silhouette cameo 2 lcd screen replacement free sample

You guys, this is huge! HUGE!! Silhouette announced last week the launch of the NEW and improved Silhouette CAMEO! And this machine is going to rock! Lots of great upgrades and new technology. Love it! And it just went on sale yesterday. You can snag the New Silhouette CAMEO here {if there’s any left!! They will sell out.}

Disclosure: I voluntarily wrote this post on my own because I love Silhouette products. I have used their products for over 5 years now and stand behind them. I was not given free product for this post. Affiliate links may be used in this post. All opinions are 100% my own. See my disclosure page for a complete statement.

If your Silhouette makes noise while cutting, it is probably normal. Lift your Silhouette’s lid to make sure any tape that is connecting the motor to the side of the unit has been removed. If this was not previously removed, this would be the cause of the excessive noise. Remove the tape and power the Silhouette unit back on.

If when your Silhouette is powered on, it immediately begins to go through cutting motions (starts to cut the same job repeatedly or the blade taps up and down rapidly) prior to you sending a cut job, another device is trying to communicate with your machine. The issue stops if the USB cord is removed, but is repeated without stopping if the unit is powered on and the USB cord is connected to the computer.

This will direct the older unit’s driver, which is no longer present, to stop trying to take up the USB connection and subsequently stop it from confusing your Silhouette machine.

If pressing “Pause” does not immediately stop the job, it is because it is waiting to stop the job after it has completed the current continuous line it is working on. For example, if your Silhouette was cutting a series of circles, pressing the Pause button would not stop the cutting action until the Silhouette stopped cutting the circle it was working on when the button was pressed. It would then stop and not move to complete further circles.

The only immediate method to stop a cut job would be to power off the Silhouette completely. This will abandon the job rather than pause it. If you power off the Silhouette to stop the job, please note that the job cannot be resumed where it left off.

If the cutting process pauses for prolonged periods of time (up to several minutes at a time) and the power light flashes, your machine is overwhelmed by the amount of data being sent. This is most common with the Original Silhouette.

This has nothing to do with the processing speed or ability of your computer, but rather the Silhouette machine itself. The power light flashing indicates that the Silhouette is on standby and will resume cutting after a few moments.

If this does not resolve the concern and the Original Silhouette model is in use, slow down the cutting Speed setting to 3 (or lower). Slowing the speed will resolve the issue by sending a slower data stream. The Silhouette should no longer stop in the middle of the job. This only needs to be performed for jobs where your Silhouette appears to stop and goes on standby (the power light flashes) in the middle of the job.

Go to the Send panel in Silhouette Studio®. Choose your material for your project. Click “Edit Material”. and check the “Track Enhancing” option. This feature will feed the material through your Silhouette several times prior to the cutting operation and create a “track” for the Silhouette to roll on during the job in question. This can help with proper alignment of the secondary passes performed.

If your cutting mat or material is moved in and out through your Silhouette, but the motor does not move side-to-side during cutting, the following could be your concern:

The motor is stuck (generally due to unremoved packing tape). Lift your Silhouette’s lid and remove any blue translucent tape that is connecting the motor to the body of the unit or appearing anywhere on the blade carrier. Perform the following steps:

There is not a direct connection between the Silhouette and the computer tower/laptop (i.e. the USB cord is being run through a hub, USB extension cord, through a monitor or keyboard USB port, etc.).

The blade is not lowering properly or at all during the cutting process. Observe the blade to see whether or not it is lowering during cutting process. If it’s not, please make sure you are using the USB cord that came with your machine to connect your Silhouette to your computer.

Once the blade has been placed all the way down into the blade holder receptacle, you will want to ensure that the lock lever is turned to the right to lock the blade into place. You may want to make sure the blade’s fin is pointing forward in the 6 o’clock position in order to ensure the fin is not hitting the back of the holder. If using the original Silhouette, ensure that the blade’s fin is pointing to the right in the 3 o’clock position.

Your design is on a smaller scale or is more intricate and is being cut on a thicker material type. The quality of cut depends on the combination of the scale, intricacy, and thickness of material being used. For example, an intricate image cut on a small scale may cut out well in a thinner material such as vinyl, but may not cut out well on the same scale with cardstock. As the scale is decreased and intricacy increased along with thicker material types, you may expect to see lower quality cutting results, especially around corners or detailed areas. If you are cutting a combination of a smaller, more intricate images on thicker material, enlarge the image or use material type that is thinner. Please note that some fonts and images may not be designed for optimal cutting on smaller scales. Silhouette cannot guarantee that every design will cut well with the Silhouette on any scale or any material type.

The blade level controls how far the blade is exposed in 0.1 mm increments. This should correlate with how thick the material is. For example, a blade level of 1 = .01 mm, a level of 2 = 0.2 mm, etc. If you have a material like cardstock where the actual thickness is 0.3 mm, setting the blade to a higher exposure (such as 0.6 mm or a setting of 6) would mean you are exposing the blade beyond the actual depth of the material. This does not allow the blade to cut better. It just exposes more of the blade and extending beyond the actual thickness of the material can dull down the blade tip much more quickly. This would result in ragged cutting results. From that point on, you would then have to expose the blade to a higher level because a setting of 6 would actually be only exposed 0.3 mm since you had worn down the excess tip beyond the material’s thickness. So, we discourage attempts to overexpose the blade to try and get a “better” cut.

The key to successful cutting results is to find the lowest blade setting and force setting combination where the Silhouette is still able to cut your material successfully. For example, if a specific material is able to be cut with a blade setting of 3 or 4, you should opt to go with the lower setting that is still allowing you to have a clean final cut. Likewise, if the Force setting works at 28, it would likely also work at 30. However, the lower setting should be selected to avoid over-exerting the blade beyond what is necessary to achieve a clean successful cut.

If your Test Cut works but you find there are areas not getting a clean cut on denser materials, you may wish to slow down the Speed and increase the number of Passes (Double Pass in older versions). This will have the Silhouette cut your image twice or more, ensuring any problem areas are given an extra pass during the cut job.

If your Silhouette stops cutting after it has started prior to fully completing the job and reports that the job is complete, or if your Silhouette cuts a stray line through the middle of the job (generally a diagonal line), then the issue probably that a larger packet of information is being pushed from the computer to your Silhouette. The Silhouette is not able to handle the larger stream of information. As such, the Silhouette abandons the job or cuts a stray line since it cannot properly assess the information being received.

Less commonly, this issue can be caused by the presence of a small bit of un-removed blue packing tape found on the black motor case where the blade is seated. This tape covers certain sensors on the unit that confuses the Silhouette and makes it think the job is completed when it is not. Under and to the left of the blade, if you find a small piece of translucent blue tape that was not initially removed, please remove this tape and discard it.

If your Silhouette goes through and completes the entire cutting process, but part of the image appears to be uncut (not ragged or torn, but simply not cut at all) while others are cut properly, it could be one of the following:

If one specific side of every image is not cut well or at all, the issue is with the blade itself. Take the blade out of your Silhouette grip the tip of the blade and unscrew it. Please use caution as the blade is sharp. Proceed to carefully make sure the blade swivels or rotates freely. This can be done by carefully taking the blade and pressing the tip lightly onto a firm surface. Rotate the blade a full 3600 so that the blade can be confirmed to swivel all the way around. Swiveling the blade around manually should get it unstuck and back into proper working condition.

If one specific side or area of the mat is not cut well or at all, the issue is with the cutting mat being worn down in that area, or with the cutting strip being cut into in the offending area. This may occur on either side or in the center and be a large or small area that is affected. Lift the lid of your Silhouette and inspect the black cutting strip. If materials have been used without the cutting mat and the Force setting (Thickness in older versions) too high, the cutting strip may have been inadvertently damaged. Such would impair further cutting results. Indentations on this strip are normal and will be experienced. The cutting strip will be naturally indented with the cutting process. Fraying, however, indicates the strip is damaged. The cutting strip typically doesn’t need to be replaced unless it is affecting cutting results. If this is the concern, a replacement cutting strip can be purchased.

Check the loading method on your Silhouette machine to make sure the correct loading option is being selected. Since the loading methods will feed the mat or material in at differing distances, if the wrong loading method is being used, then the registration marks will not be found.

Make sure the material is being loaded in the proper orientation as shown on screen. If there a cutting mat is not being use, then ensure the material is loaded into the Silhouette in the direction of the arrow shown on the computer screen. If a cutting mat is in use, then ensure the material is placed onto the mat exactly as shown on the computer screen.

Make sure the registration marks are printed clearly and properly. The optic scanner is only able to read marks that are clearly printed. The printer may be printing the lines too lightly if the ink or toner cartridge is low, or it is possible that the printing preferences are set to a lower quality. The Silhouette’s optic scanner is also unable to read marks that may have been smudged or have bled into the material in use. This has especially been found with certain cardstock materials. A good test to determine if this is the case would be to re-print the job onto a regular piece of white copy paper and retry the job.

Check the material color. There may be an issue with reading registration marks that are printed onto select materials colors. The Silhouette may not be able to read the black registration marks on darker or other select material colors. This is especially true with green and blue tone material colors.

Check the Registration Mark Format type. If using the Cameo or Portrait model, then the Type 1 format should be used. If using any other older Silhouette model, the Type 2 format should be used.

Check the material color. There may be an issue with reading registration marks that are printed onto select materials colors. The Silhouette may not be able to read the black registration marks on darker or other select material colors. This is especially true with green and blue tone material colors.

Check to make sure the actual printed registration marks on the printed page are fully present. If they do not appear as shown on screen and part of the mark is not completely present, there may be a concern with the printer margins or page size.

Check to ensure the printer settings match the Page Settings. There may be a problem where the page size, orientation, and settings for what the printer are set to over-ride the settings that have been defined in Silhouette Studio®.

Registration marks may not work on textured surfaces, such as textured cardstock, or other select cardstock materials. Silhouette cannot guarantee that registration marks will work on all materials.

Generally, there is an assumption made that if registration marks are read but the cutting alignment is off, then there is a problem with the Silhouette’s calibration. This is rarely the case. Calibration should rarely be necessary. Before attempting to calibrate the Silhouette, review the previous points first regarding misalignment on Print & Cut jobs.

If your Silhouette has been powered off in the middle of a cutting job and the cutting mat remains stuck after the Silhouette is powered back on, do the following:

Clean the mat between uses to ensure there are no fibers or other materials which cause papers or other materials to not be gripped as well. You can use a disposable lint roller to clean these fibers from your mat if you’d like. Also, use your Silhouette scraper to push any stray pieces off your mat.

If the cutting mat is too sticky, check what material type you are using. While many materials can be used with the Silhouette, some materials may not perform as well and may rip or tear when you attempt to remove it from the cutting mat. As the mat is initial fairly sticky, you may wish to take the mat prior to initial use and “season” it a bit by placing it against a surface that is not overly linty, such as jeans or a cotton tee. This can allow the adhesive to become less aggressively sticky.

Also, we highly recommend our Silhouette Spatula tool. This tool can aid in the removal of certain more delicate materials and cutout items from the mat.

If you are using a Cameo, the right-hand pinch roller is not locked into place. Ensure the white lock lever is pointing upward and that the right-hand pinch roller appears to be fully gripping the edge of the right-hand side of the mat.

If you are using a Cameo, the pinch rollers are not in the correct position for the size mat or material is use. If using a material size that is smaller on the 12 in. x 12 in. cutting mat, please note that it is still necessary to have the pinch roller in the default position for the 12 in. x 12 in. mat (rather than adjusting the right-hand pinch roller over to the left for a smaller page size).

There is no cut information present (generally because the image is an external imported file and has not yet had cut lines created). Usually, this is the concern and you simply need to use the Trace feature to create cut lines for your Silhouette to see. For a more info on tracing images, see page 76.

The blade has been manually moved prior to you sending the job, so the option to Cut is instead returning to the origin point and then stopping to await the action to Cut again. The Silhouette needs to start in the default origin point and then cut according to where the image is placed on the screen.

If the image in question was obtained from the Design Store, attempt to right-click and Ungroup the image. If attempts to cut are successful from that point, please report the image ID back to support@silhouetteamerica.com so we can have the original image corrected and the lines enabled by default.

If you are printing a document from Silhouette Studio® and the page is blank or only has registration marks printed if you have enabled them, there is no print information in the file.

While there appears to be an object on screen to print, there is actually no print information present in the file. Cut lines and print information are handled differently. The Silhouette Studio® software program does not print outlines or cut images unless the lines are specifically enabled to print.

If a font name appears in the Fonts section of the Library as a blank image noting the font name, but has no preview to show the actual font style image, the font was not properly installed. This is usually due to a permissions error where the Operating System needs to allow access to Silhouette Studio® to have permission to install a font onto the computer. The following steps may be taken to resolve this concern:

This process will only work for fonts downloaded from the Silhouette Design Store. If the font was obtained from another source, it should not be installed into the Fonts section of the Library. Other fonts may simply be installed into the Fonts directory of the computer and then reopen the software.

If there is no response when you are trying to access the Silhouette Studio® manual (via the Help menu in the software), there is probably an issue with the PDF reader program on your computer.

Credits expire 60 days after they are added to your account, no matter if you made a one-time purchase or picked up a subscription. For example, if you have a subscription and credits are added to your account each month, then two months later those credits will expire if you haven’t used them. You can find out when your credits will expire by clicking the credit amount for your account in the Silhouette Design Store.

If you open Silhouette Studio® for the first time and the library appears to be empty and the preloaded content included on the Silhouette product box is missing from your library, your Silhouette model has not yet been detected by Silhouette Studio®. The content included with your Silhouette purchase is controlled by what model you have and detected in order to provide proper access to coinciding preload content. The following steps can be taken to resolve the concern:

If a thumbnail for an image is blank in Silhouette Studio®, there was a concern with the original download due to security settings on the computer, or there was a corruption in the original downloaded file. The image title is present and the image can be opened without concern, but the thumbnail simply does not appear when viewing the library. The following attempts can be performed to explore the concern further:

If the concern is that a recent order is not showing up properly in the Silhouette Studio® library, this can indicate that the content was not purchased directly through the software, or that the Silhouette Design Store did not detect that it was being run through the software during the initial download process. It may also indicate an unknown download concern or break in internet connectivity during the original download attempt.

Silhouette America maintains a database of all Silhouette users and their download histories. In the event of a computer crash, computer replacement, or reformatting, after re-loading the software onto the computer, you may recover as follows:

You will need to access the store through the software. The download and recovery process will only download content to the Library when you are downloading or recovering through the Silhouette Design Store through the software.

If your Library is missing, there is no need to be alarmed. Your library is safe. In most instances, updating to the Cloud version of the Silhouette Studio® software migrates your library successfully.

The preloaded content allotted with the purchase and connection of a Silhouette cutting machine cannot be moved out of the Local User section of the library. These images reside in the “Recent Downloads” folder in this section. Typically they will show in counts of 50, 100, 150, or 200 depending on the machines that have been connected.

Content obtained from the Silhouette Design Store cannot be moved out of the Cloud User Library section. All Silhouette content can be rearranged, at will, within the Cloud User section. All content obtained from the Silhouette Design Store, while stored in the Cloud User library, have a copy downloaded locally to your computer. An active internet connection is only required on initial download of the content. Any use thereafter does not require and active internet connection.

If your library is showing “synced”, but all content obtained from the Silhouette Design Store is not actively downloaded, you may need to force an update of your library. A fully “synced” Cloud User library is indicated with a white check-mark within a green circle next to your user name. If yours doesn’t look like this, do the following:

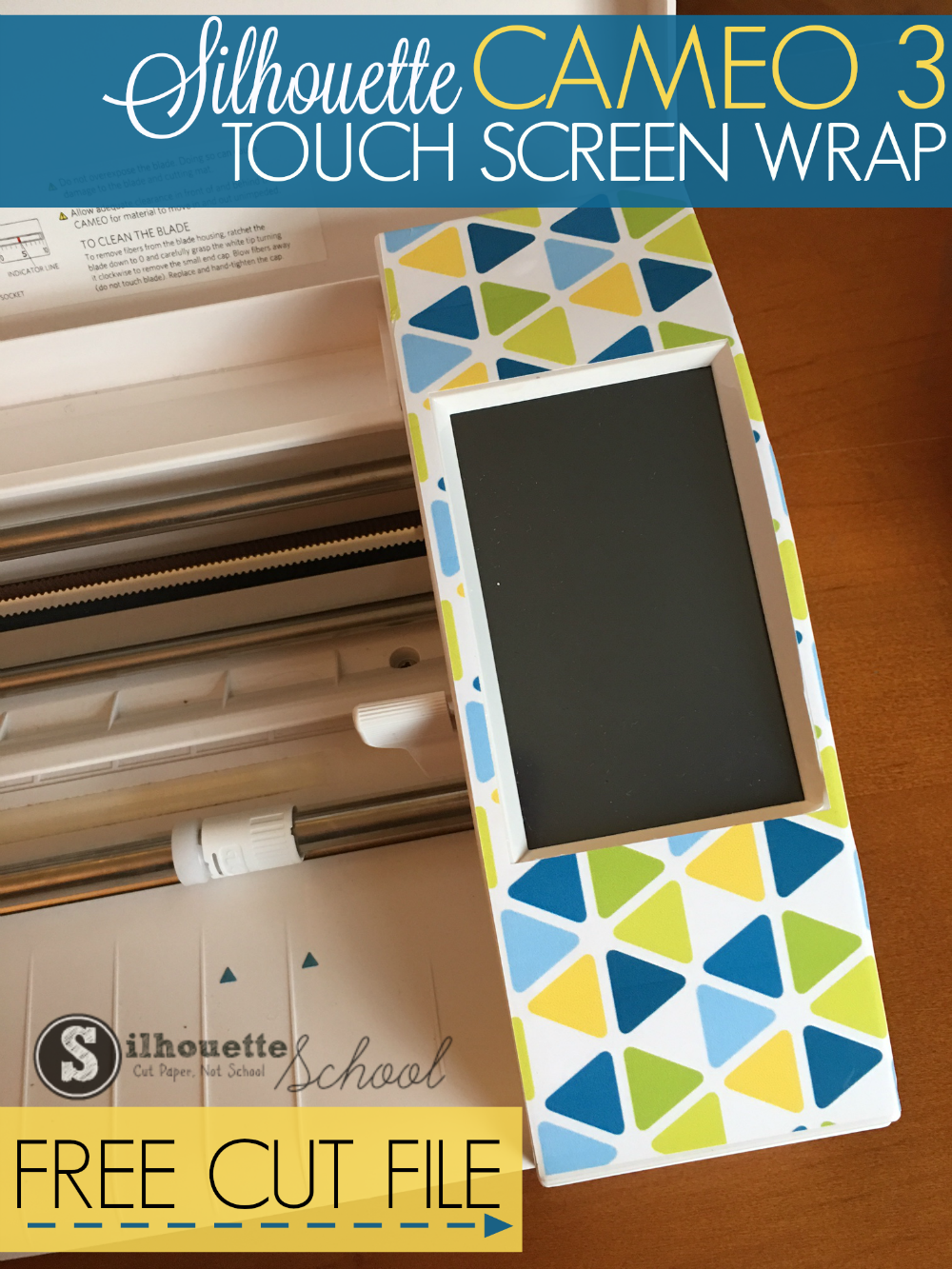

Want to bling out your Silhouette CAMEO 3? It"s your lucky day. Today I"m sharing a free Silhouette Studio cut file for a CAMEO 3 touch screen skin...and again I"m spreading my love for removable sticker paper which is my top choice of materials for cutting this shape.

The Silhouette CAMEO 1 included a free cut file when you downloaded the 50 free designs and I created a CAMEO 2 control panel shape, but the CAMEO 3"s been patiently waiting for some TLC.

The control panel shape is perfectly sized so all you have to do is download it below and open in Silhouette Studio. Do not resize it at all or it won"t fit around your Silhouette Cameo 3 touchscreen.

With registration marks on, two Silhouette CAMEO 3 control panel shapes fit on a sheet. I filled each with a different custom pattern that I had previously imported into the My Patterns folder.

Online Labels has recommended Silhouette cut settings for all of their products so I always refer to their list. For this removable printable sticker paper a blade depth of 3 with a thickness of 10 and a speed of 4 work perfectly to give you a kiss cut.

The great thing about this Online Labels sticker paper is the quality - it can stand up to transfer tape - which is necessary to use when moving the sticker to the CAMEO. There"s no way you"d be able to do this without transfer tape due to those thin areas on either side of the touch screen panel.

Once the sticker is in place around the touch screen, burnish it with your finger or the Silhouette scraper and then peel away the transfer tape. I had one bubble on the bottom section, but was able to easily peel up the bottom part of the sticker and then re-stick it! That"s the beauty of the repositionable sticker paper.

The other great thing about Online Label"s removable sticker sheets are you can easily remove them...hence the name. This makes it super easy to swap out your Silhouette CAMEO 3 skin whenever you want. Just peel off the sticker and replace it with a new one....which is why you print and cut two on the sheet!

Alright now for what you came for the free Silhouette CAMEO 3 control panel shape...just click the link below to download it. Then open it in Silhouette Studio. Remember not to resize it!

Note: This post may contain affiliate links. By clicking on them and purchasing products through my links, I receive a small commission. That"s what helps fund Silhouette School so I can keep buying new Silhouette-related products to show you how to get the most out of your machine!

I love it when new die cut machines come out…and I always buy them. Sometimes, they’re not a big hit with me and sometimes they are. I thought that the Silhouette SD was a cool machine, then when the original Silhouette Cameo came out, I was elated. (Later the Silhouette Portrait and Curio took the place of the SD.) Then the Silhouette Cameo 2 came out and I thought it was a nice improvement over the original. Did you know that the new Silhouette Cameo 3 is actually the 4th Cameo machine release? It is. It’s the 3rd new Cameo, but there was a change and reissue of the original Cameo. Here are the differences between the Silhouette Cameo 2014 Compared to the Original Silhouette Cameo. You can also learn about the differences in the reissued machine in that post, and see which one you might have!

The box. I think it’s probably helpful to see it, in case you receive a box that doesn’t look like this, you might want to go over the machine really well to make sure you actually have the Silhouette Cameo 3. I like the fruit on top!

Yes, Bluetooth. That is definitely one of the biggest selling points of this machine. This is Silhoutte’s first Cameo that has Bluetooth capabilities.

I bought this bundle deal from Amazon and all of these things came with it. If you buy the Silhouette Cameo 3 machine and it’s not part of a bundle, you can count on receiving the machine, a mat and all of the cords you’ll need to get started.

These things were part of my bundle, but you can buy the Deluxe Tool Kit (or the regular tool kit), Metallic Sketch Pens, regular mat and PixScan mat individually. You can buy more self-adjusting AutoBlades too. One of the nice things about this machine is that the new AutoBlade will adjust to the blade depth that’s associated with the material you’re using, which you’ll choose in the software settings. This machine will also accept the previous Silhouette blade. So, if you’re like me and stocked up on those, you haven’t lost anything.

Once you open the Silhouette Cameo 3, you’ll see a few new things: an open storage area on the far left, a dual head carriage for a blade, pens and other tools, and a pull out tray.

See? Folding out those little arms gives the mat a larger area to rest. It’s nice because previously the mat would dip a bit. Usually that didn’t matter, but if your mat lost it’s stickiness, it could cause your material to come up where it dipped or bent. I used to deal with that by putting a block of wood under there. I’m really glad that I don’t have to do that any more. It can also be helpful if you’re using a 12 x 24 mat.

Here’s a close up of the dual carriage with the AutoBlade and a Silhouette Sketch pen in the holders. The bar can rise to 2mm and the rollers are now easier to move. You can actually push them out of the way now, which is nice if you want to keep roller tracks off of foil, foam and other materials that can get smashed or smudged.

The Silhouette Cameo 3 has several new offerings compared to the Silhouette Cameo 2. You’ll notice some changes in the menus. The 3, on the left, has removed the “load media” option. Keeping this menu fairly succinct. The purple hue has changed too, but you still only have 3 screen color choices. I like the pink/purple color.

The Silhouette Cameo 3 now includes some helpful tutorials. Notice the “Sounds” button? Here’s a tutorial showing exactly how to turn off the sound on the Cameo 3.

It will show you to do some basic operations that are pretty important. For example, you can learn how to load materials, load and adjust the blade and adjust the roller bars. I think this is a nice addition for people who are new to the Cameo, and a helpful reminder to more seasoned users.

I’d say the most important difference between the Silhouette Cameo 3 compared to Silhouette Cameo 2 is Bluetooth. I didn’t have any trouble syncing it to my Ipad, but once I did, I was not impressed with the app. You can download the app for free and see what you think, but when I tried it for the first time a few weeks ago, I thought it was a mess. That being said, Silhouette’s software has always been why I choose it over other machines. I think it’s very user friendly. So, I’m sure they can and will make changes to make the app rise up to meet the expectations of Silhouette users. I’m crossing my fingers on that one, but don’t take my word for it. Go check it out for yourself. That’s the best way to know for sure. After all, some people hate the Silhouette software and prefer Cricut’s. I’ve said it before, and I’ll say it again, “The best machine is the one that works best for you.” That goes for software too.

There’s a BIG change to the outside of the Silhouette Cameo 3 and the Silhouette Cameo 2. The Cameo 3’s lid has been extended to cover and protect the touch screen, as well as enclose more of the cutting area.

You can see the differences here with the lids open. The Silhouette Cameo 2 is in the front. The 3 has the dual carriage, storage on the left, and a different overall look.

When I said BIG change,I meant that the Silhouette Cameo 3 got bigger. It’s possible that the 3 could eat the 2. The 3 is wider, longer and heavier. Personally, I don’t like that it had to grow up so much, but I guess I’ll get used to it. Those cool covers (like this Hey, Gorgeous one)that fit the original and the 2, forget about it. They will not cover the 3. We’ll just have to get crafty!

Where the Silhouette Cameo 2 had storage on the side (see this post for more about the Cameo 2), the 3 incorporates it into the front part of the machine. Both machines have the removable crosscutter blade. It’s helpful when cutting rolls of vinyl and excess paper. By the way, if you’re new to vinyl, it’s a super fun! Check out these projects for some free files and ideas.

Well, I think that covers all of the offerings of the new Silhouette Cameo 3 and how it compares to the Silhouette Cameo 2. I hope it helps you pick the best one for you!

When I first considered buying a die-cutting machine, I did some research on the types of machines available. I found the original Silhouette machine by accident in a web search and was thrilled with the possibilities. I loved the flexibility of being able to use any font already on my computer (I’m a self-professed font junkie) and design anything I could imagine.

Now, 9 years later, I can honestly say these machines have far exceeded my expectations. I am blown away every day by the projects I see being created and by how the machines are being used in so many different industries outside of just papercrafting. I originally purchased the machine to make cards. Now I also use it for personalizing just about anything with heat transfer material, vinyl and rhinestones, for jewelry-making, for creating my own nail stamping plates, for home décor, and so much more. If you are a creative type who wants to let your imagination soar and have a machine to help your vision come to life, I can heartily recommend the Silhouette line of machines.

All Silhouette machines use included computer software to design images and to send projects to the machine. Because of this, you want to be aware of the minimum recommended computer requirements. All Silhouette software programs (see more info below on what those are) will run on either Mac or Windows computers. Chromebook is not currently supported. The software will not run on a tablet such as an i-Pad, as they do not use the same operating system as a computer. There is an app in development, but it is not currently available and will probably be limited. You need a computer, not a mobile device.

Silhouette Studio is the software that is used for Portrait, Cameo and Curio cutting machines, as well as all older models. For Mac users, you will need OS X 10.7 or higher. Windows computers need to be Windows 7 or above. Although you can run a lower version of the software on an older computer, the newer machines require newer computers. For example, version 2 of the software can be run on a Windows XP computer, but the current Cameo models will not work from it. We are currently on version 4 of the software so version 2 is quite old by now. Plus, XP is no longer supported by Microsoft so it not safe or reliable. You want to check minimum requirements for both the software AND the machine.

2 GHz or faster processor. Be careful here! Even new computers can have older or slower processors, which makes the software sluggish. This is a powerful software — you need a good processor. Also watch for the memory speed.

Silhouette America and online retailers often offer machines in bundles. These bundles include everything listed above as well as extras. I am often asked which bundle is best to get. The answer depends on what you will use. Here are some thoughts.

–If you intend to primarily cut materials like vinyl or heat transfer vinyl without the mat, it is also a good idea to have an extra cutting strip on hand at all times. Get these from the Silhouette America website under

In general, the Silhouette can cut paper, vinyl, heat transfer material (HTV), rhinestone template material, stabilized fabric, and other materials that

For materials Silhouette America does not sell, there’s no hard and fast rule for what can be cut successfully, but the Silhouette Model Comparisons chart linked above gives you general guidelines. It’s only limited in helpfulness, however, because it’s not been updated for the

There are many user groups on social media dedicated to using a Silhouette machine. These are great places to ask questions. For example, there are a large group of folks who use the Curio to cut metal clay for jewelry.

—Adobe Illustrator CS4-CS6, CC, CC2014, CC2015 or CorelDraw X4-X7 (full version only – does not support Home and Student or Essentials editions or illegal copies)

This app is for cutting on the go. It will NOT replace a computer for using with the Silhouette machines. The designing takes place in the full software on your computer. You can then save the file to your library, go somewhere with your machine but not your computer, and cut the file. It’s helpful if, say, your computer is in one room and your machine is in another, or if you want to take your machine to a craft fair but not your computer.

The Silhouette CAMEO� connects to your computer, allowing you the freedom to cut all your fonts, download thousands of designs from the Silhouette Online Store, or design shapes of your own with the included software.

Based on years of cutting plotter technology by GRAPHTEC, the Silhouette Cameo™ Electronic Craft Cutter brings professional style computer controlled cutting to the desktop.

Previously known as the Silhouette SD, the Silhouette Cameo™ electronic cutting tool is your gateway to creative freedom. It"s perfect for vinyl lettering, school projects, sticker and decal vinyls, masking film for painting or etching, scrap booking, paper crafting, stencil making, various kinds of T-shirt heat transfer materials, small business applications and more.

The Silhouette CAMEO™ connects to your computer, allowing you the freedom to cut all your fonts, download thousands of designs from the Silhouette Online Store, or design shapes of your own with the included software.

The Silhouette Studio� is a FREE software included with every Silhouette CAMEO™. It is Mac� and PC compatible and contains powerful design tools to create your own shapes

Silhouette Cameo™ Electronic Craft Cutter is 20.9" x 5.0" x 6.5" and is smaller than most inkjet printers. It only weighs 11.25 lbs. Don"t be deceived by it"s small size. It can handle media up to 12 inches wide by 12 inches long, with a cutting area of 11.6" inches wide by 10" in extended mode with roll media.What"s Included:

Ms.Josey

Ms.Josey

Ms.Josey

Ms.Josey