lcd screen 3d model manufacturer

We invented LCD screen 3D printing- the technology has enabled the transition from just prototyping to full scale plastic part production. Since our inception we have innovated in a broad range of printing applications to increase reliability, quality while at the same time, reducing cost for the user. Our sole corporate drive combines our innovations to deliver autonomous, digital manufacturing processes for factories of the future.

Photocentric, a Peterborough-based 3D printer and materials manufacturer, has introduced the largest LCD 3D printer. The Liquid Crystal (LC) Maximus is designed to be used for mass production and large-scale prototyping.

Sally Tipping, Sales Director at Photocentric said, “LCD screen-based 3D printers have been the fastest growing area in 3D resin printing; this machine cements our position as the leading innovator in this exciting sector.”

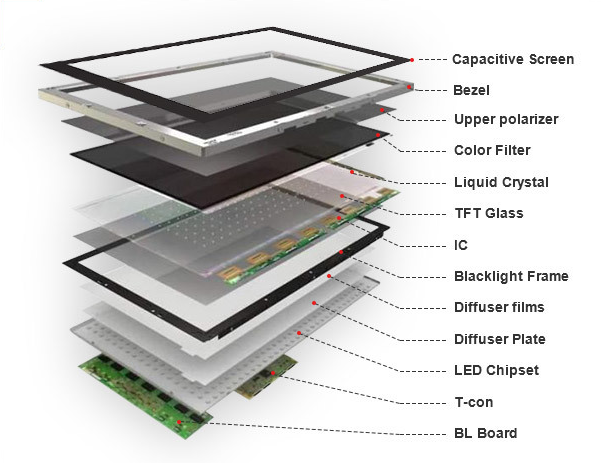

The light source in SLA/DLP is purpose-built, whereas Photocentric’s 3D printers use mass-produced LCD screens from mobiles, tablets, and large screen televisions. For this reason, LCD 3D printers tend to be cheaper than SLA/DLP printers but offer the same print quality.

As the DPP uses LCD screens to harden the resin, the chemistry of the liquid material needs to be different from the one used in UV printing. Photocentric manufactures and sells specific daylight resins which harden with exposure to LCD screen light.

Photocentric printers offer high quality and affordable alternative to SLA/DLP 3D printers. This year, the company’s Liquid Crystal Precision was also shortlisted for the 3D Printing Industry Award in the category of

The latest 3D printer from Photocentric, the LC Maximus, uses a 4K 40” LCD screen to cure each individual layer at an interval of 15 seconds with XY resolution of 230 microns.

The massive 700 x 893 x 510mm build size of the printer makes it ideal for mass producing parts, such as dental models and manufacturing large-scale prototypes. To demonstrate these capabilities, Photocentric is currently running a Facebook campaign.

Photocentric is prototyping a life-size model of a motorbike. Every Sunday at 6 p.m (GMT) leading up to formnext 2018 Photocentric’s team 3D prints and assembles a motorbike prototype part.

With the rear wheel, exhaust system and the engine 3D printed, and assembled, the project is now 45% complete. The finished bike will be exhibited at formnext 2018, where Photocentric will be in Hall 3.1, Stand A10.

To gain speed over its competitors, Photocentric has also announced a partnership with Germany’s BASF, the largest chemical producer in the world. The collaboration will see the development of photopolymers and 3D printers for mass production.

Designed for use with FDM 3D printers, the 5” capacitive touchscreen display features a resolution of 800 x 480 and comes complete with IPS technology, providing a wider and more comfortable viewing angle. Beyond just 3D printers, however, the full-color Raspberry Pad 5 is also suitable for a variety of other tech applications like smart mirrors, digital photo frames, wall calendars, robotics, and even mini computers.

Eric Zhang, Founder of BIGTREETECH, said, “The Raspberry Pad 5 is an affordable mainboard solution for your 3D printer and other devices. Compatible with all series of the Raspberry Pi CM4 board, the device makes for a perfect main control board system. As well as 3D printing applications, it’s also intended for makers to use in a variety of DIY projects.”

Founded back in 2015, BIGTREETECH has become a big player in the game of 3D printer electronics, specializing in control boards, display screens, and driver boards. Over the past seven years, the company has shipped its products to over 100 countries across the world.

Under its BIQU brand, the firm also develops its own consumer-grade desktop FFF 3D printers. The first of these, the BIQU B1, was launched in June 2020 and shortly after in August 2020, the company launched its flagship BIQU BX on Kickstarter. The final printer in the portfolio is the user-friendly BIQU B1 SE PLUS.

Additionally, BIQU is also home to a wide variety of 3D printing peripherals and add-ons such as extruders, hotends, heat sinks, linear guides, fans, PTFE tubing, timing belts, and even filaments. Just recently, the firm announced the launch of two new high-performance FFF extruder kits – the H2O and H2 500℃.

BIGTREETECH’s Raspberry Pad 5 measures 121 x 75.9mm, while the actual screen size clocks in at 108 x 64.8mm. This is larger than the default touchscreens of most 3D printing systems, so you can expect it to grant users with a more premium-feeling control experience.

The LCD screen comes complete with two buttons on the side for adjusting the display brightness, and another button to flip the screen. It also sports a wide variety of interfaces to provide flexible connectivity options, including HDMI, 40 pin GPIO, RJ45 Ethernet, USB Type-C, three USB 2.0 slots, and a CSI Port.

When integrated with an FDM 3D printer, the Raspberry Pad 5 will need to be combined with a Raspberry Pi CM4 board and allows users to run Klipper firmware.

Subscribe to the3D Printing Industry newsletterfor the latest news in additive manufacturing. You can also stay connected by following us onTwitter, liking us onFacebook, and tuning into the3D Printing Industry YouTube Channel.

With 4D_Additive, CAD data of all common formats can be imported and optimized for 3D printing processes by means of the advanced B-Rep functions. After this the optimized data can be sent to the printer directly. Automatic analysis and repair functions ensure watertight models and perfect printing quality.Especially for metal printing processes, semi-automatic support structures can be generated in 4D_Additive support structures. For lightweight construction and material savings, lattice geometries can be created very easily.

Batch processing for analysis functions such as wall thickness checking and undercut analysis, as well as general part properties and attributes automatically assess and categorize CAD models suitable for 3D Printing.

Thus, large volumes of data can be analyzed and categorized automatically with the help of special test profiles, with regard to the various 3D printing processes.

Nostalgia. Is something that’s only a few years old ‘Nostalgic’? Seems like Touch Screen Full Color Graphical LCD screens for 3D Printers are all the rage today. Me, I like the old monochrome push-knob types like this one: lots of options, infinite control, audible feedback. Feels like safe-cracking sometimes. Ah, the good old days…

Far more than just a device able to make calls, send emails, play music, take pictures, and share those pictures on social media, cell phones are capable of amazing feats when paired with 3D printing. They can be turned into microscopes and other medical devices, and even be used to power a 3D printer. But another trend that’s picking up steam is using your smartphone as an actual 3D printer.

Back in 2015, researchers from MIT were working to develop new algorithms that could harness polarized light from smartphones for 3D printing. That very same year, we first heard about the OLO (now called the ONO), the world’s first smartphone 3D printer. 2015 was clearly an important time for this type of work, as a professor of mechanical engineering at Taiwan Tech also created a smartphone-based 3D printer that year. In just about all of these cases, light emanating from the phone’s screen was used to cure resin, rather than using UV lights.

“Instead of using a laser or a projector to cure the polymer, we use unmodified LCD screens and our specially formulated Daylight polymer,” the company’s website reads. “All other 3D printers that polymerise resin use a combination of both daylight and UV light at considerably higher intensities. We have been able to make this work by developing the world’s most sensitive daylight resins. Utilising mass produced screens designed for use in mobiles, handheld devices enable us to use the highest resolution screens, offering phenomenal value for money, which we can then pass on to our customers. The opportunities are limitless; higher and higher resolution screens becoming available in all formats from mobiles to large format televisions provide the lowest cost imaging systems ever imagined. We call this Daylight Polymer Printing.”

While 3D printing is used for both small-scale and large-scale manufacturing across many industries, Photocentric, which holds patents in visible light curing technologies, believes that the technology still costs too much to be adopted on a wide scale. That’s why the company is focused on using the LCD screens we interact with every day on our TVs, smartphones, laptops, and tablets to transform 3D printing and make it less expensive.

To 3D print an object with resin-based 3D printers, the material is typically cured and hardened with a laser, or a digital light projector. But Photocentric is using LCD screen illumination to lower the cost of 3D printing, so that the technology can be used in more applications.

Now, Photocentric is totally focused on powering 3D printing using the illumination from LCD screens, mostly from the visible part of the spectrum, which is required when it comes to visual display screens. This could be the future of industrial 3D printing someday.

“Today it seems obvious that the highest resolution, largest format and lowest cost digital light source available is the visual display screen we all use in our pockets or on our walls,” said Paul Holt, the Founder of Photocentric. “But it can only work in 3D printing because our photopolymers can harden in light within the visible spectrum.

“We are now doing research into all formats of 3D printers with LCD screens from the nano – using tiny screens from near-eye virtual reality headsets – through to mobiles, tablets, right up to the largest TV screens. In fact, we just won a grant to manufacture what will be the largest 3D printer in the world, based on a 98-inch HDTV screen. Our goal is to change world manufacturing, not just 3D printing, by making 3D printing low cost, large scale and functional.”

In terms of making the technology more affordable, there are millions of LED screens manufactured by the electronics industry. It seems like nearly every quarter, cell phone, tablet, and TV screens change in size and affordability. If this industry takes its cue from Photocentric and focuses its R&D efforts on using these screens for 3D printing, the technology will inevitably become less expensive.

However, don’t expect to use your cell phone’s LCD screen to make large 3D printed objects. Regardless of how ingenious the idea is, the light output will likely be pretty low, and not enough to fabricate big parts. But it could be helpful when 3D printing lots of smaller objects.

“This time we are using light and a binder to fix the shape of a metal rich formulation using light from LCD screens,” Holt explained. “The object will then be slowly heated to remove the binder and sinter (fuse together) the metal. This technology can then be applied to all small-volume manufacturing of metal parts.”

While 3D printing in metal could eventually have a major impact on materials manufacturing, the 3D printing work that Photocentric is doing with metals is still mostly confined to the lab and is not a working solution just yet.

Ms.Josey

Ms.Josey

Ms.Josey

Ms.Josey