thinnest lcd screen manufacturer

A wide variety of ultra thin lcd screen options are available to you, such as mp3, video playback and wifi.You can also choose from ntsc(60hz), ultra thin lcd screen,As well as from hotel tv, {2}, and {3}. And whether ultra thin lcd screen is pal, ntsc, or {3}.

We"ve compiled this list of our thinnest displays available. You will find some amazingly thin OLED displays, the thinnest ePaper modules as well as a couple of slim OLEDs and even a TFT LCD that"s less than 2mm thick.

ePaper in general is one of the thinnest display technologies. Most of our ePaper display modules are less than 2mm! Click to see all of our ePaper display modules. The absolute thinnest ePaper we have is an amazing 0.3mm thick!!

OLED displays have been getting thinner over time, with many under 5mm. Our thinnest OLED display is as thin as our thinnest ePaper at an amazing 0.3mm!! For reference graphite in a mechanical pencil is often 0.7mm - more than twice as thick!

Finding standard LCDs or TFTs that are smaller than 2mm remains difficult. We have a few thin LCDs and they"re very popular! Probably not just because they"re thin. Maybe it"s because they are beautiful as well?

LG Display developed a 5.2" Full-HD LCD panel that is only 2.2 mm thick. They say this is the world"s thinnest Full-HD LCD panel. It"s also the narrowest panel as it has a 2.3 mm bezel. This is the first panel to use LGD"s Advanced One-Glass-Solution (OGS).

This is impressive for an LCD, but OLEDs are much thinner. In fact 6" Full-HD glass based OLED will be only 1.5 mm thick. A plastic-based AMOLED will be only 0.5 mm thick - less than a quarter than even the thinnest LCD.

LG Display has recently announced the production of the world’s thinnest LCD television. The company’s new line of products consists of TV sets with the thickness of a mere 5.9 millimeters.

“The development of the world’s slimmest LCD TV panel demonstrates our leading edge-lit LED backlight technology that enables thinner designs in addition to our direct-lit type LED backlight assembly which delivers superior picture quality” – said LG Display’s CTO and Executive Vice-President Chung In-Jae.

TFOT has previously covered LG’s HDTV with an unprecedented billion-to-one contrast, and LG’s Privacy Protection LCD, a 14.1-inch LCD panel for notebook PCs. Another related TFOT story covers Sharp’s 108-Inch LCD, the world’s largest LCD display, unveiled a year ago.

1. Is the recent development of optically rewritable LCDs. Like conventional LCD displays, the display is structured like a sandwich, with a liquid crystal filling between two plates. Unlike conventional liquid crystals where electrical connections on the plates create the fields required to switch individual pixels from light to dark, optically rewritable LCDs coat the plates with special molecules that realign in the presence of polarized light and switch the pixels. This removes the need for traditional electrodes, reduces the structure’s bulk and allows more choices in the type and thickness of plates. Consequently, optically rewritable LCDs are thinner than traditional LCDs, at less than half a millimeter thick, can be made from flexible plastic, and weigh only a few grams. “It’s only a little thicker than paper,” said Jiatong Sun, a co-author from Donghua University in China.

Optically rewritable LCDs are durable and cheap to manufacture because of their simple structure. Moreover, like an electronic paper screen in an e-book, energy is only required to switch display images or text. Therefore, running costs are low because these new LCDs don’t need power to sustain an image once it is written on the screen.

2. Another innovation is the spacers that create the separation of the plastic or glass plates. “We put spacers between glass layers to keep the liquid crystal layer uniform,” Sun said. Spacers are used in all LCDs to determine the thickness of the liquid crystal. A constant thickness is necessary for good contrast ratio, response time and viewing angle. However, when plates bends, it forces the liquid crystal away from the impact site and leaves sections of the screen blank and so alterations in spacer design are critical to prevent liquid crystal in flexible LCDs from moving excessively. Developing a flexible design that overcomes this barrier has proven challenging.

According to LG, their new organic light-emitting diode (OLED) displays are not only flexible enough to curve around the walls and corners of your home or office, they"re virtually impossible to break, and are thinner and lighter than any LCD screen currently on the market. You just need to attach a thin, magnetic base to your wall, and the "wallpaper" screen can be placed on and peeled off at your leisure (see the video below).

The company has been able to achieve a 4-mm thickness thanks to the OLED technology - because the display produces its own light, no backlight is required to bulk up the design. The screen also offers a brighter, clearer picture than current LCD screens, with a high-definition resolution of 1,200 x 810. "The new transparent OLED panel is said to have a 30 percent transmittance, or clarity, which is far more than the usual 10 percent transmittance of existing transparent LCD panels, according to LG," Dara Kerr reports for CNET.

But don"t let go of your impossibly thin television dreams just yet. With the likes of Samsung, Nokia and Apple also well on their way to developing super-thin and flexible smartphone and tablet screens, good old-fashioned competition will likely steamroll this thing into our homes sooner rather than later.

Seoul, Korea (December 21, 2009) – LG Display Co., Ltd. [NYSE:LPL, KRX:034220], a leading innovator of thin-film transistor liquid crystal display (TFT-LCD) technology, announced today that it has developed the world"s thinnest LCD TV panel measuring 2.6mm.

The development of extremely slim LCD panel was possible by applying the company"s accumulated "slimming" technologies including the use of an ultra-slim, edge-lit LED backlight system and proprietary optical film technology.

In May, LG Display broke the record by unveiling 42- and 47 inch LCD TV panels measuring 5.9mm - the world"s thinnest panels at the time. By nearly halving its record in just seven months, the company maintains its position as the technology leader in ultra-slim LCD panels.

Dr. In Jae Chung, LG Display"s CTO and Executive Vice President noted, "With the development of the world"s thinnest LED LCD TV panel that is only 2.6mm thick, LG Display has once again demonstrated its technical prowess to satisfy customer demand for high resolution and slim design products. We will continue to spur R&D activities in order to provide our customers and the market with the differentiated products that they desire."

BEIJING: Scientists from China and Hong Kong have designed a paper-thin LCD screen that is light and flexible, paving the way for smart daily newspapers that could be uploaded onto the display in real time.

Researchers from Donghua University in Shanghai and Hong Kong University of Science and Technology estimate that the technology would be cheap to produce, costing about USD 5 for a 5-inch screen.

Unlike conventional liquid crystals where electrical connections on the plates create the fields required to switch individual pixels from light to dark, optically rewritable LCDs coat the plates with special molecules that realign in the presence of polarized light and switch the pixels.

Consequently, optically rewritable LCDs are thinner than traditional LCDs, at less than half a millimetre thick, can be made from flexible plastic, and weigh only a few grams.

Optically rewritable LCDs are durable and cheap to manufacture because of their simple structure. Moreover, like an electronic paper screen in an e-book, energy is only required to switch display images or text.

Spacers are used in all LCDs to determine the thickness of the liquid crystal. A constant thickness is necessary for good contrast ratio, response time and viewing angle.

However, when plates bend, it forces the liquid crystal away from the impact site and leaves sections of the screen blank and so alterations in spacer design are critical to prevent liquid crystal in flexible LCDs from moving excessively.

The researchers tried three different spacer designs and found that a mesh-like spacer prevented liquid crystal from flowing when their LCD was bent or hit.

An additional innovation involved improved colour rendering. The scientists report that until this study, optically rewritable LCDs had only been able to display two colours at a time.

Now, their optically rewritable LCD simultaneously displays the three primary colours. They achieved this by placing a special type of liquid crystal behind the LCD, which reflected red, blue and green.

FlexEnable’s glass-free organic LCD (OLCD) delivers high-brightness, long lifetime flexible displays that are low cost and scalable to large areas, while also being thin, lightweight and shatterproof.

OLCD is a plastic display technology with full colour and video-rate capability. It enables product companies to create striking designs and realise novel use cases by merging the display into the product design rather than accommodating it by the design.

Unlike flexible OLED displays, which are predominantly adopted in flagship smartphones and smartwatches, OLCD opens up the use of flexible displays to a wider range of mass-market applications. It has several attributes that make it better suited than flexible OLED to applications across large-area consumer electronics, smart home appliances, automotive, notebooks and tablets, and digital signage.

OLCD can be conformed and wrapped around surfaces and cut into non-rectangular shapes during the production process. Holes can be also added to fit around the functional design of the system – for example around knobs and switches.

As with glass-based LCD, the lifetime of OLCD is independent of the display brightness, because it is achieved through transmission of a separate light source (the backlight), rather than emission of its own light. For example OLCD can be made ultra-bright for viewing in daylight conditions without affecting the display lifetime – an important requirement for vehicle surface-integrated displays.

OLCD is the lowest cost flexible display technology – it is three to four times lower cost that flexible OLED today. This is because it makes use of existing display factories and supply chain and deploys a low temperature process that results in low manufacturing costs and high yield.

Unlike other flexible display approaches, OLCD is naturally scalable to large sizes. It can be made as small or as large as the manufacturing equipment used for flat panel displays allows.

The flexibility of OLCD allows an ultra-narrow bezel to be implemented by folding down the borders behind the display. This brings huge value in applications like notebooks and tablets where borderless means bigger displays for the same sized device. The bezel size allowed by OLCD is independent of the display size or resolution. In addition, OLCD can make a notebook up to 100g lighter and 0.5mm thinner.

OLCD is the key to the fabrication of ultra-high contrast dual cell displays with true pixel level dimming, offering OLED-like performance at a fraction of the cost. The extremely thin OLCD substrate brings advantages in cost, viewing angle and module thickness compared to glass displays. At the same time OLCD retains the flexibility required for applications such as surface-integrated automotive displays.

Due to its unique properties, OLCD has the potential to transform how and where displays are used in products. The videos below give a glimpse into this innovative technology.

OLCD brings the benefits of being thin, light, shatterproof and conformable, while offering the same quality and performance as traditional glass LCDs. The mechanical advantages of plastic OLCD over glass LCD are further enhanced by the technology’s excellent optical performance, much of which originates from the extreme thinness of plastic TAC substrates compared to glass.

STONE Technologies is a proud manufacturer of superior quality TFT LCD modules and LCD screens. The company also provides intelligent HMI solutions that perfectly fit in with its excellent hardware offerings.

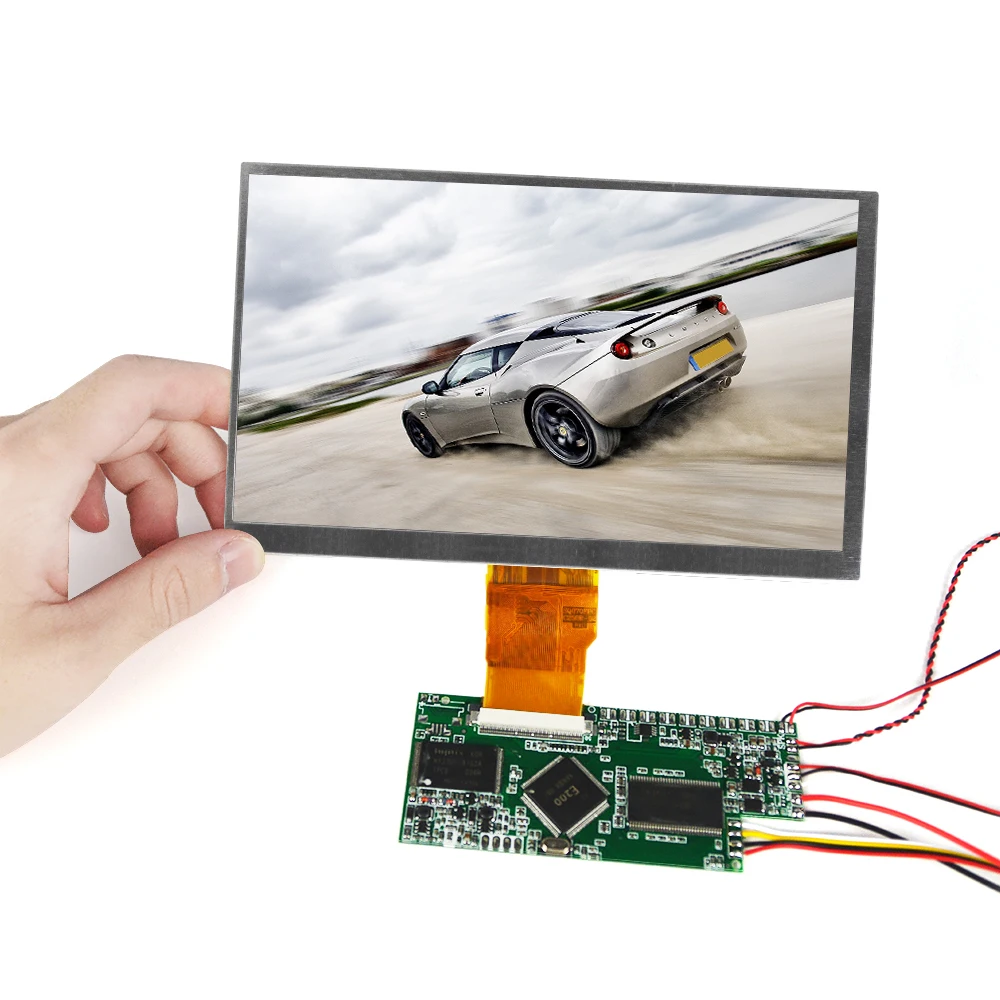

STONE TFT LCD modules come with a microcontroller unit that has a 1GHz Cortex-A8 CPU. Such a module can easily be transformed into an HMI screen. Simple hexadecimal instructions can be used to control the module through the UART port. Furthermore, you can seamlessly develop STONE TFT LCD color user interface modules and add touch control, features to them.

Becoming a reputable TFT LCD manufacturer is no piece of cake. It requires a company to pay attention to detail, have excellent manufacturing processes, the right TFT display technology, and have a consumer mindset.

Now, we list down 10 of the best famous LCD manufacturers globally. We’ll also explore why they became among the top 10 LCD display Manufacturers in the world.

LG Display is a leading manufacturer of thin-film transistor liquid crystal displays (TFT-LCD) panels, OLED, and flexible displays.LG Display began developing TFT-LCD in 1987 and currently offers Display panels in a variety of sizes and specifications using different cutting-edge technologies (IPS, OLED, and flexible technology).

With innovative and differentiated technologies, QINNOOptoelectronics provides advanced display integration solutions, including 4K2K ultra-high resolution, 3D naked eye, IGZO, LTPS, AMOLED, OLED, and touch solutions. Qinnooptoelectronics sets specifications and leads the market. A wide range of product line is across all kinds of TFT LCD panel modules, touch modules, for example, TV panel, desktop and laptop computer monitor with panels, small and medium scale “panels, medical, automotive, etc., the supply of cutting-edge information and consumer electronics customers around the world, for the world TFT – LCD (thin-film transistor liquid crystal display) leading manufacturers.

AU Optronics Co., LTD., formerly AU Optronics Corporation, was founded in August 1996. It changed its name to AU Optronics after its merger with UNIOPtronics in 2001. Through two mergers, AU has been able to have a full range of generations of production lines for panels of all sizes.Au Optronics is a TFT-LCD design, manufacturing, and r&d company. Since 2008, au Optronics has entered the green energy industry, providing customers with high-efficiency solar energy solutions.

Sharp has been called the “father of LCD panels”.Since its founding in 1912, Sharp developed the world’s first calculator and LIQUID crystal display, represented by the living pencil, which was invented as the company name. At the same time, Sharp is actively expanding into new areas to improve people’s living standards and social progress. Made a contribution.

BYD IT products and businesses mainly include rechargeable batteries, plastic mechanism parts, metal parts, hardware electronic products, cell phone keys, microelectronics products, LCD modules, optoelectronics products, flexible circuit boards, chargers, connectors, uninterruptible power supplies, DC power supplies, solar products, cell phone decoration, cell phone ODM, cell phone testing, cell phone assembly business, notebook computer ODM, testing and manufacturing and assembly business, etc.

Tianma microelectronics co., LTD., founded in 1983, the company focus on smartphones, tablets, represented by high order laptop display market of consumer goods and automotive, medical, POS, HMI, etc., represented by professional display market, and actively layout smart home, intelligent wear, AR/VR, unmanned aerial vehicles (UAVs) and other emerging markets, to provide customers with the best product experience.IN terms of technology, the company has independently mastered leading technologies such as LTPS-TFT, AMOLED, flexible display, Oxide-TFT, 3D display, transparent display, and in-cell/on-cell integrated touch control. TFT-LCD key Materials and Technologies National Engineering Laboratory, national enterprise Technology Center, post-doctoral mobile workstation, and undertake national Development and Reform Commission, The Ministry of Science and Technology, the Ministry of Industry and Information Technology, and other major national thematic projects. The company’s long-term accumulation and continuous investment in advanced technology lay the foundation for innovation and development in the field of application.

Flat-panel displays are thin panels of glass or plastic used for electronically displaying text, images, or video. Liquid crystal displays (LCD), OLED (organic light emitting diode) and microLED displays are not quite the same; since LCD uses a liquid crystal that reacts to an electric current blocking light or allowing it to pass through the panel, whereas OLED/microLED displays consist of electroluminescent organic/inorganic materials that generate light when a current is passed through the material. LCD, OLED and microLED displays are driven using LTPS, IGZO, LTPO, and A-Si TFT transistor technologies as their backplane using ITO to supply current to the transistors and in turn to the liquid crystal or electroluminescent material. Segment and passive OLED and LCD displays do not use a backplane but use indium tin oxide (ITO), a transparent conductive material, to pass current to the electroluminescent material or liquid crystal. In LCDs, there is an even layer of liquid crystal throughout the panel whereas an OLED display has the electroluminescent material only where it is meant to light up. OLEDs, LCDs and microLEDs can be made flexible and transparent, but LCDs require a backlight because they cannot emit light on their own like OLEDs and microLEDs.

Liquid-crystal display (or LCD) is a thin, flat panel used for electronically displaying information such as text, images, and moving pictures. They are usually made of glass but they can also be made out of plastic. Some manufacturers make transparent LCD panels and special sequential color segment LCDs that have higher than usual refresh rates and an RGB backlight. The backlight is synchronized with the display so that the colors will show up as needed. The list of LCD manufacturers:

Organic light emitting diode (or OLED displays) is a thin, flat panel made of glass or plastic used for electronically displaying information such as text, images, and moving pictures. OLED panels can also take the shape of a light panel, where red, green and blue light emitting materials are stacked to create a white light panel. OLED displays can also be made transparent and/or flexible and these transparent panels are available on the market and are widely used in smartphones with under-display optical fingerprint sensors. LCD and OLED displays are available in different shapes, the most prominent of which is a circular display, which is used in smartwatches. The list of OLED display manufacturers:

MicroLED displays is an emerging flat-panel display technology consisting of arrays of microscopic LEDs forming the individual pixel elements. Like OLED, microLED offers infinite contrast ratio, but unlike OLED, microLED is immune to screen burn-in, and consumes less power while having higher light output, as it uses LEDs instead of organic electroluminescent materials, The list of MicroLED display manufacturers:

LCDs are made in a glass substrate. For OLED, the substrate can also be plastic. The size of the substrates are specified in generations, with each generation using a larger substrate. For example, a 4th generation substrate is larger in size than a 3rd generation substrate. A larger substrate allows for more panels to be cut from a single substrate, or for larger panels to be made, akin to increasing wafer sizes in the semiconductor industry.

"Samsung Display has halted local Gen-8 LCD lines: sources". THE ELEC, Korea Electronics Industry Media. August 16, 2019. Archived from the original on April 3, 2020. Retrieved December 18, 2019.

"TCL to Build World"s Largest Gen 11 LCD Panel Factory". www.businesswire.com. May 19, 2016. Archived from the original on April 2, 2018. Retrieved April 1, 2018.

"Panel Manufacturers Start to Operate Their New 8th Generation LCD Lines". 대한민국 IT포털의 중심! 이티뉴스. June 19, 2017. Archived from the original on June 30, 2019. Retrieved June 30, 2019.

"Samsung Display Considering Halting Some LCD Production Lines". 비즈니스코리아 - BusinessKorea. August 16, 2019. Archived from the original on April 5, 2020. Retrieved December 19, 2019.

Herald, The Korea (July 6, 2016). "Samsung Display accelerates transition from LCD to OLED". www.koreaherald.com. Archived from the original on April 1, 2018. Retrieved April 1, 2018.

"China"s BOE to have world"s largest TFT-LCD+AMOLED capacity in 2019". ihsmarkit.com. 2017-03-22. Archived from the original on 2019-08-16. Retrieved 2019-08-17.

LG Display has developed a prototype LCD panel for television sets that"s less than a quarter the thickness of the company"s current production panels. The new screen could enable TV set makers to produce even thinner flat-panel sets but there are no current plans for mass production.

The 42-inch panel, which is still a prototype, measures 2.6-millimeters thin. That"s half the thickness of LG Display"s previous thinnest prototype panel, a 5.9mm model that was unveiled in May, and much thinner than its current thinnest production panel, which is 11.9mm thin.

LCDs require a light source to illuminate the displayed image and this is typically provided by a backlight panel that sits behind the screen. Placing it behind the screen makes the overall LCD module thicker so LG Display has placed multiple LED lights around the edge of the screen so they shine light into the panel. It makes the overall module wider and taller but helps keep it as thin as possible.

The company said its new 5.2-inch (132 mm) display panel has a resolution of 1,080 x 1,920 pixels and is brighter than current full HD phone panels on the market. LG did not reveal when the panel will become available on the market, but showed images of it working and said its results had been independently verified by testing firm Intertek. LG Display said the screen"s bezel is a fraction thicker at 2.3 mm.

LG said it has used a new in-house technology it calls "Advanced One-Glass-Solution." One-glass solution technology, or OGS, puts the touch screen layer of a display directly onto the underside of the cover glass, combining the two. This eliminates the need for a separate touch-screen layer and allows more light through. It also has the potential to make manufacturing simpler and save costs.

Displays, batteries and camera modules are among the thickest components in smartphones. Slim designs and low weight have proven to be major motivators for consumers for consumers, and so manufacturers are eager to flatten their devices. The display and touch screen together make up the most expensive component on a smartphone, followed by NAND flash memory and the main processor.

Last month, China"s Huawei announced it will soon launch the world"s thinnest smartphone, the Ascend P6, which is just 6.18 mm thick. Apple"s iPhone 5 is 7.6 mm thick, while Samsung"s Galaxy S4 measures 7.9 mm.

Our new line of 10.1” TFT displays with IPS technology are now available! These 10.1” IPS displays offer three interface options to choose from including RGB, LVDS, and HDMI interface, each with two touchscreen options as capacitive or without a touchscreen.

The new line of 3.5” TFT displays with IPS technology is now available! Three touchscreen options are available: capacitive, resistive, or without a touchscreen.

In both LCD and OLED displays, producing these cells – which are highly complex – is by far the most difficult element of the production process. Indeed, the complexity of these cells, combined with the levels of investment needed to achieve expertise in their production, explains why there are less than 30 companies in the whole world that can produce them. China, for instance, has invested more than 300 billion yuan (approximately $45 billion USD) in just one of these companies – BOE – over the past 14 years.

Panox Display has been involved in the display industry for many years and has built strong and long-term partner relationships with many of the biggest OLED and LCD panel manufacturers. As a result, we are able to offer our clients guaranteed access to display products from the biggest manufacturers.

Founded in 2001, AUO – or AU Optronics – is the world’s leading TFT-LCD panel manufacturer (with a 16% market share) that designs, develops, and manufactures the world’s top three liquid crystal displays. With panels ranging from as small as 1.5 inches to 46 inches, it boasts one of the world"s few large-, medium -and small-sized product lines.

AUO offers advanced display integration solutions with innovative technologies, including 4K2K ultra-high resolution, 3D, ultra-thin, narrow bezel, transparent display, LTPS, OLED, and touch solutions. AOU has the most complete generation production line, ranging from 3.5G to 8.5G, offering panel products for a variety of LCD applications in a range of sizes, from as small as 1.2 inches to 71 inches.

Now Sharp is still top 10 TV brands all over the world. Just like BOE, Sharp produce LCDs in all kinds of size. Including small LCD (3.5 inch~9.1 inch), medium LCD (10.1 ~27 inch), large LCD (31.5~110 inch). Sharp LCD has been used on Iphone series for a long time.

Beside those current LCDs, the industrial LCD of Sharp is also excellent and widely used in public facilities, factories, and vehicles. The Sharp industrial LCD, just means solid, high brightness, super long working time, highest stability.

Truly’s factory in Shanwei City is enormous, covering an area of 1 million square meters, with a net housing area of more than 100,000 square meters. It includes five LCD production lines, one OLED production line, three touch screen production lines, and several COG, LCM, MDS, CCM, TAB, and SMT production lines.

Its world-class production lines produce LCD displays, liquid crystal display modules (LCMs), OLED displays, resistive and capacitive touch screens (touch panels), micro camera modules (CCMs), and GPS receiving modules, with such products widely used in the smartphone, automobile, and medical industries. The LCD products it offers include TFT, TN, Color TN with Black Mark (TN type LCD display for onboard machines), STN, FSTN, 65K color, and 262K color or above CSTN, COG, COF, and TAB modules.

In its early days, Innolux attached great importance to researching and developing new products. Mobile phones, portable and mounted DVD players, digital cameras, games consoles, PDA LCDs, and other star products were put into mass production and quickly captured the market, winning the company considerable market share.

Looking forward to the future, the group of photoelectric will continue to deep LCD display field, is committed to the development of plane display core technology, make good use of global operations mechanism and depth of division of labor, promise customers high-quality products and services, become the world"s top display system suppliers, in 2006 in the global mobile phone color display market leader, become "Foxconn technology" future sustained rapid growth of the engine.

The company has three LCD factories and one LCM factory. It has acquired state-of-the-art TFT-LCD manufacturing technology, which enables it to achieve the highest efficiency in the mass production of thin-film transistor liquid crystal display production technology. Its customers include many of the biggest and most well-known electronics companies and computer manufacturers in Taiwan and overseas.

Tianma Microelectronics was founded in 1983 and listed on the Shenzhen Stock Exchange in 1995. It is a high-tech enterprise specializing in the production of liquid crystal displays (LCD) and liquid crystal display modules (LCM).

After more than 30 years of development, it has grown into a large publicly listed company integrating LCD research and development, design, production, sales, and servicing. Over the years, it has expanded by investing in the construction of STN-LCD, CSTN-LCD, TFT-LCD and CF production lines and module factories across China (with locations in Shenzhen, Shanghai, Chengdu, Wuhan and Xiamen), as well R&D centers and offices in Europe, Japan, South Korea and the United States.

JDI (Japan Display Inc.) was established on November 15, 2011, as a joint venture between the Industrial Innovation Corporation, Sony, Hitachi, and Toshiba. It is dedicated to the production and development of small-sized displays. It mainly produces small- and medium-sized LCD display panels for use in the automotive, medical, and industrial fields, as well as personal devices including smartphones, tablets, and wearables.

Ms.Josey

Ms.Josey

Ms.Josey

Ms.Josey