lcd panel assembly process manufacturer

Important technical improvements of LCD, such as LED backlighting and wide viewing Angle, are directly related to LCD. And account for an LCD display 80% of the cost of the LCD panel, enough to show that the LCD panel is the core part of the entire display, the quality of the LCD panel, can be said to directly determine the quality of an LCD display.

The production of civil LCD displays is just an assembly process. The LCD panel, the main control circuit, shell, and other parts of the main assembly, basically will not have too complex technical problems.

Does this mean that LCDS are low-tech products? In fact, it is not. The production and manufacturing process of the LCD panels is very complicated, requiring at least 300 process processes. The whole process needs to be carried out in a dust-free environment and with precise technology.

The general structure of the LCD panel is not very complex, now the structure of the LCD panel is divided into two parts: the LCD panel and the backlight system.

Due to the LCD does not shine, so you need to use another light source to illuminate, the function of the backlight system is to this, but currently used CCFL lamp or LED backlight, don’t have the characteristics of the surface light source, so you need to guide plate, spreadsheet components, such as linear or point sources of light evenly across the surface, in order to make the entire LCD panel on the differences of luminous intensity is the same, but it is very difficult, to achieve the ideal state can be to try to reduce brightness non-uniformity, the backlight system has a lot to the test of design and workmanship.

In addition, there is a driving IC and printed circuit board beside the LCD panel, which is mainly used to control the rotation of LCD molecules in the LCD panel and the transmission of display signals. The LCD plate is thin and translucent without electricity. It is roughly shaped like a sandwich, with an LCD sandwiched between a layer of TFT glass and a layer of colored filters.

LCD with light refraction properties of solid crystals, with fluid flow characteristics at the same time, under the drive of the electrode, can be arranged in a way that, in accordance with the master want to control the strength of the light through, and then on the color filter, through the red, green, blue three colors of each pixel toning, eventually get the full-screen image.

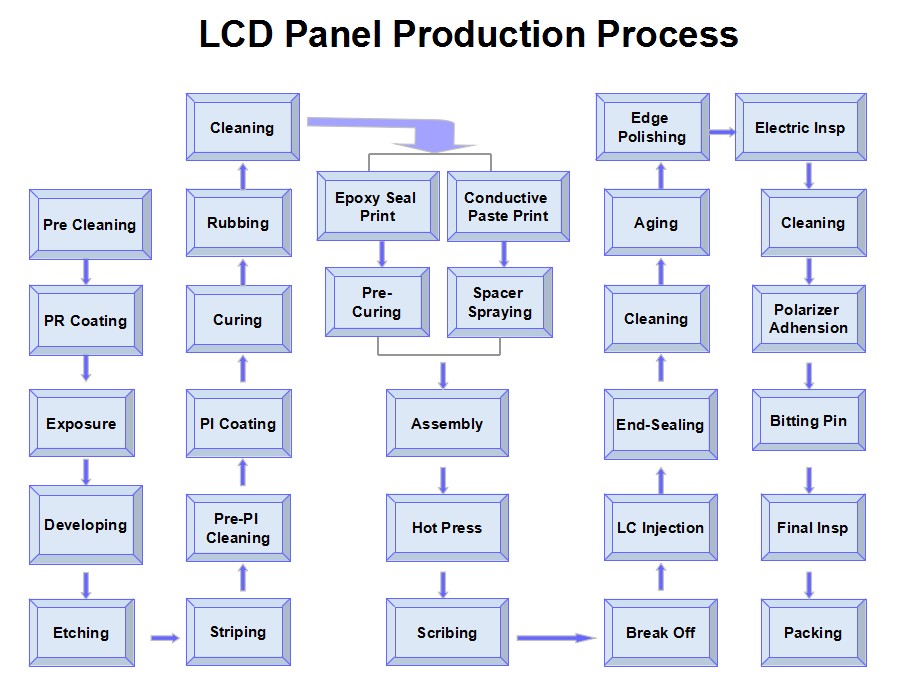

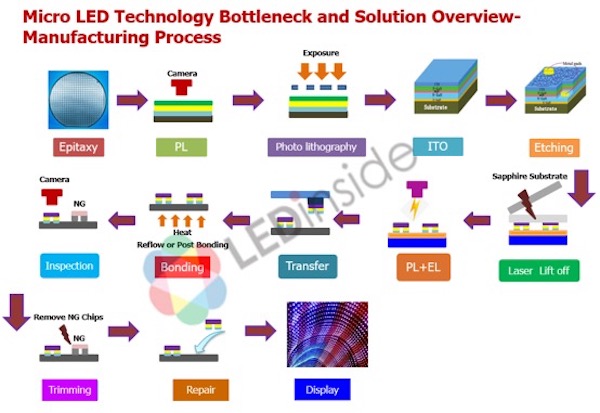

According to the functional division, the LCD panel can be divided into the LCD panel and the backlight system. However, to produce an LCD panel, it needs to go through three complicated processes, namely, the manufacturing process of the front segment Array,the manufacturing process of the middle segment Cell, and the assembly of the rear segment module. Today we will be here, for you in detail to introduce the production of the LCD panel manufacturing process.

The manufacturing process of the LCD panel Array is mainly composed of four parts: film, yellow light, etch and peel film. If we just look at it in this way, many netizens do not understand the specific meaning of these four steps and why they do so.

First of all, the motion and arrangement of LCD molecules need electrons to drive them. Therefore, on the TFT glass, the carrier of LCD, there must be conductive parts to control the motion of LCD. In this case, we use ITO (Indium Tin Oxide) to do this.ITO is transparent and also acts as a thin-film conductive crystal so that it doesn’t block the backlight.

The different arrangement of LCD molecules and the rapid motion change can ensure that each pixel displays the corresponding color accurately and the image changes accurately and quickly, which requires the precision of LCD molecule control.ITO film needs special treatment, just like printing the circuit on the PCB board, drawing the conductive circuit on the whole LCD board.

Rinse the basic label of glass with an organic solution and remove the photolithographic tape after reaction to keep the glass clean. This completes the first thin-film conductive crystal process, which generally requires at least five identical processes to form a complex and sophisticated pattern of electrodes on the glass.

This completes the previous Array process. It is not difficult to see from the whole process that ITO film is deposited, photoresist coated, exposed, developed, and etched on TFT glass, and finally, ITO electrode pattern designed in the early stage is formed on TFT glass to control the movement of LCD molecules on the glass. The general steps of the whole production process are not complicated, but the technical details and precautions are very complicated, so we will not introduce them here. Interested friends can consult relevant materials by themselves.

The glass that the LCD board uses makes a craft also very exquisite. (The manufacturing process flow of the LCD display screen)At present, the world’s largest LCD panel glass, mainly by the United States Corning, Japan Asahi glass manufacturers, located in the upstream of the production of LCD panel, these manufacturers have mastered the glass production technology patents. A few months ago, the earthquake caused a corning glass furnace shutdown incident, which has caused a certain impact on the LCD panel industry, you can see its position in the industry.

As mentioned earlier, the LCD panel is structured like a sandwich, with an LCD sandwiched between the lower TFT glass and the upper color filter. The terminal Cell process in LCD panel manufacturing involves the TFT glass being glued to the top and bottom of a colored filter, but this is not a simple bonding process that requires a lot of technical detail.

As you can see from the figure above, the glass is divided into 6 pieces of the same size. In other words, the LCD made from this glass is finally cut into 6 pieces, and the size of each piece is the final size. When the glass is cast, the specifications and sizes of each glass have been designed in advance.

Directional friction:Flannelette material is used to rub the surface of the layer in a specific direction so that the LCD molecules can be arranged along the friction direction of the aligned layer in the future to ensure the consistency of the arrangement of LCD molecules. After the alignment friction, there will be some contaminants such as flannelette thread, which need to be washed away through a special cleaning process.

After the TFT glass substrate is cleaned, a sealant coating is applied to allow the TFT glass substrate to be bonded to the color filter and to prevent LCD outflow.

Finally, the conductive adhesive is applied to the frame in the bonding direction of the glass of the color filter to ensure that external electrons can flow into the LCD layer. Then, according to the bonding mark on the TFT glass substrate and the color filter, two pieces of glass are bonded together, and the bonding material is solidified at high temperatures to make the upper and lower glasses fit statically.

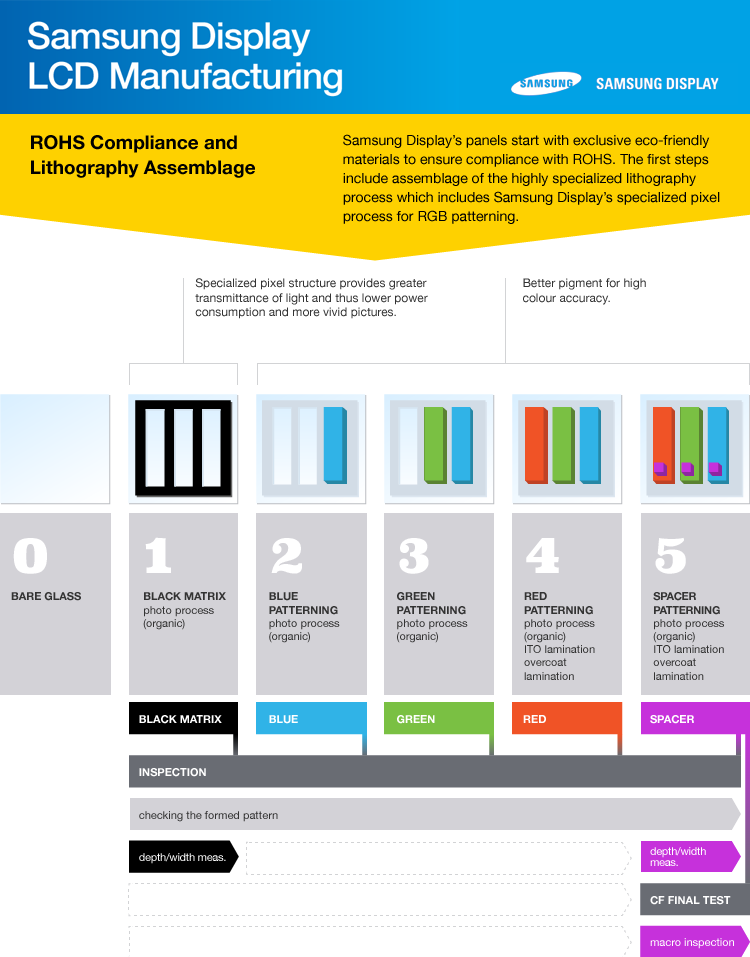

Color filters are very important components of LCD panels. Manufacturers of color filters, like glass substrate manufacturers, are upstream of LCD panel manufacturers. Their oversupply or undersupply can directly affect the production schedule of LCD panels and indirectly affect the end market.

As can be seen from the above figure, each LCD panel is left with two edges after cutting. What is it used for? You can find the answer in the later module process

Finally, a polarizer is placed on both sides of each LCD substrate, with the horizontal polarizer facing outwards and the vertical polarizer facing inwards.

When making LCD panel, must up and down each use one, and presents the alternating direction, when has the electric field and does not have the electric field, causes the light to produce the phase difference and to present the light and dark state, uses in the display subtitle or the pattern.

The rear Module manufacturing process is mainly the integration of the drive IC pressing of the LCD substrate and the printed circuit board. This part can transmit the display signal received from the main control circuit to the drive IC to drive the LCD molecules to rotate and display the image. In addition, the backlight part will be integrated with the LCD substrate at this stage, and the complete LCD panel is completed.

Firstly, the heteroconductive adhesive is pressed on the two edges, which allows external electrons to enter the LCD substrate layer and acts as a bridge for electronic transmission

Next is the drive IC press. The main function of the drive IC is to output the required voltage to each pixel and control the degree of torsion of the LCD molecules. The drive IC is divided into two types. The source drive IC located in the X-axis is responsible for the input of data. It is characterized by high frequency and has an image function. The gate drive IC located in the Y-axis is responsible for the degree and speed of torsion of LCD molecules, which directly affects the response time of the LCD display. However, there are already many LCD panels that only have driving IC in the X-axis direction, perhaps because the Y-axis drive IC function has been integrated and simplified.

The press of the flexible circuit board can transmit data signals and act as the bridge between the external printed circuit and LCD. It can be bent and thus becomes a flexible or flexible circuit board

The manufacturing process of the LCD substrate still has a lot of details and matters needing attention, for example, rinse with clean, dry, dry, dry, ultrasonic cleaning, exposure, development and so on and so on, all have very strict technical details and requirements, so as to produce qualified eyes panel, interested friends can consult relevant technical information by a search engine.

LCD (LC) is a kind of LCD, which has the properties of light transmission and refraction of solid Crystal, as well as the flow property of Liquid. It is because of this property that it will be applied to the display field.

However, LCD does not emit light autonomously, so the display equipment using LCD as the display medium needs to be equipped with another backlight system.

First, a backplate is needed as the carrier of the light source. The common light source for LCD display equipment is CCFL cold cathode backlight, but it has started to switch to an LED backlight, but either one needs a backplate as the carrier.

CCFL backlight has been with LCD for a long time. Compared with LED backlight, CCFL backlight has many defects. However, it has gradually evolved to save 50% of the lamp and enhance the transmittance of the LCD panel, so as to achieve the purpose of energy-saving.

With the rapid development of LED in the field of lighting, the cost has been greatly reduced.LCD panels have also started to use LED as the backlight on a large scale. Currently, in order to control costs, an LED backlight is placed on the side rather than on the backplate, which can reduce the number of LED grains.

At the top of the diffusion plate, there will be 3~4 diffuser pieces, constantly uniform light to the whole surface, improve the uniformity of light, which is directly related to the LCD panel display effect. Professional LCD in order to better control the brightness uniformity of the screen, panel procurement, the later backlight control circuit, will make great efforts to ensure the quality of the panel.

Since the LCD substrate and the backlight system are not fixed by bonding, a metal or rubber frame is needed to be added to the outer layer to fix the LCD substrate and the backlight system.

After the period of the Module, the process is completed in LCM (LCDModule) factory, the core of this part of the basic does not involve the use of LCD manufacturing technology, mainly is some assembly work, so some machine panel factories such as chi mei, Korea department such as Samsung panel factory, all set with LCM factories in mainland China, Duan Mo group after the LCD panel assembly, so that we can convenient mainland area each big monitor procurement contract with LCD TV manufacturers, can reduce the human in the whole manufacturing and transportation costs.

However, neither Taiwan nor Korea has any intention to set up factories in mainland China for the LCD panel front and middle manufacturing process involving core technologies. Therefore, there is still a long way to go for China to have its own LCD panel industry.

The cutting-edge G10 production line is a result of cutting-edge technology. To consistently manufacture LCD panels using the G10 glass substrates, each individual manufacturing process incorporates a range of unique know-how. Developed in collaboration with several world-leading production equipment manufacturers, SDP"s large-scale, one-of-a-kind manufacturing equipment delivers state-of-the-art accuracy and performance levels. One example is the photolithography machine, which is about the size of a tennis court. Our master-craftsmen operate and monitor this machine with the utmost care, to manufacture next-generation products.

In this process, the entire G10 glass substrate is covered with various types of film, such as the circuitry that forms the TFT* (thin-film transistor). There are numerous, extremely large pieces of equipment that produce uniform layers across the entire glass substrate—for example, a sputtering machine that deposits a metallic film, and a CVD (chemical vapor deposition) system that deposits an insulation film and a semiconductor film using the plasma-enhanced chemical vapor deposition method.

In the etching process, portions not covered by resist are removed to form the transistor circuits. There are two kinds of etching machines: a dry etching machine that uses corrosive gas to decompose and remove the insulation film and semiconductor film; and a wet etching machine that uses a liquid chemical to dissolve the metal film. After etching, a resist stripping machine is used to remove the photoresist.

For over 20 years we"ve been helping clients worldwide by designing, developing, & manufacturing custom LCD displays, screens, and panels across all industries.

Newhaven Display has extensive experience manufacturing a wide array of digital display products, including TFT, IPS, character displays, graphic displays, LCD modules, COG displays, and LCD panels. Along with these products, we specialize in creating high-quality and affordable custom LCD solutions. While our focus is on high-quality LCD products, we also have a variety of graphic and character OLED displays we manufacture.

As a longtime leader in LCD manufacturing, producing top-quality LCD modules and panels is our highest priority. At Newhaven Display, we’re also incredibly proud to uphold our reputation as a trusted and friendly custom LCD manufacturing company.

As a custom LCD manufacturing company, we ensure complete control of our custom displays" reliability by providing the industry"s highest quality standards. Our design, development, production, and quality engineers work closely to help our clients bring their products to life with a fully custom display solution.

Our excellent in-house support sets Newhaven Display apart from other display manufacturers. Modifications in the customization process are completed at our Illinois facility, allowing us to provide an exceptionally fast turnaround time.

Customer support requests sent by phone, email, or on our support forum will typically receive a response within 24 hours. For custom LCD project inquiries, our response time can take a few days or weeks, depending on the complexity of your display customization requirements. With different production facilities and a robust supply chain, we are able to deliver thefastest turnaround times for display customizations.

Our excellent in-house support and custom display modifications set Newhaven Display apart from other LCD display manufacturers. From TFTs, IPS, sunlight readable displays, HDMI modules, EVE2 modules, to COG, character, and graphic LCDs, our modifications in the customization process are completed at our Illinois facility, allowing us to provide quality and fast turnaround times.

As a display manufacturer, distributor, and wholesaler, we are able to deliver the best quality displays at the best prices. Design, manufacturing, and product assembly are completed at our headquarters in Elgin, Illinois. Newhaven Display International ensures the best quality LCD products in the industry in this newly expanded facility with a renovated production and manufacturing space.

With assembly facilities in the US, manufacturing facilities in China, and distribution channels worldwide, we pride ourselves on delivering high-quality custom display solutions quickly to locations worldwide.

Flat-panel displays are thin panels of glass or plastic used for electronically displaying text, images, or video. Liquid crystal displays (LCD), OLED (organic light emitting diode) and microLED displays are not quite the same; since LCD uses a liquid crystal that reacts to an electric current blocking light or allowing it to pass through the panel, whereas OLED/microLED displays consist of electroluminescent organic/inorganic materials that generate light when a current is passed through the material. LCD, OLED and microLED displays are driven using LTPS, IGZO, LTPO, and A-Si TFT transistor technologies as their backplane using ITO to supply current to the transistors and in turn to the liquid crystal or electroluminescent material. Segment and passive OLED and LCD displays do not use a backplane but use indium tin oxide (ITO), a transparent conductive material, to pass current to the electroluminescent material or liquid crystal. In LCDs, there is an even layer of liquid crystal throughout the panel whereas an OLED display has the electroluminescent material only where it is meant to light up. OLEDs, LCDs and microLEDs can be made flexible and transparent, but LCDs require a backlight because they cannot emit light on their own like OLEDs and microLEDs.

Liquid-crystal display (or LCD) is a thin, flat panel used for electronically displaying information such as text, images, and moving pictures. They are usually made of glass but they can also be made out of plastic. Some manufacturers make transparent LCD panels and special sequential color segment LCDs that have higher than usual refresh rates and an RGB backlight. The backlight is synchronized with the display so that the colors will show up as needed. The list of LCD manufacturers:

Organic light emitting diode (or OLED displays) is a thin, flat panel made of glass or plastic used for electronically displaying information such as text, images, and moving pictures. OLED panels can also take the shape of a light panel, where red, green and blue light emitting materials are stacked to create a white light panel. OLED displays can also be made transparent and/or flexible and these transparent panels are available on the market and are widely used in smartphones with under-display optical fingerprint sensors. LCD and OLED displays are available in different shapes, the most prominent of which is a circular display, which is used in smartwatches. The list of OLED display manufacturers:

MicroLED displays is an emerging flat-panel display technology consisting of arrays of microscopic LEDs forming the individual pixel elements. Like OLED, microLED offers infinite contrast ratio, but unlike OLED, microLED is immune to screen burn-in, and consumes less power while having higher light output, as it uses LEDs instead of organic electroluminescent materials, The list of MicroLED display manufacturers:

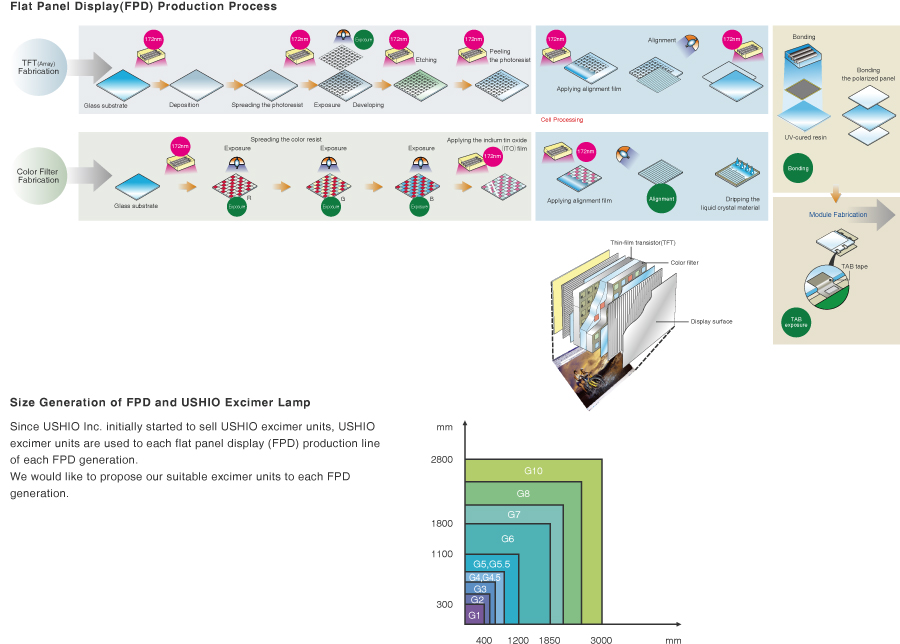

LCDs are made in a glass substrate. For OLED, the substrate can also be plastic. The size of the substrates are specified in generations, with each generation using a larger substrate. For example, a 4th generation substrate is larger in size than a 3rd generation substrate. A larger substrate allows for more panels to be cut from a single substrate, or for larger panels to be made, akin to increasing wafer sizes in the semiconductor industry.

"Samsung Display has halted local Gen-8 LCD lines: sources". THE ELEC, Korea Electronics Industry Media. August 16, 2019. Archived from the original on April 3, 2020. Retrieved December 18, 2019.

"TCL to Build World"s Largest Gen 11 LCD Panel Factory". www.businesswire.com. May 19, 2016. Archived from the original on April 2, 2018. Retrieved April 1, 2018.

"Panel Manufacturers Start to Operate Their New 8th Generation LCD Lines". 대한민국 IT포털의 중심! 이티뉴스. June 19, 2017. Archived from the original on June 30, 2019. Retrieved June 30, 2019.

"TCL"s Panel Manufacturer CSOT Commences Production of High Generation Panel Modules". www.businesswire.com. June 14, 2018. Archived from the original on June 30, 2019. Retrieved June 30, 2019.

"Samsung Display Considering Halting Some LCD Production Lines". 비즈니스코리아 - BusinessKorea. August 16, 2019. Archived from the original on April 5, 2020. Retrieved December 19, 2019.

Herald, The Korea (July 6, 2016). "Samsung Display accelerates transition from LCD to OLED". www.koreaherald.com. Archived from the original on April 1, 2018. Retrieved April 1, 2018.

"China"s BOE to have world"s largest TFT-LCD+AMOLED capacity in 2019". ihsmarkit.com. 2017-03-22. Archived from the original on 2019-08-16. Retrieved 2019-08-17.

6. To form usable thin film transistors, it is necessary to repeat the process of cleaning, coating, photoresist, exposure, development, etching, and photoresist removal. Generally speaking, to manufacture TFT-LCD, it is necessary to repeat 5 to 7 times.

1. After completing the thin-film transistor glass substrate, we will proceed to the combination of the liquid crystal module. The liquid crystal panel is composed of the transistor glass substrate and the color filter. First, we must clean the glass first, and then proceed The next step. The entire manufacturing process of TFT-LCD must be in a clean room, so that there will be no impurities in the display.

3. During the entire assembly process, first we have to coat a layer of chemical film on the glass and color filter covered with transistors, and then perform the alignment action.

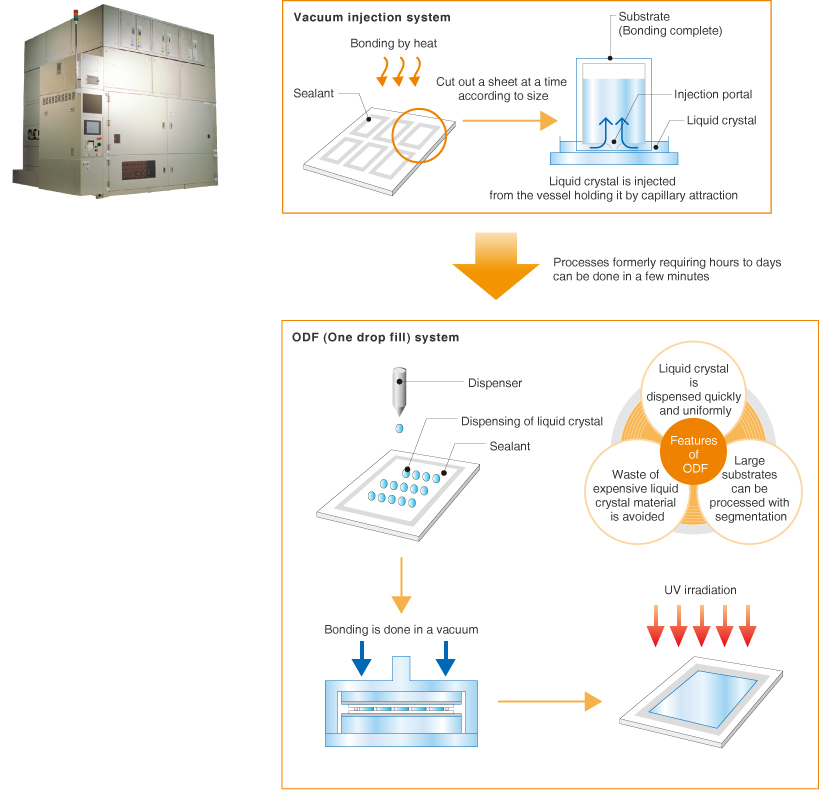

4. Before combining the two glass plates, we must first evenly cover the spherical-like gaps at a fixed interval to prevent the two glass plates from bending inward after the liquid crystal display is combined. Usually, when the liquid crystal panel is assembled, one or two gaps are left to facilitate the subsequent filling of the liquid crystal, and then the edge of the two pieces of glass is sealed with frame glue and conductive glue, thus completing the glass assembly.

5. After sealing the frame, place the LCD panel in the vacuum chamber, and drain the air from the LCD panel through the gap just reserved, and then pour the liquid crystal with the help of atmospheric pressure, and then close the gap. The liquid crystal is a kind of The compound substance between solid and liquid has the characteristic of regular molecular arrangement.

2. Then connect the input end of the DRIVE IC to the circuit board by soldering. In this way, the signal can be sent out smoothly, and then the image on the control panel is ready.

3. The light of the LCD module is emitted from the backlight. Before assembling the backlight, we will first check whether the assembled LCD panel is perfect, and then assemble the backlight. The backlight is the source of light behind the LCD panel.

5. After that, we entered the final critical test process. The assembled MODULE was subjected to aging test, and products with poor quality were screened out in the state of electrification and high temperature.

6. The best quality products can be packaged and shipped. In this way, the liquid crystal module undergoes many inspection and testing procedures to deliver the most perfect product to the customer, and this is the real completion of the entire liquid crystal display manufacturing process.

Actually, the monitors 20 year ago were CRT (Cathode Ray Tube) displays, which requires a large space to run the inner component. And now the screen here in your presence is the LCD(Liquid Crystal Display) screen.

As mentioned above, LCD is the abbreviation of Liquid Crystal Display. It’s a new display technology making use of the optical-electrical characteristic of liquid crystal.

STN LCD: STN is for Super-twisted Nematic. The liquid crystal in STN LCD rotate more angles than that in TN LCD, and have a different electrical feature, allowing STN LCD to display more information. There are many improved version of STN LCD like DSTN LCD (double layer) and CSTN LCD (color). This LCD is used in many early phones, computers and outdoor devices.

TFT LCD: TFT is for Thin Film Transistor. It’s the latest generation of LCD technology and has been applied in all the displaying scenario including electronic devices, motor cars, industrial machines, etc. When you see the word ‘transistor’, you may realize there’s integrated circuits in TFT LCD. That’s correct and the secret that TFT LCD has the advantage of high resolution and full color display.

In a simple way, we can divide TFT LCD into three parts, from bottom to top they are: light system, circuit system and light and color control system.In manufacturing process, we’ll start from inner light and color control system and then stretch out to whole module.

It’s accustomed to divide TFT LCD manufacturing process into three main part: array, cell and module. The former two steps are about the production of light and color control system, which contains TFT, CF (color filter) and LC (liquid crystal), named a cell. And the last step is the assembly of cell, circuit and light system.

Now let’s turn to the production of TFT and CF. Here is a common method called PR (photoresist) method. The whole process of PR method will be demonstrated in TFT production.

This marks the end of this post. If you find it useful or want to know more about TFT LCD, just leave your comment below or contact us. We’re hearing!

At present, the mainstream display on the market is TFT-LCD, that is, thin film transistor liquid crystal display (Thin Film Transistor-Liquid Crystal Display).

As we mentioned above, people may not think that filtration is so closely connected to the production of TFT-LCD. Below we will explain the importance of filtration in production for flat panel displays.

TFT-LCD combines microelectronics technology with liquid crystal display technology, and its structure is like a “sandwich”. The TFT array is processed on the glass, and the substrate with color filtering film is used to form a liquid crystal box using LCD technology, and then the polarizer is laminated to form a liquid crystal display.

The TFT-LCD array process is similar to that of semiconductors, except that semiconductors use silicon wafers, while thin-film transistors process glass substrates.

In the manufacture of flat panel displays, the glass substrate is first cleaned, and after the film is formed on the surface, the photoresist is evenly coated on the substrate, and after the processes of exposure, development, etching, and stripping, the graphics on the mask plate are transferred to the substrate to form the exact corresponding graphics.

In the TFT-LCD array process, pollutants mainly come from the manufacturing process and the handling, packaging, transportation, and storage of glass substrates, the main pollutants are dust particles, fiber paper dust, mineral oil and grease, and other greases, inorganic particles such as silicon oxide, and residues of the preparation process, water stains, fingerprints, etc.

These contaminants directly affect the quality and economic efficiency of the final product, so the product goes through a complex cleaning process, and after filtration, these cleaning solutions can be discharged or recycled.

The film-forming process is mainly divided into two ways, one is sputtering metal film deposition, by charged particles bombarding the surface of the material, so that the atoms get enough energy to enter the gas phase, deposited on the surface of the workpiece, and the use of gas is generally inert gas (such as argon);

In the lithography process of thin film transistors, each step may introduce harmful particle contamination, microbubble void defects, and metal contamination on the surface of the glass substrate, so the washing process is essential.

The etching process removes the film layer that is not masked by the photoresist, thus obtaining the exact same pattern on the film as on the photoresist. Etching methods are divided into wet etching, which uses the chemical reaction of the solution, and dry etching, which uses gas and plasma technology to etch the material.

In wet etching, the glass substrate is etched in a special tank and then cleaned in a wash tank, and finally dried, the process, as well as the flying damp solution, is as follows.

In flat panel display manufacturing, the residual photoresist needs to be peeled off after the film formation-lithography-etching process, thus bringing the process of this layer of film to an end.

With years of filtration experience and advanced manufacturing technology, Brother Filtration is able to provide helpful membrane-pleated filter cartridges and gas filter housing in every TFT-LCD production process.

With the development of digital products, people are longing for more and more high-quality products with better panel displays. Filtration is a crucial part of the production of flat panel displays and helps manufacturers to produce high-quality and more competitive products.

Brother Filtration not only manufactures all kinds of filter products that can be applied in TFT-LCD production but also offers better filtration solutions for panel display manufacturers. If you need more filtration solutions or a better filter cartridge to help your manufacturing, please feel free to contact us directly.

Liquid crystal displays are commonly known as LCD, consist of liquid crystals that are activated by electric current, and they are used to display lines of alpha-numeric information (one or more lines) in a variety of devices, for example, fax machines, answering machines call counters, laptop computer screens, scientific instruments, portablecompact disc players,clocks, and so forth. The basis of LCD technology is the liquid crystal, a substance made of complicated molecules.

LCD uses a liquid crystal to produce a visible image. Liquid crystal displays are super-thin technology display screens that are generally used in laptop computer screens, TVs, cell phones, and portable video games.Liquid crystal displays (LCDs) have become the dominant technology in televisions and monitors in our homes and offices.

In an LCD, an electric current is used to switch segments of liquid crystals from a transparent phase to a cloudy phase, each segment forming part of a number or letter. The segments can also be in the shape of tiny dots or pixels, and they can be arranged in rows and columns. They are turned on and off individually to either block or allow polarized light to pass through. When the light is blocked, a dark spot is created on the reflecting screen.

Liquid crystal display (LCD) screens are manufactured by assembling a sandwich of two thin sheets of glass. On one of the sheets are transistor “cells” formed by first depositing a layer of indium tin oxide (ITO), an unusual metal alloy that you can actually see through. That’s how you can get electrical signals to the middle of a screen. Then you deposit a layer of silicon, followed by a process that builds millions of precisely shaped transistor parts. This patterning step is repeated to build up tiny little cells, one for each dot (known as a pixel) on the screen. Each step has to be precisely aligned to the previous one within a few microns. Remember, the average human hair is 40 microns in diameter.

On the other sheet of glass, you make an array of millions of red, green, and blue dots in a black matrix called a color filter array (CFA). This is how you produce the colors when you shine light through them. Then you drop tiny amounts of liquid crystal material into the cells on the first sheet and glue the two sheets together. You have to align the two sheets so the colored dots sit right on top of the cells, and you can’t be off by more than a few microns in each direction anywhere on the sheet. The sandwich is next covered with special sheets of the polarizing film, and the sheets are cut into individual “panels” – a term that is used to describe the subassembly that actually goes into a TV.

Clean ITO glass with the cleaning agent and deionized water (DI water), wash impurities and oil stains on the ITO surface with physical or chemical methods and then remove and dry the water to ensure the processing quality of the next process.

Photoresist Glue coatingis the first process ofphotolithography. It is to coat a layer of photoresist evenly on the ITO surface of ITO glass. The effect of coating directly affects the quality of photolithography. Its main control content is photoresist Preparation, coating thickness, and uniformity, coating surface state, etc.

Process control:temperature, time (pulling speed) exposure Use ultraviolet light to irradiate the photoresist surface through the premade film (selective irradiation) to make the photoresist layer of the part irradiated by the ultraviolet light react.

Since the photoresist film softens and swells during development, which affects the anti-corrosion ability of the film, the glass must be baked at an appropriate temperature after development to remove moisture and enhance the adhesion of the film to the glass. This process is called hard film.

Etching is traditionally the process ofusing strong acid or mordant to cut into the unprotected parts of a metal surfaceto create a design in intaglio (incised) in the metal. … The plate is then dipped in a bath of acid, known as the mordant (French for “biting”) or etchant, or has acid washed over it.

Generally, a brush is used toscrubat the same time to enhance the stripping effect. Then use DI water to clean and dry the glue crumbs. Generally, the above processes are calledlithography processes, which play a key role in LCD manufacturing.

Generally, the orientation materials for the production of low- and medium-grade LCDs are made of PA, that is, polyimide acid, which is made by the polymerization reaction of dianhydride and diamine at low temperature. It is dehydrated and cured at high temperature (the upper chemical layer is a kind of ring Chemical reaction), it becomes polyimide (PI). Polyimide has good chemical stability, excellent mechanical properties, high insulation, high-temperature resistance, high dielectric constant, radiation resistance, and non-flammability.

Flexo printing is offered in order to form polyimide layers in glass plates for LCD manufacturing. We can integrate these machines in an in-line production street or in a polyimide cluster, consisting of a polyimide printing machine, a coupled hot plate curing system and related automation incl. loading and unloading devices.

The glass coated with a photoresist is baked for a period of time at a certain temperature to volatilize the solvent in the photoresist and increase its adhesion to the glass surface. the glass will be processed by high temperature again, making the photoresist stronger.

Punctuation silkscreen is used to connect the circuits of the LCD because there are 2 glasses of the LCD. up one and down. Only the pin side glass has an electricity connection, that dots are for supplying electricity for the glass which doesn’t have electricity. that dots are for supplying electricity for the glass which doesn’t have electricity.

As described above already, the seal has to be finally cured after the cell assembly process. This has to be done under pressure in order to make sure that the seal thickness is properly related to the spacer diameter and the calculated liquid crystal thickness can be reached with low tolerances. Hotpress ovens are available as a batch process tool and as a single panel press oven. The batch oven requires a previous collection of panels and preparation of a larger pile of panels that are pressed together. The pressed pile of wafers is then cured in a clean convection oven. The single panel hot press oven is easier to integrate with automatic lines and works continuously.

Usually, a pair of ITO glasses can make multiple liquid crystal cells. In order to expose the LCD filling port, the glass must be appropriately cut into strips or granules.

The two glass substrates must be cut to the proper size, polished, and washed. Cutting can be done with a diamond saw or scribe while polishing involves a process called lapping, in which the glass is held against a rotating wheel that has abrasive particles embedded in it.

This stage includes filling the liquid crystal into the prepared empty cell and sealing the filling hole so that the liquid crystal cell is basically made. Generally, a special liquid crystal filling machine is used to form a vacuum in the liquid crystal cell, and then the liquid crystal is filled into the LCD cell by the pressure difference and the capillary action of the liquid crystal cell.

Detection Visuallyinspects the appearance and background color of semi-finished LCD products under the polarized light table and picks out the unqualified products.

The electrical testis to check the display graphics, electrical and functional defects, and other appearance defects of the LCD screen under the power-on state.

This is the most important point in LCD manufacturing, where silkscreens are used for printing. High-resolution silkscreens have more than 130 meshes per cm, enabling them to print lines with a width down to 50µm. The layer thickness is in the range of 10µm normally, which is regarded as a “thick” layer in LCD manufacturing.

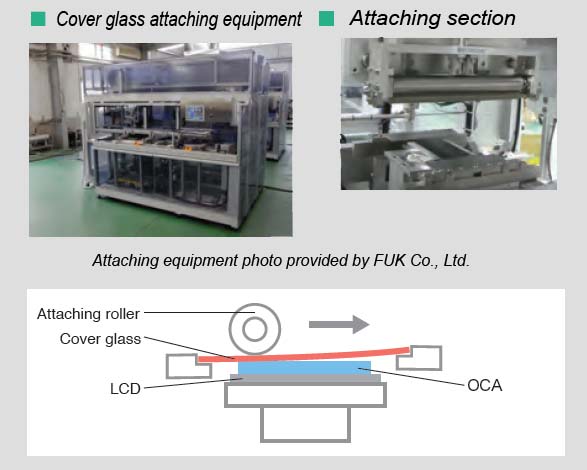

The UV photocuring equipment used for bonding of LCD panels makes full use of the technique of UV curing. In LCD panels, the liquid crystal is sealed between two sheets of glass, but the liquid crystal has a delicate chemical structure that cannot tolerate the use of heat to harden the adhesive used to bond the pieces of glass together. The method used to deal with this in the past was to bond the two pieces of glass together in advance, and then inject the liquid crystal through a gap left open for the purpose. However, the larger the LCD panel, the more difficult it becomes to quickly achieve uniform distribution of the liquid crystal between the sheets. To resolve this problem, an innovative method of dropping the liquid crystal directly onto one of the glass sheets and then bonding the second sheet of glass to the first came into use starting from about the year 2000. This new method is called the "one drop fill" (ODF) method. The fundamental technology on which the ODF method is based is UV curing, which allows rapid curing, low-temperature processing, and precision bonding. Today, UV irradiation units made by Ushio for bonding of LCD panels have a 70% world-wide market share.

As display panels get bigger, thinner and more expensive, manufacturers look to the semiconductor industry for guidance on how to get particle contamination under control

As consumer demand for giant screen TVs, advanced gaming devices, and huge computer monitors grows, the display industry rushes to advance its technology and fabs to accommodate the need. New glass technology and world-class processes are constantly moving forward to address the continual development of larger, thinner, lighter, sharper and more cost-efficient displays.

In the beginning, consumers were happy with boxy 30-inch TVs and would tolerate a few blank spots on an otherwise working screen, but today expectations are much higher. Liquid crystal displays (LCDs), which offer several advantages over traditional cathode-ray tube (CRT) displays, are becoming the norm for today’s TV and computer screens. Since 2000, glass substrate size has approximately doubled every 1.5 years. It took ten years for the display industry to migrate from Generation One glass sizes to Generation Four, but it took only four years to get from Generation Four to Generation Seven glass sizes. Generation Five and larger size substrates are expected to account for nearly 80 percent of all glass substrates produced by 2007.

This fast migration to larger-generation glass is driven both by product applications, such as bigger, flatter TVs and desktop monitors, and by economies of scale. Large generation glass offers dramatic manufacturing efficiencies, allowing display makers to produce more panels at lower costs with less waste. While a typical Generation Four sheet yields four 17-inch panels, a Generation Five sheet increases that yield threefold, to twelve 17-inch panels. A Generation Six substrate can produce eight larger panels of 32 inches, and a Generation Seven substrate can produce twelve 32-inch panels.

The industrywide migration by LCD manufacturers to large-generation substrates is expected to reduce prices to consumers, further driving the adoption of LCD technology in the desktop monitor and television market segments. LCD desktop monitors accounted for more than 50 percent of all monitors sold in 2004 and are projected to account for nearly 80 percent in 2007, which is twice the penetration rate of 2003. In 2004, LCD TVs represented only 5 percent of the color television market, but new screen sizes, falling prices and expanding availability are expected to drive market penetration to approximately 20 percent by 2007.

Contamination control, for example, is becoming more critical, and the need for standards to manage the production process is increasing, just as it did for the semi industry several years ago. As a result, display manufacturers often look to the semi industry for guidance, says Mark Merrill, vice president of Photon Dynamics, a San Jose, California-based yield management company that offers test, repair and inspection tools throughout array, cell and module fabs for the display-panel manufacturing industry (see Fig. 1). “The display manufacturing process is a lot like the semiconductor manufacturing process, it’s just simpler and bigger.”

Figure 1. Photon Dynamics offers a full suite of yield management solutions for the FPD industry, including test, repair and inspection of LCDs. Photo courtesy of Photon Dynamics, Inc.Click here to enlarge image

For display manufacturers, how well they manage contaminants in the processing environment determines increases or decreases in their yield. Even though display products keep increasing in size, particle contamination is becoming more of a problem, with tolerances for particulate size and counts continually decreasing.

As in the semi industry, where one particulate can destroy an entire chip, in large-display manufacturing one unfortunately placed particle can ruin an entire large, flat screen, which is a much more costly yield loss than the smaller panels of previous generations.

If the manufacturer is making smaller displays, a single panel of glass might be cut into 16 individual panels, whereas if it’s making larger displays, it may only be cut into four panels. “Imagine 100 particles falling on that piece of glass, and five of them cause pixel damage,” Merrill says. “That might kill five of the 16 smaller panels, but it could kill all of the four larger panels. That has a huge impact on yield.”

Managing yields through process control is an essential component of optimizing costs and time-to-market throughout the electronics industry. In the flat-panel display sector, the industry’s migration toward high-volume production of larger display panels is driving the need to maximize manufacturing yields. “They are bigger panels, but they have the same defect density,” Merrill points out, which means the environment can support fewer particles just to achieve the same yields.

A 90 percent yield may sound impressive for some industries, but in display manufacturing, where one panel costs close to $1000, a yield loss of 2 percent can cost a company several million dollars. Because of the high cost of materials used in the manufacture of LCDs, defective LCDs, especially larger displays, can be quite costly and ultimately drive up both panel and end-product costs. “That’s the reason why, in this industry, you test 100 percent of the product,” Merrill says. “We don’t just sample. We need to know that every single panel is going to work.”

As a result of the growing cost of yield loss, display fabs are fighting to achieve cleaner environments, and manufacturers are paying closer attention to the tools used to monitor and control contaminants throughout the manufacturing process (see Fig. 2).

Figure 2. Pictured here is the latest-generation ArraySaver system from Photon Dynamics, Inc. used in the manufacture of LCDs. Photo courtesy of Photon Dynamics, Inc.Click here to enlarge image

Manufacturing high performance LCDs for TV applications further increases process complexities, especially when dealing with color filters on array, viewing angle technologies, and photo spacers on color filters that are applied to the glass during processing.

Adding to the challenge of controlling particulate contamination is the fact that the fabs, the tools and the glass keep getting bigger. Every new generation of fab increases in size to accommodate the equipment needed to manage the product. Fabs today span several football fields in size, and the glass panels may be two to three meters across. Because of its size and weight, the glass is transported on ever bigger conveyers, which require larger open air spaces and broader chamber doors to move the glass in and out of the work space. The fab itself continues to expand, requiring more floor and air space, making environmental control processes more complex.

Once a fab is up and running, the display manufacturing process begins with the production of the glass, explains Peter Bocko, division vice president of commercial technology for Corning Display Technologies, maker of pristine flat glass used in LCDs for computer and electronics companies. These glass substrates are the foundation for active matrix LCDs.

The display manufacturing process has greatly improved over the last two decades, according to Bocko. He remembers a time when glass furnaces were made out of brick, and they often sat outside a machine shop perpetually encased in a cloud of dust. When the glass hardened, a worker would manually etch and break it and carry it to the next step in the process. “In the early days it was amazing what you’d find on the surface of the glass-cigarette smoke particles, lubricants, binder materials from gloves, skin flakes. Anything you can imagine,” Bocko says.

The manufacturing process has evolved dramatically since the early days, with much stricter monitoring of the process and environment, from raw material to finished product. “Today, the entire process, from melting on, is in a controlled environment,” he says.

Figure 3. To eliminate human error and because the glass is too heavy for human handling, many display fabs today use robotics in their manufacturing processes. Photo courtesy of Corning Display Technologies.Click here to enlarge image

When the molten glass achieves the right viscosity and temperature, it is fed into an arrowhead-shaped trough called an Isopipe. The glass flows evenly over both sides of the trough, meeting at the pointed bottom where it forms into a continuous sheet of viscous glass that is 0.7 to 0.5 millimeter in thickness. These thinner glass panels dramatically reduce the overall weight of the end product, but create a more delicate surface with which to work.

Because the glass sheet is formed in air, its surface is pristine and flat; no subsequent grinding or polishing, which could damage the glass, is required. The fusion process also maintains tight control over the thickness of the glass, leading to a consistent product. This is critical in the production of panels for LCD televisions, where viewing angle technology sensitizes the image to thickness differences in the glass.

“At this point in the process, the glass has the purest surface imaginable,” Bocko says. “There are no particulates or organic content anywhere. From this fusion step until it reaches the customer, it’s all about contamination control. Everything you do to it from here on only degrades the surface.”

How much degradation occurs depends on how the glass is handled and how clean the environment is in which it is processed. Every step in the process creates potential contaminants. When the glass is etched, broken and polished, particulate material is generated; the tools used to process the glass create dust and metal particles; cleaning chemicals and water used during beveling can leave residues; and transportation exposes the glass to potential damage from contaminants and movement. “There are two things that are especially bad for an LCD surface-water and particulates,” Bocko says.

At Corning, to reduce the risk of both kinds of contamination, once the glass is cut and broken using robotic devices, it is covered in a protective polymer coating sheet, which prevents environmental contamination from adhering to the glass, Bocko says. This coating, specially designed for Corning’s glass-manufacturing process, took years to develop because it required a surface that would adhere to the glass to protect it during processing but would also be easy to peel off without leaving surface material behind. “This is a highly engineered polyethylene-based adhesive that won’t leave a residue when it’s removed,” he says.

Washing is done through ultrasonic mechanical agitation, using pure water and chlorine-based detergents. It includes a soft-brush scrub, sonic rinsing processes, and drying using compressed air to push the water off the back of the glass, eliminating the risk of water residue.

Once the glass is cleaned, a worker uses a computer monitor to inspect it for defects. If particulates are discovered, the inspector must judge whether they can be removed during processing or whether the glass should be scrapped (see Fig. 4).

Figure 4. If particulates are discovered, an inspector must judge whether they can be removed during processing or whether the glass should be scrapped. Photo courtesy of Corning Display Technologies.Click here to enlarge image

Although loss of glass impacts yield, the farther a faulty piece makes it through processing the more expensive the loss is. Making correct judgments during this inspection process is, therefore, highly important.

“We monitor particulates to one micron,” Bocko says. “And if any particulate larger than three to five microns remains on the glass after it is washed, the glass can be rejected.” The size limit of three to five microns is critical because this is the thickness of the LCD layer that’s sandwiched between the layers of glass.

LCD displays utilize two sheets of polarizing material with a liquid crystal solution between them. An electric current passed through the liquid causes the crystals to align so that light cannot pass through them. Each crystal, therefore, is like a shutter, either allowing light to pass through or blocking the light. They are flat, and use only a fraction of the power required by CRTs. Thus, a particle thicker than the liquid center will create a cell gap in the final product, knocking out pixels and leaving dark spots on the screen.

If a panel is approved, the finished glass is then packed for delivery to the customer (see Fig. 5). Packaging and transporting large-generation substrates present another set of challenges.

Figure 5. If a panel is approved, the finished glass is then packed for delivery to the customer, presenting another set of challenges. Photo courtesy of Corning Display Technologies.Click here to enlarge image

In the conventional system, glass panels are packed in slotted crates to prevent them from touching as a result of vibration during transport. The air gap needed between each substrate in a slotted crate limits the number of substrates per case to twenty.

Corning recently switched to a new technique that protects the glass and allows for greater numbers of panels to be shipped in a smaller amount of space. Called the “DensePak” system, it allows for the safe transport, storage and staging of up to 500 sheets per case, in the same footprint as a 20-substrate case.

In the DensePak, another layer of polymer film is adhered to each panel, so they can be packed side-by-side in a vertical glass brick. “The polymer surface is enough to protect the glass, and it’s more efficient because it doesn’t require huge shipping boxes full of air,” Bocko says.

Once the glass is received, the film is removed and any remaining residue is cleaned away. “That cleaning process brings the glass back to the original surface quality,” Bocko says.

The glass is then reinspected and prepped for LCD applications. At this stage in the process, the two layers of glass are sandwiched together with a thin layer of LCD material between them.

Particulates continue to be an increasing risk as the display-manufacturing industry strives to master thinner LCD layers in an effort to create clearer, sharper pictures. “With thinner technology, even smaller particulates will cause problems,” Merrill says. “A half-micron particle in the right spot could take out a whole panel.”

Because the challenges of managing particulates in such a large environment are so great, and the impact on yield so significant, reliable, repeatable methods of analyzing production-line data and repairing process-related defects are essential for the production of larger, higher-quality LCDs at affordable price points. This means testing the glass at key steps in the manufacturing process to ensure that particulates have been removed before panels are permanently affixed with LCD material.

When the pixels are in place on a display prior to its completion, they can be powered up using an LCD sensor that determines whether they will turn on. If the test reveals a dark pixel due to a microscopic particle, it can often be vaporized or knocked out with a laser to fix the problem, Merrill says.

If particulate is inside, however, once the LCD material is sandwiched between the glass, it can’t be repaired. “At that point, the best you can do is try to determine the source of the contamination so you can fix it before it does more damage,” he says.

Fortunately, there are only four or five steps in the display-manufacturing process, making it easier to find the contamination culprit. The industry doesn’t always analyze the make-up of any given particulate, instead manufacturers look back over the life of the panel to identify the problem. It may be caused by failure in a process tool, human error, or a cleaning problem. “Finding the source requires a lot of excursion control,” Merrill says.

To determine whether tools are emitting high particulate counts, process inspectors may use a laser particle counter. They also perform regular airflow monitoring and use HEPA filters to remove low concentrations of airborne molecular contaminants generated during the manufacturing process or by the equipment, says Manjaya Hegde, continuous improvement leader in the Silicon Valley office of PerkinElmer, a global technology leader for health sciences, optoelectronic and photonics markets. “We have 100 percent HEPA coverage in our fabs,” he says.

Through an environmental monitoring program, Hegde’s team also regularly counts and measures particle contaminants in 500 locations in the fab, looking for changes in trends throughout the processing steps.

He’s found that the best way to monitor actual particles in the fab is to use a witness panel, which is a glass substrate with a metalized layer, left at workbench level in a working fab for up to 10 days. Hegde moves the witness panel around the fab, scanning the particles accumulated in each area. “Even with HEPA filters there are going to be a lot of particles in the environment,” he admits. “But if they get outrageous, we analyze them and try to eliminate the problem.”

The display industry is still easily a decade behind semconductor in its ability to control contaminants, and it continues to be an issue. As the display industry moves toward the future, fabs will get bigger and processors will struggle to bring yields under control. Consumers will continue to demand bigger and higher-quality screens, and their tolerance for any faults is already minimal, notes Bob Pinnel, chief technology officer for the U.S. Display Consortium in San Jose, Calif. “In the first laptops, six faulty pixels were considered acceptable,” he says. “Now it’s zero in almost all high-quality display products.”

He also suspects fabs will move toward vertical glass handling, more minienvironments within the fab, and pick-in-place robot cassettes to streamline processes. “When you get every processing step in line, you can deal with it more predictably,” Merrill says. “It’s a cleaner manufacturing process.”

Ms.Josey

Ms.Josey

Ms.Josey

Ms.Josey