calibration photometer for lcd monitors quotation

The LCD sensor analyzes color contrast and brightness in no time and with the highest accuracy. It also automates ambient light measurements in combination with Barco’s QAWeb for DIN 6868-157 software version. The optical system supports displays with all current and emerging backlight technologies, including LED.

The colorimeter’s intuitive and compact design makes it very easy to use with any Barco medical display. The Barco LCD sensor comes with a standard 2-year warranty.

• The user may view and save historical data on white level, black level, calibration and conformance tests for JCAHO/MQSA, and other medical certifications

• Workstation system performance: You can also create automatic email alerts to let you know if any settings are outside of your preferred specifications. That way, you won’t have to worry about displays that are out of compliance and can make corrections quickly.

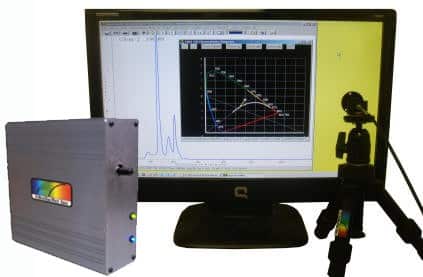

Not using a DBI monitor? You can still track calibrations and hours in use for any medical-grade LCD display via a photometer with DBI’s calibration management software.

For comprehensive calibration management software and hardware packages, DBI’s CFS™ Calibration Feedback System simplifies time-consuming management tasks and helps ensure your displays are DICOM Calibrated and meeting compliance standards.

This website is using a security service to protect itself from online attacks. The action you just performed triggered the security solution. There are several actions that could trigger this block including submitting a certain word or phrase, a SQL command or malformed data.

The Environics® Series 6123 Ozone Transfer Standard with Photometer is the ideal system for those looking for a standard for ozone monitoring and reporting programs. A sister unit to the S6103, the S6123 focuses on automatically performs zero, precision, span and multi-point calibrations using O3.

The S6103 is required if you wish to performs zero, precision, span and multi-point calibrations using O3 but also NO, NO2, SO2, CO, hydrocarbons and other gases of interest.

The 6123 meets or exceeds all U.S. Environmental Protection Agency requirements for a level 3 bench or transfer standard. It is exclusively for use with the internal ozone generator. For applications that require monitoring of external ozone sources, the Series 6103 or 6113 are required.

If you want to display your images accurately and make sophisticated decisions about how they will or could look, calibrate your monitor with hardware. Monitor calibration is a must. It’s not optional. It is easy. You need a device to do it well.

Spectrophotometers can also be used to calibrate monitors. What’s the difference between the two? Unlike a colorimeter, a spectrophotometer has it’s own light source that can be used to make printer profiles. Spectrophotometers can do more. They also cost more.

There is a difference between calibrating and characterizing devices. Calibrating a device is changing its state, like setting the brightness of a monitor. Characterizing a device is measuring and mapping the color capacity of a device or building an ICC profile to describe it. Most of the process of monitor ‘calibration’ is actually ‘characterization’.

Second, indicate your gamma and white point preferences with your software. Specify a Gamma 2.2 and a white point of D-65. Both of these items produce confusion for many. The gamma is specified based on the operating system of your computer, now the same for both Mac and PC. It is not the gamma of your editing space, monitor, or output device. The white point is specified to simulate a clean white, neither too blue and bright nor too yellow and dull. While the industry standard for building ICC printer profiles and viewing prints is D-50 or 5000K, if you specify this setting during monitor calibration, more often than not your whites will appear too dull and yellow. This is due to monitor hardware limitations; their white points are so high, well above 7500K, that when you simulate a white point lower than 6500K the monitor’s response starts to physically fail. A white point of D-65 is a simulation that generates a standard preferred appearance – or a good clean white.

Third, measure the color space and build the profile.All you have to do is click go and let the software do the rest. To find a monitor’s capacity/limitations, the measurement software will send known values to the monitor and its accompanying hardware will measure the monitor’s response. With the before and after data it will generate an ICC profile that maps the color space of the monitor. At the end of the process, make sure the title for the resulting ICC profile contains the date. This profile will be loaded automatically whenever you restart your computer until you build a new one.

Finally, confirm monitor calibration. View both synthetic test files (You can find many on my website.) and real-world images (Bill Atkinson provides an excellent evaluation file on his website.). If grayscale ramps contain color casts or crosses, repeat the process.

Note, the purpose of monitor calibration is to get a monitor to display digital image files as accurately as possible. The ICC profile will help your monitor display files better but it won’t change them. Only changing the file’s ICC profile (so the numbers in your file mean something different) or editing the file with software (so the numbers actually change) can do that.

Some of your files may contain colors that are out-of-gamut or too saturated for your monitor to display. The best monitors today can display a gamut equivalent to Adobe RGB 1998 but cannot yet display the full gamut of ProPhoto. This means that some of your files may be able to print colors that are more saturated than your display. Do build your files in ProPhoto to take full advantage of the capabilities of today’s printers and tomorrow monitors. As monitor technology evolves this will become a less frequent occurrence.

One of the advantages of calibrating your monitors to a device neutral standard is that when properly calibrated, all monitors, old or new, should generate very similar if not identical appearances with the same files. You will not have to adjust your files when you look at them on other monitors, for instance when you replace your old monitor.

The purpose of monitor calibration is not to match a print, though it will help you make all your prints more accurate. A well-calibrated monitor will help you predict what your images will look like when printed, even on multiple substrates. This is what softproofing in Photoshop is designed to achieve.

Model 202 Ozone MonitorThe Model 202 Ozone Monitor is designed to enable accurate and precise (±1.5 ppb) measurements of ozone ranging from a few ppb to 250,000 ppb (0-250 ppm) based on the well-established technique of UV absorbance at 254 nm. The Model 202 is lightweight (5.5 lb, 2.5 kg) and has a power consumption of only ~7 watts. It can be used in almost any application where much larger ozone monitors have been used in the past and in many environments where measurements using traditional ozone monitors are impossible. Flash card memory and a quiet, long-life internal air pump are now standard on the Model 202. The Model 202 has been certified by the EPA as a Federal Equivalent Method (FEM): EQOA-0410-190. The Model 202 has been used for the past decade in ozone monitoring networks of the U.S. National Park Service and National Forest Service. It also is widely used by NOAA, EPA, Environment Canada and the British Antarctic Survey for studies of ground-level ozone.

Model 205 Ozone MonitorThe Model 205 Dual Beam Ozone Monitor™ was designed for even higher precision and faster response time than our popular Model 202. Data may be output as frequently as every 2 seconds, making it ideal for vertical profiling using balloons or aircraft measurements where high temporal resolution is required. For a given averaging time, the Model 205 has a higher precision (better than 1 ppb for 10 s averaging) and a more stable baseline than the Model 202. The Model 205 has all of the features of the Model 202 single beam instrument, including a real time clock; averaging times of 10 s, 1 min, 5 min and 1 h; an internal data logger; and serial and analog data outputs. Flash card memory and a long-life, quiet internal air sampling pump are now standard on the instrument. The Model 205 Ozone Monitor has been designated as a Federal Equivalent Method (FEM) by the EPA (EQOA-0410-190).

Model 106-L Ozone MonitorThe Model 106 series of ozone monitors comprise single beam ozone monitors similar to the Model 202 in size, weight and power consumption. The 106-L, -M,-MH and -H instruments were originally designed for industrial ozone applications. However, the lower cost 106-L ozone monitor may be used for air pollution studies as well and was installed at more than 100 stations around the world in our Global Ozone Project educational outreach program. The Models 106-L and OEM-106-L have been designated by the US EPA as a Federal Equivalent Method (FEM): EQOA–0914–218. The Model 106-L was designed for manufacturability, resulting in a lower cost and more robust instrument. In the near future, the Model 106 series will include a touchscreen as the user interface. The instrument can be provided in an Industrial enclosure.

Model 106-L-OEM Ozone MonitorFor OEM applications where users want to integrate their ozone monitor into a complex system such as an air pollution measurement package, we offer an "Ozone Monitor on a Board™" solution. The entire ozone monitor is mounted on a single printed circuit board. The liquid crystal display and power switch may be removed and mounted outside the package if desired. The OEM board may be purchased with one of four different optical benches to optimize measurements in four different concentration ranges as follows:

Model 211 Scrubberless Ozone MonitorThe Model 211 Scrubberless Ozone Monitor uses the proven ultraviolet (UV) absorption method in combination with an innovative gas-phase scrubber technology to measure ozone virtually free from interferences. The Model 211 is ideally suited for measurements of ozone in heavily polluted air where interferences from particulates, mercury and VOCs may be significant. The new Model 211 combines the stability of our Model 205 Dual Beam Ozone Monitor with our selective scrubber technology to provide highly accurate ozone measurements in the most polluted air. The enhanced optical path length of 30 cm provides a precision of better than 0.5 ppb for 10-second measurements, and the instrument can output new ozone measurements as often as every 2 seconds. SD card data logging is now a standard feature.The Model 211 has been designed by the EPA as a Federal Equivalent Method (FEM), EQOA–0514–215, and is being considered as new Federal Reference Method (FRM) for ozone.

Model 211-G Ozone MonitorThe new Model 211-G Ozone Monitor uses the proven ultraviolet (UV) absorption method in combination with our patented heated graphite scrubber technology to measure ozone virtually free of interferences. The instrument is ideally suited for measurements of ozone in heavily polluted air where interferences are likely from particulates, mercury, and/or VOCs. The Model 211 combines the stability of our proven dual beam ozone monitors with our selective scrubber technology to provide accurate ozone measurements in the most polluted air. The enhanced optical path length of 30 cm provides a precision of better than 0.5 ppb for 10-second measurements, and the instrument can output new ozone measurements as often as every 2 seconds. The Model 211-G comes with SD flash card memory as a standard feature. The Model 211-G Ozone Monitor has been designated by the EPA as a Federal Equivalent Method (FEM) as a modification to our Model 211 Scrubberless Ozone Monitor:EQOA-0514-215. The Model 211-G offers the ability to measure ozone in heavily polluted urban air with negligible interferences without the use of the nitrous oxide source required by the Model 211.

Use of either the Model 211 or Model 211-G in place of conventional ozone monitors has the potential to bring many regions into compliance with the new national ambient air quality standard simply by making a more accurate measurement.

Personal Ozone Monitor (POM)2B Tech has taken the next step in miniaturization of UV-based ozone monitors by developing the Personal Ozone Monitor or "POM." The POM has dimensions of 4 x 3 x 1.5 inches and weighs only 0.75 lb. (340 g). It has a built in GPS so that ozone measurements may be logged continuously along with geographic location. Like all of our ozone instruments, the measurement is based on UV absorbance. It does NOT use a solid-state or electrochemical sensor, both of which are prone to interferences and baseline drift. By folding the optical path in the shape of a "U," it was possible to achieve the same path length in the POM as in the Models 202, 205, and 106-L and thus have similar precision and accuracy (~1.5 ppb). The POM is ideal for personal ozone exposure studies and health and safety monitoring in workplaces where ozone is produced. The US EPA has designated the POM as a Federal Equivalent Method (FEM): EQOA–0815–227.

Model 306 Ozone Calibration SourceThe Model 306 Ozone Calibration Source is a highly portable ozone transfer standard that may be used to calibrate any ozone monitor or sensor. Ozone is generated at any chosen concentration in the range 0-1000 ppb in ozone-scrubbed ambient air at a volumetric flow rate of 3 L/min. No external air source is required. The instrument may be programmed to output a series of up to 10 ozone concentration steps with a chosen time interval. It also has a scheduler that permits the user to schedule an autocalibration once daily. The Ozone Calibration Source is provided with a NIST-traceable calibration, and the menu allows the user to calibrate the output to their own reference instrument. This Ozone Cal Source, which qualifies as an EPA transfer standard, is particularly useful for calibrating networks of ozone monitors in the field.

Model UV-106-W Aqueous Ozone MonitorThe Model UV-106-W Aqueous Ozone Monitor™ uses our patented MicroSparge™ technology to measure dissolved ozone in either dirty or clean water. Unlike conventional dissolved ozone monitors, the instrument does NOT make use of a membrane that will foul over time. Instead, dissolved ozone is measured by sparging (bubbling) of ~2 mL of water with ozone-scrubbed ambient air and integrating the gas-phase concentration of ozone stripped from solution. Because ozone is measured in the gas phase, there are no interferences from particles and dissolved inorganic or organic compounds.

Model 106-L Ozone Monitor for Ambient Ozone MeasurementsThe Model 106-L is designed for ambient ozone monitoring for health and safety monitoring in an industrial ozone setting based on the accurate method of UV absorbance. A simple design with all components mounted to a single printed circuit board and a long-life pump make the instrument highly reliable and robust. Ozone is measured in the range 0-100 ppm (0-100,000 ppb) with a resolution of 0.1 ppb. Precision and accuracy for this low-concentration ozone monitor are ±2 ppb or 2% of reading. The Model 106-L has been designated by the US EPA as a Federal Equivalent Method (FEM): EQOA–0914–218. The instrument can be provided in an Industrial enclosure.

Model 106-M Ozone Monitor for Off-Gas MeasurementsThe Model 106-M provides ozone measurements by UV absorbance in the 0-1,000 ppm concentration range with a resolution of 0.01 ppm (10 ppb). This medium range ozone monitor can be used for ambient monitoring as well as off gassing from ozone-treated water. The instrument can be provided in an Industrial enclosure.

Model 106-MH Ozone Monitor for Measurements of Off-Gas and Ozone Generator OutputThe Model 106-MH provides ozone measurements by UV absorbance in the 0-10,000 ppm (0-1% vol) concentration range with a resolution of 0.01 ppm (10 ppb). This medium-high range ozone monitor can be used for measuring ozone offgas as well as the output for lower concentration ozone generators. The instrument can be provided in an Industrial enclosure.

Model 106-H Ozone Monitor for Measurements of the Outputs of High Concentration Ozone GeneratorsThe Model 106-H is a high concentration ozone monitor designed for measuring and controlling output concentration of a high concentration ozone generator. Ozone is measured in the range 0-20 wt% with a precision of 0.01 wt% or 2% of reading by the method of UV absorbance. The instrument can be provided in an Industrial enclosure.

Model 106-OEM Series Available for L, M, MH and H ModelsThe Model OEM-106 series is available in an OEM version (no instrument case) for our customers who want to build an ozone monitor into their own package. The 106 series is designed such that all components are mountable to a single printed circuit board, making it ideal for incorporation into custom ozonation equipment. The Model OEM-106-L has been designated by the US EPA as a Federal Equivalent Method (FEM):EQOA–0914–218.

Model 108 Series Ozone MonitorsOzone Monitors in our Model 108 Series offer a bare-bones "ozone monitor on a board" for easy integration into your system. With no pump and no enclosure case, instruments in this series offer the same range and precision as their Model 106 counterparts. Choose the -L, -M, -MH, or -H depending on your measurement needs. The Model 108-L has been designated by the US EPA as a Federal Equivalent Method (FEM):EQOA–0914–218.

Personal Ozone Monitor (POM)The Personal Ozone Monitor (POM™) is the "World"s Smallest Ozone Monitor." Like all of our ozone instruments, the measurement is based on UV absorbance. It does NOT use a solid-state or electrochemical sensor, both of which are prone to interferences and baseline drift. Accuracy and precision comparable to that of the Model 202 and 106-L were achieved by bending the optical path using mirrors. The POM has dimensions of 4 x 3 x 1.5 inches and weighs only 0.75 lb. (340 g). It has a built in GPS so that ozone measurements may be logged continuously along with geographic location. The POM™ is recommended for personal monitoring and any application, such as balloons and UAVs, where size and weight are critical. The US EPA has designated the POM as a Federal Equivalent Method (FEM): EQOA–0815–227.

Model 306 Ozone Calibration SourceThe Model 306 Ozone Calibration Source is a highly portable ozone transfer standard that may be used to calibrate any ozone monitor or sensor. Ozone is generated at any chosen concentration in the range 0-1000 ppb in ozone-scrubbed ambient air at a volumetric flow rate of 3 L/min. No external air source is required. The instrument may be programmed to output a series of up to 10 ozone concentration steps with a chosen time interval. It also has a scheduler that permits the user to schedule an autocalibration once daily. The Ozone Calibration Source is provided with a NIST-traceable calibration, and the menu allows the user to calibrate the output to their own reference instrument. This Ozone Cal Source, which qualifies as an EPA transfer standard, is particularly useful for calibrating networks of ozone monitors in the field.

The Model 405 nm NO2/NO/NOx Monitor is designated as a Federal Equivalent Method (FEM) for NO2 compliance monitoring (EQNA-0217-243) and is TUV-certified (QAL1) under European standards EN14211 and EN15267 (certificate 0000062070).

Personal Air Monitor (PAM)The Personal Air Monitor (PAM) was originally developed for our AQTreks educational outreach program and is now available for purchase as well. The PAM makes use of the most reliable sensors for air quality measurements for the species CO, CO2 and particulate matter. The PAM broadcasts data via Bluetooth to nearby mobile phones, and those data can be viewed on a map and as a time series on our AQTreks or 2B Connect mobile apps. Data obtained by the PAM can be uploaded via WiFi or the cell phone (or its own cellular connection, if this option is purchased) to the 2B Tech Data Portal on the web, where the data can be visualized in a variety of ways and downloaded for further analysis. Besides use as an educational tool, the PAM has found use in research and monitoring, such as the US National Forest Service studies of forest fire smoke dispersion.

Model 714 NO2/NO/O3 Calibration SourceThe Model 714 NO2/NO/O3 Calibration Source™ combines our Model 408 Nitric Oxide Calibration Source™ with our Model 306 Ozone Calibration Source™ to provide a highly portable transfer standard for three pollutant gases without the need for a compressed gas cylinder of nitric oxide. Calibrated concentrations of O3 are produced by photolysis of oxygen, and calibrated concentrations of NO are produced by photolysis of nitrous oxide. In addition, calibrated concentrations of NO2 are produced by gas-phase titration of NO with O3. Calibrations sequences can be programmed in internal memory via a user-friendly touch screen interface, and the instrument can be operated remotely via a Modbus TCP/IP interface and Ethernet connection to a computer.

Model 306 Ozone Calibration SourceThe Model 306 Ozone Calibration Source is a highly portable ozone transfer standard that may be used to calibrate any ozone monitor or sensor. Ozone is generated at any chosen concentration in the range 0-1000 ppb in ozone-scrubbed ambient air at a volumetric flow rate of 3 L/min. No external air source is required. The instrument may be programmed to output a series of up to 10 ozone concentration steps with a chosen time interval. It also has a scheduler that permits the user to schedule an autocalibration once daily. The Ozone Calibration Source is provided with a NIST-traceable calibration, and the menu allows the user to calibrate the output to their own reference instrument. This Ozone Cal Source, which qualifies as an EPA transfer standard, is particularly useful for calibrating networks of ozone monitors in the field.

Are you looking for the highest level of on-screen color accuracy for all of your screens, including projectors? Then the i1Display Pro is the solution for you! It’s two user modes, Basic and Advanced, provide serious Color Perfectionists with the perfect combination of unrivaled color precision, speed, options and controls to fit any workflow. You’ll no longer risk spending hours at your monitor perfecting images or video only to find that the display was not accurately representing the digital files. Properly profiling and calibrating your displays ensures reduced editing time and a more realistic no-surprises representation of final output.

Top-of-the-line i1Profiler color management software offers the ultimate in flexibility and control. Basic mode offers a wizard driven interface with predefined options for the quickest path to professional on-screen color. Advanced mode offers user-defined options for more sophisticated profiling workflows to deliver the highest quality color results on monitors and projectors, as well as display testing and quality assurance tools.

Compensates for the ambient light surrounding your workspace with Ambient Light Smart Control. Since the intensity or amount of ambient light in your workspace affects the way you perceive color on your display, take advantage of i1Display Pro to automatically adjust your profile or simply notify you as ambient light conditions change. With the integrated Ambient Light Measurement, i1Display Pro automatically determines the optimum display luminance for comparing prints to your display.

Flare Correct™measures and adjusts your display profile for reduced contrast ratios caused by flare light (or glare) falling on the surface of the display. By accurately measuring your effective display contrast ratio, you’ll have an even more accurate display profile.

Intelligent Iterative Profiling,an adaptive technology,produces optimized results for maximum color accuracy on each unique display every time you profile.

Next generation i1Profiler software for calibrating and profiling all modern display and projector technologies including LED & Wide Gamut LCDs. Advanced user-defined controls support more sophisticated workflows.

Save time by re-using profile settings on multiple displays connected to the same computer or multiple computers within a workgroup. In addition, Automatic Display Control (ADC) adjusts display hardware for increased speed and fewer manual adjustments.

The included i1Profiler color management software offers the ultimate in flexibility and control. Its Basic mode offers a wizard driven interface with predefined options for the quickest path to professional on-screen color. The Advanced mode offers user-defined options for more sophisticated profiling workflows to deliver the highest quality color results on monitors and projectors, as well as display testing and quality assurance tools. i1Display Pro profiling provides full support for NTSC, ITU-R-Rec.BT.709 and PAL SECAM broadcast video standards.

How much time, paper, and ink do you waste re-printing images because the color isn’t right? Before you blame your printer, consider your monitor. When you work on an un-calibrated monitor, you can’t trust the colors you see on-screen, making it hard to make good editing decisions.

At the top are the standard CIE Daylight Illuminants. D65 is the choice for most people working in photography and graphics. D50 is commonly used in prepress.

Native will use the white point of the monitor. This setting is for those of you already set the white point of your monitor through some other method (such as the monitor’s menu) and don’t want to change it.

Near the bottom are the options to set custom white point values – either using a Daylight Temperature slider control for values from 5000 to 7500, or entering the xy chromaticity coordinates.

Most LCD users find 120 is bright enough to judge color and detail in highlights and shadows, but if you’re having a hard time seeing details, try selecting a lower value.

Automatic display control takes advantage of a feature that’s available on some displays, allowing the software to access the display’s internal calibration controls. Or, you can choose to adjust your brightness and contrast manually.

This is a preview of how your monitor performed. The expected values appear in the upper left corner of each patch, and the measured values in the lower right. Click Next.

If you’re curious, click the middle Luts button (looks like a graph) to see which calibration adjustments i1 Profiler made to the computer’s video card. This fine-tuning helps match the display to the selected white point and gamma settings.

The Amprobe LM-100 light meter measures the visible light from fluorescent, metal halide, high-pressure sodium or incandescent sources. It is a portable, easy-to-use digital light meter designed for simple one-hand operation reading in Lumen (lux) or Footcandle (fc) units. The LM-100 measures a wide range of light up to 20,000 fc or lux with an accurate, high resolution of 0.01 fc/lux.

Only the DustTrak™ DRX Aerosol Monitor 8534 can simultaneously measure both mass and size fraction. The DustTrak DRX handheld monitor is a multi-channel, battery-operated, data-logging, light-scattering laser photometer that gives you real-time aerosol mass readings. It uses a sheath air system that isolates the aerosol in the optics chamber to keep the optics clean for improved reliability and low maintenance.

It is suitable for clean office settings as well as harsh industrial workplaces, construction and environmental sites, and other outdoor applications. The DustTrak DRX handheld monitor measures aerosol contaminants such as dust, smoke, fumes and mists.

Leading the industry in real-time dust monitoring, the DustTrak™ DRX Aerosol Monitor 8533 can simultaneously measure both mass and size fraction. The DustTrak DRX desktop monitor is a multi-channel, battery-operated, data-logging, light-scattering laser photometer that gives you real-time aerosol mass readings and collects a gravimetric sample. It uses a sheath air system that isolates the aerosol in the optics chamber to keep the optics clean for improved reliability and low maintenance.

It is suitable for clean office settings as well as harsh industrial workplaces, construction and environmental sites, and other outdoor applications. The DustTrak DRX monitor measures aerosol contaminants such as dust, smoke, fumes and mists.

The DiST® 1 features a large multi-level LCD which displays both TDS and temperature readings simultaneously. The TDS readings are displayed with a 1 ppm resolution and with an accuracy of ±2% full scale. The TDS range of the HI98301 is from 0 to 2000 ppm. An exposed temperature sensor allows for rapid automatic temperature compensated TDS measurements. Temperature can be set to display in ℃ or ℉. The LCD screen has stability and calibration tag indicators. The battery percent level is displayed at start up alerting the user to the remaining battery power that is available.

TDS readings are performed by an amperometric graphite electrode that resists oxidation, providing better repeatability in measurements. The use of graphite also reduces the polarization effect common with amperometric testers that use two stainless steel pins.

Calibration is performed by pressing the dedicated calibration button. Once in calibration mode submerge the probe in 1382 ppm calibration standard. When the standard value is recognized and stability reached, the meter will automatically accept and store the calibration value.

HI98301 (DiST 1) is supplied with CR2032 battery, 1382 ppm calibration solution sachet (4), storage/protection sleeve, instruction manual and quality certificate.

Galvanic’s FPA 4100 family of process photometers enables measurement of the concentration of a wide variety of analytes in both liquid and gas streams. The photonics module can accommodate either UV or visible light sources and has a temperature controlled photo diode block for maximum signal stability. The light source and detectors are coupled to a measurement cell via fiber optic cables.

The FPA 4100 controller includes an intuitive user interface with an intrinsically safe, removable keypad, LCD screen, 10 LED indicator lights, and data-loading capability. Rugged and reliable, the systems offer multi-stream-analysis capability, delivering precise continuous measurement with no reagents or compressed gases required. Easy to use and maintain with auto-calibration capability using external standards, auto-zero compensation, and digital optimization of detector gains, the detector electronics are isolated from the process for optimum safety and stability. The FPA 4100 series also enables remote operation and diagnostics via an Ethernet connection.

Consistent presentation of digital radiographic images at all locations within a medical center can help ensure a high level of patient care. Currently, liquid crystal displays (LCDs) are the electronic display technology of choice for viewing medical images. As the inherent luminance (and thereby perceived contrast) properties of different LCDs can vary substantially, calibration of the luminance response of these displays is required to ensure that observer perception of an image is consistent on all displays. The digital imaging and communication in medicine (DICOM) grayscale standard display function (GSDF) defines the luminance response of a display such that an observer’s perception of image contrast is consistent throughout the pixel value range of a displayed image. The main purpose of this work is to review the theoretical and practical aspects of calibration of LCDs to the GSDF. Included herein is a review of LCD technology, principles of calibration, and other practical aspects related to calibration and observer perception of images presented on LCDs. Both grayscale and color displays are considered, and the influence of ambient light on calibration and perception is discussed.

Consistent presentation of medical images is important to ensure a high level of patient care. Medical centers that were (or are) film-based ensured consistent image quality by distributing a single hard copy rendition of a radiographic examination to the various care providers. Given that the providers viewed the image on a light box of comparable luminance, all who viewed the image were provided the same rendition of that image. Medical practices and radiology departments are evolving to a digital rather than film-based image acquisition and distribution system. In many instances, this allows multiple providers in different locations to have simultaneous access to the images and provides the potential for better and more efficient patient care. Similar to a film-based practice, delivering a high-quality radiographic examination to all care providers helps ensure a consistent and high level of patient care.

Given that many newly acquired images are digital, there is a potential to view them on any number of computer systems. Computers as common as a standard personal computer (PC) or as sophisticated as a picture archival and communications system (PACS) work station may be used to view images. The need for consistent image presentation on this wide selection of work stations has been recognized,,

The purpose of this work is to provide an overview of DICOM grayscale calibration of medical imaging grade liquid crystal displays (LCDs). In the context of this work, a “medical imaging grade” display is a high-quality LCD, which is appropriate for medical image viewing. It has the general characteristics of minimal visual noise, an appropriately wide viewing angle range, minimal reflection of ambient light, and a grayscale luminance response that is calibrated to a known and accepted standard. Each of these display properties will be discussed, with greater detail and emphasis placed on grayscale calibration. Much of the information provided here has been presented previously by other authors and groups, and references to those works are provided. Successful calibration and use of LCDs in medical imaging requires an understanding of LCD technology. Therefore, a “Technology Overview” is provided. A combination of the GSDF and LCD technology provides the “Foundations of DICOM Calibration.” There are several “Practical Aspects of Calibration,” some of which will be discussed here. Grayscale calibration is evolving from inherently grayscale displays to grayscale calibration of color displays. The “Influence of Color” on the calibration of LCDs is underrepresented in the literature and will be discussed briefly. The light source of most LCDs is a combination of fluorescent lamps and light guides. Because the luminance output of the lamps changes over time, “Maintenance of Calibration” is required to ensure quality image presentation over time. Finally, there are several “Confounding Factors” to consider when calibrating and implementing medical imaging grade LCDs into clinical practice. These include the influence of viewing angle and ambient light. Whereas the influence of ambient light on the physical properties of a displayed image is well known, the influence of ambient light on the adaptation (and perception) of the human visual system is underrepresented in the medical imaging display literature and will be discussed briefly.

Whereas the theory of grayscale calibration of medical imaging grade LCDs is based on the known response of the human visual system to contrast stimuli, practical calibration is implemented to both accommodate and utilize the specifics of LCD technology. A basic understanding of LCD technology is essential to appreciate the methods and limitations of calibration.

An active matrix liquid crystal display is often described as an optical “stack” containing a light source, light diffusers, polarizers, color filters (especially in case of a color LCD), and thin-film transistor liquid crystal matrix. An example of an optical stack is shown in Figure 1. The backlight is a combination of a light source and optical light guides and diffusers that serve to create a uniform luminance across the LCD surface. The light source is commonly a cold-cathode fluorescent lamp and may be implemented truly as backlights or commonly as “side” lights that are positioned along the outer edge(s) of the display. Other light sources, such as light emitting diodes or xenon lamps may also be used. The amount of light transmitted through the panel is a function of the relative orientation of the rear and front polarizers and the influence of the liquid crystal on the polarized light. The liquid crystal is a thin fluid layer of elongated organic molecules between glass plates. Linear “etching” of the inner surfaces of the glass plates preferentially orients the molecules near these surfaces parallel to the direction of the etching. In a resting state, the orientation of the molecules is determined by the direction of the etched grooves. As voltage is applied across the crystal, the molecules tend to preferentially align their direction in relation to the electric field. Orthogonal direction etching of the top and bottom surfaces of the liquid crystal layer provides an inherent “twist” in the orientation of the elongated molecules when a voltage is applied across the crystal. As the polarized light interacts with the twisted crystal, the plane of polarization tends to twist with the crystal. If the front and rear polarizers are oriented perpendicular to one another and the preferential plane of the polarized light is unaffected by the crystal, then very little light will be transmitted through the panel. If the molecules are highly aligned to the orthogonally oriented etching (caused by an applied voltage), then the polarized light is twisted 90° to align with the orientation of the front polarizer and a large fraction of light is transmitted. The applied voltage level influences to what extent the elongated molecules twist, thereby influencing the orientation of the plane of propagation of the once polarized light, which ultimately determines the amount of light that is transmitted by a small portion of the liquid crystal display. This description of LCD construction and operation is provided an as example. Details of the design and function of a specific LCD may well vary from the example provided there. However, the basic interactions between light, the polarizers, and the liquid crystal are common for all LCDs.

Each addressable LCD pixel has three subpixel elements, regardless of whether the display is inherently a color or a grayscale LCD. The three subelements correspond to the standard red, green, and blue color channels (RGB). In a color LCD, the colors are created by the addition of RGB filters. The color filters are omitted in inherently grayscale LCDs. Example color and grayscale pixel elements are shown in Figure 2. The “chevron” shape on the left in Figure 2 and the linear subpixels shown on the right are typical of many types of displays. As will be discussed later, the three subpixels will prove to be useful for grayscale calibration.

Grayscale calibration of LCDs is especially important because there is generally poor consistency in the inherent response of these displays. For example, the luminance (and perceived) contrast of an uncalibrated LCD can vary greatly throughout the input digital driving level (DDL) range of a single display.

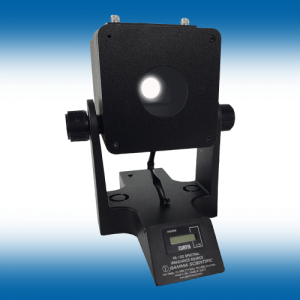

The intensity of light emitted by a display, or luminance, is typically specified to have units of candela per square meter (cd/m2). The relationship between cd/m2 and the older luminance unit foot-lamberts (fL) is given by 1 cd/m2 = 0.292 fL. Because LCDs are non-Lambertian surfaces, luminance is typically measured with a photometer, which has a narrow light acceptance angle (≤5°). Some photometers have a display to provide luminance measurements to the operator. Others interface with a computer, which can provide electronic data capture and display the luminance values. Often, medical imaging grade LCDs utilize a calibration software package that supports a limited number of photometers. For calibrating medical imaging grade displays, a photometer should be accurate to within 5% except for very low luminance levels (0.5 cd/m2) where an accuracy of 10% may suffice. The accuracy of any photometer used for calibrating medical imaging grade displays should be specified by the manufacturer. Note that photometers used for calibrating color LCDs have independent RGB measurement channels. This provides for calibration of the color tone as well as the luminance of color displays.

A photometer is an appropriate device to measure the luminance emitted (or reflected) from a display. Environmental lighting surrounding a display produces ambient light, or illuminance, which, by diffuse or specular reflection into the observer’s eye, may influence the physical contrast and the perceived contrast of a display. The typical unit of illuminance is the lux (lx). As opposed to the directionally oriented light emitted from a display, ambient light incident upon any object may come from any direction. Therefore, it cannot be measured directly with a standard narrow-angle photometer, but is rather measured using a photoreceptor behind an optical cosine diffuser. Whereas ambient light cannot be measured directly using a narrow-angle photometer, the ambient light reflected from a display can be measured with a narrow-angle photometer.

The goal of grayscale calibration of electronic displays is to ensure that images presented to an observer have equal perceived contrast appearance on all displays, independent of the luminance range of the display. To achieve this goal requires that, given a specific luminance scene, the contrast perceived by the human visual system (HVS) is well known. There are several experimental models of the perceived contrast of the human visual system. There are also multiple grayscale display function models, which have been and continue to be used to calibrate displays. These include the CIELAB display function (Commission Internationale de l’Eclariage), the log-luminance linear function,

The Barten model of the HVS5). The luminance difference of the sinusoidal visual target from the background was varied to identify the luminance change, which rendered the target just barely visible. In this manner, a just noticeable difference (JND) was defined as the luminance change in the target that was required for the target to be perceived.

Experience has shown that the overall perceived contrast of an image presented on two GSDF calibrated LCDs of similar contrast ratio but different luminance ranges exhibit similar (although not exactly the same) overall contrast appearance. Another recognized limitation of the Barten model (and thereby the GSDF) is that, for a particular uniform background luminance, the luminance change required to perceive the visual targets was determined with the HVS adapted to that background luminance. In radiographic image viewing the HVS adapts to an overall scene luminance, but is required to perceive anatomical detail over the relatively wide luminance range of a displayed image. Because the HVS perception is optimized for a relatively narrow luminance range near the adaptation luminance, perception of detail in the light and dark portions of an image may be somewhat compromised.

The DICOM grayscale standard display function describes a relationship between luminance and monitor input values such that the slope of the curve at any point, ie the contrast, is proportional (but not necessarily equal) to the contrast associated with a JND from the Barten model. The DICOM grayscale display function is often plotted graphically as luminance versus JND index (j), where the JND index values range from 0 to 1023. The DICOM grayscale display function is presented in Figure 3 this way. For a given luminance, the luminance change required to perceive a difference corresponds to a single JND. The model data have been fit to a polynomial, which provides a convenient mathematical transform to convert back and forth from units of luminance (cd/m2) to JNDj. The transform to convert from luminance (L) to JNDjj) is provided in Eq. j to luminance,,j transforms are available in tabular format.

To perform a DICOM calibration of a display, the desired postcalibration minimum (Lmin) and maximum (Lmax) luminance values are first identified. Because the luminance output of the backlights decreases over time, it may be reasonable to expect that the calibrated maximum luminance intensity selected may adversely affect the life expectancy of a display. The desired Lmax may be less than the maximum luminance that the device is capable of producing, Ldmax. Diagnostic monochrome monitors are now commonly calibrated for an Lmax of 400 to 600 cd/cm2, whereas color monitors used for clinical review will have an Lmax from 250 to 450 cd/cm2. Similarly, Lmin, corrected for ambient light effects, is often set to be larger than the black level of the display, Ldmin. The minimum possible Ldmin value is determined by the ability of an LCD to block the backlight.

Typical contrast ratios are in the range of 250 to 400 for color displays and up to 600 (or more) for inherently grayscale displays. Commonly, Lmin is specified to be slightly higher than the minimum possible value. This allows similar displays with different maximum luminance levels to be calibrated such that the luminance ratio Lmax/Lmin is the same and images appear with similar contrast.

After the Lmin and Lmax values have been specified, the corresponding JND index values (JNDmin and JNDmax) are determined using Eq. max and JNDmin defines the total number of JNDs (JNDtot) that the calibrated display can produce. For example, a display with Lmin = 0.5 cd/m2 and Lmax = 200 cd/m2 has corresponding JNDmin = 46.6 and JNDmax = 572.2. In this example, JNDtot = 525.6. Most computers, video display driver cards, and displays are capable of 8-bit graphics. Regardless of whether the display is color or grayscale, an 8-bit grayscale palette is typical. Therefore, there are typically N = 256 grayscale digital driving levels available to a display system. The purpose of calibration is to set the luminance output for each input DDL such that throughout the entire DDL range, a change in DDL results in a JND index change that is constant. To accomplish this, the total number of JNDs is divided by the number of DDLs, minus one. This defines the average number of JNDs per DDL (JNDave) of the calibrated display. Continuing with the example started above, JNDave = 525.6 / 255 = 2.06. The JNDDDL of each DDL is next calculated as

Just as the DICOM GSDF with JND indices is useful for calibrating displays, it is also useful for characterizing the contrast properties of both calibrated and uncalibrated displays. To characterize a display, luminance measurements can be converted to JND index values using Eq. 4 and and55 for both an uncalibrated and a calibrated display. In Figures 4 and and5,5, note the lack of contrast for DDL values less than 8 and the relatively increased contrast for DDL values in the range 8 to 96 compared to the GSDF. For values greater than 128, the uncalibrated display has less contrast than the calibrated display. As might be expected, the JND space of a calibrated display is linear.

Luminance as a function of digital driving level (DDL) for an uncalibrated display and a display that is calibrated to the DICOM Grayscale Standard Display Function.

Just noticeable difference index value as a function of digital driving level (DDL) for an uncalibrated display and a display that is calibrated to the DICOM Grayscale Standard Display Function.

It is worth noting that calibrating displays to the GSDF with a similar luminance ratio can provide a similar image appearance on all displays, but this does not guarantee that the images necessarily look as desired. The overall appearance of digital medical images is dependent upon many variables including image acquisition parameters (peak kilovoltage [kVp] and mAs in x-ray, for example), image processing, and the various linear and nonlinear grayscale transforms provided for by DICOM Part 14.

As shown in Figures 4 and and5,5, a luminance output that corresponds to the GSDF is not inherent to LCDs. Calibration requires creation of a look-up table (LUT) such that for each DDL, the LUT specifies a new DDL value that corresponds to a displayed luminance that matches (as closely as possible) that of an ideal DICOM display.6 shows the JND/DDL contrast of an ideal GSDF calibrated display and a display that has been calibrated using an 8-bit LUT.

With the 8-bit-to-8-bit calibration, the net result is that the overall contrast of the display has the visual appearance of being calibrated. The overall perceptual contrast of the display is as desired. However, adjacent input pixel values may have output DDLs that are exactly the same, resulting in no displayed contrast between adjacent input levels. This effect is represented by the JND/DDL values in Figure 6, which have a value of zero. Also, adjacent input values may have output DDLs that differ by more than 1 (of 256) and the displayed contrast between adjacent input levels is excessive. This is also shown in Figure 6. Note that, for this example, the 8-bit-to-8-bit conversion resulted in 218 of a possible 256 unique gray levels in the calibrated grayscale function. The grayscale discontinuity caused by the 8-bit-to-8-bit LUT may result in “scalloping” or grayscale “banding” artifacts in a displayed image. Given that 8-bit-to-8-bit calibration generally results in loss of local contrast combined with excessive local contrast, it is generally not a satisfactory calibration method.

Use of an expanded grayscale palette, achieved by addressing the subpixels independently, provides the foundation for a more effective grayscale calibration. With the expanded palette, the output luminance can be made to more closely match the ideal luminance indicated by the GSDF. In contrast to the 8-bit palette, the same luminance value need not be used multiple times and the potential for very large and small contrast changes for adjacent DDLs is reduced. This results in a calibrated display, which more closely approximates that of an ideal display, as shown in Figure 6. Along with spatial dithering, the use of temporal modulation or temporal dithering of subpixels has been implemented by some manufacturers to further refine the luminance difference between LUT palette entries.

“Theory of Calibration” describes how a calibration LUT is derived once the desired Lmin and Lmax have been specified. For grayscale displays, typical calibrated Lmax values are in the range of 400 to 600 cd/m2. These displays generally have a contrast ratio of approximately 600:1. Therefore, Lmin could be specified as low as 0.66 to 1 cd/m2 to achieve a displayed luminance ratio equal to the device contrast ratio. Whereas the HVS can adapt to a large range of luminance levels, the luminance range of an adapted HVS is relatively limited.,Lmax = 525 and Lmin = 1.5 will have a luminance ratio of 350. The Lmax of color displays is generally less than that of grayscale displays, and may range between 250 and 450 cd/m2. For the same luminance ratio, a color monitor thus has a lower Lmin, making them more susceptible to the adverse effects of ambient light.

It is important to note that GSDF calibration of different displays does not necessarily result in displays which are exactly perceptually matched. The GSDF ensures that the perceived contrast is consistent throughout the grayscale range of a given display, but calibrated displays that have substantially different maximum luminance values or contrast ratios will not provide an exact perceptual match. For example, a brighter display will still look brighter after calibration and a higher contrast display will still have higher contrast. Because the luminance and contrast properties of medical imaging grade LCDs is not widely variable, GSDF calibration of these displays will ensure that an image presented on each display will have a similar appearance.

It might be considered that calibration based on initial measurement of the luminance at every palette LUT value provides the best grayscale calibration. For cathode ray tube (CRT) displays, luminance output is well behaved with driving level and most calibration software coarsely sampled the palette and interpolated the intervening values. Therefore, the typical number of luminance measurement points used for CRT calibration is often in the range of 18 to 32. Note that American Association of Physicists in Medicine (AAPM) TG18 recommends measurement of 18 points along the grayscale range to assess GSDF conformance. Therefore, a display that was calibrated using measurements from the same 18 points would be expected to have a favorable TG18 luminance response evaluation.

For LCD displays, the luminance can vary discontinuously between adjacent palette LUT entries. Therefore, the number of calibration points should be much larger than the number of points used for CRT devices, and preferably equal to the full size of the grayscale palette. Similarly, calibration conformance should be checked for all 256 drive levels.

Postcalibration measurement of the grayscale response of a display can be used to assess the quality of the calibration. Detailed discussion of the methods used to assess calibrated display performance are available in the literature.,,Lmin and Lmax. A comprehensive assessment of display grayscale calibration involves measuring the luminance for each of the 256 DDL values. For a small sample of displays, this may be done using a quality photometer and manual recording of the data. Preferably, this can be done by using a photometer that interfaces directly to a computer. Characterization of calibrated displays via measurement of all 256 steps in the DDL range provides an overall assessment of the grayscale response. Both “macro-grayscale” (over a subset of DDLs) and “micro-grayscale” (between individual DDLs) can be assessed. Macroscale assessment may be performed by calculating the JND/DDL contrast between DDL values that are coarsely spaced. For example, the large scale conformance to the GSDF may be calculated using DDL values that are separated by 15. This is equivalent to the 18-step assessment recommended by the AAPM TG-18. Of course, assessment of the macro-grayscale conformance does not require measurement at all 256 DDL values. The additional value of measuring the luminance at each of the 256 DDL values is characterization of the micro-grayscale response. This is more important for LCD displays than for CRT displays. Discrepancy between the ideal GSDF and the actual micro-grayscale response can be considered an assessment of the contribution of an imperfect grayscale calibration to the noise of the displayed image.

Figure 7 shows the macro- and micro-grayscale response of a calibrated grayscale display. The macro-grayscale JND/DDL contrast measurement may be considered to be a local average of the micro-grayscale measurement. As shown in Figure 7, the macro-grayscale measurements do not provide a good indication of the precision of the micro-grayscale response. The TG-18 report and the DICOM GDFS recommend calculating the root mean squared error (RMSE) of the micro-grayscale JND/DDL contrast to characterize the calibration precision. It may be reasonable to calculate the normalized RMSE (nRMSE) by dividing by the average JND/DDL. The nRMSE provides a measurement of the relative noise, which may be useful for comparing displays with different average JND/DDL contrast values. The average JND/DDL contrast of the micro-grayscale JND/DDL contrast of Figure 7 was 2.7; the RMSE was 0.29; and the nRMSE was 0.11. Note that calibration noise should be considered in a relative comparison to other sources of noise in the medical image acquisition and display chain.,

There are many possible mechanisms to store and utilize calibration data. Only an introduction to these mechanisms is provided here. Depending upon implementation, the calibration look-up table may be stored on a host PC as an International Color Consortium (.icc) color profile (or similar). The computer operating system, in combination with the video card, can modify the DDL values sent to the display via the .icc profile. As a general rule, the .icc profile is available to both analog or digital visual interface (DVI) video output formats. The calibration data may also be stored in firmware of the LCD. In general, this type of implementation has the limitation that it can be applied only to a DVI input signal, but has the advantage that the calibration is immediately available if the display is moved to another PC with a DVI output channel. Certainly, other vendor-specific solutions to calibration storage and portability exist. Also, note that many imaging grade displays have other calibrated display function settings in addition to the GSDF setting (such as log-linear or CIELab), which are provided by the manufacturer and delivered as part of a new display.

Not surprisingly, grayscale calibration was originally performed on inherently grayscale displays. Grayscale calibration of color LCDs for medical image display is a relatively new practice. The implications of color on the grayscale calibration palette were discussed in “Expanded Palette Calibration”. Color displays have an inherent advantage for displaying radiographic images that contain color, such as nuclear medicine, Doppler ultrasound, and functional magnetic resonance images. Also, recent work has indicated that using color displays likely does not limit the ability of an expert observer to diagnose disease in chest radiographs.

The construction of grayscale and color LCDs is similar, except that the color displays have red, green, and blue (RGB) color filters. Each of the color filters preferentially blocks a portion of the color spectrum contained in the “white” backlight source. Therefore, the maximum luminance output of color displays is considerably less than that of inherently grayscale displays. Although color displays are inherently dimmer than their grayscale counterparts, it is worth noting that there is currently an upward trend in the maximum luminance of color medical imaging grade LCDs.

All LCDs, including grayscale, have a color tone. The color tone of grayscale displays is a function of the fluorescent (or other) backlight and the transmission properties of the optical stack that may be included to adjust the color tone. For example, some grayscale displays have a blue hue similar to that of blue-base film. Contrary to what one might expect, identical models of grayscale displays may have noticeably different color tones. This is due primarily to variations in the manufacture of the backlights. The AAPM TG-18 report provides guidelines for establishing measurable color differences such that the color tone differences are not perceivable. The color tone of color displays can generally be specified during calibration. Therefore, it is reasonable to expect that no color difference should be perceived between similarly calibrated color displays.

Liquid crystal displays commonly use fluorescent lamps as the backlight source. The luminance output of the backlight is subject to change over time and therefore requires some sort of maintenance to ensure luminance stability. Most medical imaging grade displays have built-in backlight luminance sensors with feedback circuits to maintain the desired maximum luminance of the LCD based on proper calibration of the backlight sensor. Some of them also have sensors that measure the luminance output of a small area near the edge at the front of the display. The front of screen sensor has the potential to measure not only the maximum luminance, but can also be used to measure the luminance throughout the entire DDL range, albeit in a small area at the periphery of the display. The sensors in turn are calibrated with respect to the center of the LCD. That the front of screen sensor can measure luminance values throughout the entire DDL range can help to provide assurance that conformance to the GSDF is maintained over time. Whether an automated front of screen sensor is required to maintain conformance has not be established. Often, the sensor values are provided to administrative software that allows remote monitoring of the luminance properties as measured by back and/or front of screen sensors. Note that the luminance values obtained remotely are as reliable as the electronic sensors that measure them. Periodic, on-site evaluation of medical imaging grade LCDs is recommended to ensure overall display quality. Experience has shown that quarterly on-site evaluation is initially appropriate. It may be reasonable to modify the frequency of the on-site visits based on the frequency and severity of the problems found during these initial quarterly visits.

The luminance and contrast properties of LCDs are dependent upon the angle (with respect to the plane of the display face) from which the light photons are emitted and subsequently observed. Grayscale calibration of medical imaging grade LCDs assures conformance to the GSDF when a display is viewed from an angle

Ms.Josey

Ms.Josey

Ms.Josey

Ms.Josey