white lines on a tft display supplier

Alibaba.com features an exciting range of white lines lcd screen that are suitable for all types of residential and commercial requirements. These fascinating white lines lcd screen are of superior quality delivering unmatched viewing experience and are vibrant when it comes to both, picture quality and aesthetic appearances. These products are made with advanced technologies offering clear patterns with long serviceable lives. Buy these incredible white lines lcd screen from leading suppliers and wholesalers on the site for unbelievable prices and massive discounts.

The optimal quality white lines lcd screen on the site are made of sturdy materials that offer higher durability and consistent performance over the years. These top-quality displays are not only durable but are sustainable against all kinds of usages and are eco-friendly products. The white lines lcd screen accessible here are made with customized LED modules for distinct home appliances and commercial appliances, instruments, and have elegant appearances. These wonderful white lines lcd screen are offered in distinct variations and screen-ratio for optimum picture quality.

Alibaba.com has a massive stock of durable and proficient white lines lcd screen at your disposal that are worth every penny. These spectacular white lines lcd screen are available in varied sizes, colors, shapes, screen patterns and models equipped with extraordinary features such as being waterproof, heatproof and much more. These are energy-efficient devices and do not consume loads of electricity. The white lines lcd screen you can procure here are equipped with advanced LED chips, dazzling HD quality, and are fully customizable.

Save money by browsing through the distinct white lines lcd screen ranges at Alibaba.com and get the best quality products delivered. These products are available with after-sales maintenance and are also available as OEM orders. The products are ISO, CE, ROHS, REACH certified.

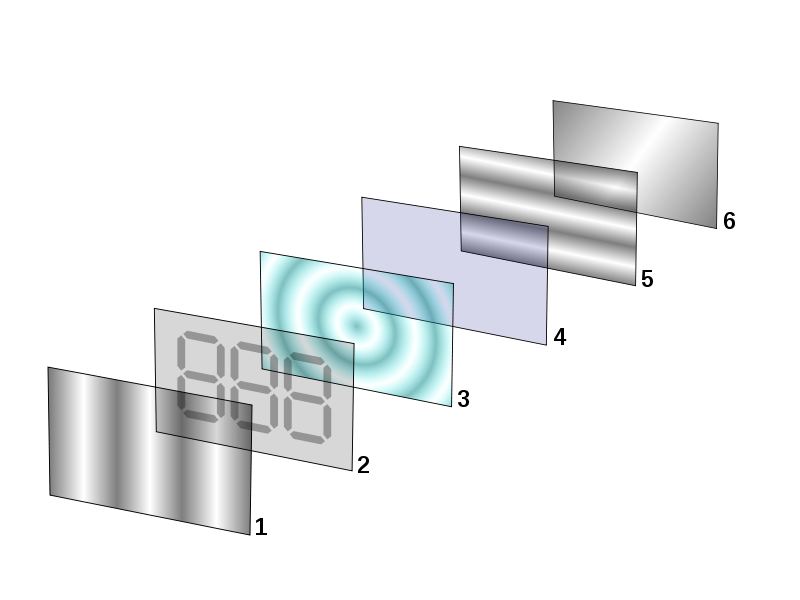

The basic feature of the liquid crystal is the ability to twist on 45 degrees or 90 degrees, relative to the axis of the particles arranged in parallel between both electrode surfaces.

In LCD the light transit through two polarizers, which are arranged perpendicular, then through the liquid crystal layer. The layer can block the transition of the light or change polarization. Finally, the light falls on the color filters, which give it a set colorcreating the image.

The LCD TFT screens are built of thin-film transistors. The transistor is produced by chemical vapor deposition (CVD), based on the use of liquid hydrogen mixture and silicon mixture in an organic solvent, and using the rotation application method of the thin semiconductor.

In the TFT matrix, each pixel is controlled by four transistors, whereone of them is responsible for brightness, and three remain for basic color (red, blue, green). As a result, this solution allows the high resolution, better color and generally higher parameters of displayed images – comparing to common LCD matrix.

Because of the material the TFT is built from, which isglass, TFT displays havelow mechanical toughness,so can be easily damaged. The most popular damage of TFT is:

The horizontal lines on the screen (Fig. 3) may indicate an interruption of the ITO lines, which control the transistors. In most cases the whole line of the transistors would be interrupted, therefore the defects are observed as a line.

The majority of damage occurs during the assembly process in the end user devices. Too much pressure on the fragile TFT construction can damage the structure of the liquid crystal or electric lines.

We recommend that you are always careful during the process of assembling the module. This special treatment is necessary to protect the matrix of the display against being hit or put under too much pressure.

The module can be held strictly by the housing, and the unnecessary thrust on display should be avoided. The disassembling of the display housing is not recommended, because this process is very destructive and in most cases, it will leave you with a damaged TFT .

I have been working with a variety of TFTs as of late from different suppliers from 2.4" to 7". I have an issue with a current set up that just has me puzzled.

Sainsmart TFT mega shield V1.0 (elecfreaks is the same board as far a pins and resistors, but better documents) http://www.elecfreaks.com/store/lcd-tft01-mega-shield-v10-p-214.html

I generally begin with the UTFT library and for the SSD1963 use the Demo 480x272 UTFT myGLCD(ITDB43,38,39,40,41);. I understand this is not a named supported display but the SSD1963 is supported in the screen size. It is possible my initialization should be different?

When powered via USB or wallwart the screen performs the clr.scrn command, visually wiping the screen left to right, occasionally it will show the sine wave of the demo, and then the screen develops white lines that run through the screen vertically then, slowly (4 seconds) fades to white.

There’re more than 300 procedures to produce TFT LCD. The most advanced LCD, in which the array and cell process are highly automatic. Technically, every step in the process can lead to defects, and most of the defects have been eliminated through the development of TFT LCD technology.

In the LC filling process, if the quantity of LC injected is not enough, the spare space will form bubbles. And loose LC containing sealant will result in LC leakage.

Point defect is a kind of defect that some point on your screen don’t display correctly. There are mainly three situations: the point keeps displaying black or whitewhen the screen is working or the point can only display a single color.

For the first two situations, that’s because the circuit on the TFT and CF controlling that defective pixel point is shorted or broken. While the third situation is caused by damaged color pixel.

The production of the circuit and color pixel is under micro scale, and the technology is similar to semiconductor technology. Hundreds of thousands micro materials will be printed during the production process, you can understand some of the materials not being printed correctly, which result in the point defect.

Unlike point defect, this larger scale defect is caused by the failure of external FPC or PCBA, or a bad connection between FPC and cell. Therefore, a bunch of pixels connected to these IC are out of control, and we see those defects.

Usually, assembly of cell and IC is under heat and should be positioned accurately. Problems with IC connection will be checked out very soon, followed by the adjustment on machine parameter.

In LCD, newton’s rings may occur on screen when two glass substrate haven’t been sealed well, so that one of the glass may form a convex lens and lead to light interference.

To avoid this problem, we have to pay attention to the gap distance parameter in sealing process. By the way, newton’s rings has became a method to exam the glass sealing process in reverse .

The black matrix on CF glass or a additional shield bar is used to avoid this problem. So if this problem occurs, we have to check the CF deposition process.

You may notice there are some screens have uneven display, which means some white area appears in dark picture or vice versa. We call this ‘mura’, a word originated from Japanese.

Mura is very common but it doesn’t affect the screen function severely, however it still bring bad look. Hence, many high end display manufacturers have their own standards of mura, and the displays without mura are of the best quality.

Among the causes listed, thickness of the whole cell is the most critical one, and there are many factors related to that. Researches provide a lot of advice to adjust the thickness of the whole cell:

Note: We do not own the images used in this post. Feel free to contact us if they belong to you, and we’ll take them down as quickly as we possibly can.

Vertical lines appearing on LCD screen is very common. Whether the screen belongs to a laptop computer or desktop PC, mobile phone, or even a television, the fault is usually due to the ribbon cable and its connections.

A faulty ribbon cable can cause all sorts of havoc manifesting in bright vertical lines. Sometimes they can be coloured lines such as blue, green, grey, black, and red. The lines can appear thick or thin and on just one-half of the screen. Sometimes the fault will manifest as two vertical white lines. You can even get horizontal lines as well.

If you have lines appearing on the LCD screen, then the first simple thing to check is the seating of the ribbon cable that connects the display panel to the motherboard. Most of the time, the fault is with the poor connection made by the ribbon cable.

One of the most common problems with ribbon cables is oxidation of the contacts. It can happen either on the ribbon cable contacts or on the socket contacts. Manufacturers often use a mix of gold and copper for the electrical contacts, however, if they have not used enough gold, then oxidation occurs over time. This results in a working television or laptop screen suddenly exhibiting lines.

The solution is of course very simple, one needs to clean the contacts with a high quality electrical contact cleaner. It is best to clean the socket and the ribbon cable contacts, which will solve the fault.

One of the most common faults with laptops is that the ribbon cable connecting to the LCD panel cracks. It typically fails near the hinge area due to flexing in that region, and over time, some of the tracks on the plastic cable breaks. I have seen these types of faults on many laptops. It does not matter whether it is a Lenovo, IBM, Acer, Samsung, Toshiba, or even a MacBook Pro!

It is also possible to have a dislodged cable, which typically occurs on mishandled laptops. The plastic clip that holds the ribbon cable is very small and delicate and if the laptop receives an impact, the ribbon cable can dislodge.

This type of fault can also occur on LCD televisions; however, it tends to be on new units, where the box has received an impact during transit from the factory.

In this situation, the repair can be easy, as the cable will simply require reseating. However, there is still the labour time to consider as it can take the best part of the day to gain access to the ribbon cable.

If the laptop has a socket that provides a VGA output, then the first thing to do is to hook up another good monitor to it to see if the picture is good. If the picture on another monitor is good, then you can be sure that the video chipset and the motherboard electronics are operating properly, and it is a connection issue.

I used this same method of troubleshooting to repair an LCD television recently. Modern televisions have a video out socket, and if you feed the signal from that to another monitor, you can check for the quality of the video display. If the external monitor does not show lines, then you know for sure that it is a connection issue. Hence, this method of troubleshooting works for some of the modern televisions as well.

When half of the vertical interlace is missing showing a picture that is broken up vertically, the display appears with vertical lines. This is usually due to a cracked ribbon cable.

Generally, for laptops a replacement cable is always required due to it breaking near the hinge. I had this Dell laptop and replacing the LCD ribbon cable solved the problem. I managed to buy a replacement from Dell for a modest price £6.00. The laptop was just outside the warranty period; however, they still shipped out the cable free of charge. This is the reason why people buy Dell. In my experience Dell tend to stand by their customers and products, and their prices for replacement parts are realistic and down to earth.

Replacing a laptop ribbon cable is simple, and the top-half of the laptop, and keyboard needs removing to gain access to the socket on the motherboard side. As you can see, it flexes near the hinge area and breaks where the ribbon cable wraps around the hinge.

TFT displays are full color LCDs providing bright, vivid colors with the ability to show quick animations, complex graphics, and custom fonts with different touchscreen options. Available in industry standard sizes and resolutions. These displays come as standard, premium MVA, sunlight readable, or IPS display types with a variety of interface options including HDMI, SPI and LVDS. Our line of TFT modules include a custom PCB that support HDMI interface, audio support or HMI solutions with on-board FTDI Embedded Video Engine (EVE2).

Ampire is a Taiwan-based LCD module manufacturer with over 15 years’ experience in the field. To satisfy various needs, Ampire provides diversified and high-quality products (TFT, CSTN, FSTN, STN, TN) with different technologies (COG, TAB & COB), and custom designs when necessary.

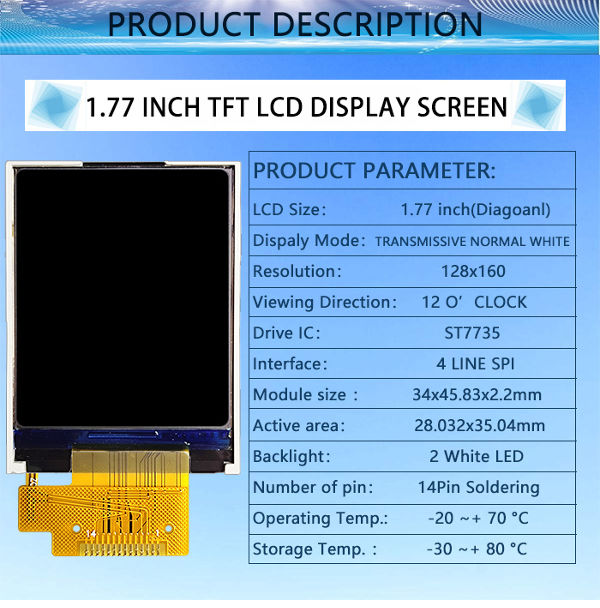

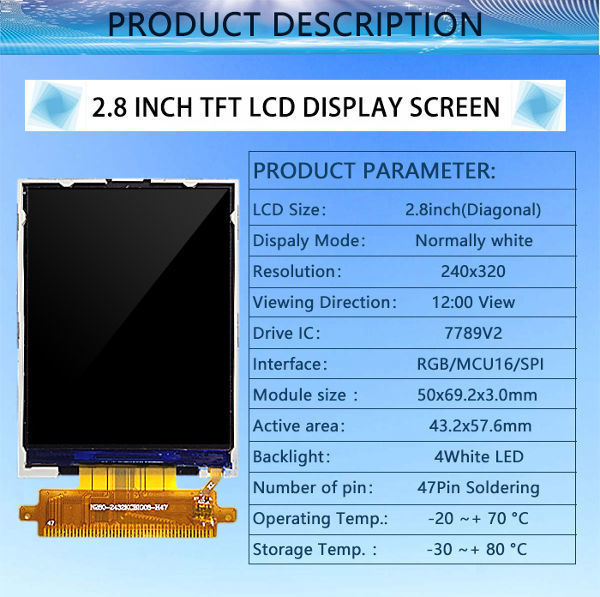

Winstar is a global leading Manufacturer of TFT LCD display based in Taiwan and China. Winstar offers a wide product range of small to medium sizes TFT display modules in sizes ranging such as 0.96",1.28", 1.77, 2", 2.4", 2.8", 3.2", 3.5", 4.3", 5" 5.6", 5.7", 7", 8", 9", 10.1", 10.2", 12.1" , 12.3" and 15" TFT (diagonal size of the active area) and so on . There are more than 250 TFT standard models listed on this website; furthermore, almost each item is acceptable to derivate from the standard items to meet the customers" requirement.

Winstar TFT displays are qualified under industrial standard including standard TFT-LCD modules, IPS TFT, High brightness TFT LCD (sunlight readable display), TFT panels with controller boards, Bar Type TFT, Wide Temperature TFT LCD, Winstar Clever System TFT and Touch screen display. These displays include landscape or portrait modes. Winstar has Mono TFT displays and full color TFTs in line, these displays are available in various resolutions as well as touch screen optional in resistive and projected capacitive (PCAP touch screen) technology. Many of our TFT display modules have more than one interface available including MCU, RGB, TTL, LVDS and MIPI DSI. Winstar TFT modules are perfect for a number of applications including industrial control, coffee machine, medical equipment, POS system, automation, GPS navigator, white goods, energy control, telecoms, medical equipment and etc.

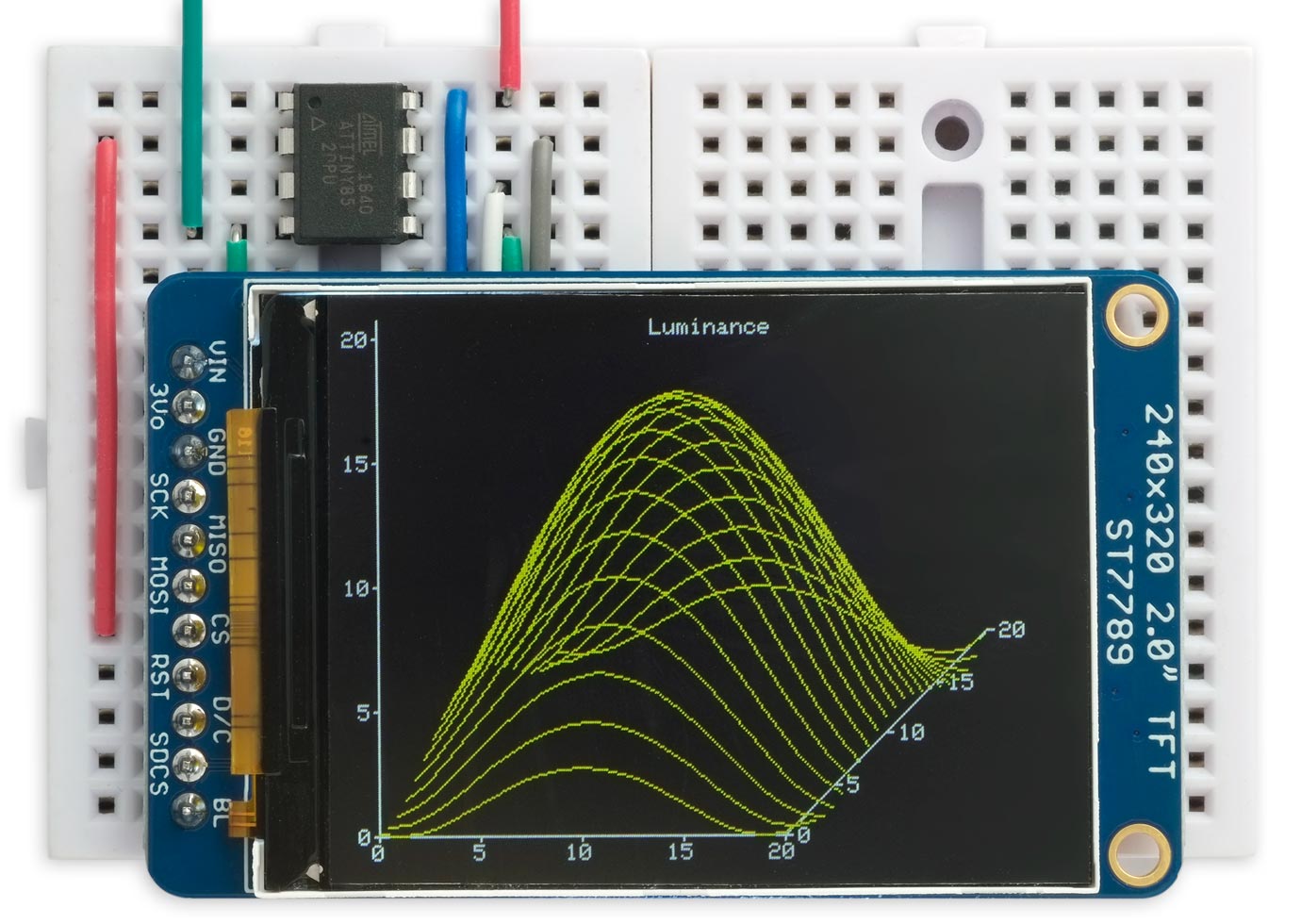

In this article, you will learn how to use TFT LCDs by Arduino boards. From basic commands to professional designs and technics are all explained here.

In electronic’s projects, creating an interface between user and system is very important. This interface could be created by displaying useful data, a menu, and ease of access. A beautiful design is also very important.

There are several components to achieve this. LEDs, 7-segments, Character and Graphic displays, and full-color TFT LCDs. The right component for your projects depends on the amount of data to be displayed, type of user interaction, and processor capacity.

TFT LCD is a variant of a liquid-crystal display (LCD) that uses thin-film-transistor (TFT) technology to improve image qualities such as addressability and contrast. A TFT LCD is an active matrix LCD, in contrast to passive matrix LCDs or simple, direct-driven LCDs with a few segments.

In Arduino-based projects, the processor frequency is low. So it is not possible to display complex, high definition images and high-speed motions. Therefore, full-color TFT LCDs can only be used to display simple data and commands.

In this article, we have used libraries and advanced technics to display data, charts, menu, etc. with a professional design. This can move your project presentation to a higher level.

In electronic’s projects, creating an interface between user and system is very important. This interface could be created by displaying useful data, a menu, and ease of access. A beautiful design is also very important.

There are several components to achieve this. LEDs, 7-segments, Character and Graphic displays, and full-color TFT LCDs. The right component for your projects depends on the amount of data to be displayed, type of user interaction, and processor capacity.

TFT LCD is a variant of a liquid-crystal display (LCD) that uses thin-film-transistor (TFT) technology to improve image qualities such as addressability and contrast. A TFT LCD is an active matrix LCD, in contrast to passive matrix LCDs or simple, direct-driven LCDs with a few segments.

In Arduino-based projects, the processor frequency is low. So it is not possible to display complex, high definition images and high-speed motions. Therefore, full-color TFT LCDs can only be used to display simple data and commands.

In this article, we have used libraries and advanced technics to display data, charts, menu, etc. with a professional design. This can move your project presentation to a higher level.

Size of displays affects your project parameters. Bigger Display is not always better. if you want to display high-resolution images and signs, you should choose a big size display with higher resolution. But it decreases the speed of your processing, needs more space and also needs more current to run.

After choosing the right display, It’s time to choose the right controller. If you want to display characters, tests, numbers and static images and the speed of display is not important, the Atmega328 Arduino boards (such as Arduino UNO) are a proper choice. If the size of your code is big, The UNO board may not be enough. You can use Arduino Mega2560 instead. And if you want to show high resolution images and motions with high speed, you should use the ARM core Arduino boards such as Arduino DUE.

In electronics/computer hardware a display driver is usually a semiconductor integrated circuit (but may alternatively comprise a state machine made of discrete logic and other components) which provides an interface function between a microprocessor, microcontroller, ASIC or general-purpose peripheral interface and a particular type of display device, e.g. LCD, LED, OLED, ePaper, CRT, Vacuum fluorescent or Nixie.

The display driver will typically accept commands and data using an industry-standard general-purpose serial or parallel interface, such as TTL, CMOS, RS232, SPI, I2C, etc. and generate signals with suitable voltage, current, timing and demultiplexing to make the display show the desired text or image.

The LCDs manufacturers use different drivers in their products. Some of them are more popular and some of them are very unknown. To run your display easily, you should use Arduino LCDs libraries and add them to your code. Otherwise running the display may be very difficult. There are many free libraries you can find on the internet but the important point about the libraries is their compatibility with the LCD’s driver. The driver of your LCD must be known by your library. In this article, we use the Adafruit GFX library and MCUFRIEND KBV library and example codes. You can download them from the following links.

You must add the library and then upload the code. If it is the first time you run an Arduino board, don’t worry. Just follow these steps:Go to www.arduino.cc/en/Main/Software and download the software of your OS. Install the IDE software as instructed.

By these two functions, You can find out the resolution of the display. Just add them to the code and put the outputs in a uint16_t variable. Then read it from the Serial port by Serial.println(); . First add Serial.begin(9600); in setup().

First you should convert your image to hex code. Download the software from the following link. if you don’t want to change the settings of the software, you must invert the color of the image and make the image horizontally mirrored and rotate it 90 degrees counterclockwise. Now add it to the software and convert it. Open the exported file and copy the hex code to Arduino IDE. x and y are locations of the image. sx and sy are sizes of image. you can change the color of the image in the last input.

Upload your image and download the converted file that the UTFT libraries can process. Now copy the hex code to Arduino IDE. x and y are locations of the image. sx and sy are size of the image.

In this template, We just used a string and 8 filled circles that change their colors in order. To draw circles around a static point ,You can use sin(); and cos(); functions. you should define the PI number . To change colors, you can use color565(); function and replace your RGB code.

In this template, We converted a .jpg image to .c file and added to the code, wrote a string and used the fade code to display. Then we used scroll code to move the screen left. Download the .h file and add it to the folder of the Arduino sketch.

In this template, We used sin(); and cos(); functions to draw Arcs with our desired thickness and displayed number by text printing function. Then we converted an image to hex code and added them to the code and displayed the image by bitmap function. Then we used draw lines function to change the style of the image. Download the .h file and add it to the folder of the Arduino sketch.

In this template, We created a function which accepts numbers as input and displays them as a pie chart. We just use draw arc and filled circle functions.

In this template, We added a converted image to code and then used two black and white arcs to create the pointer of volumes. Download the .h file and add it to the folder of the Arduino sketch.

In this template, We added a converted image and use the arc and print function to create this gauge. Download the .h file and add it to folder of the Arduino sketch.

while (a < b) { Serial.println(a); j = 80 * (sin(PI * a / 2000)); i = 80 * (cos(PI * a / 2000)); j2 = 50 * (sin(PI * a / 2000)); i2 = 50 * (cos(PI * a / 2000)); tft.drawLine(i2 + 235, j2 + 169, i + 235, j + 169, tft.color565(0, 255, 255)); tft.fillRect(200, 153, 75, 33, 0x0000); tft.setTextSize(3); tft.setTextColor(0xffff); if ((a/20)>99)

while (b < a) { j = 80 * (sin(PI * a / 2000)); i = 80 * (cos(PI * a / 2000)); j2 = 50 * (sin(PI * a / 2000)); i2 = 50 * (cos(PI * a / 2000)); tft.drawLine(i2 + 235, j2 + 169, i + 235, j + 169, tft.color565(0, 0, 0)); tft.fillRect(200, 153, 75, 33, 0x0000); tft.setTextSize(3); tft.setTextColor(0xffff); if ((a/20)>99)

In this template, We display simple images one after each other very fast by bitmap function. So you can make your animation by this trick. Download the .h file and add it to folder of the Arduino sketch.

In this template, We just display some images by RGBbitmap and bitmap functions. Just make a code for touchscreen and use this template. Download the .h file and add it to folder of the Arduino sketch.

The speed of playing all the GIF files are edited and we made them faster or slower for better understanding. The speed of motions depends on the speed of your processor or type of code or size and thickness of elements in the code.

LCD is the abbreviation for liquid crystal display. An LCD basically consists of two glass plates with a special liquid between them. The special attribute of this liquid is that it rotates or “twists” the plane of polarized light. This effect is influenced by the creation of an electrical field. The glass plates are thus each coated with a very thin metallic film. To obtain polarized light, you apply a polarization foil, the polarizer, to the bottom glass plate. Another foil must be applied to the bottom glass plate, but this time with a plane of polarization twisted by 90°. This is referred to as the analyzer.

In the idle state, the liquid twists the plane of polarization of the incoming light by 90° so that it can pass the analyzer unhindered. The LCD is thus transparent. If a specific voltage is applied to the metallic film coating, the crystals rotate in the liquid. This twists the plane of polarization of the light by another 90°, for example: The analyzer prevents the light getting through, and the LCD thus becomes opaque.TN, STN, FSTN, blue mode, yellow-green mode

Liquids that twist the plane of polarized light by 90° are referred to as TN (Twisted Nematic). STN (Super Twisted Nematic) liquids twist the plane of polarized light by at least 180°. This gives the display improved contrast. However, this technology does color the display to a certain extent. The most common colors are referred to as yellow-green and blue mode. There is also a gray mode, which in practice is more blue than gray, however.

In order to counteract the undesired color effect, the FSTN technology uses an additional foil on the outer side, but this causes a loss of light and means that this technology is only effective with lit displays.

However, the different colors occur only in displays that are either not lit or that are lit with white light. If there is any color in the lighting (e.g. yellow-green LED lighting), it overrides the color of the display. A blue-mode LCD with yellow-green LED lighting will always appear yellow-green.Static or multiplex driving method

Small displays with a small viewing area are generally statically driven. Static displays have the best contrast and the largest possible angle of view. The TN technology fulfills its purpose to the full here (black and white display, reasonably priced). The bigger displays get, however, the more lines become necessary in static operation (e.g. graphics 128x64=8192 segments =8192 lines). Since there is not enough space on either the display or a driver IC for so many lines, multiplexing is used. The display is thus divided up into rows and columns, and there is a segment at each intersection (128+64=192 lines). Scanning takes place row by row (64x, in other words a multiplex rate of 1:64). Because only 1 row is ever active at any one time, however, the contrast and the angle of view suffer the higher the multiplex rate becomes. This makes it essential to use STN.Angle of view 6°°/12°°

Every LCD has a preferred angle of view at which the contrast of the display is at its optimum. Most displays are produced for the 6°° angle of view, which is also known as the bottom view (BV). This angle corresponds to that of a pocket calculator that is lying flat on a desktop.

12°° displays (top view, TV) are best built into a table-top unit. All displays can be read vertically from the front.Reflective, transflective, transmissive

LCDs without lighting are hard to imagine these days. However, since there are basically four different types of lighting, the type selected depends very much on the application. Here is a brief overview to clarify the situation:LED

However, the lighting also determines the optical impression made by the display, and the display mode; blue or yellow-green – does not always have an influence. Below you can see the EAP162-3N display with different types of lighting by way of example:Lighting

Standard LCDs have a temperature range of 0 to +50°C. High-temperature displays are designed for operation in the range from -20 to +70°C. In this case, however, additional supply voltage is generally required. Since the contrast of any LCD is dependent on the temperature, a special temperature-compensation circuit is needed in order to use the entire temperature range, and this is particularly true for high-temperature displays (-20 to +70°C). Manual adjustment is possible but rather impractical for the user.

However, the storage temperature of a display should never be exceeded under any circumstances. An excessively high temperature can destroy the display very quickly. Direct exposure to the sun, for example, can destroy an LCD: This is because an LCD becomes darker (in positive mode) as it gets hotter. As it gets darker, it absorbs more light and converts it to heat. As a result, the display becomes even hotter and darker... In this way, temperatures of over 100°C can quickly be reached.Dot-matrix, graphics and 7-segment displays

The first LCDs were 7-segment displays, and they are still found today in simple pocket calculators and digital watches. 7 segments allow all of the digits from 0 to 9 to be displayed.

Text displays require what is known as a dot matrix, an area consisting of 5x7=35 dots, in order to display all of the letters in the alphabet as well as various special characters. Graphics displays have a similar structure to text displays. In this case, however, there are no spaces between the lines and characters.Display drivers and controllers

The semiconductor industry now offers a very large range of LCD drivers. We generally distinguish between pure display drivers without intelligence of their own, controllers with a display memory and possibly a character set, and micro-controllers with integrated LC drivers.

Pure display drivers work in a similar way to a shift register. They generally have a serial input. They require an external pulse, and in multiplex operation with high frequency they require new display data continuously in order to achieve a refresh frequency that is as high as possible (MSM5219, UPD7225, HD44100, LC7942, etc.). An example of a genuine controller is theHD44780 for dot-matrix displays: Once it has received the ASCII code, the controller manages its character set, memory and multiplexing entirely on its own. The following controllers are widely used for graphics displays: HD61202/3, HD61830, SED1520, SED1330, T6963.

Many ask themselves, "What is the difference between an LCD display and a TFT-display?" or "What is the difference between a TFT and an OLED display?". Here are these 3 sometimes extremely different display technologies briefly explained. LCD vs. TFT vs. OLED (comparison).

- The LCD (Liquid Crystal Display) is a passive display technology. The operation and the structure are described above. Passive means that an LCD can only darken or let out light. So it always depends on ambient light or a backlight. This can be an advantage because the power consumption of a LCD display is very, very low. Sometimes even less than the accumulated power consumption of an E-paper display, which in static operation requires absolutely no energy to maintain the content. To change the contents, however, a relatively large amount of power is required for an E-paper display.

LCDs can also be reflective, so they reflect incident light and are therefore legible even at maximum brightness (sunlight, surgical lighting). Compared to TFT and also OLED, they have an unbeatable advantage in terms of readability and power consumption :; the "formula" is: Sunlight = LCD.

- A TFT-display (of Thin-Film Transistor) is usually a color display (RGB). From the construction and the technology it corresponds to the LCD. It is also passive, so it needs a backlight. This is in any case necessary except for a few, very expensive constructions. However, a TFT needs much more light than the monochrome relatives, because the additional structures on the glass as well as the additional color filters "swallow" light. So TFTs are not particularly energy-efficient, but can display in color and at the same time the resolution is much higher.

- OLED displays (by Organic-Light-Emitting-Diode) are as the name implies active displays - every pixel or sign generates light. This achieves an extremely wide viewing angle and high contrast values. The power consumption is dependent on the display content. Here OLEDs to TFTs and LCDs differ significantly, which have a nearly constant power consumption even with different display contents. Unfortunately, the efficiency of converting the electric current into light energy is still very poor. This means that the power consumption of OLEDs with normal content is sometimes higher than that of a TFT with the same size. Colored OLEDs are increasingly used in consumer devices, but for the industry, due to their availability and lifetime, currently only monochrome displays are suitable (usually in yellow color).

In the reaction time, the OLEDs beat each TFT and LCD by worlds. Trise and Tfall are about 10μs, which would correspond to a theoretical refresh rate of 50,000 Hz. Possibly an advantage in very special applications.

Finally the question "What is better, LCD, OLED or TFT?" Due to the physical differences you can not answer that blanket. Depending on the application, there are pros and cons to each individual technology. In addition to the above differences, there are many more details in the design and construction that need to be individually illuminated for each device. Write us an e-mail or call us: we have specialists with some 20- and 30-year experience. We are happy to compare different displays together with you.AACS and IPS technology

Once more the new AACS technology (All-Angle-Color-Stability) improves the color stability for different viewing angles. It"s providing same color for 90° straight view as for 20° or 160° bottom or top view. There"s no more color shift or inverting effect.

A thin-film-transistor liquid-crystal display (TFT LCD) is a variant of a liquid-crystal display that uses thin-film-transistor technologyactive matrix LCD, in contrast to passive matrix LCDs or simple, direct-driven (i.e. with segments directly connected to electronics outside the LCD) LCDs with a few segments.

In February 1957, John Wallmark of RCA filed a patent for a thin film MOSFET. Paul K. Weimer, also of RCA implemented Wallmark"s ideas and developed the thin-film transistor (TFT) in 1962, a type of MOSFET distinct from the standard bulk MOSFET. It was made with thin films of cadmium selenide and cadmium sulfide. The idea of a TFT-based liquid-crystal display (LCD) was conceived by Bernard Lechner of RCA Laboratories in 1968. In 1971, Lechner, F. J. Marlowe, E. O. Nester and J. Tults demonstrated a 2-by-18 matrix display driven by a hybrid circuit using the dynamic scattering mode of LCDs.T. Peter Brody, J. A. Asars and G. D. Dixon at Westinghouse Research Laboratories developed a CdSe (cadmium selenide) TFT, which they used to demonstrate the first CdSe thin-film-transistor liquid-crystal display (TFT LCD).active-matrix liquid-crystal display (AM LCD) using CdSe TFTs in 1974, and then Brody coined the term "active matrix" in 1975.high-resolution and high-quality electronic visual display devices use TFT-based active matrix displays.

The liquid crystal displays used in calculators and other devices with similarly simple displays have direct-driven image elements, and therefore a voltage can be easily applied across just one segment of these types of displays without interfering with the other segments. This would be impractical for a large display, because it would have a large number of (color) picture elements (pixels), and thus it would require millions of connections, both top and bottom for each one of the three colors (red, green and blue) of every pixel. To avoid this issue, the pixels are addressed in rows and columns, reducing the connection count from millions down to thousands. The column and row wires attach to transistor switches, one for each pixel. The one-way current passing characteristic of the transistor prevents the charge that is being applied to each pixel from being drained between refreshes to a display"s image. Each pixel is a small capacitor with a layer of insulating liquid crystal sandwiched between transparent conductive ITO layers.

The circuit layout process of a TFT-LCD is very similar to that of semiconductor products. However, rather than fabricating the transistors from silicon, that is formed into a crystalline silicon wafer, they are made from a thin film of amorphous silicon that is deposited on a glass panel. The silicon layer for TFT-LCDs is typically deposited using the PECVD process.

Polycrystalline silicon is sometimes used in displays requiring higher TFT performance. Examples include small high-resolution displays such as those found in projectors or viewfinders. Amorphous silicon-based TFTs are by far the most common, due to their lower production cost, whereas polycrystalline silicon TFTs are more costly and much more difficult to produce.

The twisted nematic display is one of the oldest and frequently cheapest kind of LCD display technologies available. TN displays benefit from fast pixel response times and less smearing than other LCD display technology, but suffer from poor color reproduction and limited viewing angles, especially in the vertical direction. Colors will shift, potentially to the point of completely inverting, when viewed at an angle that is not perpendicular to the display. Modern, high end consumer products have developed methods to overcome the technology"s shortcomings, such as RTC (Response Time Compensation / Overdrive) technologies. Modern TN displays can look significantly better than older TN displays from decades earlier, but overall TN has inferior viewing angles and poor color in comparison to other technology.

Most TN panels can represent colors using only six bits per RGB channel, or 18 bit in total, and are unable to display the 16.7 million color shades (24-bit truecolor) that are available using 24-bit color. Instead, these panels display interpolated 24-bit color using a dithering method that combines adjacent pixels to simulate the desired shade. They can also use a form of temporal dithering called Frame Rate Control (FRC), which cycles between different shades with each new frame to simulate an intermediate shade. Such 18 bit panels with dithering are sometimes advertised as having "16.2 million colors". These color simulation methods are noticeable to many people and highly bothersome to some.gamut (often referred to as a percentage of the NTSC 1953 color gamut) are also due to backlighting technology. It is not uncommon for older displays to range from 10% to 26% of the NTSC color gamut, whereas other kind of displays, utilizing more complicated CCFL or LED phosphor formulations or RGB LED backlights, may extend past 100% of the NTSC color gamut, a difference quite perceivable by the human eye.

The transmittance of a pixel of an LCD panel typically does not change linearly with the applied voltage,sRGB standard for computer monitors requires a specific nonlinear dependence of the amount of emitted light as a function of the RGB value.

In-plane switching was developed by Hitachi Ltd. in 1996 to improve on the poor viewing angle and the poor color reproduction of TN panels at that time.

Initial iterations of IPS technology were characterised by slow response time and a low contrast ratio but later revisions have made marked improvements to these shortcomings. Because of its wide viewing angle and accurate color reproduction (with almost no off-angle color shift), IPS is widely employed in high-end monitors aimed at professional graphic artists, although with the recent fall in price it has been seen in the mainstream market as well. IPS technology was sold to Panasonic by Hitachi.

Most panels also support true 8-bit per channel color. These improvements came at the cost of a higher response time, initially about 50 ms. IPS panels were also extremely expensive.

IPS has since been superseded by S-IPS (Super-IPS, Hitachi Ltd. in 1998), which has all the benefits of IPS technology with the addition of improved pixel refresh timing.

In 2004, Hydis Technologies Co., Ltd licensed its AFFS patent to Japan"s Hitachi Displays. Hitachi is using AFFS to manufacture high end panels in their product line. In 2006, Hydis also licensed its AFFS to Sanyo Epson Imaging Devices Corporation.

It achieved pixel response which was fast for its time, wide viewing angles, and high contrast at the cost of brightness and color reproduction.Response Time Compensation) technologies.

Less expensive PVA panels often use dithering and FRC, whereas super-PVA (S-PVA) panels all use at least 8 bits per color component and do not use color simulation methods.BRAVIA LCD TVs offer 10-bit and xvYCC color support, for example, the Bravia X4500 series. S-PVA also offers fast response times using modern RTC technologies.

When the field is on, the liquid crystal molecules start to tilt towards the center of the sub-pixels because of the electric field; as a result, a continuous pinwheel alignment (CPA) is formed; the azimuthal angle rotates 360 degrees continuously resulting in an excellent viewing angle. The ASV mode is also called CPA mode.

A technology developed by Samsung is Super PLS, which bears similarities to IPS panels, has wider viewing angles, better image quality, increased brightness, and lower production costs. PLS technology debuted in the PC display market with the release of the Samsung S27A850 and S24A850 monitors in September 2011.

TFT dual-transistor pixel or cell technology is a reflective-display technology for use in very-low-power-consumption applications such as electronic shelf labels (ESL), digital watches, or metering. DTP involves adding a secondary transistor gate in the single TFT cell to maintain the display of a pixel during a period of 1s without loss of image or without degrading the TFT transistors over time. By slowing the refresh rate of the standard frequency from 60 Hz to 1 Hz, DTP claims to increase the power efficiency by multiple orders of magnitude.

Due to the very high cost of building TFT factories, there are few major OEM panel vendors for large display panels. The glass panel suppliers are as follows:

External consumer display devices like a TFT LCD feature one or more analog VGA, DVI, HDMI, or DisplayPort interface, with many featuring a selection of these interfaces. Inside external display devices there is a controller board that will convert the video signal using color mapping and image scaling usually employing the discrete cosine transform (DCT) in order to convert any video source like CVBS, VGA, DVI, HDMI, etc. into digital RGB at the native resolution of the display panel. In a laptop the graphics chip will directly produce a signal suitable for connection to the built-in TFT display. A control mechanism for the backlight is usually included on the same controller board.

The low level interface of STN, DSTN, or TFT display panels use either single ended TTL 5 V signal for older displays or TTL 3.3 V for slightly newer displays that transmits the pixel clock, horizontal sync, vertical sync, digital red, digital green, digital blue in parallel. Some models (for example the AT070TN92) also feature input/display enable, horizontal scan direction and vertical scan direction signals.

New and large (>15") TFT displays often use LVDS signaling that transmits the same contents as the parallel interface (Hsync, Vsync, RGB) but will put control and RGB bits into a number of serial transmission lines synchronized to a clock whose rate is equal to the pixel rate. LVDS transmits seven bits per clock per data line, with six bits being data and one bit used to signal if the other six bits need to be inverted in order to maintain DC balance. Low-cost TFT displays often have three data lines and therefore only directly support 18 bits per pixel. Upscale displays have four or five data lines to support 24 bits per pixel (truecolor) or 30 bits per pixel respectively. Panel manufacturers are slowly replacing LVDS with Internal DisplayPort and Embedded DisplayPort, which allow sixfold reduction of the number of differential pairs.

Backlight intensity is usually controlled by varying a few volts DC, or generating a PWM signal, or adjusting a potentiometer or simply fixed. This in turn controls a high-voltage (1.3 kV) DC-AC inverter or a matrix of LEDs. The method to control the intensity of LED is to pulse them with PWM which can be source of harmonic flicker.

The bare display panel will only accept a digital video signal at the resolution determined by the panel pixel matrix designed at manufacture. Some screen panels will ignore the LSB bits of the color information to present a consistent interface (8 bit -> 6 bit/color x3).

With analogue signals like VGA, the display controller also needs to perform a high speed analog to digital conversion. With digital input signals like DVI or HDMI some simple reordering of the bits is needed before feeding it to the rescaler if the input resolution doesn"t match the display panel resolution.

The statements are applicable to Merck KGaA as well as its competitors JNC Corporation (formerly Chisso Corporation) and DIC (formerly Dainippon Ink & Chemicals). All three manufacturers have agreed not to introduce any acutely toxic or mutagenic liquid crystals to the market. They cover more than 90 percent of the global liquid crystal market. The remaining market share of liquid crystals, produced primarily in China, consists of older, patent-free substances from the three leading world producers and have already been tested for toxicity by them. As a result, they can also be considered non-toxic.

Kawamoto, H. (2012). "The Inventors of TFT Active-Matrix LCD Receive the 2011 IEEE Nishizawa Medal". Journal of Display Technology. 8 (1): 3–4. Bibcode:2012JDisT...8....3K. doi:10.1109/JDT.2011.2177740. ISSN 1551-319X.

Brody, T. Peter; Asars, J. A.; Dixon, G. D. (November 1973). "A 6 × 6 inch 20 lines-per-inch liquid-crystal display panel". 20 (11): 995–1001. Bibcode:1973ITED...20..995B. doi:10.1109/T-ED.1973.17780. ISSN 0018-9383.

Richard Ahrons (2012). "Industrial Research in Microcircuitry at RCA: The Early Years, 1953–1963". 12 (1). IEEE Annals of the History of Computing: 60–73. Cite journal requires |journal= (help)

K. H. Lee; H. Y. Kim; K. H. Park; S. J. Jang; I. C. Park & J. Y. Lee (June 2006). "A Novel Outdoor Readability of Portable TFT-LCD with AFFS Technology". SID Symposium Digest of Technical Papers. AIP. 37 (1): 1079–82. doi:10.1889/1.2433159. S2CID 129569963.

Kim, Sae-Bom; Kim, Woong-Ki; Chounlamany, Vanseng; Seo, Jaehwan; Yoo, Jisu; Jo, Hun-Je; Jung, Jinho (15 August 2012). "Identification of multi-level toxicity of liquid crystal display wastewater toward Daphnia magna and Moina macrocopa". Journal of Hazardous Materials. Seoul, Korea; Laos, Lao. 227–228: 327–333. doi:10.1016/j.jhazmat.2012.05.059. PMID 22677053.

This website is using a security service to protect itself from online attacks. The action you just performed triggered the security solution. There are several actions that could trigger this block including submitting a certain word or phrase, a SQL command or malformed data.

So, I have a purpose built pcb with the teensy 4.0 footprint (little did I know the financial implications this would have...I"ve been through >�60 worth of teensy 4.0).

My PCB board size is about 100mm-80mm (all hand soldered with a hot air tool, soldering iron, heat bed not to blow my own trumpet, but I am very good at pcb assembly by hand + I find it therapeutic).

So after half a days soldering, I fire up the board and excellent, the ILI9341 is running at a clock speed of 100mhz (not scoped), lightning fast! Dropped the speed to a more reasonable 20mhz and left overnight for a board test (i always do this, as i have lipos connected etc and like to see if there are any heat issues etc after a 24h run). Found no issues the next morning, graphics test still running so powered off the device.

Powered back up after my return from work @20mhz and the graphics test worked fine. Enabled my SD circuitry (solder jumpers), reran the test and both the ILI9341 and SD were both running sweet.

No changes made, powered up on the third day, and nothing but a white screen on the ILI9341? So i say, must have blew the t4 some how. Hot air removed the t4, on goes the new one and again a few runs later and i get a white screen again? Checked all my pin assignments, voltages and they are all good.

I came to the conclusion that as I was forcing the T4 to be powered of of 3v3 as per (https://forum.pjrc.com/threads/64468...V-power-supply) this was somehow messing with the SPI communication. I canned the T4 and designed and built a T4-SAMD51 clone.

I picked up the project again today and de-soldered my SAMD51 T4 clone pcb as I need speed! The T4 would have been perfect, so tried a few code changes, got the screen running in the setup function (static text etc), but as soon as it enters the loop(), you guessed it....white screen. Its as if the t4 is too fast on spi or something, but I have changed the clock speeds down to 5mhz and yield the same results...

To confirm, I had the T4 intermittently working on both the adafruit ili9341 library and the optimised ili9341_t3. I"ve been through 3 T4s and I have 5 different ILI934 displays. (all give the same results, pull ups, no pullups, removed sd circuitry, ran the T4 at 5v I"ve tried it all!)

Do you remember the old style cameras? They had a flash that used to make a whining noise after every photo taken. That"s the capacitor charging. Same thing with your monitor.

Why does it make that sound only in some patterns? Due to pixel overdrive. What happens is, when the pixel color changes from white to dark, the monitor supplies higher voltage so the LCD crystal changes state faster. You can see the oscilloscope photos from here http://www.tomshardware.com/reviews/viewsonic-overdrive-lcds,1042-8.html

The page you linked produces a series of fast changes, probably making the monitor overdrive a lot more than normal. Higher voltage means the AC to DC converter has to supply more power and the capacitors have to unload and reload more often, thus everything producing more of that whiny noise.

A static image can still make the monitor "work harder" due to the way it drives the pixels. Depending on the panel type, the logic behind the screen is different and can have some unfortunate worst-case arrangements. This also produces pixel-walk. Here"s a page where they have some examples of such cases: http://www.lagom.nl/lcd-test/inversion.php

Due to the fact that the issue is isolated to a single line (even with multiple pixels in height) it"s unlikely it"s the actual signal (e.g. cable or connector pins).

Some issue with the connection would most likely screw up several lines and/or the whole image and it won"t be isolated to exactly one line (especially with digital connections).

In a similar way, issues with the graphics card should most likely cause issues with the whole screen (like garbage/random patterns). Those shouldn"t be isolated to a single line.

Turn off the monitor, disconnect all cables, and put it flat on your table (screen up) so it"s sitting plane on the table. Let it sit there for a night, then try again.

If everything else fails, what happens if you use your finger nail and pull it over the faulty line? Don"t push too hard, just so there"s some pressure (typically shows some short colored trail that should disappear within 1-2 seconds). Can you see any additional patterns or "waves" that don"t fit to what you see in other areas of the screen?

How many times when answering the video doorphone you heard "Please open. Letter carrier", after which a suspicious man without a uniform appeared in the stairwell? Or how much would you give on a Saturday night knowing that a curious neighbor from the property next door calls your wicket, not your colleagues? If your intercom does not give you full control over who you let into your property or company, it is time to choose a modern solution, which is a video doorphone. It is a device thanks to which you will not only see and hear the person at the door but also open the entrance gate without leaving the house. The Qoltec brand has in its offer video doorphone, which are ideal for both your company and home.

Ms.Josey

Ms.Josey

Ms.Josey

Ms.Josey