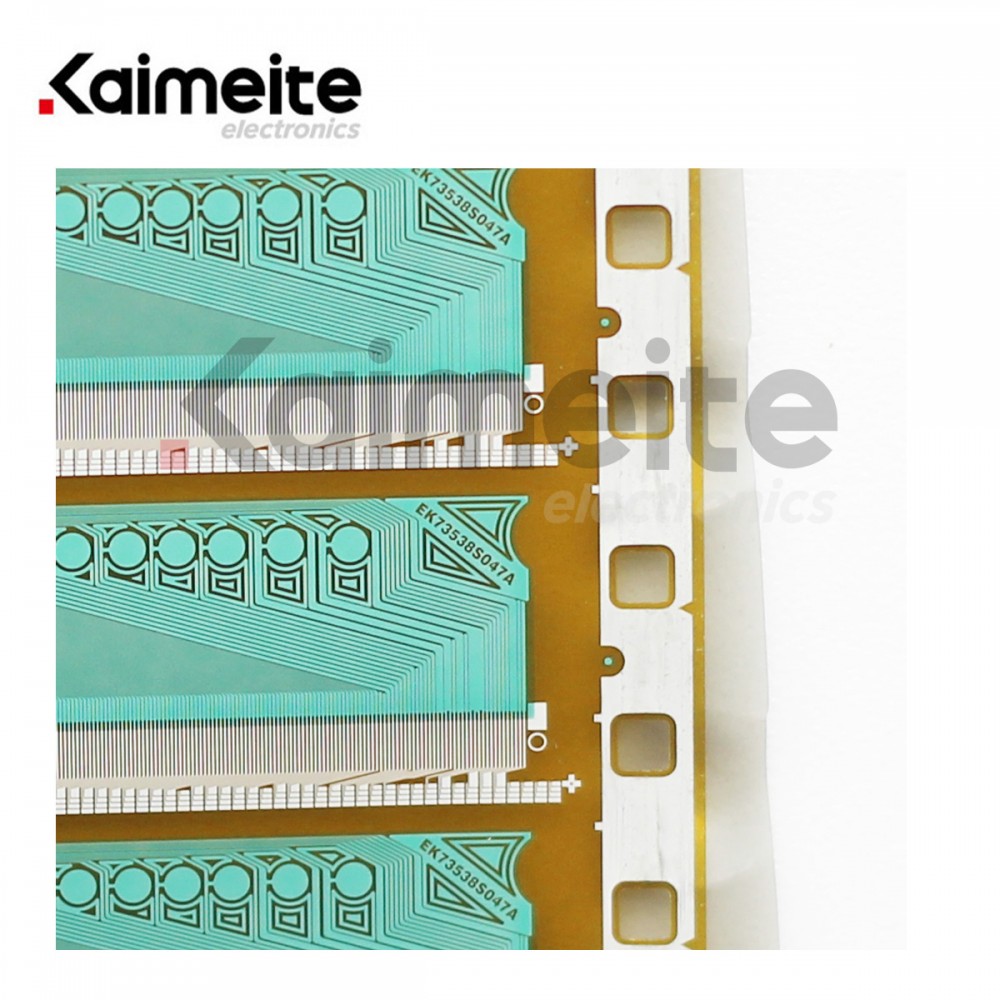

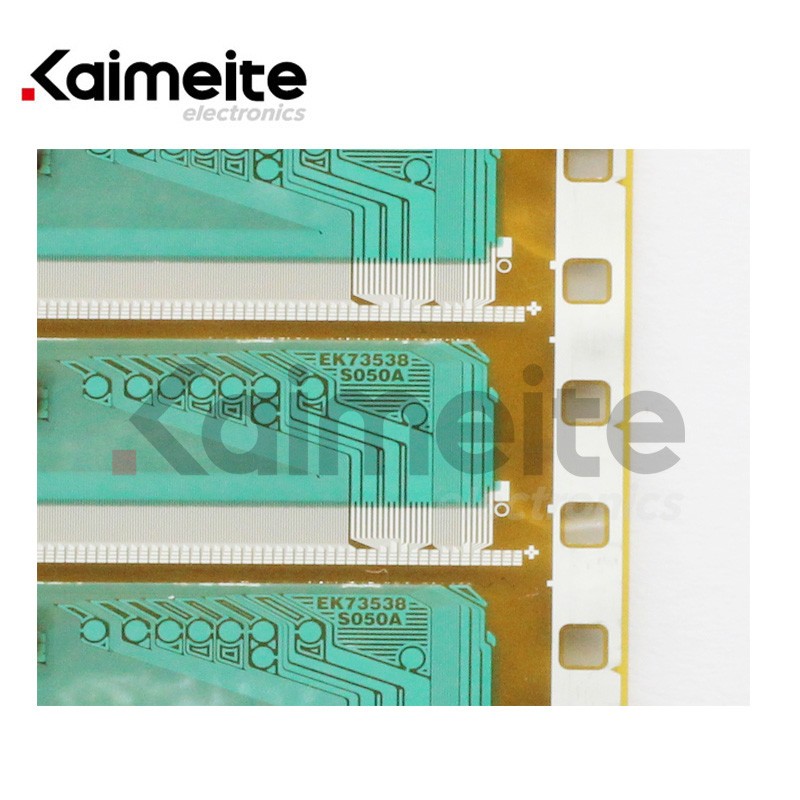

lcd panel side cof data manufacturer

COF IC is the only IC that connects TV PANEL with the T-CON board physically. SO today in this article I will explain full information about COF IC and also tell you how to get and download COF IC datasheet. If you want to know the process of COF IC downloading, read this article very carefully.

You can not COF IC data from the official site of any number COF IC. You already know about me and here I’ll give you Panel COF data downloading link which I get while repairing. And if you do not get your COF data which you need to comment down below. I will update you on the COFdatasheet as soon as possible.

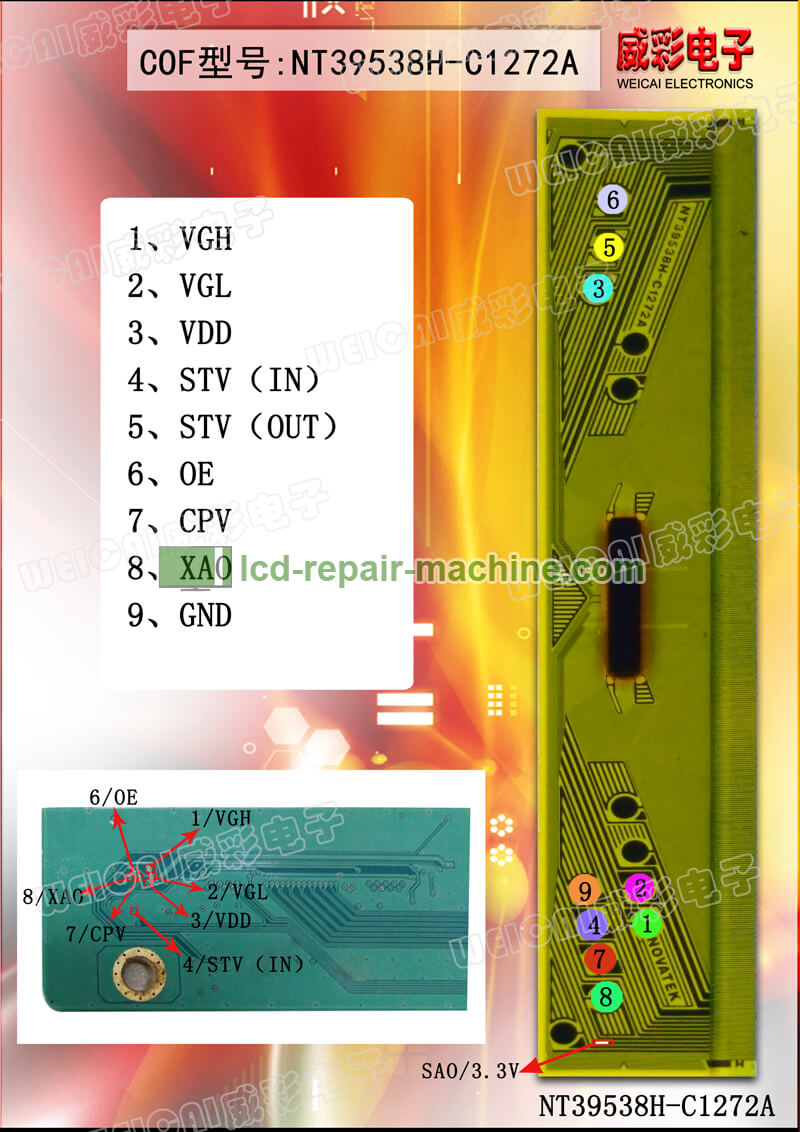

If you are an Electronics technician especially LCD/LED, Definitely you have to know about COF IC. How to work COF IC and working principle of this IC. Also you have to know the voltage value of this IC. If you are interested to know about COF IC voltage value click here and know how many types of voltage has present in this IC.

Every single panel have their own development and manufacturing COF IC. I make a video on this topic and post an article, If you want to see click here.

P.S: With just one television repaired successfully from the help of my“LCD LED Master"s” book, you immediately get your return investment back a few times over, from just one TV repair!"

This article analyzes and introduces Samsung screens, Chi Mei and other screens. It mainly explains the function and composition of the side board, the circuit introduction of the side board (T-CON board), how to identify the representative symbols of the LCD screens of various manufacturers, and the common problems on the side board. Analysis, analysis of maintenance ideas for the side board part and analysis of maintenance cases. 1. The role and composition of the side boardThe information transmission between the main board and the screen body mainly includes the T-CON circuit, the side board and the COF. The latter two are the signal link lines, which are the link between the OC and the PCB, so Focus on the principle and maintenance of T-CON circuit. According to the different manufacturer’s screen design, it mainly includes the following forms:

This is a traditional circuit combination form, a single edge strip is used by most manufacturers, and the failure rate is also the highest, especially for LG’s edge strips, as long as the water enters, the note must be replaced, and the COF will be damaged in serious cases. The LVDS signal generated by the main board is sent to the TCON board for processing and conversion into various control signals (STV, CKV, STH, CKH, POL) and image data signals (RSDS) required. Add to the OC in parallel to present the image.

STV, CKV, STH, CKH, POL and image data signal (RSDS) to the side board, generally use flat cable to enter the side board. Many of the current integrated boards use this form, which brings inconvenience to maintenance.

The faults in the side strips are mainly manifested as: black screen, gray screen, blurred screen, vertical lines on the screen, vertical strips, etc.The main cause of the above-mentioned faults is caused by water in the side strips!

A. Causes of water ingress in the edge strips: Traditional CRT TVs are made of the entire glass cone with no connectors around. The current LCD screens use TAB elements, components, and COF to connect with the PCB board.The user still wipes the screen with a wet cloth like CRT, it is easy to get water in, especially when the LG screen side board is inverted , The sidebar is below, the failure rate is particularly high. As long as the water enters the side board, it will corrode and seriously burn out the COF and OC. Because the user’s home is too tightly sealed and poorly ventilated in winter, it is easy to produce water vapor under the action of heating, which flows to the side along the screen On the board. In summer, under the drive of air conditioning, it is easy to cause water in the edge strips. Especially in the south, it is wet and humid, and the failure rate of the edge strips is higher. Household cleaning is also an important link that causes water to enter the side strips. There are also reasons such as children playing with water guns and installing TVs under the air conditioner, etc., which may cause water to enter the screen.

The maintenance idea of the side board part analyzes the gray screen, black screen or abnormal screen light-emitting maintenance methods: when the LCD screen has the edge strips, the main manifestations are the following situations: 1. The TV can be watched normally, but occasionally the grating side is bad. The phenomenon can be normal in an instant, and it is generally difficult to find. 2. The left or right grating appears on the TV screen. .3. The backlight is bright and the screen is not bright. Maintenance method: For the fault that the backlight is bright and the screen is not bright, you should first measure whether the logic board LVDS power supply 12 volts is normal. There are two situations at this time: (1) Normal. (2) The fuse has blown. If 12 volts is normal, you should measure the relevant voltages such as VCOMVGH, VGL, and focus on measuring the output voltage VG1-VG21. If it is still abnormal, the logic board is damaged. If it is normal, there is no doubt that water has entered the side board. For the open circuit fault of the fuse on the logic board, it is not allowed to replace the fuse or directly short-circuit with a wire. The resistance value of the two ends of the fuse to the ground should be measured. If there is a short-circuit to ground, please check the cause. If the resistance to ground is large, it means that there is no short-circuit problem. You should disconnect the flexible cable between the logic board and the edge strip and replace the fuse. If it is normal at 12 volts, it means the LCD screen Water in. At this time, you can connect the two flexible cables from the logic board to the side board only one way to determine the position of the water inlet.

1. #Confirm whether the COF on side X is hot compared with the normal temperature, whether there is fracture or wear crack, and whether the COF is burnt.

2. #Confirm whether the VAA is normal (normally about 17V). If abnormal, disconnect the RP32 to confirm whether it is caused by DC/DC loop or X-side COF: disconnect RP32, if the VAA is normal, the COF is bad, CO must be changed; COF can be Disconnect one by one to determine which NG disconnects RP32, VAA NG, try to change UP1; at the same time, confirm whether the continuity of the surrounding triode is OK.

3. #Confirm whether the RSDS value is correct, normal RSDS is about 1.2v, and the signal difference is about 200mV; At the same time, we can confirm the resistance between RSDS signal (normal 100 or 50 ohms) and RSDS resistance to ground. If the voltage is NG, check if the ASIC and X-COF are hot.

2. #Confirm VGH/VGL voltage (about 30V VGH and -6v VGL), and confirm whether it is DC/DC loop NG or COF IC NG; The corresponding resistance of disconnected VGH and VGL can determine whether it is a DC/DC problem or a COF-IC problem. If it is DC/DC NG, try to replace UP1 or confirm whether the corresponding transistor is OK.

3. #Confirm whether the gate IC is OK. There is a signal test point on the back of COG IC, which can scrape the green paint for measurement confirmation; Or cut COF halfway from G3. If there is a gate-ic problem, which IC fault can be confirmed.

B. Confirm VAA resistance to ground at VAA test point of R plate (A short circuit usually occurs), disconnect the corresponding capacitance of the following 3 COF, and confirm VAA resistance to the ground again. If OK, replace the capacitor, if NG, replace COF. If VAA is still NG, confirm DC/DC loop as all models.

3. #Shaking module, if vertical lines disappear or reappear, then it can be judged that the possible cause is COF pin broken, and the crease should be found under the OM microscope.

4. #Press the LCD glass side of the panel, if the vertical lines disappear or reappear, it can be judged that the cause of poor contact, OM checking should be able to find the poor contact.

5. #If there is no display change in pressing, confirm whether ITO is damaged under the OM microscope, or pin signal waveform corresponding to needle COF.

The above is the full text of LCD screen failure repair guide, we hope it is helpful to you. If you need to buy LCD and find a reliable LCD supplier, we suggest you to read our other great blog – How to find a reliable LCD supplier.

Founded in 2014, VISLCD is a professional LCD supplier. We provide LCD modules, touch LCD and customized LCD in various sizes with stable quality and competitive price. Welcome to contact us for any LCD demand, thank you.

This website is using a security service to protect itself from online attacks. The action you just performed triggered the security solution. There are several actions that could trigger this block including submitting a certain word or phrase, a SQL command or malformed data.

TAB/COF/COG Bonding Machine : We have VD-680-PS tab/COF/COG bonding machine . This machine is famous across the world . We have also VD512 laser lcd repair machine . All the machine are highly popular and designed with latest technologies . Our latest machine VD512 can repair screens without any consumables needed.

I have two LCD one of Panasonic 32 inches its panel was damaged last 5 days and 2nd one 32 inches Samsung LCD in this problem is from the 2-3 inches upper side shows black n white with one horizontal line in the panel.this is repairable or not. My no-9899702493,9999000471

i have a cracked LCD panel from a LG 43LF510V . Screen model is HC430DUN-SLNX1 How much would it kost to ship in Italy ? In euro please. Thank you very much.

Used to describe a clocked parallel TFT connection that uses 18 data lines (6 for Red, 6 for Green, 6 for Blue) as well as Hsync, Vsync, data enable, and pixel clock to transfer data to the TFT. Theoretical color depth is 218 or 262,144 colors.

Used to describe a clocked parallel TFT connection that uses 24 data lines (8 for Red, 8 for Green, 8 for Blue) as well as Hsync, Vsync data enable, and pixel clock to transfer data to the TFT. Theoretical color depth is 224or 16,777,216 colors.

6800 is a parallel interface that uses Read/Write signal and an Enable signal to control the data bus. Communications with a display are only enabled when the enable signal is pulled high. The level of the Read/Write signal then determines whether data will be read from the display or written to the display. If the Read/Write signal is high, data will be read from the display whereas if the Read/Write signal is low, data will be written to the display. Sometimes the Write will be shown as a “notted” signal. For instance, there may be a bar over the name, a preceding exclamation mark, slash, or dash. While this looks like negation notation, in this context it simply means the signal is active low.

In theory, a material that perfectly reflects all light energy at every visible wavelength. In practice, a solid white (with known spectral data) that is used as the “reference white” for all measurements of absolute reflectance.

A liquid crystal display structure in which switching transistors or diodes are attached to each pixel to control the on/off voltage. It produces a brighter and sharper display with a broader viewing angle than a passive matrix display. Also known as AMLCD (active matrix liquid crystal display). See TFT (thin film transistor).

A/D or ADC converters must be used to process, store, or transport virtually any analog signal in digital form. TV tuner cards, for example, use fast video analog-to-digital converters. On-chip 8, 10, 12, or 16 bit analog-to-digital converters are common in microcontrollers. Digital storage oscilloscopes need very fast analog-to-digital converters. ADC converters are integral to current music reproduction technology. They are needed to create the pulse-code modulation (PCM) data streams that go onto CDs and digital music files.

This is often described as a matte coating as it is non-reflective to the user since it diffuses rather than reflects ambient light. It provides a method for manufacturers to avoid glare on the viewing surface from other light sources and has been used in the LCD monitor market for many years since the first TFT displays started to emerge. The matte coating is included as an outer polarizing later which has been coarsened by mechanical or chemical processes. This achieves a surface coating which is not smooth and so can diffuse ambient light rather than reflect it.

An adhesive is applied between the display and touch panel using the inactive area around the perimeter of the module. This bonding method results in some inactive space ‘air gap’ between the touch panel substrate and the display. This is the most cost-effective and common solution.

An anti-reflection (AR) coating is a type of optical coating applied to the surface touch panel to reduce reflection. Many coatings consist of transparent thin film structures with alternating layers of contrasting refractive index. Layer thicknesses are chosen to produce destructive interference in the beams reflected from the interfaces, and constructive interference in the corresponding transmitted beams.This makes the structure’s performance change with wavelength and incident angle, so that color effects often appear at oblique angles. Good performance can often be achieved for a relatively wide range of frequencies: usually a choice of IR, visible, or UV is offered.

A backlight is used behind the LCD glass to allow the LCM to be read in dark conditions. The vast majority of backlights are now LED. Historically there were also EL (electroluminescent) and CCFL (Cold Cathode Fluorescent Light) backlights, but as LED efficiency has increased and cost has decreased, EL and CCFL backlights have all but disappeared.

A frame of plastic or metal, fitting over the LCD glass, to protect the edges of the glass and actas a pressure device, compressing the elastomer connector between the PCB and LCD glass.

BGA stands for Ball Grid Array. A type of high-density electronic component package for integrated circuits. The BGA has solder balls on its backside, which line up with corresponding contacts on the front side of the PCB.The part and PCB are heated until the solder balls melt.

Normally an LCD’s backlight is set to the brightness that will make a white pixel fully illuminated. CABC automatically dims the backlight to the lowest level required for the brightest pixel on the display.

Character LCDs include a fixed CGROM to define the bulk of the characters they display. However, since the CGROM cannot be changed the designers also included the CGRAM — a small number of characters (typically 8) that can be redefined at run-time. These eight characters are usually mapped to characters 0DEC (0x00HEX) to 7DEC (0x07HEX). The CGRAM definitions can be used to make small animations, bar graphs, and similar small graphic or sprite images. This term very likely has its beginning in the granddaddy of all LCD controllers, the venerable Hitachi HD44780.

The CGROM stores the font that is displayed on a character LCD. When you tell a character LCD to display the letter ‘A’, it needs to know which dots to turn on so that we see an ‘A’. This information is stored in the CGROM. By definition, (since it is a ROM) the font that is stored in the CGROM cannot be changed. Be sure to check the datasheet of the character LCD module to make sure that it can display the characters you need. Typically, a CGROM for a character display module has 240 characters defined. The lower half of the CGROM maps to the normal ASCII characters. Since the early character display controllers were designed in Japan, many CGROM have Japanese characters in the upper 128 positions. There are also some CGROMs that have European or Cyrillic characters in these upper locations.

The WS0010 is a more modern character OLED controller, and the designers have included several CGROMs that can be chosen at run-time, so there is not the need to lock in a particular character set at design time. Since the CGROM is completely determined at the time of manufacture of the LCD controller, the designers also included a CGRAM, which allows the bitmaps of a few characters to be redefined at run-time. This term very likely has its beginning in the granddaddy of all LCD controllers, the venerable Hitachi HD44780).

A capacitive touchscreen panel consists of an insulator such as glass, coated with a transparent conductor such as indium tin oxide (ITO). As the human body is also an electrical conductor, touching the surface of the screen results in a distortion of the screen’s electrostatic field,measurable as a change in capacitance. Different technologies may be used to determine the location of the touch. The location is then sent to the controller for processing.

The Display Data RAM holds the letters that get shown on the LCD of a character LCD module. For instance, the letter ‘A’ is stored in its ASCII equivalent 65DEC (0x41HEX) in the DDRAM.

So a 20×2 character LCD would have enough DDRAM to store 40 letters. The value in the DDRAM is used to find the correct bitmap in the CGROM (Character Generator ROM) or CGRAM (Character Generator RAM), it is this small bitmap that gets displayed on the LCD. This term very likely has its beginning in the granddaddy of all LCD controllers, the venerable Hitachi HD44780.

Translucent material used for light diffusion placed between backlight lighting sources and the back side of an LCD. This material will create a more uniform backlight for an LCD from several unique sources of light.

Apple has been granted a patent in 2011 that describes a method for fabricating thin DITO (Double-Sided Indium Tin Oxide) or SITO (Single-Sided Indium Tin Oxide) touch sensor panels with a thickness less than a minimum thickness tolerance of existing manufacturing equipment. In one embodiment, a sandwich of two thin glass sheets is formed such that the combined thickness of the glass sheets does not drop below the minimum thickness tolerance of existing manufacturing equipment when a thin film process is performed on the surfaces of the sandwich during fabrication. The sandwich may eventually be separated to form two thin SITO/DITO panels.

Another fabrication process involves laminating two patterned thick substrates, each having at least the minimum thickness tolerance of existing manufacturing equipment. One or both of the sides of the laminated substrates are then thinned so that when the substrates are separated, each is a thin DITO/SITO panel having a thickness less than the minimum thickness tolerance of existing manufacturing equipment.

EMI is disturbance that affects an electrical circuit due to either electromagnetic induction or electromagnetic radiation emitted from an external source. The disturbance may interrupt, obstruct, or otherwise degrade or limit the effective performance of the circuit. These effects can range from a simple degradation of data to a total loss of data. The source may be any object, artificial or natural, that carries rapidly changing electrical currents.

Refers to a graphic controller from Bridgetek/FTDI. EVE graphic controllers are easy to use and can control the display, touch, backlight, and audio features of an embedded system, with each appearing to the host MCU as a memory-mapped SPI device. The host MCU sends commands and data using SPI protocol. EVE modules accept high level commands, simplify writing images and fonts (included angled fonts) on TFTs. Fonts, buttons, and tables can each be easily sent to a TFT using a one-line command.

A silicone rubber strip made up of sequentially spaced conductive and non-conductive material. A thin conductive material used to make connections between an LCD and a PC board.

A dead short is created when excess DC voltage is applied to an LCD. Conductive particles from one piece of glass are transferred through the liquid crystal fluid and deposited on the conductive surface of the opposite piece of glass.

The space left between the epoxy seals on one end of the LCD glass after assembly. This space,used to fill the glass with the liquid crystal fluid, is noted by a mound of epoxy.

An LCD construction technique where the cell geometry is optimized for maximum contrast and viewing angle. The geometry is different for each LCD fluid.

The advantages of GFF are low capital cost, suitable for small quantity batch production, and light structure. GG is suitable for mass production and has better appearance properties, but it has high investment costs and is heavier than film-based panels.

HDMI means it is able to send a lot of data, very quickly. However, HDMI isn’t an analog communication like VGA, S-Video or parallel like 24-bit or 18-bit RGB TFTs. HDMI is actually a high-speed serial interface using a fancy TMDS (Transition Minimized Differential Signaling) protocol.

In a typical I2C application, there will be one master, and one or more slaves. The specification allows for multiple masters, but this is not common in the field. I2C has two signals: SCL: Serial Clock; SDA: Serial Data. The I2C transfer includes an address, so multiple slaves can exist on the same I2C bus.

Typically, both the master and slave are implemented in hardware. The I2C master can be implemented in software quite easily, but it can be rather difficult to meet the timing requirements of I2C in a software slave implementation. As micro controllers continue to get faster, writing an I2C software slave will become easier. The I2C standard is pretty well defined, so there is not a huge amount of variation in I2C as it is implemented on LCD, capacitive touch and OLED controllers.

An in-cell display is a touch display in which the touch sensors are embedded within the screen. Traditional capacitive touchscreens have multiple layers of glass, including a capacitive touchscreen layer. In-cell displays eliminate the need for these external touch panel. This results in a thinner and lighter display than a comparative display with an external touch panel, enabling a sleeker final product for devices using an in-cell display.

An LCD is composed of two pieces of glass with a thin layer of liquid crystals between the glass layers. When a voltage is applied to the glass, the orientation of the crystals can be changed. This change in the crystal’s orientation (called polarization) will make either a dark or a light area, creating a character or image on the display.

A twisted nematic LCD design where the backlight is blocked when pixels are in the unselected state. Therefore, when no voltage is applied, the screen is black.

A twisted nematic LCD design where light is transmitted when pixels are in the unselected state. Therefore, when no voltage is applied, the screen is white.

OCA is also called dry bonding. Optical bonding, including LOCA (Liquid Optically Clear Adhesive) and non-liquid OCA tape, are used in a wide range of electronic equipment – especially those with touch panels. The adhesive is used to bond the touch panel to the main liquid crystal display, and also to bond any protective cover, such as the lens, to the touch panel. The adhesive is then cured onto the device through UV, heat, moisture, or a combination of these three methods, depending on the manufacturer and specifications. Major applications include capacitive touch panels, 3D televisions (3D TV), and glass retarders.

Optical bonding improves the optical performance of the display. It eliminates the air gap between the cover glass and the LCD, and usually includes an anti-reflective (A/R) coating (as well as anti-smudge and anti-glare treatments on the cover glass). Optical bonding improves the contrast ratio by reducing the amount of reflected light, thus improving the viewability of the LCD screen. This is especially important in outdoor.

Besides the optical advantages, bonding a sheet of glass to the LCD also improves the durability of the display. It can resist scratches, condensation, and has an improved range of operating temperatures. As touchscreen devices become ubiquitous in consumer markets, this increased ruggedness becomes even more important. Also, by reducing the light loss due to reflection, the battery life of the device can be extended as the device does not need as much backlight to power the display.

On-Cell Touch (OCT) technology permits the Projected Capacitive (PCAP) touch sensor layer to be built into the LCD structure. With this integrated structure, the touch functionality is embedded within the display itself rather than a separate touch screen component on top of the display. The reduction in the number of layers also reduces parallax errors providing a superior touch interface. Fewer layers also means backlight intensity can be reduced while providing the same brightness level. The usual multitouch display has an 88% transparency while an OCT display is 93%. This helps reduce lighting power requirements and extends battery life.

For optical bonding optically clear adhesive is applied over the entire surface between the display assembly and touch panel. This bonding method removes all air and air bubbles from the viewing area providing a more rugged and optically attractive solution. Removal of ‘air gap’ between the module and touch panel eliminates surface-to-surface reflections which degrade contrast and ultimately viewing angles, especially significant in sunlight conditions.

This is memory that may be written to some value, then later read. RAM is the normal memory in a computer system. RAM only holds data when the RAM is powered. If power is interrupted, the data stored in the RAM is lost.

A resistive touch screen is made of two transparent layers of glass or plastic, each coated with a conducting layer of Indium Tin Oxide (ITO). The conducting sides face one another and are separated by an air gap. When pressure is applied by the user, the top layer bends and touches the bottom layer. This causes a small amount of current to flow at the point where they connect. The location of the touch event can then be measured by the sensors.

A technique where the alignment layer (Polyimide) on the LCD substrate is rubbed in one or more directions. This process aligns the liquid crystal molecules parallel to the buffing direction.

SPI is a simple serial bus that is often used by LCD or OLED controllers. SPI as implemented for OLED and LCD controllers typically uses a “3-wire SPI” or “4-wire SPI” scheme. SPI was originally championed by Motorola (now Freescale). In its original “pure” form SPI uses four signals:

TFTs are also known as “Active Matrix TFT LCD modules” and have an array of these thin film transistors fabricated on the glass that makes the LCD. By using this active transistor-per-pixel architecture, the contrast of each pixel is good, allowing bright full-color, full motion images to be displayed.

VA is also called VTN, PMVA, GDV, etc. it is a type of LCD in which the liquid crystals naturally align vertically to the glass substrates. When no voltage is applied, the liquid crystals remain perpendicular to the substrate, creating a black display between crossed polarizers. When voltage is applied, the liquid crystals shift to a tilted position, allowing light to pass through and create a gray-scale display depending on the amount of tilt generated by the electric field. VA displays have a deeper-black background, a higher contrast ratio, a wider viewing angle, and better image quality at extreme temperatures over traditional twisted-nematic displays.

COF Points Detect Data for LCD LED TV Panel Part 1 Very Soon Upload Parr2 for more details please visit our website. Subscribe our channel for more informat...

Ms.Josey

Ms.Josey

Ms.Josey

Ms.Josey