lcd panel assembly process price

Factors that may influence the price of a certain type of LCD include: screen size, viewing angle, maximum brightness, color display,resolution and frame rate.

Screen size: larger size display more, and larger size cost more, these’re common sense. For example, in last year’s iPhone 8P which used a 5.5-inch LCD screen, the display (including touchscreen) cost 52.5 dollars, while a 43-inch LCD TV cost 128 dollars.

Viewing angle: it’s the maximum angle at which a display can be viewed with acceptable visual performance. It’s measured from one direction to the opposite, giving a maximum of 180° for a flat, one-sided screen. Early LCDs had strikingly narrow viewing angles, for now most of the manufacturers have improved them to more than 160°.

Color display: in early or simple LCDs, only two or very few colors can be displayed. As the technology advances, TFT LCD can display up to 65536 colors.

As the diagram shows above, LCD module covers the most part of the cost of a LCD TV. Within LCD module, there’re still many components. In the following diagram we’ll show you the price breakdown of these components.

The third quarter in the year is usually the demand season of LCD module, as a result the price will be the highest. However, situation varies in different market.

Due to the massive investment and low cost of Chinese mainland manufacturer, the capacity of LCD module for TVs increases significantly, so the price of these modules stay pretty low for the past year.

In another aspect, technology innovations keep push the price of high-end LCD to a higher level. For many users that are planning to replace their old TVs, these high-end LCDs are tempting choices.

Actually, though LCD screen has many advantages, its average price is keep decreasing in the past years. New technology brings lower cost is one reason, a strong competitor called OLED is another.

Main difference between OLED and LCD is OLED can give out light itself, that is to say OLED screen can run at a lower load compared to LCD screen, at least it doesn’t need a backlight system.

This work models the cost of 10-in class active-matrix liquid-crystal display (AM-LCD) manufacturing as a function of plant capacity for both first generation plants in 1993 and second generation plants in 1995. In order to model manufacturing costs as a function of plant capacity, this work distinguishes between capacity-dependent and capacity-independent costs. Among the costs included in our model are the costs of capital equipment, materials and labor. Decreases in materials and components costs and improvements in process yield are shown to be the primary factors driving reductions in manufacturing cost per display for large-scale plants. The minimum efficient scale is found to be roughly 57000 displays per month for a first generation plant and roughly 150000 displays per month for a second generation plant.

Important technical improvements of LCD, such as LED backlighting and wide viewing Angle, are directly related to LCD. And account for an LCD display 80% of the cost of the LCD panel, enough to show that the LCD panel is the core part of the entire display, the quality of the LCD panel, can be said to directly determine the quality of an LCD display.

The production of civil LCD displays is just an assembly process. The LCD panel, the main control circuit, shell, and other parts of the main assembly, basically will not have too complex technical problems.

Does this mean that LCDS are low-tech products? In fact, it is not. The production and manufacturing process of the LCD panels is very complicated, requiring at least 300 process processes. The whole process needs to be carried out in a dust-free environment and with precise technology.

The general structure of the LCD panel is not very complex, now the structure of the LCD panel is divided into two parts: the LCD panel and the backlight system.

Due to the LCD does not shine, so you need to use another light source to illuminate, the function of the backlight system is to this, but currently used CCFL lamp or LED backlight, don’t have the characteristics of the surface light source, so you need to guide plate, spreadsheet components, such as linear or point sources of light evenly across the surface, in order to make the entire LCD panel on the differences of luminous intensity is the same, but it is very difficult, to achieve the ideal state can be to try to reduce brightness non-uniformity, the backlight system has a lot to the test of design and workmanship.

In addition, there is a driving IC and printed circuit board beside the LCD panel, which is mainly used to control the rotation of LCD molecules in the LCD panel and the transmission of display signals. The LCD plate is thin and translucent without electricity. It is roughly shaped like a sandwich, with an LCD sandwiched between a layer of TFT glass and a layer of colored filters.

LCD with light refraction properties of solid crystals, with fluid flow characteristics at the same time, under the drive of the electrode, can be arranged in a way that, in accordance with the master want to control the strength of the light through, and then on the color filter, through the red, green, blue three colors of each pixel toning, eventually get the full-screen image.

According to the functional division, the LCD panel can be divided into the LCD panel and the backlight system. However, to produce an LCD panel, it needs to go through three complicated processes, namely, the manufacturing process of the front segment Array,the manufacturing process of the middle segment Cell, and the assembly of the rear segment module. Today we will be here, for you in detail to introduce the production of the LCD panel manufacturing process.

The manufacturing process of the LCD panel Array is mainly composed of four parts: film, yellow light, etch and peel film. If we just look at it in this way, many netizens do not understand the specific meaning of these four steps and why they do so.

First of all, the motion and arrangement of LCD molecules need electrons to drive them. Therefore, on the TFT glass, the carrier of LCD, there must be conductive parts to control the motion of LCD. In this case, we use ITO (Indium Tin Oxide) to do this.ITO is transparent and also acts as a thin-film conductive crystal so that it doesn’t block the backlight.

The different arrangement of LCD molecules and the rapid motion change can ensure that each pixel displays the corresponding color accurately and the image changes accurately and quickly, which requires the precision of LCD molecule control.ITO film needs special treatment, just like printing the circuit on the PCB board, drawing the conductive circuit on the whole LCD board.

Rinse the basic label of glass with an organic solution and remove the photolithographic tape after reaction to keep the glass clean. This completes the first thin-film conductive crystal process, which generally requires at least five identical processes to form a complex and sophisticated pattern of electrodes on the glass.

This completes the previous Array process. It is not difficult to see from the whole process that ITO film is deposited, photoresist coated, exposed, developed, and etched on TFT glass, and finally, ITO electrode pattern designed in the early stage is formed on TFT glass to control the movement of LCD molecules on the glass. The general steps of the whole production process are not complicated, but the technical details and precautions are very complicated, so we will not introduce them here. Interested friends can consult relevant materials by themselves.

The glass that the LCD board uses makes a craft also very exquisite. (The manufacturing process flow of the LCD display screen)At present, the world’s largest LCD panel glass, mainly by the United States Corning, Japan Asahi glass manufacturers, located in the upstream of the production of LCD panel, these manufacturers have mastered the glass production technology patents. A few months ago, the earthquake caused a corning glass furnace shutdown incident, which has caused a certain impact on the LCD panel industry, you can see its position in the industry.

As mentioned earlier, the LCD panel is structured like a sandwich, with an LCD sandwiched between the lower TFT glass and the upper color filter. The terminal Cell process in LCD panel manufacturing involves the TFT glass being glued to the top and bottom of a colored filter, but this is not a simple bonding process that requires a lot of technical detail.

As you can see from the figure above, the glass is divided into 6 pieces of the same size. In other words, the LCD made from this glass is finally cut into 6 pieces, and the size of each piece is the final size. When the glass is cast, the specifications and sizes of each glass have been designed in advance.

Directional friction:Flannelette material is used to rub the surface of the layer in a specific direction so that the LCD molecules can be arranged along the friction direction of the aligned layer in the future to ensure the consistency of the arrangement of LCD molecules. After the alignment friction, there will be some contaminants such as flannelette thread, which need to be washed away through a special cleaning process.

After the TFT glass substrate is cleaned, a sealant coating is applied to allow the TFT glass substrate to be bonded to the color filter and to prevent LCD outflow.

Finally, the conductive adhesive is applied to the frame in the bonding direction of the glass of the color filter to ensure that external electrons can flow into the LCD layer. Then, according to the bonding mark on the TFT glass substrate and the color filter, two pieces of glass are bonded together, and the bonding material is solidified at high temperatures to make the upper and lower glasses fit statically.

Color filters are very important components of LCD panels. Manufacturers of color filters, like glass substrate manufacturers, are upstream of LCD panel manufacturers. Their oversupply or undersupply can directly affect the production schedule of LCD panels and indirectly affect the end market.

As can be seen from the above figure, each LCD panel is left with two edges after cutting. What is it used for? You can find the answer in the later module process

Finally, a polarizer is placed on both sides of each LCD substrate, with the horizontal polarizer facing outwards and the vertical polarizer facing inwards.

When making LCD panel, must up and down each use one, and presents the alternating direction, when has the electric field and does not have the electric field, causes the light to produce the phase difference and to present the light and dark state, uses in the display subtitle or the pattern.

The rear Module manufacturing process is mainly the integration of the drive IC pressing of the LCD substrate and the printed circuit board. This part can transmit the display signal received from the main control circuit to the drive IC to drive the LCD molecules to rotate and display the image. In addition, the backlight part will be integrated with the LCD substrate at this stage, and the complete LCD panel is completed.

Firstly, the heteroconductive adhesive is pressed on the two edges, which allows external electrons to enter the LCD substrate layer and acts as a bridge for electronic transmission

Next is the drive IC press. The main function of the drive IC is to output the required voltage to each pixel and control the degree of torsion of the LCD molecules. The drive IC is divided into two types. The source drive IC located in the X-axis is responsible for the input of data. It is characterized by high frequency and has an image function. The gate drive IC located in the Y-axis is responsible for the degree and speed of torsion of LCD molecules, which directly affects the response time of the LCD display. However, there are already many LCD panels that only have driving IC in the X-axis direction, perhaps because the Y-axis drive IC function has been integrated and simplified.

The press of the flexible circuit board can transmit data signals and act as the bridge between the external printed circuit and LCD. It can be bent and thus becomes a flexible or flexible circuit board

The manufacturing process of the LCD substrate still has a lot of details and matters needing attention, for example, rinse with clean, dry, dry, dry, ultrasonic cleaning, exposure, development and so on and so on, all have very strict technical details and requirements, so as to produce qualified eyes panel, interested friends can consult relevant technical information by a search engine.

LCD (LC) is a kind of LCD, which has the properties of light transmission and refraction of solid Crystal, as well as the flow property of Liquid. It is because of this property that it will be applied to the display field.

However, LCD does not emit light autonomously, so the display equipment using LCD as the display medium needs to be equipped with another backlight system.

First, a backplate is needed as the carrier of the light source. The common light source for LCD display equipment is CCFL cold cathode backlight, but it has started to switch to an LED backlight, but either one needs a backplate as the carrier.

CCFL backlight has been with LCD for a long time. Compared with LED backlight, CCFL backlight has many defects. However, it has gradually evolved to save 50% of the lamp and enhance the transmittance of the LCD panel, so as to achieve the purpose of energy-saving.

With the rapid development of LED in the field of lighting, the cost has been greatly reduced.LCD panels have also started to use LED as the backlight on a large scale. Currently, in order to control costs, an LED backlight is placed on the side rather than on the backplate, which can reduce the number of LED grains.

At the top of the diffusion plate, there will be 3~4 diffuser pieces, constantly uniform light to the whole surface, improve the uniformity of light, which is directly related to the LCD panel display effect. Professional LCD in order to better control the brightness uniformity of the screen, panel procurement, the later backlight control circuit, will make great efforts to ensure the quality of the panel.

Since the LCD substrate and the backlight system are not fixed by bonding, a metal or rubber frame is needed to be added to the outer layer to fix the LCD substrate and the backlight system.

After the period of the Module, the process is completed in LCM (LCDModule) factory, the core of this part of the basic does not involve the use of LCD manufacturing technology, mainly is some assembly work, so some machine panel factories such as chi mei, Korea department such as Samsung panel factory, all set with LCM factories in mainland China, Duan Mo group after the LCD panel assembly, so that we can convenient mainland area each big monitor procurement contract with LCD TV manufacturers, can reduce the human in the whole manufacturing and transportation costs.

However, neither Taiwan nor Korea has any intention to set up factories in mainland China for the LCD panel front and middle manufacturing process involving core technologies. Therefore, there is still a long way to go for China to have its own LCD panel industry.

LCD prices are on a relentless downward trend. Lower prices are key to stimulating more demand and further growing the total market in terms of units as well as shifting demand to larger panel sizes. In order to maintain margins as prices fall, LCD producers constantly strive to lower costs. This trend is being exacerbated by the current weak economic environment and significant oversupply, causing prices to fall near cost levels, ever intensifying the focus on cost reduction.

Accounting for 15%-25% of total module costs, backlight unit and inverters are the single most expensive components of an LCD. For this reason, it is not surprising that the backlight assembly is an important focal point of cost reduction. In the backlit unit (BLU), CCFL lamps are the most expensive components, accounting for 30%-40% of the bill of materials — and in the case of LED-based BLUs, the lamps are substantially more expensive.

Increasing LCD panel transmissivity has now become an industrywide goal — not for the purpose of increasing on screen brightness, but rather to maintain brightness and reduce backlight lamps, inverters, and optical films in order to lower panel costs. Another benefit of improved transmissivity is power reduction. Not only is lower power consumption “green,” but in conventional LCDs the large majority of illumination generated by the backlight lamps is lost from polarizer absorption, shading by the TFT array aperture ratio, color filter, etc. so that only about 5% of the light emitted makes it to the front of the screen.

Even small improvements in transmissivity can lead to large gains in BLU lamp reduction. For example, a typical 400-nit panel with 5% transmissivity has 8000-nits luminance at the backlight. If transmissivity is increased from 5% to 10%, the same amount of front of panel luminance can be achieved with a 4000-nit backlight. In other words, the number of backlight lamps and inverters can be reduced by 50%.

There are a variety of technologies in production or in development by different panel manufacturers that target transmissivity improvements. Some of the most important include:

Adoption of low resistance gate and data lines provides multiple benefits that include reduced RC delay that improves performance and can potentially eliminate requirements for dual scan driving. In addition, due to lower resistivity, the width of the bus line can be reduced, which increases aperture ratio without sacrificing performance. Since copper has a very low resistance, it is the material of choice. Already LG Display is mass-producing the majority of its larger panels using Cu, and over the next five years Cu and Cu-alloy application is expected to grow substantially.

In PSA, a polymer alignment layer is formed over a conventionally coated polyimide by mixing a UV curable monomer into the LC. The monomer is then activated by UV radiation while applying an AC voltage. The monomer reacts with the polymer layer to form a surface that fixes the pre-tilt angle of the LC. Because it eliminates a protrusion from the color filter side of the display, aperture ratio is increased and panel brightness can be improved by more than 20%; contrast ratio and LC switching speed are also improved. At the same time, costs are reduced because the protrusion mask step can be eliminated from the color filter process.

PSA technology was originally developed by Fujitsu, and now AUO is bringing it to mass production, showing stunning examples of its technology (called “AMVA-III”) at this year’s FPD International. PSA offers multiple benefits, with minimum trade-offs. Several panel makers are expected to start mass production of PSA for both small/medium and large size LCDs over the next year.

In the color filter process, panel manufacturers are reducing the width of the black matrix (BM). Similar to reducing the width of gate and data lines, a thinner BM translates to a wider aperture ratio.

COA is another CF related manufacturing technology that moves RGB pixels from the common electrode glass to the array glass. There are multiple variations of this technology, but all increase transmissivity by widening the aperture ratio as well as improve contrast. However, moving color pixels to the array creates multiple process challenges, specifically yield loss. For this reason, COA is not yet widely adopted. TMDisplay and Samsung are currently the two main producers of COA based LCDs.

Lowering LCD costs are essential to maintain margins, and in the current environment, just to stay in business. Panel makers are applying a holistic strategy to cost reduction, which includes implementing new manufacturing technologies. Of these, improving panel transmission in order to lower backlight costs has emerged as a key trend. What technologies will be adopted will vary by panel maker, but those that both reduce cost and at the same time improve performance with minimal trade-offs will see the highest adoption rates. Particularly, LCDs adopting low-resistance bus lines, thinner BM, and PSA are already available in stores, and expect more in the near future.

How much does it cost to replace a MacBook Air screen? The cost to replace a MacBook Air screen is $299 for most models. The A1466 model is $179, while the A1932 and A1279 models are $299. The A2337 model is $299 for the LCD or $429 for the entire display.

This was the longest-running design for the screen on the MacBook Air. All the different models within these years are compatible with the same LCD panels. The cost seems to be coming down on the screen repairs for these A1369 and A1466 models. The cost to repair the screen on a 2010-2017 MacBook Air is $179. This will cover the LCD panel itself, the labor to install it, and the shipping to get the computer back to you.

Apple finally did a complete rebuild on the MacBook Air in 2018 and created a new model number A1932. The newer model has a redesigned display assembly that utilizes a different LCD panel and overall build than the prior 7 years of MacBook Air models. The cost to repair the screen of a 2018-2019 MacBook Air is $299.

The 2020-2021 MacBook Air looks basically identical to the 2018-2019 model, but the new model requires a different LCD panel than the older version of the laptop. There are actually 2 variations on this LCD panel. One is used for the intel-based models, and the other is used for the M1 models. I expect these LCD panels will be one of the harder-to-get models as it was only used for a single model of production.

The cost to replace a cracked LCD panel on an M1 2020 model A2337 MacBook Air is $299. If you would like to have the entire display assembly replaced with a genuine Apple display assembly, the .

Apple once again created an entirely new model with a completely redesigned screen in 2022 with their M2 MacBook Air. This new model hasn’t been out long enough for us to see what the price will end up being once the LCD panel is available on its own. For now, the cost to replace the full display assembly on the 2022 MacBook Air is $450-$750.

There are multiple parts in a display assembly, and chances are they do not all need to be replaced in order to get your computer fully working again. Knowing the basic parts that are required to complete your MacBook screen repair will help you select the correct repair for your needs.

The LCD panel is the part of the screen that displays the image, it is the part of the screen that you can touch when the computer is open. This is the most commonly broken part on a MacBook Air screen. If you have a cracked screen, there is a very big chance that what you need is an LCD replacement.

The display assembly is the entire top half of the computer. It includes the LCD panel, the back housing where the Apple logo is, the clutch cover along the bottom of the screen where it says “MacBook Air”, the iSight camera, and the hinges. If there are any bends or dents on the corners of your display, you will likely need to replace the entire display assembly.

The clutch cover runs along the bottom of the MacBook screen. It is the part that says “MacBook Air” on it. Sometimes I see clutch covers that are cracked or broken while the LCD panel itself is working fine! This means the computer works perfectly and the entire screen is visible and working, but there is a crack along the bottom of the screen in the part that says “MacBook Air” on it. If this is the issue you have, you just need a clutch cover replacement rather than an LCD replacement.

The MacBook Air camera almost never has an issue. If the camera does stop responding, the issue is almost always with the logic board inside your computer rather than the camera itself. Sometimes though, the cameras will fail and require replacement. Unfortunately with the way these MacBook Airs are assembled, you usually have to replace the LCD panel when you replace the camera.

The back housing is sometimes referred to as the “lid”. It is the part that has the Apple logo on it. Usually, the housing does not need to be replaced, but if there is a dent on the corner of the housing, a dent on the housing itself, or if liquid damage is present in the housing, then you will need the housing replaced as well as the LCD. Again, because of the way these are assembled you normally can’t replace just the housing by itself.

The hinges are exactly what they sound like, the hinge where the display meets the computer. Older model Macs from the 2006-2012 era sometimes had hinges that would crack or break and cause the display to not stay up properly. That is much rarer on the MacBook Airs, but it can happen. Some models require an entire display replacement in order to replace the hinges, while others you can replace separately. Because Apple routes cables through the hinges, you usually have to replace the entire display assembly if you have issues with the hinges.

What is the shop’s policy on data privacy? Make sure you’re comfortable with how your personal information will be treated. Some repairs require the technician to log in to your computer during the repair process, while other repairs do not.

The MacBook Air LCD replacement process is one that I don’t recommend for a beginner to an intermediate-level technician to attempt. It is best to start practicing with bad screens before moving on to these repairs. They are delicate and you can cause all kinds of problems during the repair by scratching backlight sheets or ripping cables under the LCD panel.

The display assembly replacement is a lot easier and can be completed by somebody with some technical repair experience. Apple has a self-repair program that covers the A2337 model MacBook Air. You can read about the program and get links in my 2020 M1 MacBook Air screen replacement guide.

I will say I have seen a lot of damaged screens when people attempt to repair the LCD panel on a MacBook Air themselves. Normally the damage is not fixable and you have to then replace the entire display assembly. I have a troubleshooting page for the A1466 MacBook Air if you have attempted a repair and ran into problems.

If you are experienced enough to complete the repair, you can find the panels on public sites like iFixit, eBay, Amazon, etc. As a shop, you will probably want to work with your vendor to get panels that have a guarantee so you can hold them in stock. The price for panels usually ranges from around $100 to about $400 for the newest model. Generally, the panels decrease in price with time, but sometimes if an LCD panel is not used frequently by apple, they will become rare and cost more over time for new ones.

I have put together a few guides on how to replace the LCD yourself. I currently have a 2010-2017 display and LCD replacement guide available. I also have started working on an A2337 display replacement guide that is still a work in progress. I am also working on making video guides for screen repair and hope to have those posted by the March of 2023.

The cost to replace a MacBook Air screen is $299 for most models. The A1466 model is $179, while the A1932 and A1279 models are $299. The A2337 model is $299 for the LCD or $429 for the entire display.

DHAs are more efficiently designed when Cevians’ multidisciplinary team with expertise in all of the subcomponents collaborates to optimize each of the design features. Technical risks are greatly reduced when we, as a single design authority, ensure the highest accountability towards the final product’s performance. Cevians integrates its custom AMLCD and optical products in its DHA.

Our unique capability of integrating all electro-mechanical components and man-machine interfaces with the various AMLCD elements provides significant technical, cost, and time to market efficiencies. In all cases, the resulting number of components in the integrated DHA is reduced, increasing reliability and reducing cost. Most design features perform much more than one role. For example, a light cavity wall can be eliminated and a structural wall in the MMI can take its place.

Liquid Crystal Displays or more commonly known as LCDs are one of the most common electronic components which help us interact with an equipment or a device. Most personal portable equipment and even gigantic industrial equipment utilize a custom segment display to display data. For many portable consumer electronics, a segment LCD display is one of the biggest contributors to the overall cost of the device, hence designing a custom segment display can drive the cost down while also utilizing the display area in the most optimum manner. These displays have the lowest cost per piece, low power requirements, and a low tooling fee too.

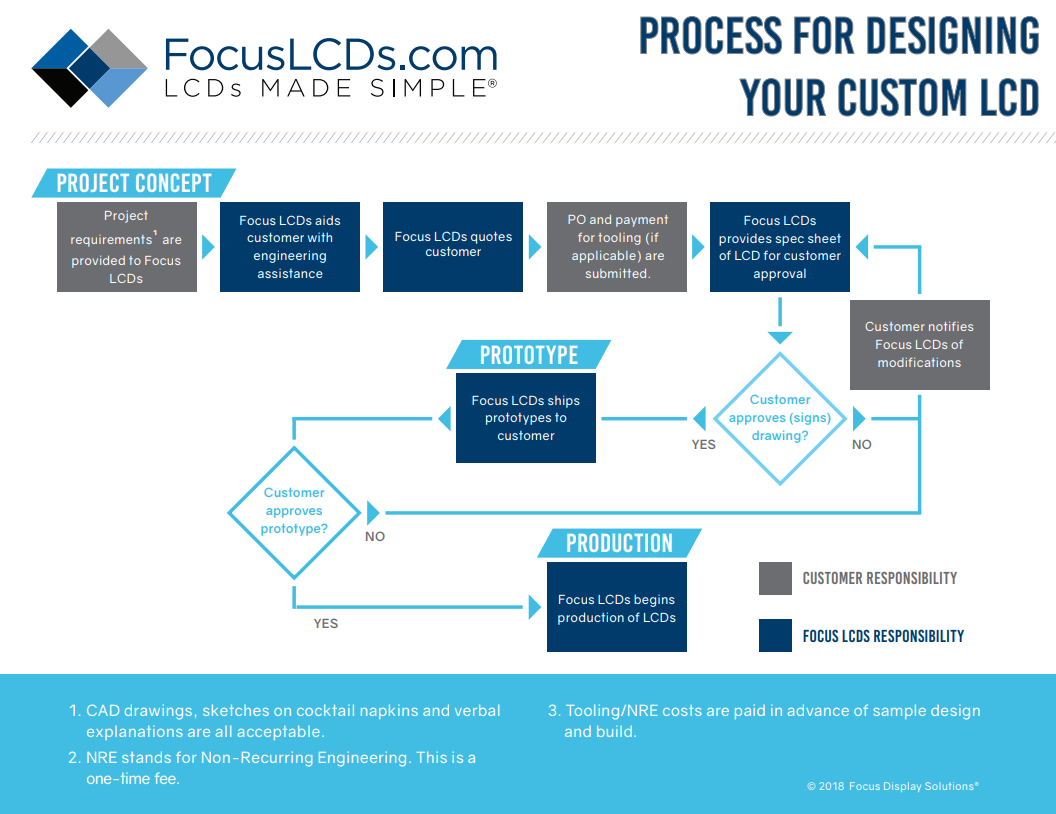

At first thought, designing a custom segment LCD might look like a Herculean task, but trust me that it is easier than it seems. In this article, we have summarised and compared the display types and available technologies which are required to construct a custom segment LCD. We have also provided a flowchart that can act as a step-by-step guide while you design your own custom LCD. We have also provided the process we followed, a require gathering sheet we used for communicating our needs to the manufacturer, and a few other data and the quotation we received from the manufacturer.

LCD Bias– It denotes the number of different voltage levels used in driving the segments, static drives (explained later in this article) only have 2 voltage levels or 2 bias voltage while multiplex drives have multiple voltage levels. For example, 1/3 will have 4 bias voltages.

LCDs utilizes the light modulating properties of liquid crystals which can be observed by using polarizing filters. Polarizing filters are special materials that have their molecules aligned in the same direction. If the light waves passing through polarisers have the same orientation as the filter, then the molecules of lights are absorbed by the filter, hence reducing the intensity of light passing through it, making it visible.

A custom LCD is important for maximizing the efficiency of the display area by adding custom symbols and characters. It also helps in reducing the cost and improving energy efficiency of the product. A higher number of custom symbols and specified placement of numerical and alphanumerical characters make the display more informative and readable for the user. This makes it look better than the plain old boring displays we get in the market. Furthermore, we can specify the viewing angle, contrast, and other specifications which can increase durability or give a better value for money for our intended usage. A typical Custom Segment display is shown below, we will also show you how to design and fabricate the same further in the article.

The LCD display doesn’t emit any light of its own, therefore it requires an external source of illumination or reflector to be readable in dark environments.

While designing a custom segment LCD display, we have the leverage of choosing a lot of parameters that affect the final product. From the color of the display to the illumination technique and color of illumination as well as the type of input pins. Some important considerations we need to take while designing a custom 7 segment display are - the type of display, i.e. positive or negative, illumination method, driving technique, polarising type, and connection method. All these design criteria are explained below:

So, which one should you choose? When the displays are to be used in areas with higher ambient light, we should select positive segment LCD display as it has better visibility than negative segment LCD displays without using a backlight.

As we know that LED displays don’t emit any light, hence to illuminate it and make it visible in a dark environment, we can use different methods of illumination. The most common LCD Illumination methods are compared below:

A polarizer film is the most important component of an LCD display, which makes it possible to display characters by controlling the light. There are 3 types of polarizers that can be used in the LCD display, the properties and difference are given below:

If your products need to be used with a switchable backlight, then trans-reflective reflectors are best to be used for front reflectors. If the device has to be used without backlight, then we can select a reflective polarizer for the back-panel as it gives the best contrast ratio.

If your displays have fewer segments, then static LCD drive is preferred as it is easier to control and cheaper to construct, and has a better contrast ratio. But let’s say that if the number of segments in the display are more than 30-40 then a multiplex LCD drive should be preferred as it has multiple common pins, hence reducing the total number of pins required to drive the display.

Choosing a connector type!!! For the prototyping phase or if you need to connect your LCD display on a Microcontroller directly, a pin type connector is the best and most economical option you have. If you need to connect your LCD display in a final product with a high volume of production which also requires to be extremely durable, but at the same time should not take up a lot of space, a Flex type LCD Connector will work best for you

LCDs have limited viewing angles and when seen from an angle they lose contrast and are difficult to be observed. The viewing angle is defined by the angles perpendicular to the center of the display towards its right, left, up, and down which are denoted by the notations 3:00, 9:00, 12:00, and 6:00 respectively. The viewing angle of LCD can be defined as the angle w.r.t. to the bias angle at which the contrast of segments is legible.

To improve the viewing angle in an LCD, a Bias is incorporated in the design which shifts the nominal viewing angle with an offset. Another technique is to increase the Voltage, it affects the bias angle, making the display crisper when viewed from a direction.

For example, the viewing angle of a TN type TFT LCD is 45-65 degrees. Extra-wide polarising film (EWP) can increase the viewing angle by 10 degrees, using an O film polariser can make the viewing angles 75 degrees but these come at a cost of reduced contrast.

LCD Control chip or LCD driver chips can be mounted on the flex cable, display, or externally on a PCB. The placement of LCD control chip can affect the cost and size of the display. The 2 most common methods of chip placement are-Chip of Board (COB)and Chip on Glass(COG) which are described below:

COG can be used as it is cheaper and makes the assembly process simpler, but if the dimensions are a constraint, then the COB is also a viable option.

We planned to design an air quality monitoring system for which we needed a custom segment LCD panel for an air quality monitoring device. Our product needs to display the following data: 2.5-micron and 10-micron particulate matter (PM) suspended in the air; the units should be in parts per million (PPM). CO2 in the air in PPM along with total volatile organic compounds present in the air in parts per billion (PPB). To make the product more usable, we included time in 24-hour format, Temperature in ºC, Battery status, loudspeaker status, Bluetooth status, and Wi-Fi status. And for some personal touch, we also added how good the air quality in the room is by using 3 different smileys.

We realized that it was impossible to provide all these data in a generic LCD available in the market, thus decided to build a custom LCD for our project.

A step-by-step flowchart is shown below to walk you through each and every step of selecting components and getting your custom segment LCD manufactured.

Usually, the displays are mounted at a height of 4.5 feet from the ground, thus the viewing direction was selected to be 12"O clock with an operating frequency of 64Hz. We selected a Transmissive polarizer for the front glass and a reflective polarizer for the rear glass so that the natural light can pass through the front panel and the display can achieve the maximum contrast without the need for backlighting and we opted for the pin type connectors as they are easy for prototyping and are suitable for harsh environment with a lot of vibrations and shocks which best suited our purpose.

We mailed our requirements to multiple LCD manufacturers, (you will find a lot of LCD manufacturers on the Internet). Most LCD manufacturers have competitive pricing, and reply within a week. A sample requirement sheet is shown above which a customer needs to fill to specify all the details to the manufacturer.

This is a sample Custom Segment LCD quotation we got from one of the manufacturers. As you can see, the cost is based on the quantity. Higher the quantity, lower the cost. Apart from the cost per quantity, there is one more component called tooling fees. Tooling fee is a one-time fee charged by the manufacturer. It is for the technical design, support, and customization of the product. Customization of PCB or tooling of LCD can drive the tooling price higher or lower.

A custom segment LCD can help you personalize your product while also saving the overall cost of your product. The whole process will take you around 2-3 months, which will include the designing phase, prototyping phase, and getting your custom segment LCDs delivered to your doorstep. Higher ordering quantity will reduce the cost per piece of each unit, thus driving down the cost of your final product.

LCD executives expect “to cut manufacturing costs to one-third of current levels over the next five years” according to a recent analysis of the market by noted Japanese economic expert Naoki Tanaka. Tanaka’s observation was reported in Nikkei Microdevices’ Flat Panel Display 2005 Yearbook . The publication, just released in its English-language translation, is said to be an essential source of insights into Japanese and Asian strategies for flat-panel-display development. Tanaka’s remarks were part of his introduction in the 2005 edition, in which he analyzes market trends and upcoming benchmarks.

The trends analysis is backed by extensive data and interviews with senior executives from the major Japanese, Korean, Taiwanese, and mainland Chinese manufacturers of LCDs, plasma displays, microdisplays, and similar products, says Interlingua, provider of translation and international intelligence services and translator of the yearbook. It reports the next five years will be marked by a flat-panel explosion, the end of CRT television, and intense competition among plasma, projection, and new-technology displays.

Do you have experience and expertise with the topics mentioned in this content? You should consider contributing to our CFE Media editorial team and getting the recognition you and your company deserve. Click here to start this process.

500 hours? I"m surprised. I would have thought some of the prints would take 5-10 hours, which makes that 50-100 prints per panel. That seems low. Quoting from that page:

Ms.Josey

Ms.Josey

Ms.Josey

Ms.Josey