calibration photometer for lcd monitors factory

EIZO’s ColorEdge monitors with built-in calibration sensors are developed and manufactured entirely in-house. See how they achieve the color precision and consistent image display needed for creative fields.

In February 2021, four of EIZO’s lead innovators accepted an Academy Sci-Tech Award (Technical Achievement) for the ColorEdge CG Series monitors with built-in calibration sensors. EIZO was the first manufacturer in the world to bring a self-calibrating color precision solution to market in 2010, and continues to commit itself to providing highly precise and sophisticated imaging solutions made with dedication and care.

In September 2020, the ColorEdge PROMINENCE CG3146 HDR reference monitor was awarded the 2020 Hollywood Professional Association (HPA) Award for Engineering Excellence. As the first true HDR reference monitor in the world to be equipped with a built-in calibration sensor, it was recognized for its advanced technologies that put it at the forefront of innovation in creative visual solutions.

ColorEdge is a line of color management monitors developed specifically for addressing users in photography, film, broadcasting, printing, and other creative fields. For these industries, not only color fidelity, but display characteristics such as brightness, gamma, and uniformity across the screen need to be maintained so the final output content displays as intended in the target environment.

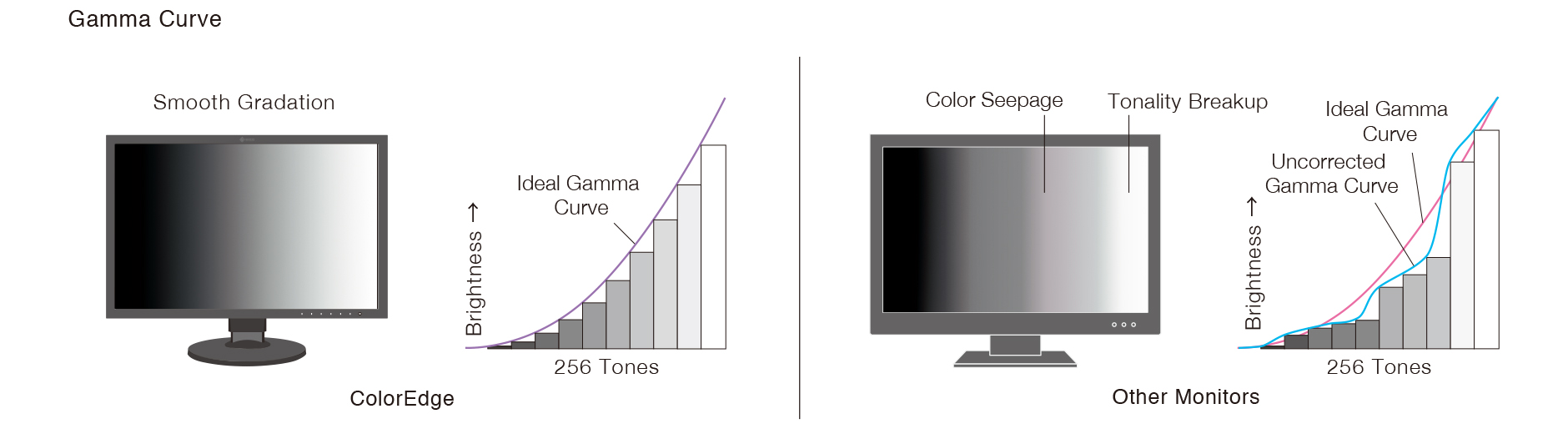

Each ColorEdge monitor undergoes rigorous quality control during production and is individually adjusted in-house using one of the color industry’s highest end, professional spectrophotometers. The human perception of color varies greatly depending on several factors such as ambient lighting, surrounding color, angle of observation, and individual optical variances. Using a high-quality sensor to adjust the monitors to meet certain color standards ensures consistency by minimizing the effect these variables have in the measurement results. EIZO’s factory uses sophisticated machinery in its production line to automatically carry out calibration for each monitor in a controlled environment. The sensor is placed directly over the monitor and red (R), green (G), and blue (B) gamma values are measured from 0 – 255. Then the monitor’s 16- or 24-bit LUT (look-up-table) is used to select the 256 most appropriate tones from trillions of perceivable colors to achieve the smoothest color gradations. This results in an image without deviated steps.

LCD monitors commonly exhibit fluctuations in brightness and chromaticity across the screen, which affects color precision. To counter this, EIZO also measures and adjust multiple points on each monitor to achieve stable brightness and chromaticity across the entire screen and correct deviations using its patented digital uniformity equalizer (DUE) technology. DUE controls the tone values pixel-by-pixel across the monitor for evenly distributed luminance.

It really is that simple. People often ask me about why their prints don’t come out as expected. The first thing I ask is whether or not their monitor is calibrated. If it isn’t, I tell them to calibrate their monitors and if they still have a problem, then we can discuss the problem further. Don’t get me wrong, there are plenty of reasons why a print may not match one"s expectations; however, you have to start ruling some things out. A good place to start would be to ensure that you actually know what your images look like. Read our article on Soft Proofing and discover why monitor calibration is so important.

In order to make it easier for people to determine which monitor calibration system to purchase, American Frame hired me to test a number of the current offerings on the market and see how they work in the real world. My first selection criteria was the ability to support the latest versions of Windows 7 and Mac OSX Lion as well as Windows Vista and Mac OSX Snow Leopard. There are some older devices out that don’t work with the latest operating systems, so I didn’t include them. Ultimately, I decided upon both an entry level and an advanced outfit from each of the big players in the field: Datacolor and X-Rite. Thus the lineup consisted of the Datacolor Spyder 4 Express, the Datacolor Spyder 4 Elite, the X-Rite ColorMunki Display, and the X-Rite I1 Display Pro.

If you just want to know which one I recommend for all but the most advanced users, allow me to cut to the chase: I recommend the X-Rite ColorMunki Display. It is a great combination of simplicity and power. The fun name speaks to the light hearted nature of the package. The software is by far the most well refined and easiest to use of the bunch. The software walks you through each step of the process and offers a very well made video tutorials, should you need them, for nearly each step. The results are also right on. From install to complete calibration can be achieved in less than 15 minutes. At this writing, the X-Rite ColorMunki Display retails for $199, but can be found for around $175.

Let’s begin with a basic understanding of what a monitor calibration outfit is and what it does. There are a just a few companies that make packages to calibrate monitors. The packages always consist of software and hardware in the form of an electronic device called a colorimeter or spectrophotometer that measures how color and tone are displayed on your monitor. All the packages here come with a colorimeter. A colorimeter differs from a spectrophotometer in that it can only measure transmitted light whereas a spectrophotometer can also measure reflected materials. This means that a spectrophotometer can be used to calibrate and create printer profiles, whereas a colorimeter can only calibrate and produce monitor profiles. That being said, this allows colorimeters to be tailored to the task. I wouldn’t dwell on the details of it other than to say that all the kits I am reviewing only allow you to calibrate your monitor.

All these packages have the same goal: to remove subjective human judgment from the process in an attempt to make monitor calibration truly objective. Essentially, the software displays color swatches on the screen and the device records the value of the color that is displayed on your monitor. Thus, it discovers the limits of the monitor. They also measure the brightness and tone response of the display. The software can then direct you to make changes in the brightness and contrast of the monitor as needed. Depending on the monitor used, the software can actually adjust the brightness of the monitor for you. This is a really nice feature as it makes everything truly automatic (and fast!).

White point is the color of white. That may seem like a silly statement. Of course white is white, right? Not really though. Look around you. Look at all the many different items that we call white. Notice the slight differences in color? Which one is truly white? Well, that depends on what white you want! While there is no industry standard, there is industry consensus that a white point of 6500 Kelvin (or 65k which is its close cousin) is a nice target value. It is an ever so slightly blue white. All these packages shoot for this by default. Since all colors relate to how white looks, it has a major impact on how all the colors are displayed. Many monitors come from the factory set to overly bright and too blue. Often after calibration, people find their monitors to appear dark and yellow.

Another key setting is gamma. Gamma is the setting that determines how the monitor will display the contrast of the image. It is a function of input to output. The human eye doesn’t see light in a linear fashion. A gamma function is used to map linear input data to a non-linear output that looks natural to us. If you have a background in black and white photography, it helps to think of the gamma as being similar to contrast graded printing papers. Depending on the grade of paper selected, an image printed from the same negative will have more or less contrast than when printed on a different grade of paper. Similarly, when a digital image is viewed with a Gamma of 1.8, it appears to have more contrast than when viewed on a monitor with the Gamma set to 2.2.The industry consensus is 2.2. All these packages shoot for this by default. If you are an advanced user and need to select a different gamma, then go with the Spyder4 Elite of the X-Rite I1 Display Pro.

Brightness, also referred to as Luminance, is the last criteria. The default target value of the X-Rite software is 120 cd/m². Unless you have a reason to change it, I suggest you stick with this. By default, X-Rite’s ColorMunki Display and X-Rite’s I1 Display Pro will use this as a target value. By default, the Datacolor units will not change the brightness of the display. I don’t like this. The number one complaint about prints is that they appear too dark in relation to the image on the monitor. This is largely due to the default brightness of monitors being much too bright. It has been my experience that most monitors are set at upwards of 250 cd/m² by default. Setting the brightness in the range of 120 or so will generally result in a darker monitor. A brightness of 120 cd/m² is bright enough to comfortably edit images and for general use without being too bright. It will also go a great ways towards achieving a screen to print match. I generally set my brightness to 120 cd/m² on all my monitors. On a side note, many students have told me how much nicer it is to work on a calibrated monitor as it isn’t so hard on the eyes. This may seem trivial, but if you work on the computer all day, you will appreciate the ‘kinder’ on your eyes look of a calibrated monitor with reduced brightness.

Be sure to have your monitor on for at least one half hour before trying to calibrate it to ensure that it has warmed up and reached stable color. Also, be sure not to that you don’t have any bright light hitting the monitor. Move any lamps that may be beaming onto the display. I suggest that you work in an area with reduced brightness if possible (if nothing else, don’t turn all the lights on and open up all the blinds).

I began this review with some biases based on experience. I have owned and/or used a large number of monitor calibration packages over the years. During most of this time, my go-to device has been an X-Rite i1 Pro that I used with Gretag Macbeth’s i1 Match for nearly a decade. Recently, i1Match was replaced by i1 Publish/Profiler. The X-Rite i1 Pro device is actually a spectrophotometer as opposed to all the devices in this review which are colorimeters. This means that it can measure both reflective and trans missive light. Functionally, that means it can be used to create both monitor and printer profiles. It was around $1,500 when purchased new (it has just recently been replaced by the i1 Pro 2). I like the system and I am comfortable with its use.

I also had an X-Rite PrintMunki for awhile. It is an entry level spectrophotometer system that allows for the creation of printer and monitor profiles. I never really warmed up to it. I thought the device itself was very fussy. Let’s just say; neoprene and a zipper were needlessly involved. It never sat well against the monitor. I thought the results were good, but I just never liked using it.

I have read much about the new Datacolor Spyder 4 line up and was excited to try it. For years, I used Datacolor’s/Colorvision’s OptiCal, with an early Spyder, in a school where I taught. It worked fine. I was interested in seeing the latest and greatest version.

This website is using a security service to protect itself from online attacks. The action you just performed triggered the security solution. There are several actions that could trigger this block including submitting a certain word or phrase, a SQL command or malformed data.

Monitor calibration is very important to a creative professional"s workflow, but pretty much anyone can benefit from properly adjusting your monitor. Calibration will deliver color accuracy, it will correct most problems with how a monitor ships from the factory including white balance, gamma and oversaturation issues, and it can also help when trying to color match two different displays for a consistent experience.

This article will detail the method that we use for display calibration in our monitor reviews, albeit a bit simplified in some areas. We"ll talk about the hardware you need, how to set up your monitor for calibration, and which settings are best to use within the software. We don"t anticipate any of this will be too technical, provided you have the tools this is a relatively straightforward process.

So let"s start by talking about the tools, because this is going to be a stumbling block for many people. It"s not possible to calibrate a monitor by eye or without any external hardware, you"ll need to purchase a color calibration tool to use during the process.

For those with budget monitors this may not make sense as the calibration hardware can be more expensive than the monitor itself, but if you have a high quality display or have multiple displays, a color calibration tool can be a good investment.

Calibration tools are generally split into two families: colorimeters, and spectrophotometers. Colorimeters are particularly good at handling a wide range of luminances, so they"re great at low light readings and very well suited to contrast measurements. Spectrophotometers are more accurate at handling color readings and are more versatile, but are not as good for lower light measurements, generally speaking.

But for most consumer applications and casual users, the main difference between these devices will be the price. Like with any tool, you can get scientific-grade colorimeters and spectrophotometers with price tags in the thousands of dollars, but for entry-level devices, colorimeters are far cheaper. You can get a very capable colorimeter for around $100 to $200, while spectrophotometers tend to start at over $1,000, putting them out of reach of most non-professional calibrators.

In other words, if you"re just starting out with calibration and want a basic yet capable tool for your monitors, the best option will be a colorimeter. Later, if you want the higher accuracy and greater capabilities of a spectrophotometer, they are a good upgrade path and it"s what we use for our reviews, but we wouldn"t recommend them for most people just starting out.

There are several different colorimeter options on the market, the two most popular are the X-Rite i1Display series and the Datacolor Spyder series. Either one will be fine, though if we were to recommend a specific model, we"d choose the X-Rite i1Display Pro. It"s accurate, fast, works across a range of display types. For just over $200, we think it delivers great value given the specifications. The Spyder series tend to be a bit cheaper though, so it might depend on your budget.

For this guide we"ll be using the i1Display Pro, but the principles should apply to other colorimeter models on the market. Using a spectrophotometer is a tad different though, so if you"ve splurged on a higher end device, this guide won"t be for you.

We have our calibration hardware, now let"s set up the display so it"s ready for calibration. During the calibration process, we"ll be generating an ICC profile, which is essentially a software table that tells your operating system and applications how to translate colors so they appear accurately on your display. But software profiles are a little finicky, they don"t work in all applications and this translation process can"t necessarily fix all the accuracy problems with your monitor.

For this reason, it"s super important that we do as much of the calibration process as possible in the actual hardware of the display. The less the ICC profile needs to do, the better results we"ll get. On most consumer or gaming displays, there"s not a whole lot we can do to calibrate them by changing settings in the on screen display. Typically you"ll need a professional grade display to gain access to more hardware calibration features, but we"re not covering that in this guide. Still, it"s important to go through and assess what changes we can make.

The best starting point with most monitors is simply to reset the settings to their factory default. With most modern displays, this will put us in a nice default position we can work with. Contrast is one example of a setting that generally comes optimized from the factory, whatever setting is the default tends to be as high as you can push contrast without distorting or clipping the image. Similar with settings like sharpness, gamma and saturation: these tend to come optimized by default, and changing them will negatively affect the image.

With more advanced calibration software like Portrait Display"s CALMAN we can go further into calibration and analyze then optimize settings like gamma, contrast and saturation with advanced, professional grade software tools. But CALMAN is expensive professional software, and for the purpose of this guide, we"re using a free tool that"s more suited to entry-level calibrators. This is why in this guide we"d recommend leaving some color settings at their defaults.

There are a range of settings that should be disabled before we calibrate the display. Most of these settings hurt accuracy and should be disabled anyway if you want the best color experience, but on occasion they can be useful in some conditions.

Low blue light filters should be disabled, as should shadow boosting modes for game cheating. We"d also recommend disabling any dynamic contrast features, image "enhancement" modes, backlight strobing modes or really anything that post processes the image in the display. On some monitor brands like LG for example, we"d also recommend disabling the eco or power saving modes as they can affect accuracy through luminance compensation.

For wide gamut displays that have an sRGB gamut clamp or gamut toggle in the settings, generally we"d recommend calibrating with the toggle disabled, giving the calibration software access to the full gamut of the display. However in some circumstances you may want to calibrate with the sRGB gamut clamp enabled, such as if you always want an sRGB gamut, even in apps that don"t support the ICC profile.

If you use software like f.lux or any other tool that changes white balance depending on the time of day, I"d also uninstall this software if you"re interested in calibration. You simply won"t ever get an accurate image when using a tool like that. Some monitors have this functionality built in so naturally we"d disable that, too.

From here, the next most important thing is to choose a brightness level you want to use the monitor at. Changing the brightness of the monitor after calibration can affect accuracy and the results - typically not by much, but it"s still an important consideration. You should settle on a brightness level first that you want to maintain throughout the calibration process.

Also, ensure your monitor has been operating for at least 30 minutes, allowing it to warm up, before calibration. Color performance can change slightly with temperature, so it"s really important that you"re sitting in a steady warm state, not a fresh cold state, before proceeding.

For calibration, we"ll be using DisplayCAL, which is an excellent free tool that covers all the basics and even some advanced functionality for display calibration. Given the complexities involved with color science it"s amazing this tool is available for free, though you can always support them with a donation.

Install DisplayCAL and when presented the option, you should let the software handle calibration profile loading. The DisplayCAL Profile Loader is far better than the color management system included with Windows. You should, of course, also install the driver package for the colorimeter you"ll be using throughout this process and plug it in.

Upon opening DisplayCAL for the first time you"ll be prompted to perform some additional setup, like installing the color engine for the software. In the main window of DisplayCAL, you"ll want to check and make sure your colorimeter is appearing correctly.

At this point your instrument should be appearing. The mode should also be set to LCD by default, if you are calibrating a CRT or Plasma display you"ll want to change that to refresh mode, but for most users, keep it on LCD. You should also see under "Display" the exact monitor you want to calibrate, if you have multiple monitors, this is the place to select the display for calibration. All other checkboxes should be left unchecked, unless you are calibrating an OLED, in which case you should enable white level drift compensation.

The single most important setting to modify here is the correction. Colorimeters require a correction profile to more accurately analyze and calibrate displays, because unlike a more expensive spectrophotometer, they are unable to spectrally profile a display from scratch in their hardware. So depending on the type of display you are calibrating, you need to select a correction that matches the technology being used.

Without guidance, this is a tricky proposition, because it requires knowing what sort of technology your monitor is using. So we"ll provide our thoughts, based on the corrections available for the i1Display Pro. As you can see there are lots of options.

For most standard monitors that only have an sRGB gamut, you want to use the LCD White LED family correction. This is the most common profile to use and it should be selected by default. Most monitors released in the last decade that are sRGB-only, so no wide gamut or DCI-P3 support, will be compatible with this correction.

With wide gamut monitors, it"s more tricky. For most wide gamut displays, I"d recommend using the LCD PFS Phosphor WLED family correction. As of the current version of DisplayCAL there are three other PFS Phosphor corrections available, but unless you are calibrating the specific models listed there (or similar types), we"d recommend using the "PFS Phosphor WLED family" correction. If you are completely unsure about which wide gamut technology you have, we"d also just recommend sticking to PFS Phosphor WLED family.

If you have an old wide gamut monitor, you might get better results using one of the LCD GB-r-LED profiles. However the PFS Phosphor profile is better suited to modern displays. If you have a Samsung monitor or display that uses their Quantum Dot technology, use the Quantum Dot LED profile. The other LCD corrections are generally more niche and unless you specifically know it"s the right profile to use, stick to the ones we"ve mentioned.

If you are calibrating a display that doesn"t use LCD technology, you"ll also see several other correction profiles for CRT, Plasma, Projector and OLED displays. We recommend using the RGB OLED family profile for most OLED displays, unless you are calibrating a TV that uses an LG OLED panel. In that situation you should use the WOLED profile, and we should note that most OLED TVs use LG panels, so it"s the most appropriate to use for OLED TVs.

Alright, at this point you should have selected the appropriate correction for the display you are calibrating. Now we need to choose the right calibration settings.

For most people, we"d simply recommend using the drop down at the top of DisplayCAL and choosing the sRGB settings profile. If you know what you"re doing, you could mess around further with the settings under the "Calibration" tab if you specifically wanted to use different gamma or white points, but the default sRGB profile is best for most monitor calibration.

We should also note here that even if you have a wide gamut monitor, say 95% P3 support, you should still use the sRGB settings profile for calibration. These settings merely outline the correct gamma and whitepoint to calibrate to, it doesn"t force the display into a specific color gamut. Assuming you didn"t clamp the gamut using your monitor"s OSD, the ICC profile you end up with will always support the full gamut of the display. Whether an application chooses to utilize the entire gamut or just the sRGB portion is up to the application and the content it"s displaying. This ensures accuracy for all types of content.

With our settings dialed in, our display is selected, and our calibration tool has the appropriate correction applied. Now it"s time to calibrate and profile the display.

DisplayCAL will set up the instrument, then eventually the buttons will no longer be greyed out. From here we want to hit start measurement again. This will give us some basic RGB color information as well as a luminance level for the display. Here is where we"ll perform the final bit of hardware calibration before proceeding.

The goal is getting the three RGB gain bars at the same height, while maintaining the luminance or brightness level we initially chose. To do this, we want to find the white balance or color controls in the monitor"s on screen display, and set the white balance to user mode. This will usually bring up three controls for the red, green and blue channels. Then, with DisplayCAL running, we want to adjust each of these settings until the bars are the same height and DisplayCAL gives us the green text tick of approval. If while changing the white balance, the luminance also changes, now is a good time to re-adjust the brightness of your monitor to bring it back up to where it started.

As we"ve mentioned in countless display reviews, ICC profiles can only do so much to correct a monitor"s performance. If even after setup the display is very inaccurate, the ICC profile will only deliver mediocre results. It"ll be better than stock, but not perfect. And there are plenty of applications that don"t interact well with ICC profiles either, like some games and non creative productivity apps, so doing as much calibration on the hardware side as you can is always the best approach. As you should expect though, all the big important apps for color accuracy like the Adobe suite, DaVinci Resolve and even Chrome support ICC profiles quite well.

How much time, paper, and ink do you waste re-printing images because the color isn’t right? Before you blame your printer, consider your monitor. When you work on an un-calibrated monitor, you can’t trust the colors you see on-screen, making it hard to make good editing decisions.

At the top are the standard CIE Daylight Illuminants. D65 is the choice for most people working in photography and graphics. D50 is commonly used in prepress.

Native will use the white point of the monitor. This setting is for those of you already set the white point of your monitor through some other method (such as the monitor’s menu) and don’t want to change it.

Near the bottom are the options to set custom white point values – either using a Daylight Temperature slider control for values from 5000 to 7500, or entering the xy chromaticity coordinates.

Most LCD users find 120 is bright enough to judge color and detail in highlights and shadows, but if you’re having a hard time seeing details, try selecting a lower value.

Automatic display control takes advantage of a feature that’s available on some displays, allowing the software to access the display’s internal calibration controls. Or, you can choose to adjust your brightness and contrast manually.

This is a preview of how your monitor performed. The expected values appear in the upper left corner of each patch, and the measured values in the lower right. Click Next.

If you’re curious, click the middle Luts button (looks like a graph) to see which calibration adjustments i1 Profiler made to the computer’s video card. This fine-tuning helps match the display to the selected white point and gamma settings.

Image quality assurance has traditionally been a high priority in medical imaging departments. Recently, it has often been neglected with the transition from hard copy (film) to soft copy (computer) display systems, which could potentially result in difficulty in reading images or even misdiagnosis. This transition therefore requires careful management such that comparable image quality is achieved at a minimum. It is particularly difficult to maintain appropriate image quality in the clinical settings outside of medical imaging departments because of the volume of display systems and the financial restraints that prohibit the widespread use of dedicated computers and high-quality monitors. In this study, a protocol to test and calibrate display systems was developed and validated by using an inexpensive calibration tool. Using this protocol, monitors were identified in a hospital in which image quality was found to be inadequate for medical image viewing. It was also found that most monitors could achieve a substantial increase in image quality after calibration. For example, the 0 and 5% luminance difference was discernable on 30% of the piloted display systems before calibration, but it was discernable on 100% post calibration. In addition, about 50% of the piloted display systems did not have the maximum luminance (white level) suitably set, and 35% of them did not have the minimum luminance (dark level) suitably set. The results indicate that medical display systems must be carefully selected and strictly monitored, maintained, and calibrated to ensure adequate image quality.

Key words:Image quality, display system, calibration, quality control, quality assurance, monitor, medical imaging, softcopy, cathode ray tube, liquid crystal display, DICOM 14, Grayscale Standard Display Function, SMPTE, luminance

Although the quality of medical images (digital or otherwise) is strictly controlled during acquisition, it is often poorly maintained for soft-copy image review. Image quality control of softcopy display systems is often neglected because it can be an expensive and complex process to ensure. Most health institutions cannot afford to standardize on high-end medical display systems, but instead have a mix of various types

This article discusses and demonstrates the importance of maintaining image quality of soft-copy display systems, the development of a calibration protocol, and recommendations on how to achieve image quality control.

Display systems should be cleaned regularly with monitor cleaner to remove fingerprints and other stains. There are many different types of commercial monitor cleaners, including sprays (to be sprayed on a soft cloth before application), individual wipes, and boxed wipes. Cleaning solutions can vary from being polymer-based to a solution of 50% water and 50% isopropyl. Care should be taken not to use alcohol-based or ammonia-based cleaners because it could permanently damage the screen surface (e.g., turning LCD screens yellow and brittle, or damaging CRT monitor antiglare coatings).

The minimum luminance (dark level) must first be properly set by changing the “brightness setting.” Ideally, monochrome CRT monitors can be set between 0.2 and 0.5 cd/m2. Monochrome LCD monitors can usually be set at about 1.0 cd/m2. The lower the dark level the better, but at the same time, the monitor must be able to provide a maximum luminance adequate for the particular application (e.g., 170 cd/m2 for most images displayed on color monitors, and 350 cd/m2 for most images displayed on monochrome monitors).

The maximum luminance should be set by changing the “contrast setting.” The optimal value for this setting will depend on several factors. If there is a high level of ambient lighting in the room, then a higher maximum luminance will be required to give the same image quality that is required in a darker area. If the maximum luminance, however, is set too high for a particular monitor, it will significantly shorten its useful life span. The ambient lighting should therefore be minimized if at all possible. For new monochrome monitors, the optimal scenario to prolong their useful life span would be to drive the monitor at 50% of its capable maximum luminance to achieve 300–350 cd/m2. New color monitors should be driven at about 70% of their capable maximum luminance (about 250 cd/m2) to achieve about 170 cd/m2.

To ensure that as much information as possible can be seen by the human eye, display systems should be set to the Digital Imaging and Communications in Medicine (DICOM) 14 Grayscale Standard Display Function (GSDF) (see Fig 1). This is necessary because the response of the human eye to light is not linear. This step is achieved by mapping bit values representing different gray levels to specific luminance values. The mapping is stored in look-up tables (LUT) on the graphics card or in the monitors.

DICOM 14 Grayscale Standard Display Function (GSDF). The Just Noticeable Difference (JND) index is the minimum amount that the luminance can be changed for the human eye to perceive a difference.

The final step is a visual check. There are several geometric patterns and patterns of varying luminosity that can be helpful. One that is often used is the Society of Motion Picture and Television Engineers (SMPTE) pattern (see Fig 2). This pattern can be used to detect areas that are unfocused (horizontal and vertical thin lines that should be discernable) and to determine the proper contrast (especially the 0 to 5% luminance difference and the 95 to 100% luminance difference). The SMPTE pattern can also be used to align the window vertically and horizontally and to determine if there is skewing or bowing (pincushion effect). Other parameters to check include ghosting (i.e., when previous images linger), burn-in on CRT monitors, pixel dropout in LCD monitors, and nonuniformity of luminance (see Fig 3). Uniformity of luminance can be measured by placing the photometer on different quadrants of the monitor. Luminance nonuniformity is usually not a problem with LCD monitors, but can be a problem with CRT monitors. This can occur if the CRT phosphor coating is not applied evenly, if the phosphor on the edges of the screen gets less light than in the middle of screen due to the distorted electron beam, or if there is a misalignment in the CRT components. Nonuniformity is also prevalent in CRT monitors that are within a magnetic field.

A variety of clinical and radiological Picture Archiving and Communication Systems (PACS) workstations from a multisite teaching hospital were identified for use in a pilot study for the protocol. The purpose of the pilot study was (1) to determine the value of a monitor quality control program through an assessment of their current state and noting any improvements after application of the protocol, (2) to validate and if necessary, to modify the protocol, and (3) to determine the resource requirements to perform the quality control program.

Sixteen PACS workstations (11 dual-monitor systems and 5 single-monitor systems) were calibrated during the study. Three of the workstations were intentionally included for the pilot due to complaints of poor image quality, whereas the other workstations were randomly chosen out of approximately 1,000 workstations that are used for viewing medical images. They were selected from radiology reading rooms and clinics to represent a range of monitor types.

Four monitors out of the 27 monitors tested were found to be inadequate for medical image review even after calibration. The monitors were inadequate because either the maximum luminance for these monitors were about 90 cd/m2, which was much lower than the ideal maximum luminance of 170 cd/m2 for color monitors, or the monitors were visibly unfocused. In addition, the calibration photometer was not able to connect to two workstations, which had computers that were nonstandard to the hospital and were not supported by the hospital IT department. Both of the workstations had monitor quality deemed inadequate for image review and have been excluded from the following results summary.

Most monitors showed significant image quality improvements from calibration (Fig 4). Before calibration to the GSDF, on approximately 70% of the monitors, the difference between 0 and 5% luminance could not be seen on the SMPTE pattern. After calibration, this difference was discernible on all the monitors. The maximum luminance and dark levels were often adjusted to prolong longevity of the monitors while trying to optimize image quality. Other image-quality-degrading factors that were found include areas that are unfocused, phosphor burn-in from a static image (hospital logo used as the Windows desktop wallpaper) left on the monitor too long, incorrectly set aspect ratios, and dirty screens.

Image quality improvements through calibration. 1, Monitors able to discern between 0 and 5% luminance values; 2, monitors able to discern between 95 and 100% luminance values; 3, monitors with maximum luminance not optimally set (difference between calibrated and original values >10 cd/m2); 4, monitors with dark levels not optimally set (difference between calibrated and original values >0.2 cd/m2).

It took on average 30 min to calibrate a display system by a trained technician with limited experience performing the protocol. An experienced technician could calibrate a display system in about 15 min.

Initial calibration and periodic testing of PACS monitors are important for maintenance of image quality. A degradation of image quality over a long time is often difficult for clinicians to detect. This can result in a delay in reporting of problems until the viewing of the images is severely degraded by the display.

The frequency of calibration and testing can vary greatly. Hospitals have performed weekly, quarterly, or even daily monitor tests, whereas others do not calibrate monitors at all.

In addition to the methods described above, the following are other means to facilitate the maintenance of image quality:The use of a maintenance database to record calibration results, age, warranty, location, etc. of the PACS monitors would provide several benefits. For example, it would allow a convenient method of scheduling monitor maintenance.

Disabling user control of the display settings and training the users to modify window and leveling in the PACS viewer application instead of changing the monitor contrast and brightness will also help reduce the frequency of required calibration.

Procedures for escalation and maintenance of PACS display systems should be streamlined. This would include clarifying who is first-line support and having backup hardware on-site.

Environmental factors, such as ambient room lighting, glare, and placement of the monitor ateye level, should also be considered for optimizing medical image viewing.,

Precalibration, clinicians had complained about the inadequate image quality of some of the monitors that were calibrated for this study. After calibration or replacement of the monitors, the clinicians no longer complained about the image quality. This suggests that the clinicians did notice the postcalibration improvements. An in-depth investigation into the clinical perception of the image quality improvements from calibration was outside the scope of this study.

Adding to the complexity of ensuring adequate image quality is choosing the proper supporting hardware (monitors, computers, and graphics cards). Although standardizing on a single vendor of PACS hardware can assist in the maintenance of the equipment, it is often difficult to achieve in practice because of financial constraints and/or the need to select different monitors for different applications. Space requirements might dictate theuse of an LCD monitor instead of the larger CRT monitor. The once prohibitively high cost of high-bright grayscale LCD monitors is becoming less of a problem as the cost of LCD monitors continually drop, whereas concurrently, the advancements in LCD technology lead to increasingly better image quality.

CRT and LCD monitors have their own strengths and weaknesses, but more institutions are moving from using CRT monitors to LCD monitors. Table 1 summarizes their characteristics.

The type of images that will be viewed on the PACS workstation will also influence the monitor selection and computer configuration. Here are some questions that need to be asked when developing a display system.Are the images monochrome or in color? The trade-off of color monitors is that they cannot achieve the level of luminance of grayscale monitors.

Are the images high-resolution and high-contrast (e.g., computed radiography) or low-resolution and low-contrast (e.g., magnetic resonance imaging) images? This will determine the required monitor resolution and the suitability of using grayscale monitors.

Is the display system going to be used for primary diagnosis or for a clinical review? Are the structures that need to be identified gross structures (e.g., metal leads that were inserted into the body) or small, hard to discern structures (e.g., in mammography images)? This will influence several decisions regarding hardware selection, including the required bit depth of the graphics card. Most graphics cards are 8-bit digital to analog converters (DAC) allowing 256 levels of intensity for each red, green, and blue channel, but often higher-bit depth cards are preferable (10-bit cards) for monochrome monitors.

Will past and current images of the same patient need to be compared side by side? Will multiple views of the anatomy need to be viewed simultaneously? If so, then dual monitors will likely be required. In this case, care must be taken in choosing a graphics card that has two LUTs so that both monitors can be calibrated to the DICOM GSDF. Most graphics cards, especially the less expensive ones, do not have dual LUTs, which means that only one monitor can be calibrated.

It is also beneficial to obtain clinical feedback on the type of PACS workstation hardware that will be put into a particular unit. Unfortunately, this is often not done due to time constraints or lack of available hardware. Whenever possible, demo units should be trialed to obtain clinical feedback before the hardware is purchased. This should be done for several days to give all the staff adequate opportunity to use the equipment and to provide verbal or written feedback on a survey form.

Several medical display manufacturers are starting to develop methods to help achieve and maintain stable image quality. Many high-end monitors are now strictly factory-calibrated for medical viewing. There are also LCD monitors available that do periodic self-calibration with an internal backlight sensor or with a permanent photometer on the corner of the monitor. Unfortunately, these are usually very expensive high-end monitors.

Remote calibration is also emerging as an option, whereby PACS workstations are connected to a main administrative computer. The main administrative computer receives alerts of monitor drift that cannot be compensated, and it can trigger the computers to do self-calibrations. Remote calibration, however, has some of the same problems as the self-calibration monitors. Presently, remote calibration requires all of the monitors to be of a single brand. Standardizing onto a single high-end monitor brand would be prohibitively costly and impractical for most institutions.

The proliferation of PACS has permitted the softcopy review of medical images outside, as well as within, the radiology department. Although the selection of proper display system hardware will vary depending on the application and the environment, maintaining proper image quality should always be a consideration for the system"s ongoing use. This is often a difficult program to establish and maintain due to limited human and financial resources, the large number of display systems that are often nondedicated standard desktop computers and monitors, and the lack of comprehensive standards.

It has been shown through the pilot of a monitor quality assurance protocol that a proactive calibration program can ensure adequate image quality. An inexpensive method of monitor calibration has been described that can be applied to any type of monitor. Substantial image quality improvements were seen postcalibration, and monitors that were no longer adequate for medical image display were identified and replaced. The use of an image quality maintenance protocol will lead to more efficient image review and more accurate diagnoses.

7. Wang J, Peng Q. An interactive method of assessing the characteristics of softcopy display using observer performance tests. J Digit Imaging.2002;15(Suppl 1):216–218. doi: 10.1007/s10278-002-5003-3. [PubMed] [CrossRef]

8. Wang J, Compton K, Peng Q. Proposal of a quality-index or metric for soft copy display systems: contrast sensitivity study. J Digit Imaging.2003;16(2):185–202. doi: 10.1007/s10278-003-1657-8. PubMed] [CrossRef]

9. American Association of Physicists in Medicine (AAPM), Task Group 18. Assessment of Display Performance for Medical Imaging Systems: Pre-final Draft (Version 8.1), February 2002

10. Gray JE, Lisk KG, Haddick DH, Harshbarger JH, Oosterhof A, Schwenker R. Test pattern for video displays and hard-copy cameras. Radiology.1985;154:519–527. [PubMed]

12. Parsons DM, Kim Y, Haynor DR. Quality control of cathode-ray tube monitors for medical imaging using a simple photometer. J Digit Imaging.1995;8(1):10–20. [PubMed]

13. Chakrabarti K, Kaczmarek RV, Thomas JA, Romanyukha A. Effect of room illuminance on monitor black level luminance and monitor calibration. J Digit Imaging.2003;16(4):350–355. doi: 10.1007/s10278-003-1720-5. PubMed] [CrossRef]

14. Ratib O, Amato C, Balbona JA, Boots K, McCoy JM. Design and implementation of a multi-task radiology workstation ergonomically tailored for fully digital reading rooms. Proc SPIE.2001;4323:93–96. doi: 10.1117/12.435461. [CrossRef]

15. Blume H, Ho AMK, Stevens F, Steven PM. Practical aspects of greyscale calibration of display systems. Proc SPIE.2001;4323:28–41. doi: 10.1117/12.435509. [CrossRef]

No matter how perfectly a monitor was calibrated at the factory - it still needs to be recalibrated at regular intervals. This must be done to correct the unavoidable ageing processes of the panel,and to calibrate individual targets suitable for the application andlighting conditions at the workplace.

An external attachment sensor is usually used for this purpose, which always involves extra effort. The user must remember to recalibrate and take the time to interrupt their actual work and perform the calibration process. With a built-in calibration sensor, this process can be automated and moved to a time when the monitor is not in use.

So with CG Series ColorEdge monitors, you can arrange for the monitor to recalibrate itself periodically (e.g. at night) when you"re not using it. This means you can always be sure you are working with a consistently accurate monitor.

The advantages of CG Series monitors with their built-in calibration sensors are even greater in companies with numerous monitors: In combination with ColorNavigator and the cloud solution ColorNavigator Network, EIZO offers a complete colour management solution whichmakes it possible to realise complete quality assurance including regular recalibration, the distribution of calibration targets and the control of numerous monitor functions centrally and across locations.

Even if a ColorEdge monitor is delivered perfectly adjusted and calibrated, regular recalibration is necessary. The built-in calibration sensor can be used to automate this recalibration. As a user, you can schedule thisvital procedure for times when the monitor is not in use. The monitor menu or the ColorNavigator can be used to determine when the monitor should calibrate itself. This can be done either at fixed intervals or depending on the time of use. Of course, this calibration does not interrupt the user"s work, but only takes place the next time the monitor is put to sleep.

The built-in sensor is integrated inconspicuously and dust-protected in the edge of the monitor. Thanks to DUE technology, a homogeneous image display is guaranteed, which means it does not matter where the measuring sensor is located on the monitor. Each built-in sensor is calibrated and precisely adjusted at the factory with a high-precision reference spectrophotometer. The high-precision mechanics ensure there is only an extremely small distance between the measurement sensor and the monitor panel over the entire service life of the monitor, so ambient light does not affect the measurement.

Every EIZO ColorEdge is precisely calibrated and adjusted to the correct values at the factory. A highly sensitive professional spectrophotometer is used for this purpose. The gamma values of the primary colours red, green and blue in the brightness levels 0 to 255 are also measured and perfectly adjusted. As a result, the perfect combination is always selected from the billions of possibilities offered by the monitor"s 16- or 24-bit LUT (Look-Up-Table) to achieve perfect colour gradations every time. So the monitor is delivered perfectly factory calibrated. This is also the reason why EIZO recalibration is so fast. Since only the ageing process of the panel needs to be tracked during recalibration, it is sufficient to check certain support points and take their changes into account if necessary. Meaning, a time-consuming measurement of countless colour patches is not needed.

LCD monitors often have uneven brightness distribution and inconsistent colour purity across the monitor surface. These individual inaccuracies must be removed from a graphics monitor. To do this, EIZO measures each individual panel at the factory at numerous measuring points and corrects any colour and brightness deviations with its patented DUE technology (Digital Unifomity Equalizer). It is only this complex procedure which makes the use of an integrated sensor possible at all. Because only if the colour and brightness values at the edge correspond precisely to those on the rest of the display surface is a measurement at the edge also meaningful for the entire monitor.

Many post-production, VFX and television studios specify a particular spectrophotometer as the master sensor for their internal colour management. To avoid missing out on the advantages of the integrated sensor, it is possible to correlate the built-in sensor with an external master sensor. In this way, the built-in sensor adopts the measurement characteristics of the master sensor and retains its specific properties. A consistent workflow with monitors without a built-in sensor is thus guaranteed.

HDR content is becoming increasingly popular in the film industry. Extreme contrasts of up to 1,000,000:1 and brightness values of up to 1,000 cd/m² pose great challenges not only for the panel technology but also for the measurement sensor technology. Nevertheless, EIZO has succeeded in developing an integrated calibration sensor for the ColorEdge PROMINENCE CG3146 that meets the requirements of HDR applications.

While the built-in calibration sensor already means a great increase in comfort for the individual user with corresponding time savings, these time savings are multiplied accordingly in large usage scenarios. In large studios, agencies or publishing houses, people often work on joint projects across locations or even countries. This quickly brings together numerous workstations, on which the same files must naturally look the same. To achieve this, all monitors must be set to the same calibration targets and recalibrated regularly. The room for error is large and the calibration and maintenance effort enormous. To eliminate numerous sources of error and dramatically reduce the maintenance effort, EIZO offers a powerful overall colour management solution: the combination of monitors with built-in calibration sensor, the calibration software ColorNavigator and the cloud solution ColorNavigator Network allows a consistent colour-managed workflow to be centrally monitored, managed and maintained even across continents.

With ColorNavigator Network, a single administrator can provide centralised quality control of all ColorEdge CG monitors with a built-in calibration sensor on the network. The administrator can set colour modes, schedule automatic self-calibration, enable key locks, register or adjust asset management settings, and import and export monitor settings for each monitor. For large projects with multiple production steps, such as games or feature films, this ensures that the correct colour standards are used by everyone involved, and administrators can even assign custom settings for specific projects or jobs. The built-in sensor eliminates the need for a staff member to visit and recalibrate each monitor. This is done automatically. In addition, EIZO hosts the server for data exchange in a secure cloud, so there are no additional investments or ongoing costs for providing a server for the user.

The Academy of Motion Picture Arts and Sciences has honoured EIZO with the Scientific & Technical Award for the development of the CG Series ColorEdge monitors with built-in calibration sensors. The jury"s citation "EIZO"s automatically calibrating SDR monitors increase artists" confidence in the accuracy of image reproduction across the enterprise and reduce disruptions to the creative process and production workflows. They have become indispensable to many major motion picture animation and effects studios."

Mackevision trusts in the performance of the ColorEdge monitors and uses them in image production in all even remotely (colour) critical areas. Learn more

The LCD sensor analyzes color contrast and brightness in no time and with the highest accuracy. It also automates ambient light measurements in combination with Barco’s QAWeb for DIN 6868-157 software version. The optical system supports displays with all current and emerging backlight technologies, including LED.

The colorimeter’s intuitive and compact design makes it very easy to use with any Barco medical display. The Barco LCD sensor comes with a standard 2-year warranty.

If you don"t calibrate and profile your monitor, then your picture"s appearance can vary widely from the way it would look on other monitors, and can mislead you about the actual colors in your image. To address this problem, monitors can be calibrated and profiled. This process makes the device show as accurate an image as possible.

Calibration is the process of setting the monitor to the desired neutral output. It includes settings for luminance, white point and gamma. Once it"s been neutralized as well as the monitor"s controls allow, it"s time to measure the color and help to perfect it with software.

Profiling is the process of measuring the imperfections in the monitor, and creating a "filter" that compensates for those imperfections. Using the parameters set in the calibration step, profiling requires using a hardware device, often referred to as a "puck" (a Colorimeter or Spectrophotometer), that hangs over the monitor screen and reads several sets of red, green, blue and grey patches generated by the profiling software. The color patches are measured by the puck as they are displayed. The differences between the colors the monitor displays in its native state and the true colors of the patches are used to create a monitor profile which will cause the monitor to display the true colors more closely than it did in its native state.

Like high-end stereo speakers, the monitor is a place where you really do get what you pay for. The best systems are precision engineered for added fidelity and evenness across the screen.

The old-school CRT monitors are pretty much out of service. They have been replaced by LCD flat panel monitors. The newest technology is a new form of flat panel that uses LED light behind the screen.

In the 1990s, high-end CRT (cathode ray tube) monitors were considered to be state of the art. That technology has gradually given way to LCD panels. Up until now, these panels have used CCFL (cold cathode fluorescent lamp) back lights. CCFL technology is in the process of being replaced by LED (light emitting diode) backlights. LED backlights have many advantages over CCFL including requiring half the power consumption and, more importantly, they are free of mercury, a toxic material that is emitted by electronic equipment. LED backlights have another advantage: the white light they create is derived from pure red, blue and green LEDs, so the light is purer, brighter and can offer a wider color gamut than CCFL. Some LED panels that are currently available have up to 120% of the Adobe RGB (1998) color gamut, which is 25% more than the very best CCFL panels. Most likely your next LCD will be an LED backlit display.

DDC allows adjustment of the display"s brightness, contrast, white point and gamma through the profiling device and software. This will save time and improve precision when calibrating and profiling monitors. When shopping for a new monitor, it"s best to choose a DDC-compliant display if possible.

Computer monitors started out as 1-bit depth displays – good only for looking at type. Monitor development quickly progressed and now all consumer displays are 24-bit and can display over 16.7 million distinct colors. Twenty four-bit color is based on eight bits per RGB channel, which is why you may see monitors described as having 8-bit depth color. High quality graphics monitors such as the EIZO CG series have 10-, 12-, or 14-bit depth. This results in smoother transitions between tone values and the possibility of using the extra bits to extend the dynamic range of displayed images, allowing more detail to be seen in extremely bright areas and better shadow detail all at the same time. This extra headroom allows for easier editing in wide gamut color spaces. Some of this advantage is still theoretical until Photoshop supports greater than 8-bit depth all the way from the display to the pixels in an image.

Many high-end monitors advertise the fact that they can display all or nearly all of the Adobe RGB (1998) color space. At first glance, this seems like something that you would want, and in many ways it is, but there are a few trade-offs. One issue is that the visible difference between almost identical colors – meaning colors that vary by just one number in an RGB triplet, such as our example in the color management overview section of 255, 133, 1 and 255, 134, 1 – is much greater. This can make color editing more difficult. Another unwanted side-effect of wider gamut displays is that untagged colors and images on the web (which is most of them) will be greatly exaggerated. This neon effect is the result of narrow gamut sRGB images displaying in the monitor gamut space, which is what happens with non-color-managed browsers and/or untagged images. This can make web viewing an unpleasant experience on these wide gamut displays.

We can say unequivocally that this is an essential feature for a monitor to have. When you buy a new widescreen monitor you should check it for evenness. This can be most accurately done by creating a monitor profile, and then use the "validate current profile" function of the monitor profiling software to measure the four corners and side-to-side areas. If you have a spectrophotometer handy, this can be used as well. A quick-and-dirty approach is to bring up an image in Photoshop and move it around on the screen and see if it appears to get brighter or darker as you move it around.

This refers to how quickly a pixel can change colors, measured in milliseconds (ms); the fewer the milliseconds, the faster the pixels can change, reducing the ghosting or streaking effect you might see in a moving or changing image. This feature is important for watching videos or gaming but not very important if you use your monitor for editing images in Photoshop. What is important for image editing is quick screen redraw, which is governed by the amount of RAM available on the graphics card and the image cache level settings.

The best monitors come with calibration tools as part of a package. These include calibration and profiling software, and some include the hardware device or puck. These tools include DDC communication, which allows the calibration tools to adjust the monitor hardware settings directly as opposed to just adjusting the graphics card. This preserves the monitor"s dynamic range better than adjusting only the graphics card.

LCD (liquid crystal display) monitors come in several architectures. One term you may see is TFT (thin film transistor) LCD. Thin film technology improves image quality and is used in all high quality computer monitors.

In addition to TFT, other terms you may see are TN, VA, and IPS. TN (twisted nematic) technology is the most basic LCD architecture. However, TN panels are not the best for photo editing due to a limited viewing angle (meaning that the color and contrast change fairly dramatically if your viewing angle is not dead center), and low bit depth (6-bit depth is typical).

VA (vertical alignment) architecture is an improvement over TN with improved viewing angles and support for 8-bit depth. There are several variations such as MVA (multi-domain vertical alignment), PVA (patterned vertical alignment) and ASV (advanced super view).

VA architecture and its variants are an improvement over TN, but arguably the best architecture for high-quality displays (the type required for accurate photo image editing), is the IPS (in-plane switching) architecture. There are now several variants of in-plane switching as the technology continues to advance.

Many professional IPS-based LCD monitors also feature high bit-depth and ultra wide color gamuts, which we define as equal to or greater than the Adobe RGB (1998) color space.

One interesting variation of IPS is the AH-IPS architecture developed by LG Display. This type of IPS panel uses the AFFS (advanced fringe field switching). This architecture gives the best performance for smaller screens with high resolution, such as those used in handheld devices like the Apple iPad.

AH-IPS has the advantage of greater light transmission, which translates into lower power consumption. So far, this technology has been limited to small screens due to higher manufacturing costs for larger screens.

While some monitors have integrated devices for calibration and profiling, you might want to invest in a stand-alone device. You can get great results with many mid-priced monitors and low-cost calibration solutions.

Some software incorporates a verification function that essentially rechecks the profile against the color patches and creates a monitor verification report. This report can be used to check on the accuracy of the monitor profile over time and even t

Ms.Josey

Ms.Josey

Ms.Josey

Ms.Josey