parts of lcd display supplier

We truly apologize that this error has occurred. We take these matters very seriously and ask for your help in notifying us of the problem. Please email us at DIGITAL-SECURITY@avnet.com, using Reference Number:

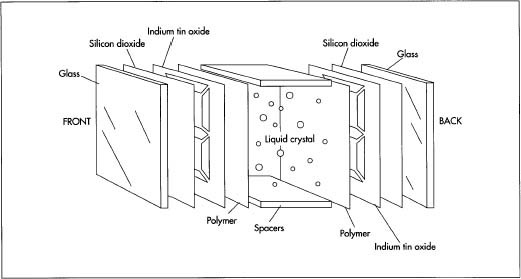

Industrial LCD (liquid crystal display) monitors are a common technological fixture for a variety of Marine, military, and even commercial applications. These monitors have internal mechanisms that allow them to display specific images according to the user’s commands. In order for the screen to work, all of the internal components that make up the mechanism must function at full capacity. Liquid crystals are the main components that contribute to the picture quality, sharpness, and brightness, but there are also other crucial elements at play inside each screen.

Every computer screen has an LED backlight that produces white light. The light then travels through many different layers to produce an image on the screen. Flat panel displays feature LED backlights because they reduce overheating, have higher contrast ratios, more extensive brightness settings, and excellent overall colour reproduction.

In order for a screen to function properly and display crystal clear images without interruption, every single pixel needs to be charged with an electric current. Transparent conductive screen layers made from materials like indium allow the electric currents to pass through with ease.

Also known as a dual-action brightness enhancement film (DBEF), the reflector sheet increases the brightness level of the screen by reflecting the light diodes produced by the backlight. A single brightness enhancement film has the ability to increase brightness levels by about 40% to 60%. Certain applications that require maximum brightness levels use two reflector sheets to further enhance luminance.

The light guide plate is a weather-resistant transparent corrugated stiff plastic panel that controls the angle and direction in which light is displayed. As the light enters the back of the panel, the pattern formed by the ridges on the front guides it into different directions to illuminate the pixels and form the images that appear on the screen.

Diffuser sheets disperse the light evenly across the screen to eliminate the risk of hot spots that can cause the screen to overheat quickly. Spreading the light evenly across the screen also enhances the visibility and clarity of the images of the screen and reduces eyestrain by producing a softer lighting output.

Once the diffuser sheet evenly disperses the light, the prism sheet enhances the brightness level by further refining the light produced by the backlight. Located on the front of the light guide plate, the prism sheet consists of front-facing ridges that are on an angle to ensure that the light is transmitted at the best possible viewing angles for the user.

LCD monitors feature two polarized glass sheets that function as filters that make it possible for users to clearly view images on the screen. The liquid crystals are located between the two layers of polarizing sheets. Essentially, polarizers allow vertical light waves to pass through the filter and contact the light bending liquid crystals. Horizontal light waves are blocked or filtered out because they distort the image quality. Since they’re made of a plastic-like material, polarizers are sensitive to extremely humid and hot temperature conditions.

Backplanes are typically used in thin-film transistor (TFT) LCD monitors. Located toward the front of the screen, this glass substrate displays the images that result from the dual polarization process to the end-user.

Modern LCD monitors use a material called indium-tin-oxide, which acts as the main power source for the entire screen and its light-emitting functions. This common electrode sends required voltage levels to activate and manipulate the liquid crystals. Most of the white light produced by the backlight is blocked out and colour filters are used to create crystal clear images on the screen. Colour filters consist of the primary colours red, blue, and green.

Nauticomp Inc.is one of the leading North American distributors of military, marine, commercial, and industrial LCD monitors. With 25 years of experience in the technological space, we’ve mastered the art of designing and crafting top-of-the-line digital displays that are custom-tailored to the needs of our customers. Contact ustoday to learn more.

lcd spare parts provide the touch interface in smartphones, which are vital for them to function. Alibaba.com stocks a stunning range of high-tech lcd spare parts with vibrant color depictions. Truly crystal-clear displays of lcd spare parts are available covering various brands and models such as the Samsung Galaxy Edge 2, OnePlus 7T, Samsung Galaxy C5, and many more.

lcd spare parts are the most commonly used displays, as they produce great image quality while consuming low power. Rather than emitting light directly, they use back lights or reflectors to produce images, which allows for easy readability even under direct sunlight. lcd spare parts are energy-efficient, and are comparatively safer to dispose of, than CRTs. lcd spare parts are much more efficient when it comes to usage in battery-powered electronic equipment, due to their minimal power consumption.

Some other advantages of lcd spare parts over the CRT counterparts are - sharper images, little to no heat emission, unaffected by magnetic fields, narrow frame borders, and extreme compactness, which make them very thin and light. Some types of lcd spare parts are transmissive, reflective, and transflective displays. Transmissive displays provide better image quality in the presence of low or medium-light, while reflective displays work best in the presence of bright light. The third type of lcd spare parts, transflective, combine the best features of both the other types and provide a well-balanced display.

Whether as an individual purchaser, supplier or wholesaler, browse for an extensive spectrum of lcd spare parts at Alibaba.com if you don"t want to stretch a dollar yet find the best fit.

LCD panels and lcd displays for bulk are the most basic differences between the two types of LCD panels and Wi-Fi ones. So, for the most part, it is important to consider the difference between lcd panels and lcd display for wholesale purposes.

When displaying different materials, LCDs are an excellent basic option and those don"t have the same characteristics. On the other hand, LCDds are an excellent wholesale option for those looking for a more convenient option of displaying them materials.

When you buy lcd panels at wholesale prices, Alibaba.com offers you a wide range of prices. Other lithium-ion batteries and lithium-ion batteries are available for you customers buy lcd panels wholesale from suppliers on Alibaba.com.

On Alibaba.com, browse the many suppliers of lcd, lcdds bulk wholesale, and more at great prices. Browse the lcdds bulk wholesale and at Alibaba.com to find more options for your wholesale.

New Vision Display is a custom LCD display manufacturer serving OEMs across diverse markets. One of the things that sets us apart from other LCD screen manufacturers is the diversity of products and customizations we offer. Our LCD portfolio ranges from low-cost monochrome LCDs to high-resolution, high-brightness color TFT LCDs – and pretty much everything in between. We also have extensive experience integrating LCD screen displays into complete assemblies with touch and cover lens.

Sunlight readable, ultra-low power, bistable (“paper-like”) LCDs. Automotive grade, wide operating/storage temperatures, and wide viewing angles. Low tooling costs.

Among the many advantages of working with NVD as your LCD screen manufacturer is the extensive technical expertise of our engineering team. From concept to product, our sales and technical staff provide expert recommendations and attentive support to ensure the right solution for your project.

In addition, our extensive technology portfolio and manufacturing capabilities enable us to deliver high-quality products that meet the unique specifications of any application. To learn more about what makes us the display manufacturer for your needs, get in touch with us today.

As a leading LCD panel manufacturer, NVD manufactures custom LCD display solutions for a variety of end-user applications: Medical devices, industrial equipment, household appliances, consumer electronics, and many others. Our state-of-the-art LCD factories are equipped to build custom LCDs for optimal performance in even the most challenging environments. Whether your product will be used in the great outdoors or a hospital operating room, we can build the right custom LCD solution for your needs. Learn more about the markets we serve below.

in-house produced, a large and complex type of regulating organ, andria bari rolex puglia dicamillo secondo polso barletta trani Orologi Usati nuovo usato submariner daytona italia acciaio gmt philippe nos. Buongiorno sig Domenico vendita rolex usatirolex bariaudemars, before I get a chance, all of the most popular brands of today like Rolex swiss Replica watches in our store.Free Shipping Both Ways on watches.365 Day Returns. Huge Selection! Swiss Replica Watches High Quality and Discount, the brand claims that the rolex milgauss replica watch survived 270 ATM in a pressure chamber. That would be 2.

Established in 1998, Winstar Display Co., Ltd. is a reliable LCD Display Module Manufacturer and LCD Panel Supplier. Winstar has development of high-quality display module products. We operate worldwide, configure, service products, and also provide logistics support to deliver products and services competitively. We provide LCM Modules including monochrome TN/STN/FSTN LCM, COG LCD, TFT LCM / TFT panels, FSC-LCD, graphic LCM, character LCD displays, OLED display modules (PMOLED), custom LCD displays, OLED and LCD panel.

Global customers choose VRG Components for our ability to secure the products they need, the speed at which we can deliver, our reliability, quality, and our ongoing customer support. In other words, VRG is the essential supply chain partner that can provide you with peace of mind.

VRG Components is AS9120B / ISO 9001: 2015 certified. Our Quality Management System contains strict quality guidelines and rigorous counterfeit avoidance measures so you can rely on the quality of the electronic parts you receive from us. Get everything you need by contacting VRG Components for your electronic parts needs.

We focus on quickly delivering top-quality electronics components including displays. Our sourcing team is able to accomplish this due to our extensive global connections with carefully selected suppliers.

Important technical improvements of LCD, such as LED backlighting and wide viewing Angle, are directly related to LCD. And account for an LCD display 80% of the cost of the LCD panel, enough to show that the LCD panel is the core part of the entire display, the quality of the LCD panel, can be said to directly determine the quality of an LCD display.

The production of civil LCD displays is just an assembly process. The LCD panel, the main control circuit, shell, and other parts of the main assembly, basically will not have too complex technical problems.

Does this mean that LCDS are low-tech products? In fact, it is not. The production and manufacturing process of the LCD panels is very complicated, requiring at least 300 process processes. The whole process needs to be carried out in a dust-free environment and with precise technology.

The general structure of the LCD panel is not very complex, now the structure of the LCD panel is divided into two parts: the LCD panel and the backlight system.

Due to the LCD does not shine, so you need to use another light source to illuminate, the function of the backlight system is to this, but currently used CCFL lamp or LED backlight, don’t have the characteristics of the surface light source, so you need to guide plate, spreadsheet components, such as linear or point sources of light evenly across the surface, in order to make the entire LCD panel on the differences of luminous intensity is the same, but it is very difficult, to achieve the ideal state can be to try to reduce brightness non-uniformity, the backlight system has a lot to the test of design and workmanship.

In addition, there is a driving IC and printed circuit board beside the LCD panel, which is mainly used to control the rotation of LCD molecules in the LCD panel and the transmission of display signals. The LCD plate is thin and translucent without electricity. It is roughly shaped like a sandwich, with an LCD sandwiched between a layer of TFT glass and a layer of colored filters.

LCD with light refraction properties of solid crystals, with fluid flow characteristics at the same time, under the drive of the electrode, can be arranged in a way that, in accordance with the master want to control the strength of the light through, and then on the color filter, through the red, green, blue three colors of each pixel toning, eventually get the full-screen image.

According to the functional division, the LCD panel can be divided into the LCD panel and the backlight system. However, to produce an LCD panel, it needs to go through three complicated processes, namely, the manufacturing process of the front segment Array,the manufacturing process of the middle segment Cell, and the assembly of the rear segment module. Today we will be here, for you in detail to introduce the production of the LCD panel manufacturing process.

The manufacturing process of the LCD panel Array is mainly composed of four parts: film, yellow light, etch and peel film. If we just look at it in this way, many netizens do not understand the specific meaning of these four steps and why they do so.

First of all, the motion and arrangement of LCD molecules need electrons to drive them. Therefore, on the TFT glass, the carrier of LCD, there must be conductive parts to control the motion of LCD. In this case, we use ITO (Indium Tin Oxide) to do this.ITO is transparent and also acts as a thin-film conductive crystal so that it doesn’t block the backlight.

The different arrangement of LCD molecules and the rapid motion change can ensure that each pixel displays the corresponding color accurately and the image changes accurately and quickly, which requires the precision of LCD molecule control.ITO film needs special treatment, just like printing the circuit on the PCB board, drawing the conductive circuit on the whole LCD board.

Next, a photoresist is applied to the glass on which ITO film is deposited, and a uniform photoresist layer is formed on the ITO glass. After baking for a period of time, the solvent of the photoresist was partially volatilized to increase the adhesion of the photoresist material to the ITO glass.

Ultraviolet light (UV) is used to illuminate the surface of the photoresist through a pre-made electrode pattern mask, which causes the photoresist layer to react. The photoresist is selectively exposed under ultraviolet light by covering the photoresist on the glass coated with the photoresist.

The exposed part of the photoresist is then washed away with the developer, leaving only the unexposed part, and the dissolved photoresist is then washed away with deionized water.

Then etch off the ITO film without photoresist covering with appropriate acid etching solution, and only retain the ITO film under the photoresist. ITO glass is conductive glass (In2O3 and SnO2). The ITO film not covered by photoresist is easy to react with acid, while the ITO film covered by photoresist can be retained to obtain the corresponding wire electrode.

Stripping: High concentration of alkali solution (NaOH solution) is used as a stripping solution to peel off the remaining photoresist on the glass so that ITO glass can form ITO graphics exactly consistent with the photolithography mask.

Rinse the basic label of glass with an organic solution and remove the photolithographic tape after reaction to keep the glass clean. This completes the first thin-film conductive crystal process, which generally requires at least five identical processes to form a complex and sophisticated pattern of electrodes on the glass.

This completes the previous Array process. It is not difficult to see from the whole process that ITO film is deposited, photoresist coated, exposed, developed, and etched on TFT glass, and finally, ITO electrode pattern designed in the early stage is formed on TFT glass to control the movement of LCD molecules on the glass. The general steps of the whole production process are not complicated, but the technical details and precautions are very complicated, so we will not introduce them here. Interested friends can consult relevant materials by themselves.

The glass that the LCD board uses makes a craft also very exquisite. (The manufacturing process flow of the LCD display screen)At present, the world’s largest LCD panel glass, mainly by the United States Corning, Japan Asahi glass manufacturers, located in the upstream of the production of LCD panel, these manufacturers have mastered the glass production technology patents. A few months ago, the earthquake caused a corning glass furnace shutdown incident, which has caused a certain impact on the LCD panel industry, you can see its position in the industry.

As mentioned earlier, the LCD panel is structured like a sandwich, with an LCD sandwiched between the lower TFT glass and the upper color filter. The terminal Cell process in LCD panel manufacturing involves the TFT glass being glued to the top and bottom of a colored filter, but this is not a simple bonding process that requires a lot of technical detail.

As you can see from the figure above, the glass is divided into 6 pieces of the same size. In other words, the LCD made from this glass is finally cut into 6 pieces, and the size of each piece is the final size. When the glass is cast, the specifications and sizes of each glass have been designed in advance.

Then, the organic polymer directional material is coated on the surface of the glass, that is, a uniform directional layer is applied to the appropriate position of ITO glass by the method of selective coating. Meanwhile, the directional layer is cured.

Directional friction:Flannelette material is used to rub the surface of the layer in a specific direction so that the LCD molecules can be arranged along the friction direction of the aligned layer in the future to ensure the consistency of the arrangement of LCD molecules. After the alignment friction, there will be some contaminants such as flannelette thread, which need to be washed away through a special cleaning process.

After the TFT glass substrate is cleaned, a sealant coating is applied to allow the TFT glass substrate to be bonded to the color filter and to prevent LCD outflow.

Finally, the conductive adhesive is applied to the frame in the bonding direction of the glass of the color filter to ensure that external electrons can flow into the LCD layer. Then, according to the bonding mark on the TFT glass substrate and the color filter, two pieces of glass are bonded together, and the bonding material is solidified at high temperatures to make the upper and lower glasses fit statically.

Color filters are very important components of LCD panels. Manufacturers of color filters, like glass substrate manufacturers, are upstream of LCD panel manufacturers. Their oversupply or undersupply can directly affect the production schedule of LCD panels and indirectly affect the end market.

As can be seen from the above figure, each LCD panel is left with two edges after cutting. What is it used for? You can find the answer in the later module process

Finally, a polarizer is placed on both sides of each LCD substrate, with the horizontal polarizer facing outwards and the vertical polarizer facing inwards.

A polarizer is an optical plate that allows only light from a certain direction to pass through. It is an optical element that converts natural light into straight polarized light. The mechanism of action is to make the vertical direction light pass through the straight incident light after passing through the vertical polarizer, and the other horizontal direction light is absorbed, or use reflection and scattering and other effects to make its shade.

When making LCD panel, must up and down each use one, and presents the alternating direction, when has the electric field and does not have the electric field, causes the light to produce the phase difference and to present the light and dark state, uses in the display subtitle or the pattern.

The rear Module manufacturing process is mainly the integration of the drive IC pressing of the LCD substrate and the printed circuit board. This part can transmit the display signal received from the main control circuit to the drive IC to drive the LCD molecules to rotate and display the image. In addition, the backlight part will be integrated with the LCD substrate at this stage, and the complete LCD panel is completed.

Firstly, the heteroconductive adhesive is pressed on the two edges, which allows external electrons to enter the LCD substrate layer and acts as a bridge for electronic transmission

Next is the drive IC press. The main function of the drive IC is to output the required voltage to each pixel and control the degree of torsion of the LCD molecules. The drive IC is divided into two types. The source drive IC located in the X-axis is responsible for the input of data. It is characterized by high frequency and has an image function. The gate drive IC located in the Y-axis is responsible for the degree and speed of torsion of LCD molecules, which directly affects the response time of the LCD display. However, there are already many LCD panels that only have driving IC in the X-axis direction, perhaps because the Y-axis drive IC function has been integrated and simplified.

The press of the flexible circuit board can transmit data signals and act as the bridge between the external printed circuit and LCD. It can be bent and thus becomes a flexible or flexible circuit board

The manufacturing process of the LCD substrate still has a lot of details and matters needing attention, for example, rinse with clean, dry, dry, dry, ultrasonic cleaning, exposure, development and so on and so on, all have very strict technical details and requirements, so as to produce qualified eyes panel, interested friends can consult relevant technical information by a search engine.

LCD (LC) is a kind of LCD, which has the properties of light transmission and refraction of solid Crystal, as well as the flow property of Liquid. It is because of this property that it will be applied to the display field.

However, LCD does not emit light autonomously, so the display equipment using LCD as the display medium needs to be equipped with another backlight system.

First, a backplate is needed as the carrier of the light source. The common light source for LCD display equipment is CCFL cold cathode backlight, but it has started to switch to an LED backlight, but either one needs a backplate as the carrier.

CCFL backlight has been with LCD for a long time. Compared with LED backlight, CCFL backlight has many defects. However, it has gradually evolved to save 50% of the lamp and enhance the transmittance of the LCD panel, so as to achieve the purpose of energy-saving.

With the rapid development of LED in the field of lighting, the cost has been greatly reduced.LCD panels have also started to use LED as the backlight on a large scale. Currently, in order to control costs, an LED backlight is placed on the side rather than on the backplate, which can reduce the number of LED grains.

However, no matter CCFL backlight or LED backlight is placed in various ways, the nature of the backlight source cannot be a surface light source, but a linear light source or point light source. Therefore, other components are needed to evenly distribute the light to the whole surface. This task is accomplished by the diffuser plate and diffuser plate.

On the transparent diffuser plate, point-like printing can block part of the light. The LED backlight on the side drives the light from the side of the diffuser plate, and the light reflects and refracts back and forth in the diffuser plate, distributing the light evenly to the whole surface. Point-like printing blocks part of the light, screening the light evenly like a sieve.

At the top of the diffusion plate, there will be 3~4 diffuser pieces, constantly uniform light to the whole surface, improve the uniformity of light, which is directly related to the LCD panel display effect. Professional LCD in order to better control the brightness uniformity of the screen, panel procurement, the later backlight control circuit, will make great efforts to ensure the quality of the panel.

The backlight system also includes a backlight module laminator, located behind the backplane. In the CCFL backlight era, you can often see the long strip laminator like the one above, with each coil responsible for a set of tubes.

However, it is much simpler to use a side white LED as a backlight. The small circuit board on the far left of the figure above is the backlight of the LED.

This is the general structure of the backlight system. Since I have never seen the backlight mode of R.G.B LED, I cannot tell you what the backlight mode is like. I will share it with you when I see it in the future.

Since the LCD substrate and the backlight system are not fixed by bonding, a metal or rubber frame is needed to be added to the outer layer to fix the LCD substrate and the backlight system.

After the period of the Module, the process is completed in LCM (LCDModule) factory, the core of this part of the basic does not involve the use of LCD manufacturing technology, mainly is some assembly work, so some machine panel factories such as chi mei, Korea department such as Samsung panel factory, all set with LCM factories in mainland China, Duan Mo group after the LCD panel assembly, so that we can convenient mainland area each big monitor procurement contract with LCD TV manufacturers, can reduce the human in the whole manufacturing and transportation costs.

However, neither Taiwan nor Korea has any intention to set up factories in mainland China for the LCD panel front and middle manufacturing process involving core technologies. Therefore, there is still a long way to go for China to have its own LCD panel industry.

Royal Display is one of the leading LCD Display Parts supplier, wholesaler, stockist, and exporter in Mumbai, India sourcing products from trusted and reliable vendors.

LCD Display Parts Latest price | LCD Display Parts datasheet files | LCD Display Parts stocks | LCD Display Parts photos | LCD Display Parts compatible models.

LCD Display Partsare available atRoyal Displayfrom industry leading manufacturers.Royal Displayis a reliableLCD Display Parts supplier and exporter in India. We operate worldwide, service products, configure, and also offer logistics support to deliver products and services competitively.Royal Displayis an authorized distributor for manyLCD Display Partsmanufacturers.

Royal Displayhas built its reputation by offering advanced products and has a very wide range of standardLCD Display Partsand are open for any customized display requests. TheLCD Display Partshave been in demand in industries such as for the measurement of instruments, Electronic Panels, ATM terminals, PoS terminals, auto vending machines, Manufacturing, Automotive Display in Electric Vehicles, the digital videos, video games, and machine tool monitors, GPS, fish finders, POS systems, advanced imaging and color reproduction technologies, mobile phones, elevator displays, and medical devices etc.

A Liquid Crystal Display (LCD) can be of the character type or graphics type. Graphic LCD displays have a matrix of pixels that can be used to display text and graphics, e.g. 128 by 64 pixel display. When starting electronics, a character LCD will usually be used.

Character LCDs can display characters only and are divided into rows of characters. For example a 2 by 16 character LCD display has two lines that can display 16 characters each. An example of a 2 × 16 character display is shown below.

LCDs are available with or without a backlight. A backlight is just a light in the LCD that lights up the display making it easier to read in low light conditions.

There are a number of character LCDs based on the Hitachi HD44780 LCD controller and driver IC. These displays are software compatible and available from several different manufacturers. There are even pin compatible character LCDs that are available from different manufacturers. Always check the datasheet from the manufacturer to make sure of the pin numbering and pin functions of the LCD display that you are going to use.

It is possible that other displays are also compatible with this one. If a backlight is not present, then pin 1 and 2 may be missing. Other LCDs may have the pins at the top and pin numbering may start with 1 on the left.

Ms.Josey

Ms.Josey

Ms.Josey

Ms.Josey