lcd panel assembly process factory

Important technical improvements of LCD, such as LED backlighting and wide viewing Angle, are directly related to LCD. And account for an LCD display 80% of the cost of the LCD panel, enough to show that the LCD panel is the core part of the entire display, the quality of the LCD panel, can be said to directly determine the quality of an LCD display.

The production of civil LCD displays is just an assembly process. The LCD panel, the main control circuit, shell, and other parts of the main assembly, basically will not have too complex technical problems.

Does this mean that LCDS are low-tech products? In fact, it is not. The production and manufacturing process of the LCD panels is very complicated, requiring at least 300 process processes. The whole process needs to be carried out in a dust-free environment and with precise technology.

The general structure of the LCD panel is not very complex, now the structure of the LCD panel is divided into two parts: the LCD panel and the backlight system.

Due to the LCD does not shine, so you need to use another light source to illuminate, the function of the backlight system is to this, but currently used CCFL lamp or LED backlight, don’t have the characteristics of the surface light source, so you need to guide plate, spreadsheet components, such as linear or point sources of light evenly across the surface, in order to make the entire LCD panel on the differences of luminous intensity is the same, but it is very difficult, to achieve the ideal state can be to try to reduce brightness non-uniformity, the backlight system has a lot to the test of design and workmanship.

In addition, there is a driving IC and printed circuit board beside the LCD panel, which is mainly used to control the rotation of LCD molecules in the LCD panel and the transmission of display signals. The LCD plate is thin and translucent without electricity. It is roughly shaped like a sandwich, with an LCD sandwiched between a layer of TFT glass and a layer of colored filters.

LCD with light refraction properties of solid crystals, with fluid flow characteristics at the same time, under the drive of the electrode, can be arranged in a way that, in accordance with the master want to control the strength of the light through, and then on the color filter, through the red, green, blue three colors of each pixel toning, eventually get the full-screen image.

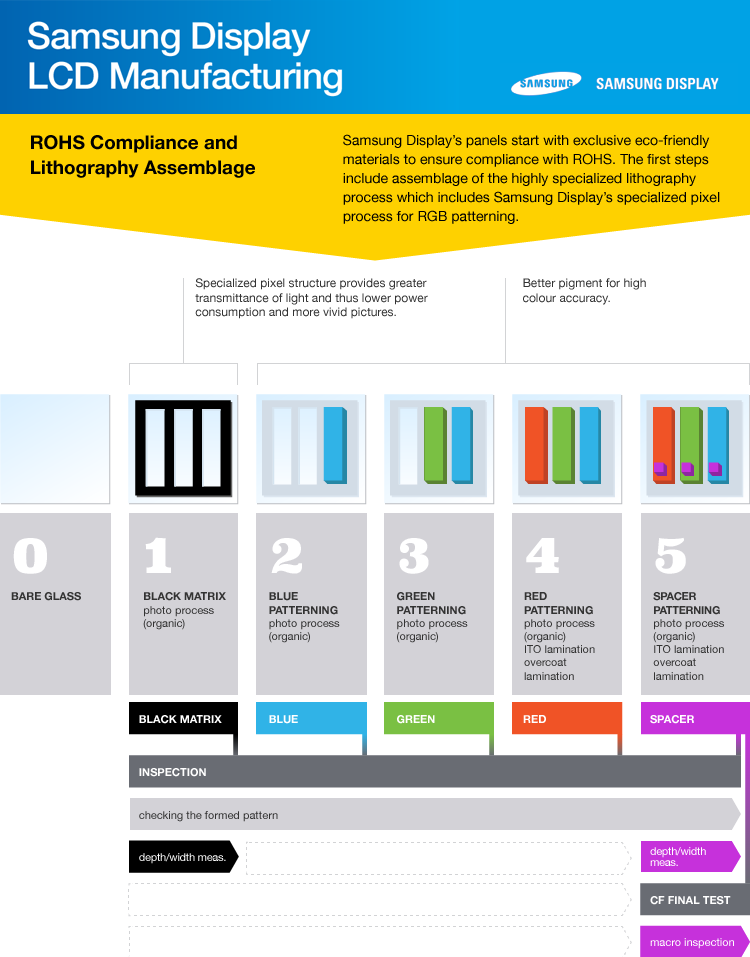

According to the functional division, the LCD panel can be divided into the LCD panel and the backlight system. However, to produce an LCD panel, it needs to go through three complicated processes, namely, the manufacturing process of the front segment Array,the manufacturing process of the middle segment Cell, and the assembly of the rear segment module. Today we will be here, for you in detail to introduce the production of the LCD panel manufacturing process.

The manufacturing process of the LCD panel Array is mainly composed of four parts: film, yellow light, etch and peel film. If we just look at it in this way, many netizens do not understand the specific meaning of these four steps and why they do so.

First of all, the motion and arrangement of LCD molecules need electrons to drive them. Therefore, on the TFT glass, the carrier of LCD, there must be conductive parts to control the motion of LCD. In this case, we use ITO (Indium Tin Oxide) to do this.ITO is transparent and also acts as a thin-film conductive crystal so that it doesn’t block the backlight.

The different arrangement of LCD molecules and the rapid motion change can ensure that each pixel displays the corresponding color accurately and the image changes accurately and quickly, which requires the precision of LCD molecule control.ITO film needs special treatment, just like printing the circuit on the PCB board, drawing the conductive circuit on the whole LCD board.

Rinse the basic label of glass with an organic solution and remove the photolithographic tape after reaction to keep the glass clean. This completes the first thin-film conductive crystal process, which generally requires at least five identical processes to form a complex and sophisticated pattern of electrodes on the glass.

This completes the previous Array process. It is not difficult to see from the whole process that ITO film is deposited, photoresist coated, exposed, developed, and etched on TFT glass, and finally, ITO electrode pattern designed in the early stage is formed on TFT glass to control the movement of LCD molecules on the glass. The general steps of the whole production process are not complicated, but the technical details and precautions are very complicated, so we will not introduce them here. Interested friends can consult relevant materials by themselves.

The glass that the LCD board uses makes a craft also very exquisite. (The manufacturing process flow of the LCD display screen)At present, the world’s largest LCD panel glass, mainly by the United States Corning, Japan Asahi glass manufacturers, located in the upstream of the production of LCD panel, these manufacturers have mastered the glass production technology patents. A few months ago, the earthquake caused a corning glass furnace shutdown incident, which has caused a certain impact on the LCD panel industry, you can see its position in the industry.

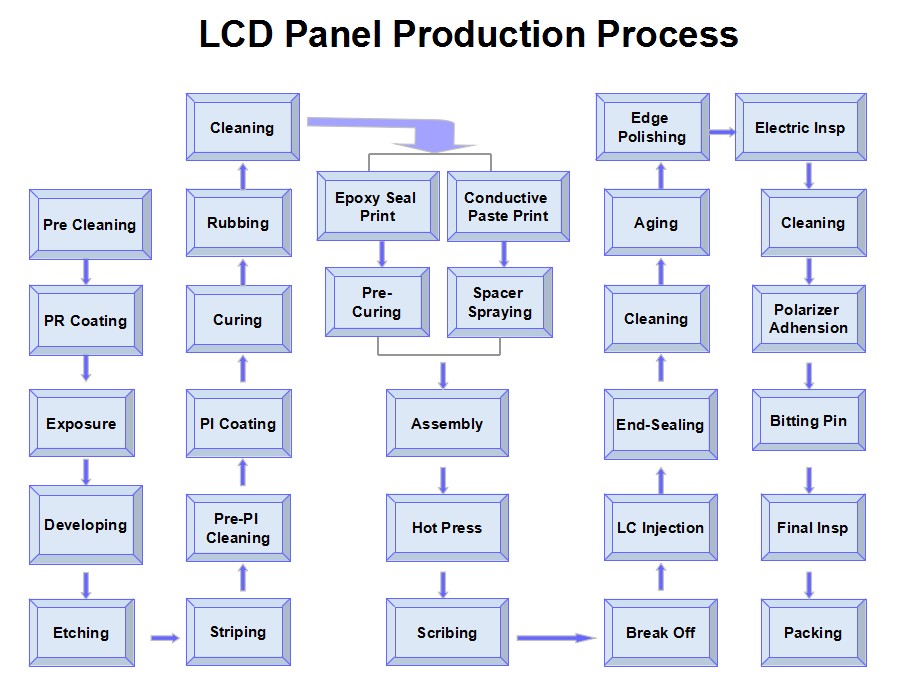

As mentioned earlier, the LCD panel is structured like a sandwich, with an LCD sandwiched between the lower TFT glass and the upper color filter. The terminal Cell process in LCD panel manufacturing involves the TFT glass being glued to the top and bottom of a colored filter, but this is not a simple bonding process that requires a lot of technical detail.

As you can see from the figure above, the glass is divided into 6 pieces of the same size. In other words, the LCD made from this glass is finally cut into 6 pieces, and the size of each piece is the final size. When the glass is cast, the specifications and sizes of each glass have been designed in advance.

Directional friction:Flannelette material is used to rub the surface of the layer in a specific direction so that the LCD molecules can be arranged along the friction direction of the aligned layer in the future to ensure the consistency of the arrangement of LCD molecules. After the alignment friction, there will be some contaminants such as flannelette thread, which need to be washed away through a special cleaning process.

After the TFT glass substrate is cleaned, a sealant coating is applied to allow the TFT glass substrate to be bonded to the color filter and to prevent LCD outflow.

Finally, the conductive adhesive is applied to the frame in the bonding direction of the glass of the color filter to ensure that external electrons can flow into the LCD layer. Then, according to the bonding mark on the TFT glass substrate and the color filter, two pieces of glass are bonded together, and the bonding material is solidified at high temperatures to make the upper and lower glasses fit statically.

Color filters are very important components of LCD panels. Manufacturers of color filters, like glass substrate manufacturers, are upstream of LCD panel manufacturers. Their oversupply or undersupply can directly affect the production schedule of LCD panels and indirectly affect the end market.

As can be seen from the above figure, each LCD panel is left with two edges after cutting. What is it used for? You can find the answer in the later module process

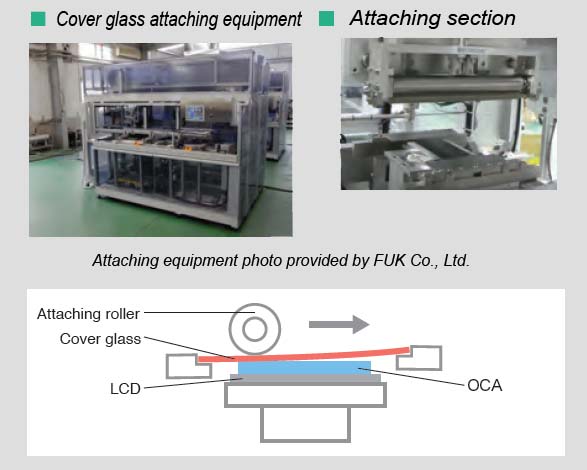

Finally, a polarizer is placed on both sides of each LCD substrate, with the horizontal polarizer facing outwards and the vertical polarizer facing inwards.

When making LCD panel, must up and down each use one, and presents the alternating direction, when has the electric field and does not have the electric field, causes the light to produce the phase difference and to present the light and dark state, uses in the display subtitle or the pattern.

The rear Module manufacturing process is mainly the integration of the drive IC pressing of the LCD substrate and the printed circuit board. This part can transmit the display signal received from the main control circuit to the drive IC to drive the LCD molecules to rotate and display the image. In addition, the backlight part will be integrated with the LCD substrate at this stage, and the complete LCD panel is completed.

Firstly, the heteroconductive adhesive is pressed on the two edges, which allows external electrons to enter the LCD substrate layer and acts as a bridge for electronic transmission

Next is the drive IC press. The main function of the drive IC is to output the required voltage to each pixel and control the degree of torsion of the LCD molecules. The drive IC is divided into two types. The source drive IC located in the X-axis is responsible for the input of data. It is characterized by high frequency and has an image function. The gate drive IC located in the Y-axis is responsible for the degree and speed of torsion of LCD molecules, which directly affects the response time of the LCD display. However, there are already many LCD panels that only have driving IC in the X-axis direction, perhaps because the Y-axis drive IC function has been integrated and simplified.

The press of the flexible circuit board can transmit data signals and act as the bridge between the external printed circuit and LCD. It can be bent and thus becomes a flexible or flexible circuit board

The manufacturing process of the LCD substrate still has a lot of details and matters needing attention, for example, rinse with clean, dry, dry, dry, ultrasonic cleaning, exposure, development and so on and so on, all have very strict technical details and requirements, so as to produce qualified eyes panel, interested friends can consult relevant technical information by a search engine.

LCD (LC) is a kind of LCD, which has the properties of light transmission and refraction of solid Crystal, as well as the flow property of Liquid. It is because of this property that it will be applied to the display field.

However, LCD does not emit light autonomously, so the display equipment using LCD as the display medium needs to be equipped with another backlight system.

First, a backplate is needed as the carrier of the light source. The common light source for LCD display equipment is CCFL cold cathode backlight, but it has started to switch to an LED backlight, but either one needs a backplate as the carrier.

CCFL backlight has been with LCD for a long time. Compared with LED backlight, CCFL backlight has many defects. However, it has gradually evolved to save 50% of the lamp and enhance the transmittance of the LCD panel, so as to achieve the purpose of energy-saving.

With the rapid development of LED in the field of lighting, the cost has been greatly reduced.LCD panels have also started to use LED as the backlight on a large scale. Currently, in order to control costs, an LED backlight is placed on the side rather than on the backplate, which can reduce the number of LED grains.

At the top of the diffusion plate, there will be 3~4 diffuser pieces, constantly uniform light to the whole surface, improve the uniformity of light, which is directly related to the LCD panel display effect. Professional LCD in order to better control the brightness uniformity of the screen, panel procurement, the later backlight control circuit, will make great efforts to ensure the quality of the panel.

Since the LCD substrate and the backlight system are not fixed by bonding, a metal or rubber frame is needed to be added to the outer layer to fix the LCD substrate and the backlight system.

After the period of the Module, the process is completed in LCM (LCDModule) factory, the core of this part of the basic does not involve the use of LCD manufacturing technology, mainly is some assembly work, so some machine panel factories such as chi mei, Korea department such as Samsung panel factory, all set with LCM factories in mainland China, Duan Mo group after the LCD panel assembly, so that we can convenient mainland area each big monitor procurement contract with LCD TV manufacturers, can reduce the human in the whole manufacturing and transportation costs.

However, neither Taiwan nor Korea has any intention to set up factories in mainland China for the LCD panel front and middle manufacturing process involving core technologies. Therefore, there is still a long way to go for China to have its own LCD panel industry.

Actually, the monitors 20 year ago were CRT (Cathode Ray Tube) displays, which requires a large space to run the inner component. And now the screen here in your presence is the LCD(Liquid Crystal Display) screen.

As mentioned above, LCD is the abbreviation of Liquid Crystal Display. It’s a new display technology making use of the optical-electrical characteristic of liquid crystal.

STN LCD: STN is for Super-twisted Nematic. The liquid crystal in STN LCD rotate more angles than that in TN LCD, and have a different electrical feature, allowing STN LCD to display more information. There are many improved version of STN LCD like DSTN LCD (double layer) and CSTN LCD (color). This LCD is used in many early phones, computers and outdoor devices.

TFT LCD: TFT is for Thin Film Transistor. It’s the latest generation of LCD technology and has been applied in all the displaying scenario including electronic devices, motor cars, industrial machines, etc. When you see the word ‘transistor’, you may realize there’s integrated circuits in TFT LCD. That’s correct and the secret that TFT LCD has the advantage of high resolution and full color display.

In a simple way, we can divide TFT LCD into three parts, from bottom to top they are: light system, circuit system and light and color control system.In manufacturing process, we’ll start from inner light and color control system and then stretch out to whole module.

It’s accustomed to divide TFT LCD manufacturing process into three main part: array, cell and module. The former two steps are about the production of light and color control system, which contains TFT, CF (color filter) and LC (liquid crystal), named a cell. And the last step is the assembly of cell, circuit and light system.

Now let’s turn to the production of TFT and CF. Here is a common method called PR (photoresist) method. The whole process of PR method will be demonstrated in TFT production.

This marks the end of this post. If you find it useful or want to know more about TFT LCD, just leave your comment below or contact us. We’re hearing!

Liquid crystal displays are commonly known as LCD, consist of liquid crystals that are activated by electric current, and they are used to display lines of alpha-numeric information (one or more lines) in a variety of devices, for example, fax machines, answering machines call counters, laptop computer screens, scientific instruments, portablecompact disc players,clocks, and so forth. The basis of LCD technology is the liquid crystal, a substance made of complicated molecules.

LCD uses a liquid crystal to produce a visible image. Liquid crystal displays are super-thin technology display screens that are generally used in laptop computer screens, TVs, cell phones, and portable video games.Liquid crystal displays (LCDs) have become the dominant technology in televisions and monitors in our homes and offices.

In an LCD, an electric current is used to switch segments of liquid crystals from a transparent phase to a cloudy phase, each segment forming part of a number or letter. The segments can also be in the shape of tiny dots or pixels, and they can be arranged in rows and columns. They are turned on and off individually to either block or allow polarized light to pass through. When the light is blocked, a dark spot is created on the reflecting screen.

Liquid crystal display (LCD) screens are manufactured by assembling a sandwich of two thin sheets of glass. On one of the sheets are transistor “cells” formed by first depositing a layer of indium tin oxide (ITO), an unusual metal alloy that you can actually see through. That’s how you can get electrical signals to the middle of a screen. Then you deposit a layer of silicon, followed by a process that builds millions of precisely shaped transistor parts. This patterning step is repeated to build up tiny little cells, one for each dot (known as a pixel) on the screen. Each step has to be precisely aligned to the previous one within a few microns. Remember, the average human hair is 40 microns in diameter.

On the other sheet of glass, you make an array of millions of red, green, and blue dots in a black matrix called a color filter array (CFA). This is how you produce the colors when you shine light through them. Then you drop tiny amounts of liquid crystal material into the cells on the first sheet and glue the two sheets together. You have to align the two sheets so the colored dots sit right on top of the cells, and you can’t be off by more than a few microns in each direction anywhere on the sheet. The sandwich is next covered with special sheets of the polarizing film, and the sheets are cut into individual “panels” – a term that is used to describe the subassembly that actually goes into a TV.

Clean ITO glass with the cleaning agent and deionized water (DI water), wash impurities and oil stains on the ITO surface with physical or chemical methods and then remove and dry the water to ensure the processing quality of the next process.

Photoresist Glue coatingis the first process ofphotolithography. It is to coat a layer of photoresist evenly on the ITO surface of ITO glass. The effect of coating directly affects the quality of photolithography. Its main control content is photoresist Preparation, coating thickness, and uniformity, coating surface state, etc.

Process control:temperature, time (pulling speed) exposure Use ultraviolet light to irradiate the photoresist surface through the premade film (selective irradiation) to make the photoresist layer of the part irradiated by the ultraviolet light react.

Since the photoresist film softens and swells during development, which affects the anti-corrosion ability of the film, the glass must be baked at an appropriate temperature after development to remove moisture and enhance the adhesion of the film to the glass. This process is called hard film.

Etching is traditionally the process ofusing strong acid or mordant to cut into the unprotected parts of a metal surfaceto create a design in intaglio (incised) in the metal. … The plate is then dipped in a bath of acid, known as the mordant (French for “biting”) or etchant, or has acid washed over it.

Generally, a brush is used toscrubat the same time to enhance the stripping effect. Then use DI water to clean and dry the glue crumbs. Generally, the above processes are calledlithography processes, which play a key role in LCD manufacturing.

Generally, the orientation materials for the production of low- and medium-grade LCDs are made of PA, that is, polyimide acid, which is made by the polymerization reaction of dianhydride and diamine at low temperature. It is dehydrated and cured at high temperature (the upper chemical layer is a kind of ring Chemical reaction), it becomes polyimide (PI). Polyimide has good chemical stability, excellent mechanical properties, high insulation, high-temperature resistance, high dielectric constant, radiation resistance, and non-flammability.

Flexo printing is offered in order to form polyimide layers in glass plates for LCD manufacturing. We can integrate these machines in an in-line production street or in a polyimide cluster, consisting of a polyimide printing machine, a coupled hot plate curing system and related automation incl. loading and unloading devices.

The glass coated with a photoresist is baked for a period of time at a certain temperature to volatilize the solvent in the photoresist and increase its adhesion to the glass surface. the glass will be processed by high temperature again, making the photoresist stronger.

Punctuation silkscreen is used to connect the circuits of the LCD because there are 2 glasses of the LCD. up one and down. Only the pin side glass has an electricity connection, that dots are for supplying electricity for the glass which doesn’t have electricity. that dots are for supplying electricity for the glass which doesn’t have electricity.

As described above already, the seal has to be finally cured after the cell assembly process. This has to be done under pressure in order to make sure that the seal thickness is properly related to the spacer diameter and the calculated liquid crystal thickness can be reached with low tolerances. Hotpress ovens are available as a batch process tool and as a single panel press oven. The batch oven requires a previous collection of panels and preparation of a larger pile of panels that are pressed together. The pressed pile of wafers is then cured in a clean convection oven. The single panel hot press oven is easier to integrate with automatic lines and works continuously.

Usually, a pair of ITO glasses can make multiple liquid crystal cells. In order to expose the LCD filling port, the glass must be appropriately cut into strips or granules.

The two glass substrates must be cut to the proper size, polished, and washed. Cutting can be done with a diamond saw or scribe while polishing involves a process called lapping, in which the glass is held against a rotating wheel that has abrasive particles embedded in it.

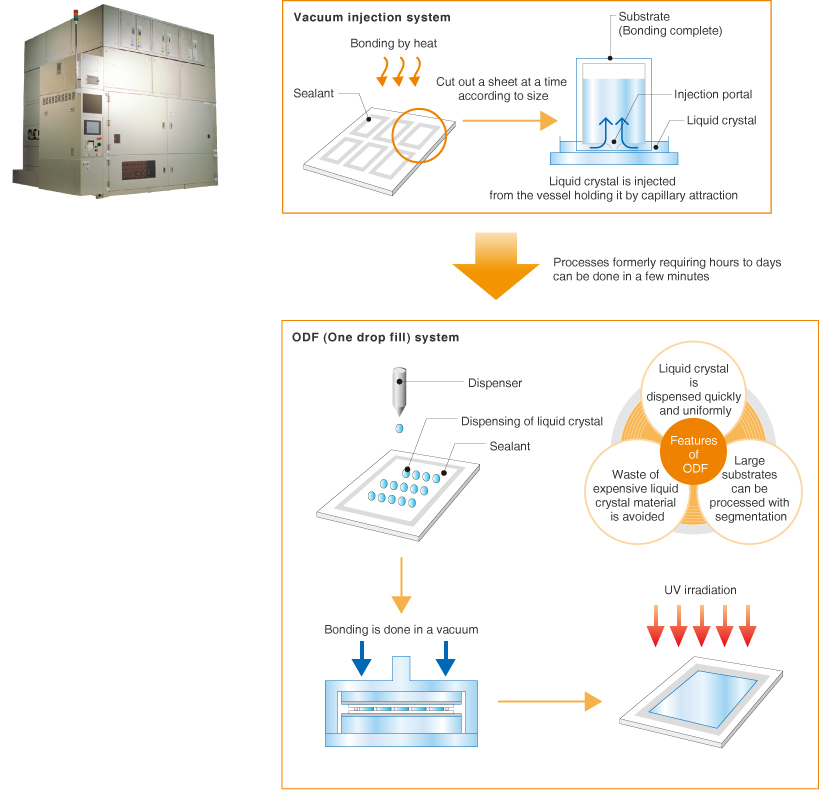

This stage includes filling the liquid crystal into the prepared empty cell and sealing the filling hole so that the liquid crystal cell is basically made. Generally, a special liquid crystal filling machine is used to form a vacuum in the liquid crystal cell, and then the liquid crystal is filled into the LCD cell by the pressure difference and the capillary action of the liquid crystal cell.

Detection Visuallyinspects the appearance and background color of semi-finished LCD products under the polarized light table and picks out the unqualified products.

The electrical testis to check the display graphics, electrical and functional defects, and other appearance defects of the LCD screen under the power-on state.

This is the most important point in LCD manufacturing, where silkscreens are used for printing. High-resolution silkscreens have more than 130 meshes per cm, enabling them to print lines with a width down to 50µm. The layer thickness is in the range of 10µm normally, which is regarded as a “thick” layer in LCD manufacturing.

The cutting-edge G10 production line is a result of cutting-edge technology. To consistently manufacture LCD panels using the G10 glass substrates, each individual manufacturing process incorporates a range of unique know-how. Developed in collaboration with several world-leading production equipment manufacturers, SDP"s large-scale, one-of-a-kind manufacturing equipment delivers state-of-the-art accuracy and performance levels. One example is the photolithography machine, which is about the size of a tennis court. Our master-craftsmen operate and monitor this machine with the utmost care, to manufacture next-generation products.

In this process, the entire G10 glass substrate is covered with various types of film, such as the circuitry that forms the TFT* (thin-film transistor). There are numerous, extremely large pieces of equipment that produce uniform layers across the entire glass substrate—for example, a sputtering machine that deposits a metallic film, and a CVD (chemical vapor deposition) system that deposits an insulation film and a semiconductor film using the plasma-enhanced chemical vapor deposition method.

In the etching process, portions not covered by resist are removed to form the transistor circuits. There are two kinds of etching machines: a dry etching machine that uses corrosive gas to decompose and remove the insulation film and semiconductor film; and a wet etching machine that uses a liquid chemical to dissolve the metal film. After etching, a resist stripping machine is used to remove the photoresist.

At present, the mainstream display on the market is TFT-LCD, that is, thin film transistor liquid crystal display (Thin Film Transistor-Liquid Crystal Display).

As we mentioned above, people may not think that filtration is so closely connected to the production of TFT-LCD. Below we will explain the importance of filtration in production for flat panel displays.

TFT-LCD combines microelectronics technology with liquid crystal display technology, and its structure is like a “sandwich”. The TFT array is processed on the glass, and the substrate with color filtering film is used to form a liquid crystal box using LCD technology, and then the polarizer is laminated to form a liquid crystal display.

The TFT-LCD array process is similar to that of semiconductors, except that semiconductors use silicon wafers, while thin-film transistors process glass substrates.

In the manufacture of flat panel displays, the glass substrate is first cleaned, and after the film is formed on the surface, the photoresist is evenly coated on the substrate, and after the processes of exposure, development, etching, and stripping, the graphics on the mask plate are transferred to the substrate to form the exact corresponding graphics.

In the TFT-LCD array process, pollutants mainly come from the manufacturing process and the handling, packaging, transportation, and storage of glass substrates, the main pollutants are dust particles, fiber paper dust, mineral oil and grease, and other greases, inorganic particles such as silicon oxide, and residues of the preparation process, water stains, fingerprints, etc.

These contaminants directly affect the quality and economic efficiency of the final product, so the product goes through a complex cleaning process, and after filtration, these cleaning solutions can be discharged or recycled.

The film-forming process is mainly divided into two ways, one is sputtering metal film deposition, by charged particles bombarding the surface of the material, so that the atoms get enough energy to enter the gas phase, deposited on the surface of the workpiece, and the use of gas is generally inert gas (such as argon);

In the lithography process of thin film transistors, each step may introduce harmful particle contamination, microbubble void defects, and metal contamination on the surface of the glass substrate, so the washing process is essential.

The etching process removes the film layer that is not masked by the photoresist, thus obtaining the exact same pattern on the film as on the photoresist. Etching methods are divided into wet etching, which uses the chemical reaction of the solution, and dry etching, which uses gas and plasma technology to etch the material.

In wet etching, the glass substrate is etched in a special tank and then cleaned in a wash tank, and finally dried, the process, as well as the flying damp solution, is as follows.

In flat panel display manufacturing, the residual photoresist needs to be peeled off after the film formation-lithography-etching process, thus bringing the process of this layer of film to an end.

With years of filtration experience and advanced manufacturing technology, Brother Filtration is able to provide helpful membrane-pleated filter cartridges and gas filter housing in every TFT-LCD production process.

With the development of digital products, people are longing for more and more high-quality products with better panel displays. Filtration is a crucial part of the production of flat panel displays and helps manufacturers to produce high-quality and more competitive products.

Brother Filtration not only manufactures all kinds of filter products that can be applied in TFT-LCD production but also offers better filtration solutions for panel display manufacturers. If you need more filtration solutions or a better filter cartridge to help your manufacturing, please feel free to contact us directly.

6. To form usable thin film transistors, it is necessary to repeat the process of cleaning, coating, photoresist, exposure, development, etching, and photoresist removal. Generally speaking, to manufacture TFT-LCD, it is necessary to repeat 5 to 7 times.

1. After completing the thin-film transistor glass substrate, we will proceed to the combination of the liquid crystal module. The liquid crystal panel is composed of the transistor glass substrate and the color filter. First, we must clean the glass first, and then proceed The next step. The entire manufacturing process of TFT-LCD must be in a clean room, so that there will be no impurities in the display.

3. During the entire assembly process, first we have to coat a layer of chemical film on the glass and color filter covered with transistors, and then perform the alignment action.

4. Before combining the two glass plates, we must first evenly cover the spherical-like gaps at a fixed interval to prevent the two glass plates from bending inward after the liquid crystal display is combined. Usually, when the liquid crystal panel is assembled, one or two gaps are left to facilitate the subsequent filling of the liquid crystal, and then the edge of the two pieces of glass is sealed with frame glue and conductive glue, thus completing the glass assembly.

5. After sealing the frame, place the LCD panel in the vacuum chamber, and drain the air from the LCD panel through the gap just reserved, and then pour the liquid crystal with the help of atmospheric pressure, and then close the gap. The liquid crystal is a kind of The compound substance between solid and liquid has the characteristic of regular molecular arrangement.

2. Then connect the input end of the DRIVE IC to the circuit board by soldering. In this way, the signal can be sent out smoothly, and then the image on the control panel is ready.

3. The light of the LCD module is emitted from the backlight. Before assembling the backlight, we will first check whether the assembled LCD panel is perfect, and then assemble the backlight. The backlight is the source of light behind the LCD panel.

5. After that, we entered the final critical test process. The assembled MODULE was subjected to aging test, and products with poor quality were screened out in the state of electrification and high temperature.

6. The best quality products can be packaged and shipped. In this way, the liquid crystal module undergoes many inspection and testing procedures to deliver the most perfect product to the customer, and this is the real completion of the entire liquid crystal display manufacturing process.

Two of technical matters to be solved by this invention is to provide the manufacture method of above-mentioned LCD panel frame, this method can reduce manufacturing cost, reduce to produce and consume, reduce the required number of devices of formed product, improve the utilization factor of material, make the simpler of manufacture method change, thereby reach the reduction cost of products, the purpose of enhancing productivity.

Step (1): make the L shaped billot of formation LCD panel frame by the progressive die (Progressive Tooling) moulding, L shaped billot is towards porose;

LCD panel frame of the present invention is welded by two symmetrical each other L shaped billots, described L shaped billot is by the progressive die (Progressive Tooling) moulding compacting, reduce manufacturing cost, reduce to produce and consume, improve the utilization factor (stock utilization reaches more than 60%) of material, make the simpler of manufacture method change, thereby reach the reduction cost of products, the purpose of enhancing productivity realizes purpose of the present invention.

TFT-LCD technology is based on semiconductor IC manufacturing processes, and is unique in that it uses glass substrates rather than traditional silicon wafers. For the TFT manufacturing process, thin film formation, such as CVD and PVD processes, is a very important part. The ODF process has been developed for the assembly of color filters and TFT substrates, and is used in large size LCDs.

The different arrangement of liquid crystal molecules and the rapid movement changes to ensure that each pixel accurately display the corresponding color, and the image changes precisely and quickly, which requires precision control of the liquid crystal molecules. ITO film requires special processing, as if printed circuitry on a PCB board, drawing conductive lines throughout the LCD board.

For array panels with back-channel etched TFT structure.The main process can be divided into 5 steps (5 lightings) according to the sequence of the layers to be made and the interrelationship between the layers.

The process includes: Gate layer metal sputtering, Gate lithography, Gate wet lithography, and other processes. After these processes, scan lines and gate electrodes are formed on the glass substrate, i.e. gate electrodes. The graphical representation of the completed process is shown in the following figure.

Photolithography is the process of copying Mask graphic structures onto the glass substrate to be etched. There are three main processes: photoresist coating, exposure, and development

Dry lithography: The chemical reaction between the process gas and the film, as well as the bombardment of the film by the plasma, is used to remove the film layer.

The process includes: PECVD triple layer continuous film formation, island lithography, island dry lithography and other processes. After these processes, the final amorphous silicon island for TFT is formed on the glass substrate. The graphics obtained after the process is completed are shown in the following figure.

Specific processes include: S/D metal layer sputtering into a film, S/D lithography, S/D wet lithography, channel dry lithography and other processes. After these processes, the source, drain, channel and data lines of the TFT are finally formed on the glass substrate. At this point, the TFT has been produced. The graphics obtained after the process is completed are shown in the following figure.

The process includes PECVD, photolithography, and dry lithography of vias. After these processes, the final TFT channel protective insulation layer and guide through the hole are formed on the glass substrate. The graphics obtained after the process is completed are shown in the following figure.

Specifically, the process includes: sputtering of ITO transparent electrode layer, ITO photolithography, ITO wet lithography and other processes. After these processes, the transparent pixel electrode is finally formed on the glass substrate. The graphics obtained after the process is completed are shown in the following figure.

At this point, the whole array process is completed. In short, the array process of 5 times of light is: 5 times of film formation + 5 times of etching

Color filters can be produced by various methods; photolithography is a typical method. In photolithography, color filters are produced by exposing a glass substrate coated with a photographic color resist through a photomask. The resist is hardened to form the RGB pattern of the LCD.

When making LCD panels it is impossible to produce them one by one, which is too inefficient, so multiple pieces are processed at once and separated by cutting.

After that is bonding IC and FPC; assembling backlight module, the whole machine shell and other processes, relative to the front of the high-precision process to be simpler.

Assembly is the combination of backlight, screen, control circuit board, and touch screen and other components together to form a complete display module. Assembly is generally done by hand, and skilled workers are very important here.

In addition to the above main process, there are some auxiliary processes in the module section, such as: laser cutting, electrical testing after cutting, electrical testing after bonding, electrical testing after assembly, microscopic inspection after cutting, microscopic inspection or automatic optical inspection after binding, shear force peel test after IC bonding, tensile peel test after FPC bonding, electrical aging after assembly, packaging and shipping, etc.

Although we are not process processing personnel, but we still need to understand the relevant things, because in the interface with other departments or personnel in order to be more comfortable. Problems can be considered in many aspects, if you do not know the process related knowledge, encounter problems simply will not think of here, so the process of understanding or necessary.

Technology trends in backplane technology are driving higher gas demand in display manufacturing. Specific gas requirements of process blocks are discussed, and various supply modes are reviewed.

There are many similarities in the display TFT manufacturing and semiconductor device manufacturing such as the process steps (deposition, etch, cleaning, and doping), the type of gases used in these steps, and the fact that both display and semiconductor manufacturing both heavily use gases.

As the display mother glass area gets bigger and bigger,so does the equipment used in the display manufacturing process and the volume of gases required. In addition, the consumer’s desire for a better viewing experience such as more vivid color, higher resolution, and lower power consumption has also driven display manufacturers to develop and commercialize active matrix organic light emitting displays (AMOLED).

In general, there are two types of displays in the market today: active matrix liquid crystal display (AMLCD) and AMOLED. In its simplicity, the fundamental components required to make up the display are the same for AMLCD and AMOLED. There are four layers of a display device (FIGURE 1): a light source, switches that are the thin-film-transistor and where the gases are mainly used, a shutter to control the color selection, and the RGB (red, green, blue) color filter.

Technology trends TFT-LCD (thin-film-transistor liquid-crystal display) is the baseline technology. MO / White OLED (organic light emitting diode) is used for larger screens. LTPS / AMOLED is used for small / medium screens. The challenges for OLED are the effect of < 1 micron particles on yield, much higher cost compared to a-Si due to increased mask steps, and moisture impact to yield for the OLED step.

Although AMLCD displays are still dominant in the market today, AMOLED displays are growing quickly. Currently about 25% of smartphones are made with AMOLED displays and this is expected to grow to ~40% by 2021. OLED televisions are also growing rapidly, enjoying double digit growth rate year over year. Based on IHS data, the revenue for display panels with AMOLED technol- ogies is expected to have a CAGR of 18.9% in the next five years while the AMLCD display revenue will have a -2.8% CAGR for the same period with the total display panel revenue CAGR of 2.5%. With the rapid growth of AMOLED display panels, the panel makers have accel- erated their investment in the equipment to produce AMOLED panels.

There are three types of thin-film-transistor devices for display: amorphous silicon (a-Si), low temperature polysilicon (LTPS), and metal oxide (MO), also known as transparent amorphous oxide semiconductor (TAOS). AMLCD panels typically use a-Si for lower-resolution displays and TVs while high-resolution displays use LTPS transistors, but this use is mainly limited to small and medium displays due to its higher costs and scalability limitations. AMOLED panels use LTPS and MO transistors where MO devices are typically used for TV and large displays (FIGURE 3).

This shift in technology also requires a change in the gases used in production of AMOLED panels as compared with the AMLCD panels. As shown in FIGURE 4, display manufacturing today uses a wide variety of gases.

Helium: H2 is used for cooling the glass during and after processing. Manufacturers are looking at ways to decrease the usage of helium because of cost and availability issues due it being a non-renewable gas.

The consumer demand for displays that offer increas- ingly vivid color, higher resolution, and lower power consumption will challenge display makers to step up the technologies they employ and to develop newer displays such as flexible and transparent displays. The transistors to support these new displays will either be LTPS and / or MO, which means the gases currently being used in these processes will continue to grow. Considering the current a-Si display production, the gas consumption per area of the glass will increase by 25% for LTPS and ~ 50% for MO productions.

The UV photocuring equipment used for bonding of LCD panels makes full use of the technique of UV curing. In LCD panels, the liquid crystal is sealed between two sheets of glass, but the liquid crystal has a delicate chemical structure that cannot tolerate the use of heat to harden the adhesive used to bond the pieces of glass together. The method used to deal with this in the past was to bond the two pieces of glass together in advance, and then inject the liquid crystal through a gap left open for the purpose. However, the larger the LCD panel, the more difficult it becomes to quickly achieve uniform distribution of the liquid crystal between the sheets. To resolve this problem, an innovative method of dropping the liquid crystal directly onto one of the glass sheets and then bonding the second sheet of glass to the first came into use starting from about the year 2000. This new method is called the "one drop fill" (ODF) method. The fundamental technology on which the ODF method is based is UV curing, which allows rapid curing, low-temperature processing, and precision bonding. Today, UV irradiation units made by Ushio for bonding of LCD panels have a 70% world-wide market share.

Ms.Josey

Ms.Josey

Ms.Josey

Ms.Josey