRect(200, 153, 75, 33, 0x0000); tft.setTextSize(3); tft.setTextColor(0xffff); if ((a/20)>99)

while (b < a) { j = 80 * (sin(PI * a / 2000)); i = 80 * (cos(PI * a / 2000)); j2 = 50 * (sin(PI * a / 2000)); i2 = 50 * (cos(PI * a / 2000)); tft.drawLine(i2 + 235, j2 + 169, i + 235, j + 169, tft.color565(0, 0, 0)); tft.fillRect(200, 153, 75, 33, 0x0000); tft.setTextSize(3); tft.setTextColor(0xffff); if ((a/20)>99)

In this template, We display simple images one after each other very fast by bitmap function. So you can make your animation by this trick. Download the .h file and add it to folder of the Arduino sketch.

In this template, We just display some images by RGBbitmap and bitmap functions. Just make a code for touchscreen and use this template. Download the .h file and add it to folder of the Arduino sketch.

With the TFT LCD display up to 800x600 resolution, PPD-1008 delivers sharpness of picture. The LED backlighting of PPD-1008 allows lower power consumption and ensures durability and energy saving for 30,000 hours LED lifetime. Within the 8 inches full flat and high brightness vivid LCD panel, PPD-1008 supports projected capacitive 10 points multi-touch technology to ensure immediate and accurate touch response. High-quality, reliability, and durability, Fametech Inc. offers a three-year warranty. FAMETECH, since 1981, is a 8-inch LCD Display with resolution 800 x 600 | POS system manufacturer based in Taiwan. With the TFT LCD display up to 800x600 resolution, PPD-1008 delivers sharpness of picture. The LED backlighting of PPD-1008 allows lower power consumption and ensures durability and energy saving for 30,000 hours LED lifetime. Within the 8 inches full flat and high brightness vivid LCD panel, PPD-1008 supports projected capacitive 10 points multi-touch technology to ensure immediate and accurate touch response. High-quality, reliability, and durability, Fametech Inc. offers a three-year warranty. The product including: payment terminal, mobile POS, barcode scanner, thermal receipt printer and label printer. ISO-9001 / 9002 certified, total AIDC & POS solutions, fast-responding pre-sale consulting service, technical support, training, after service and customized ODM & OEM service.

I"d like to receive news and commercial info from Schneider Electric and its affiliates via electronic communication means such as email, and I agree to the collection of information on the opening and clicks on these emails (using invisible pixels in the images), to measure performance of our communications and improve them. For more details, please read our

Over the past decade the TFT-LCD has been a popular flat panel display choice. With the increase in demand, the sizes of the TFT-LCDs have been getting larger. To make large-sized TFT-LCDs, the original manufacturing process needs to be changed to meet the requirements. Such a change usually results in various defects, which decrease the yield rate significantly, therefore, defect inspection plays a key role in TFT-LCD manufacture. However, in current practice, this task still relies heavily on human observers, which is not only time consuming, but also prompt to be unreliable. Accordingly, automatic optical inspection (AOI) has been suggested as the most efficient way to detect defects.

TFT-LCD manufacture consists of three processes, namely the TFT array process, the cell process, and the module assembly process. In recent years, there has been a large body of work regarding the so-called mura-defect detection, e.g., [1–4]. Mura is a serious kind of defect and needs to be detected in the cell process. Once a mura defect is found in a panel, this panel must be discarded if not repairable, which raises the production costs greatly. In fact, most mura defects are caused by the inline defects of the TFT array process. The inline defects vary greatly, and their sizes are too small to be observed, making the problem of inline defect inspection intractable.

Inline defect inspection involves three sub-tasks: defect detection, target defect identification, and classification. Defect detection refers to judging whether an image contains a defect or not, and target defect identification means determining whether the defect detected is crucial to the product yield. Defect classification plays a critical role in production-equipment diagnosis because different defects have different causes. Liu et al. [5] have recently proposed a system to deal with the problem of inline defect detection, which was developed based on the locally linear embedding (LLE) method [6] and the support vector data description (SVDD) [7]. LLE is a manifold learning method to extract nonlinear features from a pattern. However, it suffers from the out-of-sample problem [8,9]. SVDD is essentially a one-class classifier. Although it is efficient for anomaly detection, it cannot be applied in a multi-class classification problem. For inline defect classification, the SVDD is not a good candidate. Liu et al. [10] have also proposed a target defect identification system. In their work the SVDD was extended to an SVDD ensemble for modeling the target defects. If a test pattern is accepted by the SVDD ensemble, the pattern belongs to the target class. In TFT array process, the target defects would cause serious damages to the LCD panels.

According to the above analysis, it is known that the third sub-task is still an issue to be solved. In this paper we present a new inline-defect inspection scheme that not only possesses the functions of defect detection and target defect identification, but can also simultaneously accomplish the task of defect classification.

Inline defect classification is typically a pattern recognition problem. In particular, inline defect patterns suffer from large variations in shape, color, texture, and size. Therefore the two issues, how to provide an effective representation method and how to design a classifier with high generalization performance, are the keys to acheiving high defect detection accuracy.

Principal component analysis (PCA) is a popular subspace analysis method for pattern representation and reconstruction. However, due to its linear nature [11], its performance is sometimes limited. Recently, a nonlinear version of PCA has been proposed, called kernel PCA (KPCA) [12]. KPCA first maps the input data into a higher dimensional feature space via a nonlinear mapping, then performs the linear PCA in that space to find a set of eigenvectors that are nonlinearly related to the input data. Thus, KPCA can capture the nonlinear relationships between pixels in an image, and extract more discriminating features from an image and reduce the dimensionality of the input image. In face recognition studies, e.g., [13], KPCA has shown to have better performance than PCA in terms of feature extraction. To enhance the LCD defect detection/classification rate, in this paper we adopt the powerful KPCA as the feature extractor.

Aside from feature extraction, classifier design is also crucial to defect inspection. In the fields of pattern recognition and machine learning, support vector machine (SVM) has received much attention over the past decade. The learning strategy of SVM is based on the principle of structural risk minimization [14], so SVM has better generalization ability than other traditional learning machines that are based on the learning principle of empirical risk minimization, such as multi-layer neural networks trained by error back-propagation algorithm [15,16]. Thus, the SVM is a good candidate for our work. However, in practice, using the SVM as the defect classifier may not achieve the optimum classification performance due to the nature of the problem, explained as follows.

In TFT array process, various kinds of inline defects would occur. Their occurrence frequencies are different. For example, “particle” is the most commonly-seen defect while the defect “abnormal photo-resist coating” seldom appears. It implies that the available training samples for each defect would be different, leading to a very imbalanced training dataset. In SVM, the error penalties for positive and negative classes are the same. This will make the learned optimal separating hyperplane (OSH) move toward the smaller class. More precisely, if the positive class is smaller than the negative class, then the OSH will move toward the positive class, which will further result in numerous false negative errors. We call this phenomenon the “class-boundary-skew (CBS) problem”. Due to this problem, the success of using SVM in defect detection and classification is limited. Therefore, how to solve the CBS problem when applying SVM to defect inspection becomes a very critical studying issue.

Several works have proposed ways to solve the CBS problem [17–22]. The methods of [20,21] use different sampling techniques to the training data before data enter the classifier. The different error cost (DEC) algorithm of [17,19] is embedded into the formulation of SVM such that the skew phenomenon of the OSH can be corrected. This method does not change the information of the data structure beforehand. The SDC method [18] combines the SMOTE [22] and the different error cost algorithm [17]. For LCD defect inspection, since every defect image stands for one particular defect information, we do not intend to use any pre-sampling techniques like those fall into the first category that may change the data structure. Therefore, the DEC algorithm [17] is adopted in this paper to deal with the CBS problem due to the imbalanced defect training dataset. By introducing the DEC algorithm to SVM, the imbalanced SVM (ISVM), a variant of SVM is proposed. In fact, the concept of ISVM is similar to that of adaptive SVM proposed in [23]. However, in their work only 1-norm soft margin is considered. In this paper, we reformulate the ISVM with 2-norm soft margin, and provide the corresponding KKT conditions. Results will show that the proposed version of 2-norm soft margin ISVM achieves better defect classification performance.

Ms.Josey

Ms.Josey

Ms.Josey

Ms.Josey