lcd panel assembly process quotation

Liquid crystal display (LCD) is a flat panel display that uses the light modulating properties of liquid crystals. Liquid crystals do not produce light directly, instead using a backlight or reflector to produce images in colour or monochrome.

With the innovative ideas of electronic hardware, how to realize the concept into a physical product could be pretty challenging for startups, who have little experience in manufacturing and limited resources. We understand the difficulties and would like to provide the support to facilitate the startups at each phase of electronics manufacturing process. We would like to show you the tips and explanation of hardware development and manufacturing in a series of articles.

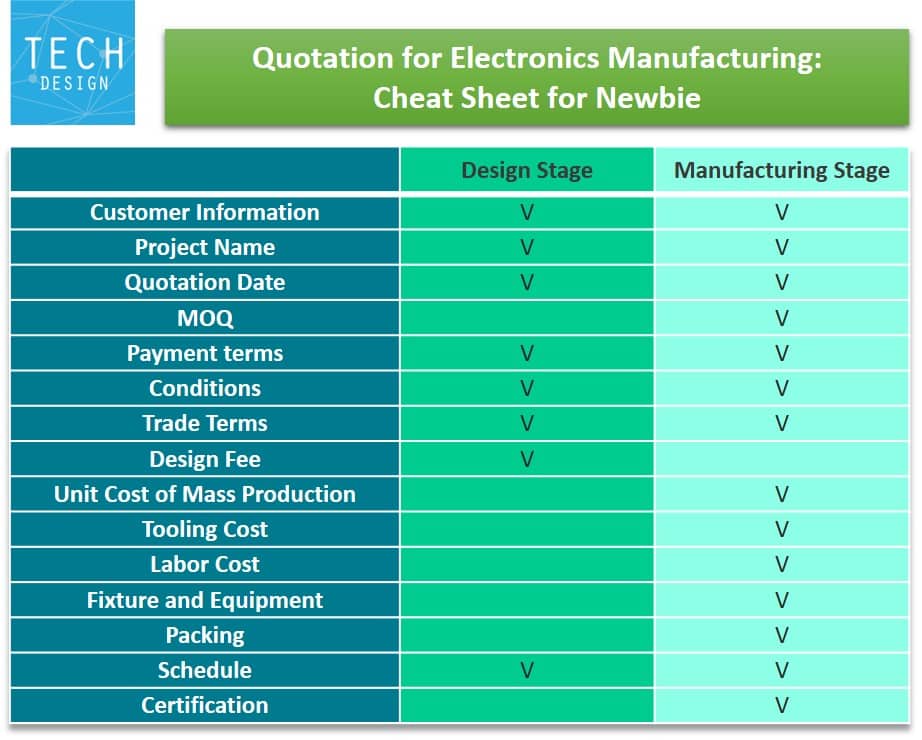

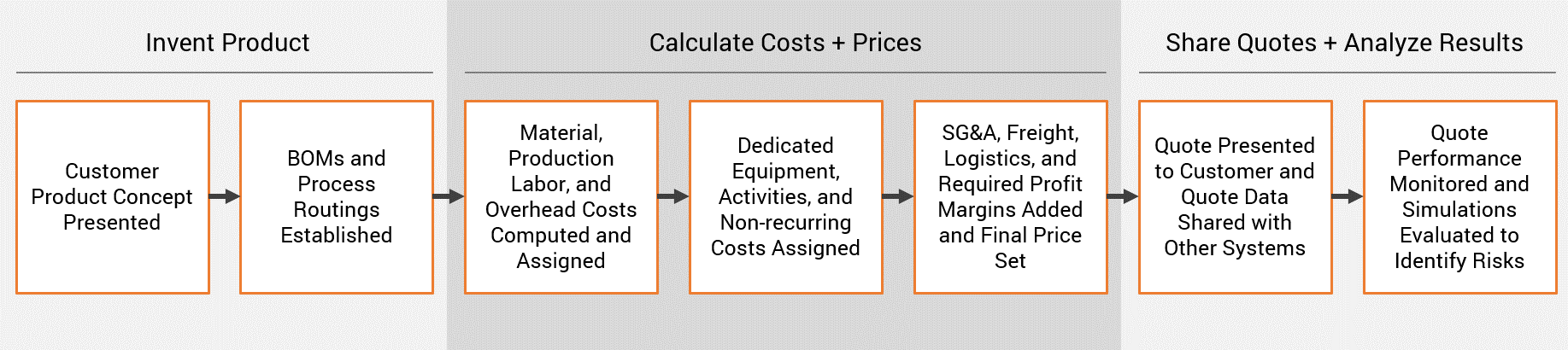

Let’s start with the definition of RFQ. RFQ stands for Request For Quotation, which is a standard business process to invite suppliers into a bidding process to bid on specific products or services. For the hardware startups whose product is ready to manufacture, preparing RFQ documents for sourcing vendors is the essential step to get proper quotations from electronics manufacturing suppliers. Meanwhile, for the suppliers who are interested in providing electronics manufacturing services, RFQ helps them fully understand the buyer’s (i.e. hardware startup’s) product and service expectation. Good RFQ contains the information of specified specification of each part and help suppliers to provide quotation accurately and efficiently. Additionally, RFQs can be the legal binding documentation for suppliers and help buyers reduce internal and external communication cost.

Before RFQ, RFI (Request for Information) is the step you should not skip to gather information and help make decisions for the next steps. RFI is a standard business process used by buyers to collect written information regarding the capabilities of various suppliers, which will better inform buying decisions. Generally speaking, the buyers need to provide the information, including user scenario, market research, and product concept. In addition, the general spec should be prepared as well, such as electrical spec, mechanical spec, schedule, new feature implementation plan, etc. If you are not sure whether the specs could be prepared by your internal resources, contacting experienced product managers for consultancy would be helpful. We could help hardware startups to find the electrical/mechanical solutions and guide you through the process of RFI and RFQ.

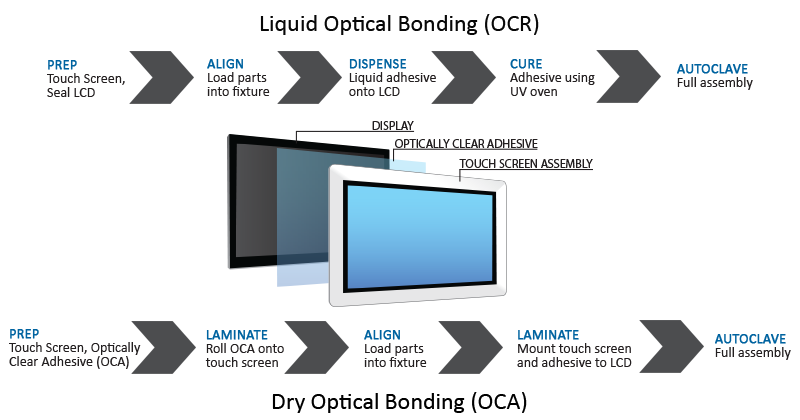

Most of times, buyers leave assembly SOP to the manufacturer to design because manufacturers have the expertise to set the production line in the most efficient way for the product. However, you will need to understand the assembly SOP as well because extra work station in the production line would cost you extra. Here, of course, you can consult with us for the support to prepare assembly SOP document and negotiate with suppliers about the execution on production lines.

This section contains the additional information that requires the manufacturers to pay attention for the special requirements while manufacturing the product. You might have collected the information in the RFI stage. Here we listed some examples for the manufacturing process. If you are still not sure what process you will need, we can provide the consultation to help you to find the items you may need.

MoldingThermoforming: it is a manufacturing process where a plastic sheet is heated to a pliable forming temperature, formed to a specific shape in a mold, and trimmed to create a usable product.

MachiningMilling: it is the machining process of using rotary cutters to remove material from a workpiece advancing in a direction at an angle with the axis of the tool.

The BOM is essentially a comprehensive list of electrical parts that the product uses. At the RFI stage, you might have surveyed all the components and electrical parts. So now at RFQ stage, the buyers need to provide BOM to get accurate quotation from suppliers. If some components require special process, please mark them. For example, some of wireless chips/modules need pre-baking before the pilot run.

To make sure your product functions correctly and meets your expectation, defining the testing requirements clearly is an indispensable process in working with manufacturers. Here are the factors you need to consider:

Liquid Crystal Displays or more commonly known as LCDs are one of the most common electronic components which help us interact with an equipment or a device. Most personal portable equipment and even gigantic industrial equipment utilize a custom segment display to display data. For many portable consumer electronics, a segment LCD display is one of the biggest contributors to the overall cost of the device, hence designing a custom segment display can drive the cost down while also utilizing the display area in the most optimum manner. These displays have the lowest cost per piece, low power requirements, and a low tooling fee too.

At first thought, designing a custom segment LCD might look like a Herculean task, but trust me that it is easier than it seems. In this article, we have summarised and compared the display types and available technologies which are required to construct a custom segment LCD. We have also provided a flowchart that can act as a step-by-step guide while you design your own custom LCD. We have also provided the process we followed, a require gathering sheet we used for communicating our needs to the manufacturer, and a few other data and the quotation we received from the manufacturer.

LCD Bias– It denotes the number of different voltage levels used in driving the segments, static drives (explained later in this article) only have 2 voltage levels or 2 bias voltage while multiplex drives have multiple voltage levels. For example, 1/3 will have 4 bias voltages.

LCDs utilizes the light modulating properties of liquid crystals which can be observed by using polarizing filters. Polarizing filters are special materials that have their molecules aligned in the same direction. If the light waves passing through polarisers have the same orientation as the filter, then the molecules of lights are absorbed by the filter, hence reducing the intensity of light passing through it, making it visible.

A custom LCD is important for maximizing the efficiency of the display area by adding custom symbols and characters. It also helps in reducing the cost and improving energy efficiency of the product. A higher number of custom symbols and specified placement of numerical and alphanumerical characters make the display more informative and readable for the user. This makes it look better than the plain old boring displays we get in the market. Furthermore, we can specify the viewing angle, contrast, and other specifications which can increase durability or give a better value for money for our intended usage. A typical Custom Segment display is shown below, we will also show you how to design and fabricate the same further in the article.

The LCD display doesn’t emit any light of its own, therefore it requires an external source of illumination or reflector to be readable in dark environments.

While designing a custom segment LCD display, we have the leverage of choosing a lot of parameters that affect the final product. From the color of the display to the illumination technique and color of illumination as well as the type of input pins. Some important considerations we need to take while designing a custom 7 segment display are - the type of display, i.e. positive or negative, illumination method, driving technique, polarising type, and connection method. All these design criteria are explained below:

So, which one should you choose? When the displays are to be used in areas with higher ambient light, we should select positive segment LCD display as it has better visibility than negative segment LCD displays without using a backlight.

As we know that LED displays don’t emit any light, hence to illuminate it and make it visible in a dark environment, we can use different methods of illumination. The most common LCD Illumination methods are compared below:

A polarizer film is the most important component of an LCD display, which makes it possible to display characters by controlling the light. There are 3 types of polarizers that can be used in the LCD display, the properties and difference are given below:

If your products need to be used with a switchable backlight, then trans-reflective reflectors are best to be used for front reflectors. If the device has to be used without backlight, then we can select a reflective polarizer for the back-panel as it gives the best contrast ratio.

If your displays have fewer segments, then static LCD drive is preferred as it is easier to control and cheaper to construct, and has a better contrast ratio. But let’s say that if the number of segments in the display are more than 30-40 then a multiplex LCD drive should be preferred as it has multiple common pins, hence reducing the total number of pins required to drive the display.

Choosing a connector type!!! For the prototyping phase or if you need to connect your LCD display on a Microcontroller directly, a pin type connector is the best and most economical option you have. If you need to connect your LCD display in a final product with a high volume of production which also requires to be extremely durable, but at the same time should not take up a lot of space, a Flex type LCD Connector will work best for you

LCDs have limited viewing angles and when seen from an angle they lose contrast and are difficult to be observed. The viewing angle is defined by the angles perpendicular to the center of the display towards its right, left, up, and down which are denoted by the notations 3:00, 9:00, 12:00, and 6:00 respectively. The viewing angle of LCD can be defined as the angle w.r.t. to the bias angle at which the contrast of segments is legible.

To improve the viewing angle in an LCD, a Bias is incorporated in the design which shifts the nominal viewing angle with an offset. Another technique is to increase the Voltage, it affects the bias angle, making the display crisper when viewed from a direction.

For example, the viewing angle of a TN type TFT LCD is 45-65 degrees. Extra-wide polarising film (EWP) can increase the viewing angle by 10 degrees, using an O film polariser can make the viewing angles 75 degrees but these come at a cost of reduced contrast.

LCD Control chip or LCD driver chips can be mounted on the flex cable, display, or externally on a PCB. The placement of LCD control chip can affect the cost and size of the display. The 2 most common methods of chip placement are-Chip of Board (COB)and Chip on Glass(COG) which are described below:

COG can be used as it is cheaper and makes the assembly process simpler, but if the dimensions are a constraint, then the COB is also a viable option.

We planned to design an air quality monitoring system for which we needed a custom segment LCD panel for an air quality monitoring device. Our product needs to display the following data: 2.5-micron and 10-micron particulate matter (PM) suspended in the air; the units should be in parts per million (PPM). CO2 in the air in PPM along with total volatile organic compounds present in the air in parts per billion (PPB). To make the product more usable, we included time in 24-hour format, Temperature in ºC, Battery status, loudspeaker status, Bluetooth status, and Wi-Fi status. And for some personal touch, we also added how good the air quality in the room is by using 3 different smileys.

We realized that it was impossible to provide all these data in a generic LCD available in the market, thus decided to build a custom LCD for our project.

A step-by-step flowchart is shown below to walk you through each and every step of selecting components and getting your custom segment LCD manufactured.

Usually, the displays are mounted at a height of 4.5 feet from the ground, thus the viewing direction was selected to be 12"O clock with an operating frequency of 64Hz. We selected a Transmissive polarizer for the front glass and a reflective polarizer for the rear glass so that the natural light can pass through the front panel and the display can achieve the maximum contrast without the need for backlighting and we opted for the pin type connectors as they are easy for prototyping and are suitable for harsh environment with a lot of vibrations and shocks which best suited our purpose.

We mailed our requirements to multiple LCD manufacturers, (you will find a lot of LCD manufacturers on the Internet). Most LCD manufacturers have competitive pricing, and reply within a week. A sample requirement sheet is shown above which a customer needs to fill to specify all the details to the manufacturer.

This is a sample Custom Segment LCD quotation we got from one of the manufacturers. As you can see, the cost is based on the quantity. Higher the quantity, lower the cost. Apart from the cost per quantity, there is one more component called tooling fees. Tooling fee is a one-time fee charged by the manufacturer. It is for the technical design, support, and customization of the product. Customization of PCB or tooling of LCD can drive the tooling price higher or lower.

A custom segment LCD can help you personalize your product while also saving the overall cost of your product. The whole process will take you around 2-3 months, which will include the designing phase, prototyping phase, and getting your custom segment LCDs delivered to your doorstep. Higher ordering quantity will reduce the cost per piece of each unit, thus driving down the cost of your final product.

Dr Pan: Hello, Greg. Segment LCD screen can only be used for simple display content of numbers and characters at a specified position. For example, the display on clock, landline, calculator, etc.

It is supposed to be a replacement for LED segment display. If we compare it with LED segment display, it is more stylish and high class, but more expensive. If we compare it with dot matrix LCD, the display content is very simple and absence of variation, but much cheaper. It is widely used in monochrome LCD screen: TN, HTN, STN, FSTN and VA because of relatively low cost.

For over 20 years we"ve been helping clients worldwide by designing, developing, & manufacturing custom LCD displays, screens, and panels across all industries.

Newhaven Display has extensive experience manufacturing a wide array of digital display products, including TFT, IPS, character displays, graphic displays, LCD modules, COG displays, and LCD panels. Along with these products, we specialize in creating high-quality and affordable custom LCD solutions. While our focus is on high-quality LCD products, we also have a variety of graphic and character OLED displays we manufacture.

As a longtime leader in LCD manufacturing, producing top-quality LCD modules and panels is our highest priority. At Newhaven Display, we’re also incredibly proud to uphold our reputation as a trusted and friendly custom LCD manufacturing company.

As a custom LCD manufacturing company, we ensure complete control of our custom displays" reliability by providing the industry"s highest quality standards. Our design, development, production, and quality engineers work closely to help our clients bring their products to life with a fully custom display solution.

Our excellent in-house support sets Newhaven Display apart from other display manufacturers. Modifications in the customization process are completed at our Illinois facility, allowing us to provide an exceptionally fast turnaround time.

Customer support requests sent by phone, email, or on our support forum will typically receive a response within 24 hours. For custom LCD project inquiries, our response time can take a few days or weeks, depending on the complexity of your display customization requirements. With different production facilities and a robust supply chain, we are able to deliver thefastest turnaround times for display customizations.

Our excellent in-house support and custom display modifications set Newhaven Display apart from other LCD display manufacturers. From TFTs, IPS, sunlight readable displays, HDMI modules, EVE2 modules, to COG, character, and graphic LCDs, our modifications in the customization process are completed at our Illinois facility, allowing us to provide quality and fast turnaround times.

As a display manufacturer, distributor, and wholesaler, we are able to deliver the best quality displays at the best prices. Design, manufacturing, and product assembly are completed at our headquarters in Elgin, Illinois. Newhaven Display International ensures the best quality LCD products in the industry in this newly expanded facility with a renovated production and manufacturing space.

With assembly facilities in the US, manufacturing facilities in China, and distribution channels worldwide, we pride ourselves on delivering high-quality custom display solutions quickly to locations worldwide.

A photosensitive suspension (photopolymer resin) is exposed by light (of certain wavelength) so it cures. The exposure pattern for each 3D slice is defined by a 2D photo mask (ultraviolet (UV) laser, UV light projector/DLP or LCD). After a layer is photocured, the Z axis moves up for the next layer of the 3D object. An FEP film clamped against the glass is used as the release layer.

With the rapid development of a new generation of information and communication technology, as a terminal device, smart phones, tablet PCs, smart homes and other products, the market demand continues to grow, LCD panel production scale has increased dramatically, becoming one of the pillars of the information industry. The rise of the LCD panel industry has led to a surge in demand for panel quality inspection. Traditional defect detection is mainly identified by the human eye, which brings great difficulties to enterprises to control production quality and improve production efficiency. In view of this, the adoption of a new panel quality inspection method to replace manual inspection is an urgent technical problem to be solved.

Thin film transistor liquid crystal display (TFT-LCD) has the advantages of high resolution and low power consumption, so it is widely used in the display industry. The production process of TFT-LCD display includes coating, etching, developing, panel combination, crystal filling and sealing, and driver chip installation, etc. The complex process leads to defects, including point defects, line defects and Mura defects. The word “Mura” comes from Japanese and translates to spot, dirt, also known as “cloud spot”, which is one of the most difficult defects to detect in display defects. The traditional Mura inspection method is achieved by manual visual inspection, mainly by naked eye discrimination. This method is inefficient and prone to visual fatigue, which leads to a lower correct result rate. Machine vision-based LCD panel inspection can be realized to detect defects generated by each production process of LCD panels, including Array (array) process, CF (color film) process, CELL (boxing) process, Module (module) process, crack (crack), broken (broken), chip (chipped), scratch (scratch), burr (burr). We can effectively detect and distinguish defects such as crack, broken, chip, scratch, burr and drop.

LCD panel production process will be probable chipping, breakage, cracks, scratches and other defects, if not found and dealt with in a timely manner, into the next production process of the main equipment, may occur during the production process in the equipment inside the glass breakage phenomenon, so that the main equipment must be shut down for maintenance and cleaning, resulting in economic losses of production downtime.

In recent years, many computer vision-based panel defect detection systems have emerged, but the defect detection algorithms utilized by various manufacturers are basically more traditional vision methods. However, as the production process continues to progress, the detection requirements are subsequently increased, the detection accuracy requirements are also increasing, and the real-time requirements for the algorithms are greatly improved. With the rise of deep learning, for such difficult-to-detect defects, we use convolutional neural networks (CNN) for the detection of screen defects. For the detection problem, there are many existing target detection algorithms that can achieve higher accuracy and real-time detection, effectively identifying and classifying LCD panel defects – achieving defect detection for chipped edges, cracks, dirt, water drops, scratches, etc., and interfacing with the main production equipment, detecting defects and then automatically making, according to the type of defect Feedback judgment: stop or alarm, no need for real-time monitoring by staff on site.

Through the digitization of quality inspection, the ability of data traceability analysis is improved, which provides a strong guarantee for improving the production process.

Using line array camera, lens, according to the detection demand items, choose to match the backlight, coaxial light or high bright line light source for LCD panel image acquisition, in the process of scanning pictures, intelligent algorithms simultaneously processing images, real-time display of the panel defect information, determine whether the surface has foreign objects, scratches, different colors, convex bags, dents, pinholes, burrs, bright spots, for defective glass, real-time linkage of the main equipment to stop and other related operations to prevent the main equipment downtime due to broken glass in the production process.

1、Open the product into 180°, place the LCD screen horizontally on the carrier table; 2、Start inspection: the carrier table moves and the camera starts to acquire images; 3、After the acquisition, the carrier table is reset; 4、Inspection software: analyze the quality of the LCD screen; 5、According to the analysis result, give the OK and NG evaluation result of the product; 6、Operator: according to the result, carry out binning operation and reinspection operation;

The PCB is something that is usually green in color and is a rigid body that holds various electronic components on it. These components are soldered upon the PCBs in the process called “PCB Assembly” or PCBA. The PCB is composed of a substrate that is made of fiber glass, the components, the copper layer that makes the traces, holes in which components are fitted and layers that can be inner layer and outer layers. At RayPCB we can deliver up to 1-36 layers for multilayer PCB prototypes and 1-10 layers for multilayer PCBs for mass production. For single sided PCB and double sided PCBs, the outer layers present but no inner layer.

The PCBs are the majority of PCBs we see all around us in various types of devices. These are hard, rigid and solid PCBs with various thickness. The main material is the fiber glass or simple “FR4”. FR4 means “Fire Retardant – 4”. The self extinguishing property of FR-4 makes it favorable for use in many hard core industrial electronic devices. The two sides of FR-4 is laminated with thin layer of copper foil also known as copper clad laminates. Main applications where FR-4 copper clad laminates are sued in are power amplifier, switch mode power supplies, servo motor drives etc. On the other hand another type of rigid PCB circuit prototype substrate commonly used in home appliances and IT products is known as Paper Phenolic PCB. They are light weight, low density, cheap and easy to punch process. Calculators, keyboards, and mouse are some of its applications.

Theflexible PCBs are made of the substrate material like Kapton that can withstand very high temperatures while the thickness is as low as 0.005 inch. The can bend easily and are used in wearable electronics, connectors of LCD displays or laptops, connectors of keyboard and camera etc.

Alternatively another PCB base material can be used like Aluminumthat is very good at dispersing heat effectively. These types of PCBs can be used in applications requiring heat sensitive components like high power LEDs, laser diodes,ultra-thin lcd pcb etc.

The component has to be inserted on one side of PCB and pulled by leg on other side and cut the leg and solder it. The THT components assembly is usually done by hand soldering and is relatively easy.

Before going to the actualPCB fabrication and PCB Assembly process, the manufacturer checks the PCB for any flaws or errors in the PCB that can result in malfunction. This process is called Design for Manufacturing (DFM) process. The Manufacturer must carry out these basic DFM steps to ensure flawless PCB.

After performing the DFM check, the manufacturer can easily reduce the cost of manufacturing by cutting down the number of scrapped boards. This will help in quick turn around by avoiding faults at DFM level. At RayPCB we provide DFM and DFT check at circuit assembly and prototyping. At RayPCB we offer PCB OEM services,wave soldering, PCB Card testing and SMT assembly using state of the art OEM equipment.

Before the advent of robotic pick and place machines, the technician will pick the components using tweezers and place it on PCB by carefully looking at the location and avoiding any jittering hands. This resulted in high level of fatigue and eyesight weakness in technicians and resulted in slowed process of PCB assembly of SMT components. Hence the chances of mistake were high.

The third step after the components are set and solder paste applied is reflow soldering. The reflow soldering is the process where the PCBs along with the components are put on the conveyer belt. This conveyer belt then moves the PCBs and components in a big oven, which creates a temperature of 250o C. This temperature is enough for the solder to melt. The melted solder will then fix the components upon the PCB and create joints. After the PCB is treated with high temperature, it then goes in to coolers. These coolers then solidifies the solder joints in controlled fashion. This will create a permanent joint between SMT component and PCB. In the case of two sided PCBs, the PCB side which has fewer or smaller components will be treated first from step 1 to 3 as mentioned above and then comes the other side.

After the reflow soldering, there is a chance that due to some erroneous movement in PCB holding tray, the components got misaligned and may result in short circuit or open connection. These flaws are need to be identified and this identification process is called inspection. Inspection can be manual and automated.

For the large batches of PCB, this method is feasible. This method uses the automated machine that has the high powered and high resolution cameras installed at various angles to view the solder joints from various directions. The light will reflect the solder joints in different angles according to the quality of solder joints. This automated Optical Inspection (AOI)machine is very high speed and take very short time to process large batches of PCBs.

The through-hole components are commonly found on many PCB boards. These components are also known as Plated through Hole (PTH). These components have leads that will pass through the hole in the PCB. These holes connect to other holes and vias by means of copper traces. When these THT components are inserted and soldered in these holes, then they are electrically connected to other hole in the same PCB as the circuit designed. These PCBs may contain some THT components and many SMD components so the soldering method as discussed above in case of SMT components like reflow soldering will not work on THT components. So the two main types of THT components soldering or prototype pcb assembly are

The manual soldering method is the common and typically takes more time than compared to automated setup for SMT. Usually one technician is designated to insert one component at a time and the board is passed on to other technician who inserts another component on the same board. So the board will move all around the assembly line to get the PTH components stuffed upon it. This makes the process lengthy and so many PCB design and manufacturing companies avoid using PTH components in their circuit design. But still the PTH components are the most favorite and common components for most of the circuit designers.

The automated version of manual soldering is wave soldering. In this method, once the PTH components are placed on the PCB, the PCB is put on the conveyer belt and is moved to specialized oven. Here a wave of molten solder is splashed on the PCB bottom layer where the components leads are present. This will solder all the pins at once. However this method is only for single sided PCBs and not for double sided because this molten solder while soldering one side of PCB can damage components on other side. After this, the pcb fabrication and assembly is moved for final inspection.

If any of the parameters of the PCB shows unacceptable results, then the PCB is discarded or scrapped as per the company standard procedures. Testing phase is very important because it determines the success or failure of the entire process of PCBA.

PCB electronic products refer to the selection of competent electronicprocessing companies to help produce products in order to focus on the research and development and market development of new products. PCBA electronic product manufacturing process mainly includes material procurement, SMT chip processing, DIP plug-in processing, PCBA testing, finished product assembly and logistics distribution. Prototype pcb assembly manufacturing process is as follows:

The electronic processing factory purchaseselectronic component materials, PCB boards, and steel mesh and fixtures according to the orders placed by customers.

Material on-line production, through solder paste printing, patch, reflow soldering, AOI inspection, DIP plug-in and wave soldering and other processing links, complete the processing and soldering of PCB, there will be quality inspection in every step of processing.

The electronic processing factory carries out testing according to its own testing process, combined with the test plan provided by the customer, and repairs the discovered defective products.

After all products are produced, they are packaged and shipped according to customer needs. PCBA electronic product processing is a relatively complicated process. In the process of production, each employee needs to work together and strictly follow the production process to control the quality, meet the customer’s quality requirements, and deliver the perfect product.

How much does it cost to replace a MacBook Air screen? The cost to replace a MacBook Air screen is $299 for most models. The A1466 model is $179, while the A1932 and A1279 models are $299. The A2337 model is $299 for the LCD or $429 for the entire display.

This was the longest-running design for the screen on the MacBook Air. All the different models within these years are compatible with the same LCD panels. The cost seems to be coming down on the screen repairs for these A1369 and A1466 models. The cost to repair the screen on a 2010-2017 MacBook Air is $179. This will cover the LCD panel itself, the labor to install it, and the shipping to get the computer back to you.

Apple finally did a complete rebuild on the MacBook Air in 2018 and created a new model number A1932. The newer model has a redesigned display assembly that utilizes a different LCD panel and overall build than the prior 7 years of MacBook Air models. The cost to repair the screen of a 2018-2019 MacBook Air is $299.

The 2020-2021 MacBook Air looks basically identical to the 2018-2019 model, but the new model requires a different LCD panel than the older version of the laptop. There are actually 2 variations on this LCD panel. One is used for the intel-based models, and the other is used for the M1 models. I expect these LCD panels will be one of the harder-to-get models as it was only used for a single model of production.

The cost to replace a cracked LCD panel on an M1 2020 model A2337 MacBook Air is $299. If you would like to have the entire display assembly replaced with a genuine Apple display assembly, the .

Apple once again created an entirely new model with a completely redesigned screen in 2022 with their M2 MacBook Air. This new model hasn’t been out long enough for us to see what the price will end up being once the LCD panel is available on its own. For now, the cost to replace the full display assembly on the 2022 MacBook Air is $450-$750.

There are multiple parts in a display assembly, and chances are they do not all need to be replaced in order to get your computer fully working again. Knowing the basic parts that are required to complete your MacBook screen repair will help you select the correct repair for your needs.

The LCD panel is the part of the screen that displays the image, it is the part of the screen that you can touch when the computer is open. This is the most commonly broken part on a MacBook Air screen. If you have a cracked screen, there is a very big chance that what you need is an LCD replacement.

The display assembly is the entire top half of the computer. It includes the LCD panel, the back housing where the Apple logo is, the clutch cover along the bottom of the screen where it says “MacBook Air”, the iSight camera, and the hinges. If there are any bends or dents on the corners of your display, you will likely need to replace the entire display assembly.

The clutch cover runs along the bottom of the MacBook screen. It is the part that says “MacBook Air” on it. Sometimes I see clutch covers that are cracked or broken while the LCD panel itself is working fine! This means the computer works perfectly and the entire screen is visible and working, but there is a crack along the bottom of the screen in the part that says “MacBook Air” on it. If this is the issue you have, you just need a clutch cover replacement rather than an LCD replacement.

The MacBook Air camera almost never has an issue. If the camera does stop responding, the issue is almost always with the logic board inside your computer rather than the camera itself. Sometimes though, the cameras will fail and require replacement. Unfortunately with the way these MacBook Airs are assembled, you usually have to replace the LCD panel when you replace the camera.

The back housing is sometimes referred to as the “lid”. It is the part that has the Apple logo on it. Usually, the housing does not need to be replaced, but if there is a dent on the corner of the housing, a dent on the housing itself, or if liquid damage is present in the housing, then you will need the housing replaced as well as the LCD. Again, because of the way these are assembled you normally can’t replace just the housing by itself.

The hinges are exactly what they sound like, the hinge where the display meets the computer. Older model Macs from the 2006-2012 era sometimes had hinges that would crack or break and cause the display to not stay up properly. That is much rarer on the MacBook Airs, but it can happen. Some models require an entire display replacement in order to replace the hinges, while others you can replace separately. Because Apple routes cables through the hinges, you usually have to replace the entire display assembly if you have issues with the hinges.

What is the shop’s policy on data privacy? Make sure you’re comfortable with how your personal information will be treated. Some repairs require the technician to log in to your computer during the repair process, while other repairs do not.

The MacBook Air LCD replacement process is one that I don’t recommend for a beginner to an intermediate-level technician to attempt. It is best to start practicing with bad screens before moving on to these repairs. They are delicate and you can cause all kinds of problems during the repair by scratching backlight sheets or ripping cables under the LCD panel.

The display assembly replacement is a lot easier and can be completed by somebody with some technical repair experience. Apple has a self-repair program that covers the A2337 model MacBook Air. You can read about the program and get links in my 2020 M1 MacBook Air screen replacement guide.

I will say I have seen a lot of damaged screens when people attempt to repair the LCD panel on a MacBook Air themselves. Normally the damage is not fixable and you have to then replace the entire display assembly. I have a troubleshooting page for the A1466 MacBook Air if you have attempted a repair and ran into problems.

If you are experienced enough to complete the repair, you can find the panels on public sites like iFixit, eBay, Amazon, etc. As a shop, you will probably want to work with your vendor to get panels that have a guarantee so you can hold them in stock. The price for panels usually ranges from around $100 to about $400 for the newest model. Generally, the panels decrease in price with time, but sometimes if an LCD panel is not used frequently by apple, they will become rare and cost more over time for new ones.

I have put together a few guides on how to replace the LCD yourself. I currently have a 2010-2017 display and LCD replacement guide available. I also have started working on an A2337 display replacement guide that is still a work in progress. I am also working on making video guides for screen repair and hope to have those posted by the March of 2023.

The cost to replace a MacBook Air screen is $299 for most models. The A1466 model is $179, while the A1932 and A1279 models are $299. The A2337 model is $299 for the LCD or $429 for the entire display.

Even when you see the benefits of a CPQ program, you may think your current process still fits the bill. But even if your current sales quote generation seems to be enough, be on the lookout for these six signs that you need CPQ:

Most companies that don’t use CPQ software have a sales process that’s slowed by the time it takes sales to deliver accurate quotes. However, these organizations rightfully don’t want to speed up the process if it means giving incorrect prices or unapproved discounts, or promising customers configurations that are unavailable. Thanks to a slew of variables that can change rapidly, the sales quote review process can become a bottleneck to closing sales. This means many companies struggle to get quotes to customers in a timely manner.

One barrier to delivering timely quotes occurs when sales reps want to offer the customer options, configurations, or prices, but have to go digging through spreadsheets to find the right pricing rules to create the quote. CPQ avoids this conflict — with the customer and within the organization — by clearly establishing preprogrammed rules. With a CPQ application, every conceivable configuration, price, discount, and scenario can be specified, making the product configurations and options straightforward based on company capability. Then, when the rep builds the quote, CPQ walks them through the process in order to create a complete, accurate quote, using a customized template, all within minutes. It’s automatically routed to the correct parties for approval, shortening the wait time even more.

CPQ software allows sales to deliver quotes quickly thanks to a streamlined quoting process — the result of the customized rules and pricing CPQ automation allows. This is true for companies with one-off sales, subscription pricing, recurring billing, and other revenue models.

Taking into account complex options and configurations, bulk pricing and discount rules, CPQ’s automation allows for personalized quotes that were once complex to build and deliver quickly to the customer. A fast sales quote process makes your company more efficient and knowledgeable and allows the deal to coast through the sales pipeline. This helps customers view your company as a partner that’s interested in helping them succeed.

The accuracy of your quote affects every department. CPQ software integrates with your existing business technology to make the entire process smoother.

Your CPQ program can be integrated with enterprise resource planning (ERP) systems, and when such integrations are established, entire processes are streamlined. CPQ and ERP integration offers a connection between sales and operations and becomes a major benefit of adopting a CPQ solution. Sales can monitor the status of deliveries, executives can monitor the sales process, and operations can monitor trends to plan for new deals. Sales can work with product design. Better, data-driven decisions can be made to meet customer needs. Combining CPQ with ERP leads to a reduction in operating costs, and on-time production is greater because operations and materials and manufacturing departments are in the loop.

When it comes time to complete the transaction and close the sale, CPQ software helps make the seamless transition from sales journey to decision. Your CPQ program lets you accurately configure products, apply pricing and quantity discounts, and have approvals already programmed into the system. This automation makes you look like a true sales professional, giving customers confidence in your processes and your company.

While business software applications like your CRM platform, knowledge management system, and web conferencing tools have increased the possibility of more efficient sales processes, CPQ applications have widespread effects on efficiency and revenue for the company.

Using CPQ applications allows sales organizations to focus on selling and replicating best sales practices rather than constantly retraining sales staff. When delivering quotes and closing sales becomes an effortless process, sales professionals see a growth in success — and with it, a growth in the company’s bottom line.

Successful CPQ deployment depends on providing careful training and support to your sales staff and implementing CPQ in tandem with other departments. When done right, investing in CPQ software helps your company lead the way to a more effective — and, importantly, profitable — sales process.

Our team will stay in touch throughout the process, making sure you have a stress-free experience — beginning with the manufacturing and shipping of your screen up until installation.

Because of the learning curve involved with implementing new technology, we"ll assign you a service manager and set up an on-site training session once your church stage screen is installed. You"ll learn more about your new panel, ranging from general integration to servicing procedures and maintenance, so you can take full advantage of all your panel has to offer.

Ms.Josey

Ms.Josey

Ms.Josey

Ms.Josey