arduino tft display and font library factory

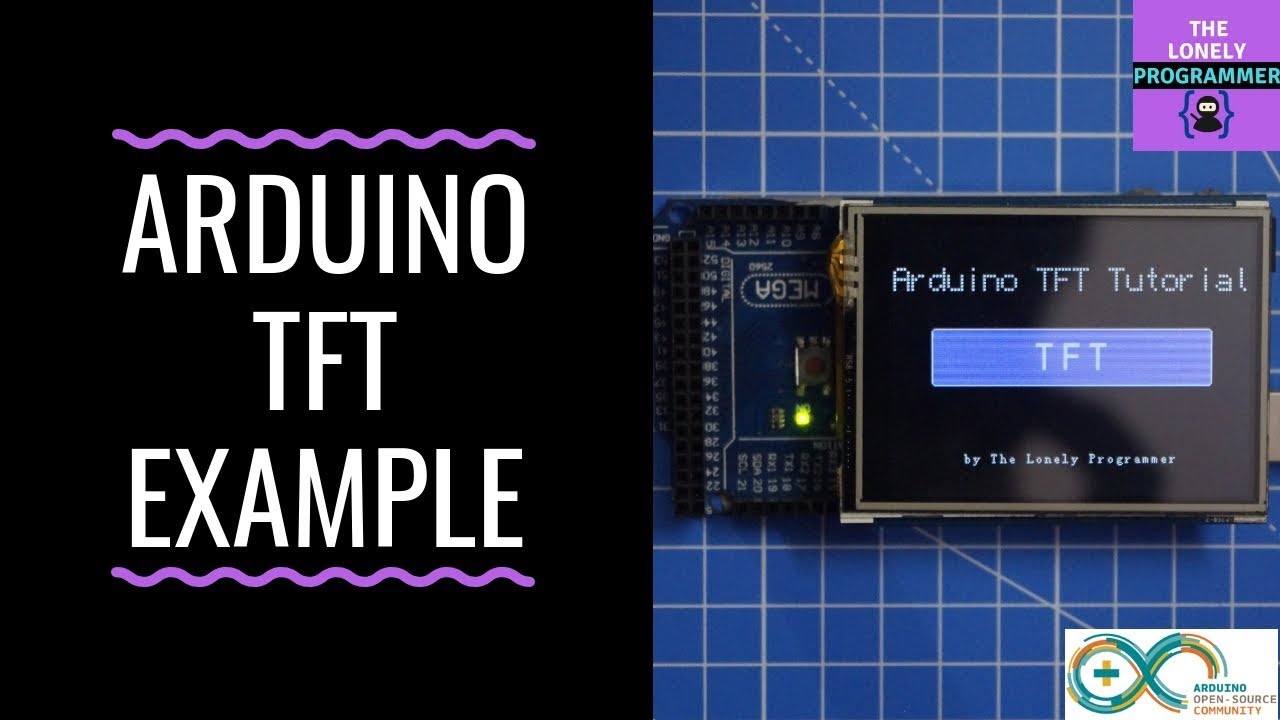

This new library is a standalone library that contains the TFT driver as well as the graphics functions and fonts that were in the GFX library. This library has significant performance improvements when used with an UNO (or ATmega328 based Arduino) and MEGA.

Examples are included with the library, including graphics test programs. The example sketch TFT_Rainbow_one shows different ways of using the font support functions. This library now supports the "print" library so the formatting features of the "print" library can be used, for example to print to the TFT in Hexadecimal, for example:

The larger fonts are now Run Length Encoded (RLE) so that they occupy less FLASH space, this frees up space for the rest of the sketch. A byproduct of the RLE approach is that the font drawing is also speeded up so it is a win-win situation.

To use the F_AS_T performance option the ILI9341 based display must be connected to an MEGA as follows:MEGA +5V to display pin 1 (VCC) and pin 8 (LED) UNO 0V (GND) to display pin 2 (GND)

In the library Font 0 (GLCD font), 2, 4, 6 and 8 are enabled. Edit the Load_fonts.h file within the library folder to enable/disable fonts to save space.

TFT_ILI9341 library updated on 1st July 2015 to version 12, this latest version is attached here to step 8:Minor bug when rendering letter "T" in font 4 without background fixed

for my recent project I need to use a tft display with an arduino due. I have a buydisplay ER-TFTM035-6 tft with the ILI9488 driver. It runs great with the modified UTFT library provided by buydisplay. The problem is that I need to use greek fonts. I know that there already made fonts for the library, but I want to make some of my own to fit my project better. I also know that there is a way of making new fonts for the UTFT but I can"t understand how. I tried to make some but without results. I found a library called dfUTFT fork that you can use fonts created with The Dot Factory, but I can"t compile the example sketch when I select the due. Is there any other way with any library to use greek fonts?

ER-TFTM070-5-4125 is 7 inch tft lcd display with RA8875 controller board,arduino shield,examples,library.Optional touch panel,arduino mega2560,due or uno board.

When I try to change the font with those provided by the adafruit free library, the text remains with the default font.I read several post and forum, tried several different things in text mode and graphics mode, nothing works, font character remains by default.

This website is using a security service to protect itself from online attacks. The action you just performed triggered the security solution. There are several actions that could trigger this block including submitting a certain word or phrase, a SQL command or malformed data.

This website is using a security service to protect itself from online attacks. The action you just performed triggered the security solution. There are several actions that could trigger this block including submitting a certain word or phrase, a SQL command or malformed data.

Spice up your Arduino project with a beautiful large touchscreen display shield with built in microSD card connection. This TFT display is big 4"(3.97" diagonal) bright (6 white-LED backlight) and colorful (18-bit 262,000 different shades)! 480x800 pixels with individual pixel control. As a bonus, this display has a optional resistive touch panel with controller XPT2046 and capacitive touch panel with FT6336.

The shield is fully assembled, tested and ready to go. No wiring, no soldering! Simply plug it in and load up our library - you"ll have it running in under 10 minutes! Works best with any classic Arduino (Due/Mega 2560).

This display shield has a controller built into it with RAM buffering, so that almost no work is done by the microcontroller. You can connect more sensors, buttons and LEDs.

Of course, we wouldn"t just leave you with a datasheet and a "good luck!" - we"ve written a full open source graphics library at the bottom of this page that can draw pixels, lines, rectangles, circles and text. We also have a touch screen library that detects x,y and z (pressure) and example code to demonstrate all of it. The code is written for Arduino but can be easily ported to your favorite microcontroller!

If you"ve had a lot of Arduino DUEs go through your hands (or if you are just unlucky), chances are you’ve come across at least one that does not start-up properly.The symptom is simple: you power up the Arduino but it doesn’t appear to “boot”. Your code simply doesn"t start running.You might have noticed that resetting the board (by pressing the reset button) causes the board to start-up normally.The fix is simple,here is the solution.

This website is using a security service to protect itself from online attacks. The action you just performed triggered the security solution. There are several actions that could trigger this block including submitting a certain word or phrase, a SQL command or malformed data.

Our new line of 10.1” TFT displays with IPS technology are now available! These 10.1” IPS displays offer three interface options to choose from including RGB, LVDS, and HDMI interface, each with two touchscreen options as capacitive or without a touchscreen.

The new line of 3.5” TFT displays with IPS technology is now available! Three touchscreen options are available: capacitive, resistive, or without a touchscreen.

The Computer-Aided Design ("CAD") files and all associated content posted to this website are created, uploaded, managed and owned by third-party users. Each CAD and any associated text, image or data is in no way sponsored by or affiliated with any company, organization or real-world item, product, or good it may purport to portray.

All returns for refund must be postmarked within fourteen (14) days of the date the item was delivered to the designated shipping address. All returned items must be in new and unused condition, with all parts & accessories included and all original tags and labels attached.

All returns for exchange must be postmarked within thirty (30) days of the date the item was delivered to the designated shipping address. All returned items must be in new and unused condition, returned with all parts & accessories included and all original tags and labels attached.

To return an item, please email customer service at service@elegoo.com / euservice@elegoo.com to obtain the address information you need regarding of returning the products. Please place the item securely in its original packaging, and mail your return through a trackable method.

After receiving your return and inspecting the condition of your item, we will process your return. Please allow at least 7 days from the receipt of your item to process your return. We will notify you by email when your return has been processed and refund you the payment via Paypal.

When contacting our customer service team, buyer must provide sufficient proof of purchase (order number from online purchases made through ELEGOO, Amazon or other ELEGOO"s authorized resellers), tell us which product you purchased, and describe the problem as clearly as possible through text, images or short videos. This will help our team to process your inquiries and help you solve the problems more efficiently.

This 2.0”LCD display adopts T7789V driver chip and has 320*240 color pixels (RGB565). It uses IPS TFT display and can display 18-bit color(16-bit is basically used). The module performs excellently in displaying color bitmap. Besides, there is an onboard MicroSD card slot for displaying more pictures. There are two connection ways for this module: pin headers and GDI. Only one fpc cable is needed when working with main-cotnrollers with GDI, which greatly reduces the complexity of wiring.

The module has the advantages of high resolution, wide viewing angle and simple wiring, and can be used in many display applications: waveform monitor display, electronic gift box, electronic weather decorations, etc.

The product is a Breakout module. It adopts SPI communication and has onboard GDI interface, which reduces the complexity of wiring and can easily display the contents read from SD card.

This is an example of commonly-used icons. 1. We use GIMP2 to convert these icons into codes for better display. 2. We provide some icons for you, Click here to find more"Click here to find more").

Along 3 years I have been trying several leg mechanism, at first I decided to do a simple desing with tibial motor where placed on femur joint.This design had several problems, like it wasn"t very robust and the most importat is that having the motor (with big mass) that far from the rotating axis, caused that in some movements it generate unwanted dynamics to the robot body, making controlability worse.New version have both motors of femur/tibial limb at coxa frame, this ends with a very simple setup and at the same time, the heaviest masses of the mechanism are centered to the rotating axis of coxa limb, so even though the leg do fast movements, inertias won"t be strong enough to affect the hole robot mass, achieving more agility.Inverse Kinematics of the mechanismAfter building it I notice that this mechanism was very special for another reason, at the domain the leg normally moves, it acts as a diferential mecanism, this means that torque is almost all the time shared between both motor of the longer limbs. That was an improvent since with the old mechanism tibial motor had to hold most of the weight and it was more forced than the one for femur.To visualize this, for the same movement, we can see how tibial motor must travel more arc of angel that the one on the new version.In order to solve this mechanism, just some trigonometry is needed. Combining both cosine and sine laws, we can obtain desired angle (the one between femur and tibia) with respect to the angle the motor must achieve.Observing these equations, with can notice that this angle (the one between femur and tibia) depends on both servos angles, which means both motors are contributing to the movement of the tibia.Calibration of servosAnother useful thing to do if we want to control servo precisely is to print a calibration tool for our set up. As shown in the image below, in order to know where real angles are located, angle protactor is placer just in the origin of the rotating joint, and choosing 2 know angles we can match PWM signal to the real angles we want to manipulate simply doing a lineal relation between angles and PWM pulse length.Then a simple program in the serial console can be wrtten to let the user move the motor to the desired angle. This way the calibration process is only about placing motor at certain position and everything is done and we won"t need to manually introduce random values that can be a very tedious task.With this I have achieved very good calibrations on motors, which cause the robot to be very simetrial making the hole system more predictable. Also the calibration procedure now is very easy to do, as all calculations are done automatically. Check Section 1 for the example code for calibration.More about this can be seen in the video below, where all the building process is shown as well as the new leg in action.SECTION 1:In the example code below, you can see how calibration protocol works, it is just a function called calibrationSecuence() which do all the work until calibration is finished. So you only need to call it one time to enter calibration loop, for example by sending a "c" character thought the serial console.Also some useful function are used, like moving motor directly with analogWrite functions which all the calculations involved, this is a good point since no interrupts are used.This code also have the feature to calibrate the potentiometer coming from each motor.#define MAX_PULSE 2500 #define MIN_PULSE 560 /*---------------SERVO PIN DEFINITION------------------------*/ int m1 = 6;//FR int m2 = 5; int m3 = 4; int m4 = 28;//FL int m5 = 29; int m6 = 36; int m7 = 3;//BR int m8 = 2; int m9 = 1; int m10 = 7;//BL int m11 = 24; int m12 = 25; int m13 = 0;//BODY /*----------------- CALIBRATION PARAMETERS OF EACH SERVO -----------------*/ double lowLim[13] = {50, 30, 30, 50, 30, 30, 50, 30, 30, 50, 30, 30, 70}; double highLim[13] = {130, 150, 150, 130, 150, 150, 130, 150, 150, 130, 150, 150, 110}; double a[13] = { -1.08333, -1.06667, -1.07778, //FR -1.03333, 0.97778, 1.01111, //FL 1.03333, 1.05556, 1.07778, //BR 1.07500, -1.07778, -1.00000, //BL 1.06250 }; double b[13] = {179.0, 192.0, 194.5, //FR 193.0, 5.5, -7.5, //FL 7.0, -17.0, -16.0, //BR -13.5, 191.5, 157.0, //BL -0.875 }; double ae[13] = {0.20292, 0.20317, 0.19904 , 0.21256, -0.22492, -0.21321, -0.21047, -0.20355, -0.20095, -0.20265, 0.19904, 0.20337, -0.20226 }; double be[13] = { -18.59717, -5.70512, -2.51697, -5.75856, 197.29411, 202.72169, 185.96931, 204.11902, 199.38663, 197.89534, -5.33768, -32.23424, 187.48058 }; /*--------Corresponding angles you want to meassure at in your system-----------*/ double x1[13] = {120, 135, 90, 60, 135 , 90, 120, 135, 90, 60, 135, 90, 110}; //this will be the first angle you will meassure double x2[13] = {60, 90, 135, 120, 90, 135, 60, 90, 135, 120, 90, 135, 70};//this will be the second angle you will meassure for calibration /*--------You can define a motor tag for each servo--------*/ String motorTag[13] = {"FR coxa", "FR femur", "FR tibia", "FL coxa", "FL femur", "FL tibia", "BR coxa", "BR femur", "BR tibia", "BL coxa", "BL femur", "BL tibia", "Body angle" }; double ang1[13] = {0, 0, 0, 0, 0, 0, 0, 0, 0, 0, 0, 0, 0}; double ang2[13] = {0, 0, 0, 0, 0, 0, 0, 0, 0, 0, 0, 0, 0}; float xi[500]; float yi[500]; float fineAngle; float fineL; float fineH; int motorPin; int motor = 0; float calibrationAngle; float res = 1.0; float ares = 0.5; float bres = 1.0; float cres = 4.0; float rawAngle; float orawAngle; char cm; char answer; bool interp = false; bool question = true; bool swing = false; int i; double eang; int freq = 100; // PWM frecuency can be choosen here. void connectServos() { analogWriteFrequency(m1, freq); //FR coxa digitalWrite(m1, LOW); pinMode(m1, OUTPUT); analogWriteFrequency(m2, freq); //femur digitalWrite(m2, LOW); pinMode(m2, OUTPUT); analogWriteFrequency(m3, freq); //tibia digitalWrite(m3, LOW); pinMode(m3, OUTPUT); analogWriteFrequency(m4, freq); //FL coxa digitalWrite(m4, LOW); pinMode(m4, OUTPUT); analogWriteFrequency(m5, freq); //femur digitalWrite(m5, LOW); pinMode(m5, OUTPUT); analogWriteFrequency(m6, freq); //tibia digitalWrite(m6, LOW); pinMode(m6, OUTPUT); analogWriteFrequency(m7, freq); //FR coxa digitalWrite(m7, LOW); pinMode(m7, OUTPUT); analogWriteFrequency(m8, freq); //femur digitalWrite(m8, LOW); pinMode(m8, OUTPUT); analogWriteFrequency(m9, freq); //tibia digitalWrite(m9, LOW); pinMode(m9, OUTPUT); analogWriteFrequency(m10, freq); //FR coxa digitalWrite(m10, LOW); pinMode(m10, OUTPUT); analogWriteFrequency(m11, freq); //femur digitalWrite(m11, LOW); pinMode(m11, OUTPUT); analogWriteFrequency(m12, freq); //tibia digitalWrite(m12, LOW); pinMode(m12, OUTPUT); analogWriteFrequency(m13, freq); //body digitalWrite(m13, LOW); pinMode(m13, OUTPUT); } void servoWrite(int pin , double angle) { float T = 1000000.0f / freq; float usec = float(MAX_PULSE - MIN_PULSE) * (angle / 180.0) + (float)MIN_PULSE; uint32_t duty = int(usec / T * 4096.0f); analogWrite(pin , duty); } double checkLimits(double angle , double lowLim , double highLim) { if ( angle >= highLim ) { angle = highLim; } if ( angle <= lowLim ) { angle = lowLim; } return angle; } int motorInfo(int i) { enc1 , enc2 , enc3 , enc4 , enc5 , enc6 , enc7 , enc8 , enc9 , enc10 , enc11 , enc12 , enc13 = readEncoders(); if (i == 0) { rawAngle = enc1; motorPin = m1; } else if (i == 1) { rawAngle = enc2; motorPin = m2; } else if (i == 2) { rawAngle = enc3; motorPin = m3; } else if (i == 3) { rawAngle = enc4; motorPin = m4; } else if (i == 4) { rawAngle = enc5; motorPin = m5; } else if (i == 5) { rawAngle = enc6; motorPin = m6; } else if (i == 6) { rawAngle = enc7; motorPin = m7; } else if (i == 7) { rawAngle = enc8; motorPin = m8; } else if (i == 8) { rawAngle = enc9; motorPin = m9; } else if (i == 9) { rawAngle = enc10; motorPin = m10; } else if (i == 10) { rawAngle = enc11; motorPin = m11; } else if (i == 11) { rawAngle = enc12; motorPin = m12; } else if (i == 12) { rawAngle = enc13; motorPin = m13; } return rawAngle , motorPin; } void moveServos(double angleBody , struct vector anglesServoFR , struct vector anglesServoFL , struct vector anglesServoBR , struct vector anglesServoBL) { //FR anglesServoFR.tetta = checkLimits(anglesServoFR.tetta , lowLim[0] , highLim[0]); fineAngle = a[0] * anglesServoFR.tetta + b[0]; servoWrite(m1 , fineAngle); anglesServoFR.alpha = checkLimits(anglesServoFR.alpha , lowLim[1] , highLim[1]); fineAngle = a[1] * anglesServoFR.alpha + b[1]; servoWrite(m2 , fineAngle); anglesServoFR.gamma = checkLimits(anglesServoFR.gamma , lowLim[2] , highLim[2]); fineAngle = a[2] * anglesServoFR.gamma + b[2]; servoWrite(m3 , fineAngle); //FL anglesServoFL.tetta = checkLimits(anglesServoFL.tetta , lowLim[3] , highLim[3]); fineAngle = a[3] * anglesServoFL.tetta + b[3]; servoWrite(m4 , fineAngle); anglesServoFL.alpha = checkLimits(anglesServoFL.alpha , lowLim[4] , highLim[4]); fineAngle = a[4] * anglesServoFL.alpha + b[4]; servoWrite(m5 , fineAngle); anglesServoFL.gamma = checkLimits(anglesServoFL.gamma , lowLim[5] , highLim[5]); fineAngle = a[5] * anglesServoFL.gamma + b[5]; servoWrite(m6 , fineAngle); //BR anglesServoBR.tetta = checkLimits(anglesServoBR.tetta , lowLim[6] , highLim[6]); fineAngle = a[6] * anglesServoBR.tetta + b[6]; servoWrite(m7 , fineAngle); anglesServoBR.alpha = checkLimits(anglesServoBR.alpha , lowLim[7] , highLim[7]); fineAngle = a[7] * anglesServoBR.alpha + b[7]; servoWrite(m8 , fineAngle); anglesServoBR.gamma = checkLimits(anglesServoBR.gamma , lowLim[8] , highLim[8]); fineAngle = a[8] * anglesServoBR.gamma + b[8]; servoWrite(m9 , fineAngle); //BL anglesServoBL.tetta = checkLimits(anglesServoBL.tetta , lowLim[9] , highLim[9]); fineAngle = a[9] * anglesServoBL.tetta + b[9]; servoWrite(m10 , fineAngle); anglesServoBL.alpha = checkLimits(anglesServoBL.alpha , lowLim[10] , highLim[10]); fineAngle = a[10] * anglesServoBL.alpha + b[10]; servoWrite(m11 , fineAngle); anglesServoBL.gamma = checkLimits(anglesServoBL.gamma , lowLim[11] , highLim[11]); fineAngle = a[11] * anglesServoBL.gamma + b[11]; servoWrite(m12 , fineAngle); //BODY angleBody = checkLimits(angleBody , lowLim[12] , highLim[12]); fineAngle = a[12] * angleBody + b[12]; servoWrite(m13 , fineAngle); } double readEncoderAngles() { enc1 , enc2 , enc3 , enc4 , enc5 , enc6 , enc7 , enc8 , enc9 , enc10 , enc11 , enc12 , enc13 = readEncoders(); eang1 = ae[0] * enc1 + be[0]; eang2 = ae[1] * enc2 + be[1]; eang3 = ae[2] * enc3 + be[2]; eang4 = ae[3] * enc4 + be[3]; eang5 = ae[4] * enc5 + be[4]; eang6 = ae[5] * enc6 + be[5]; eang7 = ae[6] * enc7 + be[6]; eang8 = ae[7] * enc8 + be[7]; eang9 = ae[8] * enc9 + be[8]; eang10 = ae[9] * enc10 + be[9]; eang11 = ae[10] * enc11 + be[10]; eang12 = ae[11] * enc12 + be[11]; eang13 = ae[12] * enc13 + be[12]; return eang1 , eang2 , eang3 , eang4 , eang5 , eang6 , eang7 , eang8 , eang9 , eang10 , eang11 , eang12 , eang13; } void calibrationSecuence( ) { //set servos at their middle position at firstt for (int i = 0; i <= 12; i++) { rawAngle , motorPin = motorInfo(i); servoWrite(motorPin , 90); } // sensorOffset0 = calibrateContacts(); Serial.println(" "); Serial.println("_________________________________SERVO CALIBRATION ROUTINE_________________________________"); Serial.println("___________________________________________________________________________________________"); Serial.println("(*) Don"t send several caracter at the same time."); delay(500); Serial.println(" "); Serial.println("Keyboard: "x"-> EXIT CALIBRATION. "c"-> ENTER CALIBRATION."); Serial.println(" "i"-> PRINT INFORMATION. "); Serial.println(" "); Serial.println(" "n"-> CHANGE MOTOR (+). "b" -> CHANGE MOTOR (-)."); Serial.println(" "m"-> START CALIBRATION."); Serial.println(" "q"-> STOP CALIBRATION."); Serial.println(" "); Serial.println(" "r"-> CHANGE RESOLUTION."); Serial.println(" "p"-> ADD ANGLE. "o"-> SUBTRACT ANGLE. "); Serial.println(" "s"-> SAVE ANGLE."); delay(500); Serial.println(" "); Serial.println("---------------------------------------------------------------------------------------------------"); Serial.print("SELECTED MOTOR: "); Serial.print(motorTag[motor]); Serial.print(". SELECTED RESOLUTION: "); Serial.println(res); while (CAL == true) { if (Serial.available() > 0) { cm = Serial.read(); if (cm == "x") { Serial.println("Closing CALIBRATION program..."); CAL = false; secuence = false; startDisplay(PAGE); angleBody = 90; anglesIKFR.tetta = 0.0; anglesIKFR.alpha = -45.0; anglesIKFR.gamma = 90.0; anglesIKFL.tetta = 0.0; anglesIKFL.alpha = -45.0; anglesIKFL.gamma = 90.0; anglesIKBR.tetta = 0.0; anglesIKBR.alpha = 45.0; anglesIKBR.gamma = -90.0; anglesIKBL.tetta = 0.0; anglesIKBL.alpha = 45.0; anglesIKBL.gamma = -90.0; } else if (cm == "i") { // + Serial.println(" "); Serial.println("---------------------------------------------------------------------------------------------------"); Serial.println("---------------------------------------------------------------------------------------------------"); Serial.println("(*) Don"t send several caracter at the same time."); delay(500); Serial.println(" "); Serial.println("Keyboard: "x"-> EXIT CALIBRATION. "c"-> ENTER CALIBRATION."); Serial.println(" "i"-> PRINT INFORMATION. "); Serial.println(" "); Serial.println(" "n"-> CHANGE MOTOR (+). "b" -> CHANGE MOTOR (-)."); Serial.println(" "m"-> START CALIBRATION."); Serial.println(" "q"-> STOP CALIBRATION."); Serial.println(" "); Serial.println(" "r"-> CHANGE RESOLUTION."); Serial.println(" "p"-> ADD ANGLE. "o"-> SUBTRACT ANGLE. "s"-> SAVE ANGLE."); Serial.println(" "); delay(500); Serial.println(" "); Serial.println("---------------------------------------------------------------------------------------------------"); Serial.println(" "); Serial.print("SELECTED MOTOR: "); Serial.print(motorTag[motor]); Serial.print(". SELECTED RESOLUTION: "); Serial.println(res); Serial.println("Actual parameters of the motor: "); Serial.print("High limit: "); Serial.print(highLim[motor]); Serial.print(" Low limit: "); Serial.print(lowLim[motor]); Serial.print(" Angle 1: "); Serial.print(ang1[motor]); Serial.print(" Angle 2: "); Serial.println(ang2[motor]); Serial.println("---------------------------------------------------------------------------------------------------"); } else if (cm == "m") { // + secuence = true; } else if (cm == "s") { // + } else if (cm == "n") { // + motor++; if (motor >= 13) { motor = 0; } Serial.print("SELECTED MOTOR: "); Serial.println(motorTag[motor]); } else if (cm == "b") { // + motor--; if (motor < 0) { motor = 13 - 1; } Serial.print("SELECTED MOTOR: "); Serial.println(motorTag[motor]); } else if (cm == "r") { // + if (res == ares) { res = bres; } else if (res == bres) { res = cres; } else if (res == cres) { res = ares; } Serial.print("SELECTED RESOLUTION: "); Serial.println(res); } } if (secuence == true) { Serial.print("Starting secuence for motor: "); Serial.println(motorTag[motor]); for (int i = 0; i <= 30; i++) { delay(20); Serial.print("."); } Serial.println("."); while (question == true) { unsigned long currentMicros = micros(); if (currentMicros - previousMicros >= 100000) { previousMicros = currentMicros; if (Serial.available() > 0) { answer = Serial.read(); if (answer == "y") { question = false; interp = true; secuence = true; } else if (answer == "n") { question = false; interp = false; secuence = true; } else { Serial.println("Please, select Yes(y) or No(n)."); } } } } answer = "t"; question = true; if (interp == false) { Serial.println("___"); Serial.println(" | Place motor at 1ts position and save angle"); Serial.println(" | This position can be the higher one"); rawAngle , motorPin = motorInfo(motor); calibrationAngle = 90; //start calibration at aproximate middle position of the servo. while (secuence == true) { /* find first calibration angle */ if (Serial.available() > 0) { cm = Serial.read(); if (cm == "p") { // + Serial.print(" | +"); Serial.print(res); Serial.print(" : "); calibrationAngle = calibrationAngle + res; servoWrite(motorPin , calibrationAngle); Serial.println(calibrationAngle); } else if (cm == "o") { // - Serial.print(" | -"); Serial.print(res); Serial.print(" : "); calibrationAngle = calibrationAngle - res; servoWrite(motorPin , calibrationAngle); Serial.println(calibrationAngle); } else if (cm == "r") { // + if (res == ares) { res = bres; } else if (res == bres) { res = cres; } else if (res == cres) { res = ares; } Serial.print("SELECTED RESOLUTION: "); Serial.println(res); } else if (cm == "q") { // quit secuence secuence = false; Serial.println(" | Calibration interrupted!!"); } else if (cm == "s") { // save angle ang1[motor] = calibrationAngle; secuence = false; Serial.print(" | Angle saved at "); Serial.println(calibrationAngle); } } } if (cm == "q") { Serial.println(" |"); } else { secuence = true; Serial.println("___"); Serial.println(" | Place motor at 2nd position and save angle"); Serial.println(" | This position can be the lower one"); } while (secuence == true) { /* find second calibration angle */ if (Serial.available() > 0) { cm = Serial.read(); if (cm == "p") { // + Serial.print(" | +"); Serial.print(res); Serial.print(" : "); calibrationAngle = calibrationAngle + res; servoWrite(motorPin , calibrationAngle); Serial.println(calibrationAngle); } else if (cm == "o") { // - Serial.print(" | -"); Serial.print(res); Serial.print(" : "); calibrationAngle = calibrationAngle - res; servoWrite(motorPin , calibrationAngle); Serial.println(calibrationAngle); } else if (cm == "r") { // + if (res == ares) { res = bres; } else if (res == bres) { res = cres; } else if (res == cres) { res = ares; } Serial.print("SELECTED RESOLUTION: "); Serial.println(res); } else if (cm == "q") { // quit secuence secuence = false; Serial.println(" | Calibration interrupted!!"); } else if (cm == "s") { // save angle ang2[motor] = calibrationAngle; secuence = false; Serial.print(" | Angle saved at "); Serial.println(calibrationAngle); } } } /*--------------------start calibration calculations------------------*/ if (cm == "q") { Serial.println("___|"); Serial.println("Calibration finished unespected."); Serial.println(" Select another motor."); Serial.print("SELECTED MOTOR: "); Serial.print(motorTag[motor]); Serial.print(". SELECTED RESOLUTION: "); Serial.println(res); } else { Serial.println("___"); Serial.println(" |___"); Serial.print( " | | Interpolating for motor: "); Serial.println(motorTag[motor]); secuence = true; //real angle is calculated interpolating both angles to a linear relation. a[motor] = (ang2[motor] - ang1[motor]) / (x2[motor] - x1[motor]); b[motor] = ang1[motor] - x1[motor] * (ang2[motor] - ang1[motor]) / (x2[motor] - x1[motor]); Serial.println(" | |"); } interp = true; } /*---------------------------make swing movement to interpolate motor encoder-----*/ if (interp == true and secuence == true) { delay(200); double x; int k = 0; int stp = 180; swing = true; i = 0; orawAngle , motorPin = motorInfo(motor); previousMicros = 0; while (swing == true) { // FIRST unsigned long currentMicros = micros(); if (currentMicros - previousMicros >= 10000) { // save the last time you blinked the LED previousMicros = currentMicros; x = x2[motor]; calibrationAngle = a[motor] * x + b[motor]; servoWrite(motorPin , calibrationAngle); rawAngle , motorPin = motorInfo(motor); if ((i % 3) == 0) { yi[k+1] = x; xi[k] = rawAngle; Serial.print(" | | Real ang: "); Serial.print(x); Serial.print(" -> Servo ang: "); Serial.print(calibrationAngle); Serial.print(" Enc: "); Serial.println(rawAngle); k++; } if (i >= stp) { swing = false; } i++; } } swing = true; i = 0; while (swing == true) { // moving unsigned long currentMicros = micros(); if (currentMicros - previousMicros >= 10000) { // save the last time you blinked the LED previousMicros = currentMicros; x = x2[motor] + float(i) * (x1[motor] - x2[motor]) / stp; calibrationAngle = a[motor] * x + b[motor]; servoWrite(motorPin , calibrationAngle); rawAngle , motorPin = motorInfo(motor); if ((i % 6) == 0) { yi[k+1] = x; xi[k] = rawAngle; Serial.print(" | | Real ang: "); Serial.print(x); Serial.print(" -> Servo ang: "); Serial.print(calibrationAngle); Serial.print(" Enc: "); Serial.println(rawAngle); k++; } if (i >= stp) { swing = false; } i++; } } swing = true; i = 0; while (swing == true) { // SECOND unsigned long currentMicros = micros(); if (currentMicros - previousMicros >= 10000) { // save the last time you blinked the LED previousMicros = currentMicros; x = x1[motor]; calibrationAngle = a[motor] * x + b[motor]; servoWrite(motorPin , calibrationAngle); rawAngle , motorPin = motorInfo(motor); if ((i % 3) == 0) { yi[k+1] = x; xi[k] = rawAngle; Serial.print(" | | Real ang: "); Serial.print(x); Serial.print(" -> Servo ang: "); Serial.print(calibrationAngle); Serial.print(" Enc: "); Serial.println(rawAngle); k++; } if (i >= stp) { swing = false; } i++; } } swing = true; i = 0; while (swing == true) { // moving unsigned long currentMicros = micros(); if (currentMicros - previousMicros >= 10000) { // save the last time you blinked the LED previousMicros = currentMicros; x = x1[motor] + float(i) * (x2[motor] - x1[motor]) / stp; calibrationAngle = a[motor] * x + b[motor]; servoWrite(motorPin , calibrationAngle); rawAngle , motorPin = motorInfo(motor); if ((i % 6) == 0) { yi[k+1] = x; xi[k] = rawAngle; Serial.print(" | | Real ang: "); Serial.print(x); Serial.print(" -> Servo ang: "); Serial.print(calibrationAngle); Serial.print(" Enc: "); Serial.println(rawAngle); k++; } if (i >= stp) { swing = false; } i++; } } swing = true; i = 0; while (swing == true) { // FIRST unsigned long currentMicros = micros(); if (currentMicros - previousMicros >= 10000) { // save the last time you blinked the LED previousMicros = currentMicros; x = x2[motor]; calibrationAngle = a[motor] * x + b[motor]; servoWrite(motorPin , calibrationAngle); rawAngle , motorPin = motorInfo(motor); if ((i % 3) == 0) { yi[k+1] = x; xi[k] = rawAngle; Serial.print(" | | Real ang: "); Serial.print(x); Serial.print(" -> Servo ang: "); Serial.print(calibrationAngle); Serial.print(" Enc: "); Serial.println(rawAngle); k++; } if (i >= stp) { swing = false; } i++; } } swing = true; i = 0; while (swing == true) { // moving unsigned long currentMicros = micros(); if (currentMicros - previousMicros >= 10000) { // save the last time you blinked the LED previousMicros = currentMicros; x = x2[motor] + float(i) * (x1[motor] - x2[motor]) / stp; calibrationAngle = a[motor] * x + b[motor]; servoWrite(motorPin , calibrationAngle); rawAngle , motorPin = motorInfo(motor); if ((i % 6) == 0) { yi[k+1] = x; xi[k] = rawAngle; Serial.print(" | | Real ang: "); Serial.print(x); Serial.print(" -> Servo ang: "); Serial.print(calibrationAngle); Serial.print(" Enc: "); Serial.println(rawAngle); k++; } if (i >= stp) { swing = false; } i++; } } swing = true; i = 0; while (swing == true) { // SECOND unsigned long currentMicros = micros(); if (currentMicros - previousMicros >= 10000) { // save the last time you blinked the LED previousMicros = currentMicros; x = x1[motor]; calibrationAngle = a[motor] * x + b[motor]; servoWrite(motorPin , calibrationAngle); rawAngle , motorPin = motorInfo(motor); if ((i % 3) == 0) { yi[k+1] = x; xi[k] = rawAngle; Serial.print(" | | Real ang: "); Serial.print(x); Serial.print(" -> Servo ang: "); Serial.print(calibrationAngle); Serial.print(" Enc: "); Serial.println(rawAngle); k++; } if (i >= stp) { swing = false; } i++; } } Serial.println(" | | Interpolation finished!"); /*-------Calculate linear interpolation of the encoder from 60 meassures done in swing------*/ double sx = 0; double sy = 0; double sx2 = 0; double sy2 = 0; double sxy = 0; double xmean = 0; double ymean = 0; int n = 300; for (int i = 0 ; i < n ; i++) { sx += xi[i+10]; sy += yi[i+10]; sx2 += xi[i+10] * xi[i+10]; sy2 += yi[i+10] * yi[i+10]; sxy += xi[i+10] * yi[i+10]; } ae[motor] = (n * sxy - sx * sy) / (n * sx2 - sx * sx); //sxy / sx2; // be[motor] = (sy - ae[motor] * sx) / n; //ymean - ae[motor] * xmean; Serial.println(" | | Moving back to ZERO position."); // turn the motor back to middle position swing = true; i = 0; while (swing == true) { unsigned long currentMicros = micros(); if (currentMicros - previousMicros >= 10000) { // save the last time you blinked the LED previousMicros = currentMicros; x = x1[motor] + float(i) * (90 - x1[motor]) / 60; calibrationAngle = a[motor] * x + b[motor]; servoWrite(motorPin , calibrationAngle); rawAngle , motorPin = motorInfo(motor); eang = ae[motor] * rawAngle + be[motor]; if ((i % 4) == 0) { Serial.print(" | | Servo ang: "); Serial.print(calibrationAngle); Serial.print(" -> Real ang: "); Serial.print(x); Serial.print(" -> Encoder ang: "); Serial.println(eang); } if (i >= 60) { swing = false; } i++; } } Serial.println("___|___|"); Serial.println(" | "); Serial.println("___"); Serial.println(" | Calibration finished satisfactory. Results data:"); Serial.print(" | HIGH lim: "); Serial.print(highLim[motor]); Serial.print(" LOW lim: "); Serial.println(lowLim[motor]); Serial.print(" | angle 1: "); Serial.print(ang1[motor]); Serial.print(" angle 2 "); Serial.println(ang2[motor]); Serial.print(" | Regression Motor a: "); Serial.print(a[motor], 5); Serial.print(" b: "); Serial.println(b[motor], 5); Serial.print(" | Regression Encoder a: "); Serial.print(ae[motor], 5); Serial.print(" b: "); Serial.println(be[motor], 5); Serial.println(" |"); Serial.println(" | ______________________________________________________________"); Serial.println(" | | |"); Serial.println(" | | This code won"t be able to save the updated parameters |"); Serial.println(" | | once the robot is shutted down. |"); Serial.println(" | | |"); Serial.println(" | | Please, write down the results |"); Serial.println(" | | and save them in the definition of each variable. |"); Serial.println(" | |_____________________________________________________________|"); Serial.println(" |"); Serial.println("___|"); Serial.println(" Select another motor."); Serial.print("SELECTED MOTOR: "); Serial.print(motorTag[motor]); Serial.print(". SELECTED RESOLUTION: "); Serial.println(res); } interp = false; secuence = false; } } SAFE = false; Serial.println("Calibration killed"); } // END OF CALIBRATION

A number of display devices like LEDs, 7-segments, character and graphic displays can be attached to microcontrollers to create an interface between the user and an electronic system for displaying data or controlling the system. Sometimes you may need to add colorful images or graphics to your project, that’s where the TFT color displays come in handy.

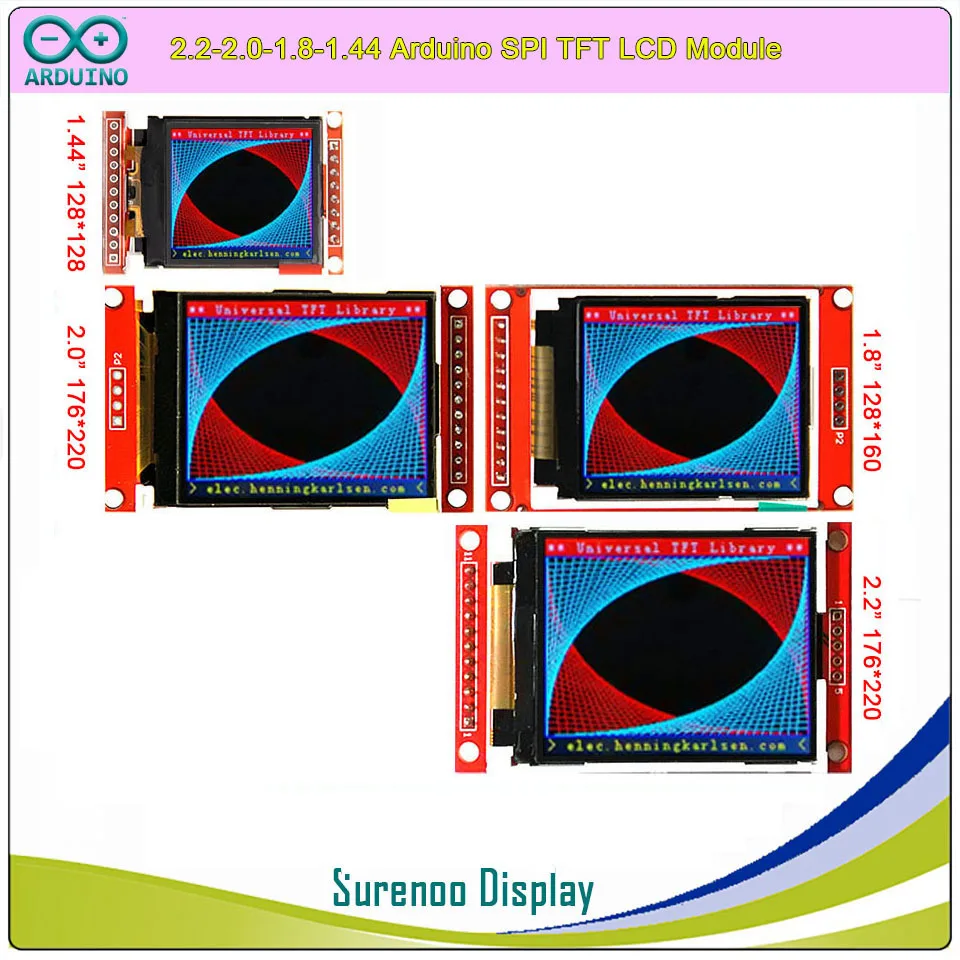

TFT LCD is a variant of a liquid-crystal display (LCD) that uses thin-film-transistor (TFT) technology to improve image qualities such as addressability and contrast. In this tutorial we are going to show how to interface a 1.44″ TFT color display based on the ST7735 driver. It has 128×128 color pixels and can display full 16-bit color.

This is the type of display am using but they come with various pin configurations. However all the displays will have the major pins stated below and should be connected to the Arduino board as follows:

This TFT display uses 3.3V but comes with an on board voltage regulator therefore the VCC can be connected to the Arduino 5V. However for best practice it’s better to use the 3.3V.

Most code Libraries for this TFT ST7735 display with Arduino are programmed with the SDA and SCL pins connected to Arduino pins 11 and 13 respectively. Make sure you don’t change that order otherwise the display may not work.

There are a number of libraries that have been developed to run the TFT ST7735 color display using Arduino but I found the Adafruit-ST7735-Librarythe best to use. Make sure you have this library installed in your IDE.

tft.fillRoundRect(x,y,w,h,r,t); function draws a filled Rectangle with r radius round corners in x and y location and w width and h height and t color.

There are many other functions and commands which you can use to program the TFT color display but the above are the commonest. You will meet many more with practice.

Before we can write our personal code we need to first test the display using the already made code examples from the installed library. This is done by going to File>Examples>Adafruit ST7735 and ST7789 Library. Then you can select any of the examples and upload it to the setup to see if the display works fine.In the diagram below I have shown how to access the graphics test code.

This document goes through various features of the current Nextion Editor. The Nextion Editor is used to rapidly create Human Machine Interface GUIs for Nextion HMI devices. As such the GUI can be created within Hours instead of Weeks, and Days instead of Months. So while we won’t be covering basics such as opening a file, we will point out somethings that might prove helpful to know, or reminders need be made.

Note: Nextion Editor has indeed evolved since its early beginnings, so I would like to take a moment for a quick review. As time has passed, many additional features and bug fixes were incorporated. The Nextion Editor is not expected to retain every previous behaviours between versions exactly. With the new, then there are indeed new behaviours and new possibilities.

The pandemic had created global supply shortages and to meet these challenges while keeping with Nextion quality then second source components/ICs were indeed needed. This said, while elder devices only require firmware level code to communicate with primary sources ICs, the newer devices with secondary source ICs (visually identified with QR codes on the microSD slot) indeed require more recent versions of the Nextion Editor (v1.63.3 and later recommended) for the firmware to communicate with the secondary source ICs. As such, newer devices with secondary source ICs can not make use of elder versions of the Nextion Editor (such as v0.38, or LTS) before such firmware level code was incorporated into the Nextion Editor version firmware.

Since 2020, the newer Nextion devices may give a Data Error when trying to attempt loading a *.TFT file that was created with an Editor version prior to version 1.63.3 that does not have the ability to communicate with second source ICs. One would need to compile their project with a version 1.63.3 or later and use that *.TFT file to upload their project to the newer Nextion device.

Now mostly Historical, those original Nextion devices from 2015/2016 with the Itead logo on the PCB may require an intermediary upgrade only if all the Legacy conditions are met (see the Legacy FAQ, v0.42 intermediary TFTs are supplied in FAQ), otherwise when every condition is not met then such an intermediary is not required. Devices that were upgraded to a version of the Nextion Editor v0.29 and later can not return to an earlier version (v0.28 and before). Devices that were upgraded to a version of the Nextion Editor v0.38 and later can not return to an earlier version (v0.37 and before). Enhanced Series models require v0.33 or later, when Enhanced models were introduced. Intelligent Series models require v0.58 or later, when Intelligent models were introduced. Discovery Series models require v1.62.2 and later, when Discovery models were introduced. The Nextion Editor LTS Edition (Long Term Support) can only be used with elder Basic and Enhanced devices without second sources ICs. And of course, any newer devices with the QR code on the microSD card slot requires v1.63.3 or later.

This Editor Guide will refer exclusively to the new and current Nextion Editor. Where an item within the guide may be specific to a particular Nextion series, the following icons will be used to represent the series: For the Basic T Series

Requirements* Windows Operating System (XP or higher). Users must know and be able to use their Windows OS. Windows OS support is beyond the scope of Nextion, so while Microsoft discontinues there support of earlier OSes, the current Nextion Editor does run on XP with the x86 .NET 3.5 and x86 2015 VC++ Redistributable. Users are expected to know their own development environment. Note: Installations on VMware and other Operating Systems may have been accomplished successfully, but is not officially supported and beyond the scope of any manual.

* As stated in the Note above, use of Nextion Editor v1.63.3 or later is required for newer Nextion devices with second source ICs, or a Data Error may occur when the *.tft file firmware can not communicate with the second source ICs

* A reasonable sized monitor for the model’s resolution you are designing for is only good sense. When designing for a 320×240 or 240×320 model then a standard monitor size is probably sufficient. However, if one is designing for 1024×600 or 600×1024 resolutions, then it would stand to good reason not to expect best ease from using an 800×600 monitor resolution. For comfort, then it is senseful to use a large enough monitor resolution so that your design canvas, tool panes, menus, and event panes fit for your designing comfort. And in the reverse, a large enough screen for for your development comfort when designing for the smallest of Nextion devices. It is not appropriate to blame the Editor software for your too small monitor when you really know you need more screen real estate.

* Basic programming skills are prerequisite. The Nextion Instruction Set is made up of ASCII text based commands inbound, and significant first byte binary Return Data. A component’s Touch Event “Send Component ID” can be used to defer programming tasks to the user’s MCU.

* As such, quickly creating an HMI GUI for Nextion does not demand extreme skills – but basic programming skill are expected. When programming logic Nextion side, then users should have a foundation in programming.

* Over 68,000 MCUs (any MCU with an internal UART module or two digital pins to bit-bang a Software Serial) can be used with Nextion in over 130 programing languages. MCU side programming is beyond the scope of Nextion and remains within the user’s domain and duty to know and understand their chosen MCU and chosen MCU side programming languages.

* Uploading your completed Nextion HMI project can be accomplished either by microSD card or over TTL Serial. As there are dozens of manufactures for each of these, it is the user’s domain and duty to know their device installation, configuration and operation.

The latest version of the Nextion Editor can be downloaded from [here]. Earlier versions of the Nextion Editor can be downloaded from the Nextion Editors and Change Logs thread in the Announcement Forum (Register for the forum, confirm and then Login to use).

2) The ZIP version can be unzipped into a user chosen folder and run directly from that folder. For maintaining multiple versions of the Nextion Editor, the ZIP version is recommended. When updating within the Nextion Editor, Manual Update will launch your web browser to the download page so you may download the ZIP version

Many of the panes can be adjusted on both size and their location. To resize, drag the splitter between panes and move to resize the panes. To move a pane to a more convenient location, drag the title of the pane and release on your preferred drop point. Panes can also be pinned to retain a fixed position or unpinned to collapse to an edge when not in focus. When needed, you can reset these and any Pane settings by selecting the Reset layoutunder the Settingmenu.

Other settings in the Nextion Editor can be configured in Configuration under the Settings menu. The default font of the Nextion Editor can now be changed to suit your taste. The default timeout of 100ms for the Debug Simulator can be adjusted from 20ms to 5000ms. Code hints, highlighting, description, tooltips and auto-complete can be set individually for the Editor and the Debug Simulator. Default path for eeprom and sd files can be customized to suit your taste. When needed, you can reset these settings by selecting the Reset layout under the Settings menu.

In the Display Tab of the Nextion Editor on starting the Editor, there is a section for listing the most Recent Projects. The number of recent projects tracked is by default 10, and can be increased. Right-clicking a project allows you to select from the following:* Open the file: if the project file exists, then opens in the Editor

The Title Bar contains the path and filename of the HMI project file when an HMI project is loaded. When an HMI project is not currently loaded, you can:* Open an existing HMI file using the Open toolbar button.

Here, Users can create a New project, Open an existing project, Save the current project, Save as to rename and save the currently loaded project, Close Project to close their current project, and Exit the Nextion Editor. Import Project will append an existing project into the current project – usually with resulting naming and renumbering issues. As such, it is recommended to either: a) load your project, adjust your device settings, and Save as under your new project name, or limit importing to individual pages if importing is required.

Clear Recent Projects used to clear the Project filenames in the Recent projects pane has been removed and is now accomplished in the Recent projects pane with context click and selecting Delete all records, or by managing the recent projects with more selectiveness.

With the new TFT File Output, users can select where the TFT file should be placed (which folder, sd card drive, other). A valid HMI without compile errors is required to generate a valid TFT output file. The option to open the output folder location in Windows Explorer can be made by clicking only open the output folder link. The old folder location C:\Users\Username\AppData\Roaming\Nextion Editor\bianyi will still contain previously compiled TFTs from elder Editor versions, and only if this is used as the TFT File Output location, will the new TFT for the current project be added to that folder.

Under the Tools menu, users can access the external tools Font Generator, GmovMaker, VideoBox and PictureBox. These are covered individually in Section 5 of this Guide.

In the Configuration menuitem, the user can choose for the Nextion Editor and the Debug Simulator if code should be highlighted or not, if Auto-Complete should be on, if the descriptions for instruction parameters should be on or not, if the tooltips should be shown when the mouse is over the toolbar buttons.

For the new Intelligent Series, the user can choose if there should be a 3 second delay at screen edge before allowing the component position to escape to the outside of the canvas area. This is useful to be on, especially in the Basic, Discovery and Enhanced models as out of bounds positioning is not permitted and will cause the project to not compile.

For the eeprom/sd folder, the user can choose to use the default path, or can set their own custom path that is more suited to their system and workflow.

Transparent color replacement value defaults to the 565 color 0 (BLACK), and is useful when importing images into the Picture Pane to convert the transparent pixels to a desired color when transparency is not supported (ie: Basic, Enhanced and Discovery Series models).

Finally, the default Font used for the Nextion Editor can be changed to suit the users taste. Currently, this default font effects both Editor wide as well as the Event code font. Resetting the font to the default Microsoft Sans Serif will return the Editor to its normal traditionally used font.

Selecting About Nextion Editor menuitem in the About menu will show the about box with the version of the Nextion Editor. Clicking the link will take you to the Nextion website where you can access the forums and other documentation.

Pay attention to any warnings as these will mean your project may not run as you expect. Pay attention to any error messages as they will need to be corrected before continuing. Error messages are descriptive, and if it is a code error then the user can click to jump directly to the coding error location.

Compile is more of a building and assembly process. This is only stated so that users do not make the wrong expectations of native machine code when making feature requests and/or Bug Reports. Nextion remains closed source.

A TFT file is no longer built and placed in the bianyi folder on Compile. To generate a TFT file, one has to use the TFT file output menuitem located under the File menu

The Nextion Editor contains a built-in Simulator that can be accessed via the toolbar Debug. To be clear this is not a precision emulator and is intended to be sufficient to assist in debugging a users project. It in no way is meant to replicate the Nextion device exactly. (Any Windows OS is already sufficient to make such precision unattainable). The Debug Simulator will be covered in more detail in Section 3 of this Guide.

If a project is not currently loaded in the Nextion Editor, Debug will open a dialog to open a compiled *.TFT file directly. This is handy for loading demos or sharing ideas without surrendering your original source code. Although the Debug Simulator can run a *.TFT file from any Nextion Series or model supported by the version of the Nextion Editor, it is important that the same version of Nextion Editor and *.TFT file is used to successfully simulate. (ie: an older v0.36 project TFT file can not be used with the current version of the Nextion Editor.)

Selecting Upload will launch an Open dialog to select a *.TFT file before the Upload to Nextion Device dialog. Ensure the Nextion is connected via serial (typically via USB to TTL adapter) before upload or the Port may not be available to select. Auto search feature will look for your Nextion’s reply to the connect instruction, but realize that data is being sent on all serial ports that are searched (and may interfere with the other connected serial devices). A better choice is to select the correct Port and Baud Rate. Proper configuration of Serial adapters, Windows drivers, device conflicts, etc is beyond the scope of Nextion support and remains the domain of user responsibility to know their used Operating System and devices.

Once Nextion has responded to the connect instruction, the upload process will begin. Do not interrupt this process until completed. If the process has been interrupted, resetting the serial port may be required. When a partial *.TFT file has been uploaded and uploading over serial is no longer an option, then the user will need to upload via the microSD method. Refer to Section 4 of this guide.

Users can select components or multiple components and then Copy, Cut, Paste or Delete as required. Paste contains a drop down option to in place paste which will copy without any vertical or horizontal offsets.

Users can select components or multiple components and then Lock or Unlock as required. Locking prevents a component from being repositioned with the mouse until unlocked. A lock icon appears in the upper right corner of the visual components when locked that can interfere with visual inspection of your HMI design.

For Renumbering components: Bring Top (Arrow Up) will take the selected component(s) and renumber to the highest .id on the page. Bring Bottom (Arrow Down) will take the selected component(s) and renumber to the lowest .id starting at 1 (page component is always 0) on the page.

For Aligning components: Align Left, Align Right, Align Top and Align Bottom will take a group of selected components (green ID labels) and bring the alignment to match the component with the blue ID label.

For Resizing components: Same Width, Same Height and Same Size will take a group of selected components (green ID labels) and set the size (width, height or both) to match the component with the blue ID label.

For Spacing components: Make horizontal spacing equal, Increase horizontal spacing, and Decrease horizontal spacing will take a group of selected components (green ID labels) and adjust the horizontal spacing between components using the component with the blue ID label as the baseline component. Likewise: Make vertical spacing equal, Increase vertical spacing, and Decrease vertical spacing will take a group of selected components (green ID labels) and adjust the vertical spacing between components using the component with the blue ID label as the baseline component.

The steps to configure your HMI project for your Nextion Series and Model are usually done at the time of creating a New project. When you need to make changes, Device will launch the following window with the Device tab selected. First select the Nextion Series: T for the Basic models, K for the Enhanced models, and P for the Intelligent models. Then select your Nextion Model. For example: the Multi-touch Capacitive Nextion NX8048K070_011C, Select K for the Enhanced series and then the select the NX8048K070_011 Nextion Model.

Selecting the DISPLAY tab, the user can select the orientation and the Character Encoding. 0° is the native viewing angle for the selected model. Users can choose alternative orientations (90°, 180° or 270°) but this will not be the native viewing angle.

Character Encoding is default iso-8859-1. Select from the character encodings that make sense for your HMI project to best display your local character sets. There are a selection of single byte and double byte character sets available.

Note: An encoding is a character mapping of value to character. Computer systems and MCUs use numeric values and not characters. A byte numeric value 0x41 in single byte ASCII encoding will reference the character A. Your MCU will not send A, it sends byte 0x41 (which in many cases maybe mapped to the letter A), but does not explicitly mean 0x41 renders A in every encoding. A Byte value of 0xC4 can map to different characters in different encodings, or even be undefined (mapping to no character). While modern computers can do translations between many encodings, your MCU will likely not. It is useful to research the character encodings you are planning to use.

Note: While the Nextion Editor HMI project can only have one base character encoding. This does not prevent the inclusion of different encoded fonts within your HMI project. Building on the above explanation, when your MCU sends a byte 0xFF to the Nextion device, the component .font attribute is responsible for which Font resource the byte 0xFF is rendered in (provided the chosen font resource has a glyph to render and is not undefined).

One-time update option will rename the *.tft file on your microSD card to a different extension after successful upload. You can now also now choose to ignore your pictures (image resources) and fonts (library resources) at compile time. While this is a small time saving step, it is recommended to turn these off when you are ready to create your final project compiled TFT.

Selecting ID to will toggle if the component .objnames are displayed in the upper left region of the component space. Yellow labelled components have a .vscope local, while black labelled components have a .vscope of global. (Hint: Event code is never global). When selecting multiple components, green labelled components indicate multiple components have been selected, while the one blue labelled component will be used as the baseline component. To change the baseline component while the group is still active selected, simply click on the already selected component you want to become the baseline component.

New to the Nextion Editor is the ability to Zoom the design canvas both in and out. Users can zoom from 20% to 600% using the slider, or increment steps using the + and – buttons on the ends of the slider. The value of the zoom is shown in percentage to the right of the Canvas Zoom. Clicking on the percentage zoomed allows you to reset the zoom back to an unzoomed 100% state. Note: Component dragging-by-edge (indicated by double ended arrow pointer) to move or resize components whether intended or accidental can cause an undesired snap-to effect in size and/or position where zoom is not at 10

Ms.Josey

Ms.Josey

Ms.Josey

Ms.Josey