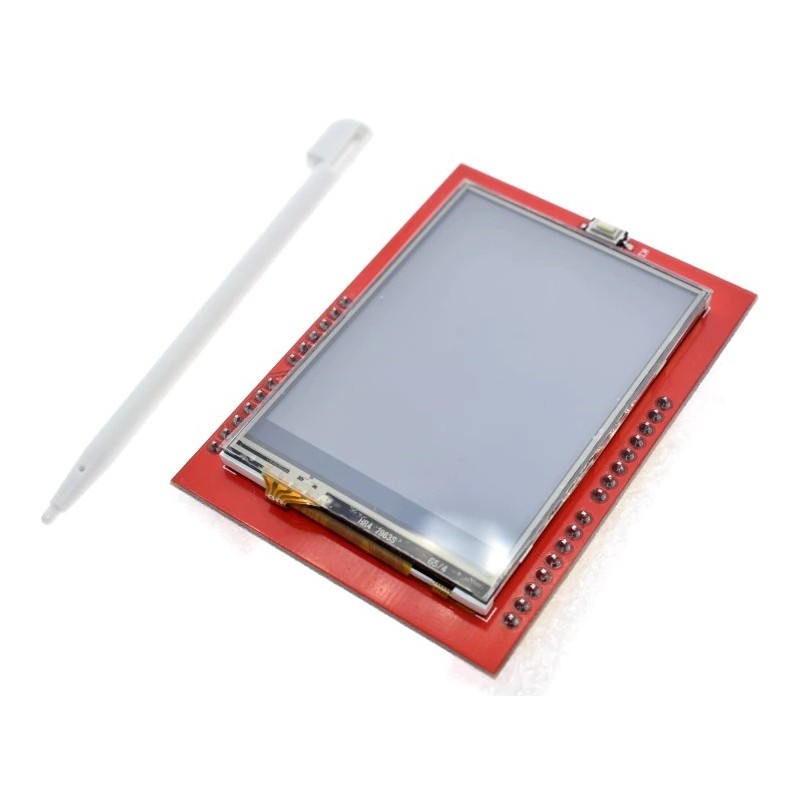

2.4 tft lcd display shield touch panel ili9341 free sample

The shield connects ILI9341"s data pins 0-7 to Arduino digital pins 2-8 (allowing parallel communication, not SPI). ILI"s RESET goes to pin to Arduino analog pin A4.CS (chip select) to A3. RS (CD command/data) to A2. WR and RD to A1 and A0.

ILI9341 is integrated inside the display. It drives the display and has nothing to do with touchscreen (Although the shield connects some pins of ILI9341 together with pins of the touchscreen).

To read a byte from ILI after sending a read command (e.g. 09h - Read Display Status) set RD from HIGH to LOW, so ILI9341 outputs data until RD returns HIGH. (see code)

To draw a rectangle (or just one pixel) on the screen you have to tell to ILI the area (start_column, end_column, start_row, end_row, commands 0x2Ah and 0x2Bh) you want to draw. Then command 0x2Ch. Then send in sequence for every single pixel in the area a value of the color to display. The color has 2 byte format.

The touch screen is attached on the surface of the display. It connects through 4 wires, which share arduino pins 8, 9, A2, A3 with ILI. So you can"t write to LCD display and read the touch screen in the same time.

Wikipedia:Touch-screen devices using resistive technology, a two-dimensional membrane potentiometer provides x and y coordinates. The top layer is thin glass spaced close to a neighboring inner layer. The underside of the top layer has a transparent conductive coating; the surface of the layer beneath it has a transparent resistive coating. A finger or stylus deforms the glass to contact the underlying layer. Edges of the resistive layer have conductive contacts. Locating the contact point is done by applying a voltage to opposite edges, leaving the other two edges temporarily unconnected. The voltage of the top layer provides one coordinate. Disconnecting those two edges, and applying voltage to the other two, formerly unconnected, provides the other coordinate. Alternating rapidly between pairs of edges provides frequent position updates. An analog-to digital converter provides output data.

First we need to detect if there is a touch. So we connect both wires of one layer/membrane, e.g. X to ground (LOW from ardiuno pins set as output) and one wire from layer Y to pull-up resistor (setting corresponding arduino pin as INPUT_PULLUP). Reading the second wire of Y layer we get HIGH if there is no touch (because of pull-up) and LOW if there is a touch (because of contact with grounded X layer).

Then we need to read a position of a touch. So we set one of the X wires to HIGH (which one depends on on which side of touch screen we want to read min/max value; see variant A/B in the code) and we read analog value on Y. The value should be in the range 0-1023, but touchscreen I tested returns 110-910 (So it need to be calibrated - run ILI9341_7.ino). Then we apply LOW-HIGH on Y layer and read analog value on X.

Touchscreen I tested sometimes wrongly detects a touch, outside of the touched point. To prevent this I added some delays and the X and Y analog value is read repeatedly and touch is approved only if values do not differ (a lot).

ILI9341 is integrated inside the display. It drives the display and has nothing to do with touchscreen (Although the shield connects some pins of ILI9341 together with pins of the touchscreen).

ILI9341 interpretes input byte as command (if RS=0) or as data/parameter (RS=1). You have first to send a command to ILI and then write or read data/parameters. CS pin has to be LOW during the communication, WR rising from LOW to HIGH tells to ILI to read byte on data pins. To read a byte from ILI after sending a read command (e.g. 09h - Read Display Status) set RD from HIGH to LOW, so ILI9341 outputs data until RD returns HIGH.

To draw a rectangle (or just one pixel) on the screen you have to tell to ILI the area (start_column, end_column, start_row, end_row, commands 0x2Ah and 0x2Bh) you want to draw. Then command 0x2Ch. Then send in sequence for every single pixel in the area a value of the color to display. The color has 2 byte format.

The touch screen is attached on the surface of the display. It connects through 4 wires, which share arduino pins 8, 9, A2, A3 with ILI. So you can"t write to LCD display and read the touch screen in the same time.

Touch-screen devices using resistive technology, a two-dimensional membrane potentiometer provides x and y coordinates. The top layer is thin glass spaced close to a neighboring inner layer. The underside of the top layer has a transparent conductive coating; the surface of the layer beneath it has a transparent resistive coating. A finger or stylus deforms the glass to contact the underlying layer. Edges of the resistive layer have conductive contacts. Locating the contact point is done by applying a voltage to opposite edges, leaving the other two edges temporarily unconnected. The voltage of the top layer provides one coordinate. Disconnecting those two edges, and applying voltage to the other two, formerly unconnected, provides the other coordinate. Alternating rapidly between pairs of edges provides frequent position updates. An analog-to digital converter provides output data.

First we need to detect if there is a touch. So we connect both wires of one layer/membrane, e.g. X to ground (LOW from ardiuno pins set as output) and one wire from layer Y to pull-up resistor (setting corresponding arduino pin as INPUT_PULLUP). Reading the second wire of Y layer we get HIGH if there is no touch (because of pull-up) and LOW if there is a touch (because of contact with grounded X layer).

Then we need to read a position of a touch. So we set one of the X wires to HIGH (which one depends on on which side of touch screen we want to read min/max value; see variant A/B in the code) and we read analog value on Y. The value should be in the range 0-1023, but touchscreen I tested returns 110-910 (So it need to be calibrated - run ILI9341_7.ino). Then we apply LOW-HIGH on Y layer and read analog value on X.

Touchscreen I tested sometimes wrongly detects a touch, outside of the touched point. To prevent this I added some delays and the X and Y analog value is read repeatedly and touch is approved only if values do not differ (a lot).

In this tutorial, you will learn how to use and set up 2.4″ Touch LCD Shield for Arduino. First, you’ll see some general information about this shield. And after learning how to set the shield up, you’ll see 3 practical projects.

The role of screens in electronic projects is very important. Screens can be of very simple types such as 7 Segment or character LCDs or more advanced models like OLEDs and TFT LCDs.

One of the most important features of this LCD is including a touch panel. If you are about to use the LCD, you need to know the coordinates of the point you touch. To do so, you should upload the following code on your Arduino board and open the serial monitor. Then touch your desired location and write the coordinates displayed on the serial monitor. You can use this coordination in any other project.

To display pictures on this LCD you should save the picture in 24bit BMP colored format and size of 240*320. Then move them to SD card and put the SD card in the LCD shield. we use the following function to display pictures. This function has 3 arguments; the first one stands for the pictures name, and the second and third arguments are for length and width coordinates of the top left corner of the picture.

If you want to display pictures without using an SD card, you can convert it to code and then display it. You can display even several photos sequentially without delay to create an animation. (Check this) But be aware that in this case, Arduino UNO may not be suitable (because of low processor speed). We recommend using the Arduino Mega or Arduino DUE.

Spice up your Arduino project with a beautiful touchscreen display shield with built in microSD card connection. This TFT display is 2.4" diagonal and colorful (18-bit 262,000 different shades)! 240x320 pixels with individual pixel control. As a bonus, this display has a optional capacitive touch panel and resistive touch panel with controller XPT2046 attached by default.

The shield is fully assembled, tested and ready to go. No wiring, no soldering! Simply plug it in and load up our library - you"ll have it running in under 10 minutes! Works best with any classic Arduino (UNO/Due/Mega 2560).

This display shield has a controller built into it with RAM buffering, so that almost no work is done by the microcontroller. You can connect more sensors, buttons and LEDs.

Of course, we wouldn"t just leave you with a datasheet and a "good luck!" - we"ve written a full open source graphics library at the bottom of this page that can draw pixels, lines, rectangles, circles and text. We also have a touch screen library that detects x,y and z (pressure) and example code to demonstrate all of it. The code is written for Arduino but can be easily ported to your favorite microcontroller!

In this Arduino touch screen tutorial we will learn how to use TFT LCD Touch Screen with Arduino. You can watch the following video or read the written tutorial below.

For this tutorial I composed three examples. The first example is distance measurement using ultrasonic sensor. The output from the sensor, or the distance is printed on the screen and using the touch screen we can select the units, either centimeters or inches.

The third example is a game. Actually it’s a replica of the popular Flappy Bird game for smartphones. We can play the game using the push button or even using the touch screen itself.

As an example I am using a 3.2” TFT Touch Screen in a combination with a TFT LCD Arduino Mega Shield. We need a shield because the TFT Touch screen works at 3.3V and the Arduino Mega outputs are 5 V. For the first example I have the HC-SR04 ultrasonic sensor, then for the second example an RGB LED with three resistors and a push button for the game example. Also I had to make a custom made pin header like this, by soldering pin headers and bend on of them so I could insert them in between the Arduino Board and the TFT Shield.

Here’s the circuit schematic. We will use the GND pin, the digital pins from 8 to 13, as well as the pin number 14. As the 5V pins are already used by the TFT Screen I will use the pin number 13 as VCC, by setting it right away high in the setup section of code.

I will use the UTFT and URTouch libraries made by Henning Karlsen. Here I would like to say thanks to him for the incredible work he has done. The libraries enable really easy use of the TFT Screens, and they work with many different TFT screens sizes, shields and controllers. You can download these libraries from his website, RinkyDinkElectronics.com and also find a lot of demo examples and detailed documentation of how to use them.

After we include the libraries we need to create UTFT and URTouch objects. The parameters of these objects depends on the model of the TFT Screen and Shield and these details can be also found in the documentation of the libraries.

Next we need to define the fonts that are coming with the libraries and also define some variables needed for the program. In the setup section we need to initiate the screen and the touch, define the pin modes for the connected sensor, the led and the button, and initially call the drawHomeSreen() custom function, which will draw the home screen of the program.

So now I will explain how we can make the home screen of the program. With the setBackColor() function we need to set the background color of the text, black one in our case. Then we need to set the color to white, set the big font and using the print() function, we will print the string “Arduino TFT Tutorial” at the center of the screen and 10 pixels down the Y – Axis of the screen. Next we will set the color to red and draw the red line below the text. After that we need to set the color back to white, and print the two other strings, “by HowToMechatronics.com” using the small font and “Select Example” using the big font.

Ok next is the RGB LED Control example. If we press the second button, the drawLedControl() custom function will be called only once for drawing the graphic of that example and the setLedColor() custom function will be repeatedly called. In this function we use the touch screen to set the values of the 3 sliders from 0 to 255. With the if statements we confine the area of each slider and get the X value of the slider. So the values of the X coordinate of each slider are from 38 to 310 pixels and we need to map these values into values from 0 to 255 which will be used as a PWM signal for lighting up the LED. If you need more details how the RGB LED works you can check my particular tutorialfor that. The rest of the code in this custom function is for drawing the sliders. Back in the loop section we only have the back button which also turns off the LED when pressed.

(The following is the touch screen signal line wiring, if you do not need to touch function or the module itself does not have touch function, you can not connect them)

This module is a 2.4-inch TFT LCD module with “320X240” resolution and 65K color display. It is suitable for Arduino Uno and Mega2560 development boards, and also supports SD card expansion function. It uses 8-bit parallel port communication, and the driver IC is ILI9341.

The 2.4-inch display is a ready-made shield for Arduino Uno, which can also be placed on the Arduino Mega. The pins of this shield are designed to be easily installed on the Arduino. The bad point about these modules is that they use all Arduino Uno pins.

Open the downloaded file and upload the main.ino code on your Arduino Board. This code is for testing the display module and comes with full screen calibration.

This is the 2.4 inch touch screen for Arduino UNO and MEGA. It use 8-bit parallel bus, faster than serial SPI refresh , support 16-bit RGB 65K color display, display rich colors , easy to expand the experiment with SD card slot.

The display has a built-in ILI9431 controller. Controlling the image through this controller is incredibly simple. For Arduino, there are a number of ready-made libraries for this controller, such as Adafruit TFT.

The display controller has been configured to work with the SPI serial interface. Thanks to it, connecting to Arduino or STM32 requires only a few pins. Save valuable microcontroller pins.

It has a touch layer applied in resistive technology. The touch is supported by a dedicated XPT2046 controller with an SPI interface. Dedicated pins are provided for touch communication. The controller can trigger an interrupt when it detects a touch.

Many Arduino projects require adequate display of what is being monitored. Think of time, temperature, humidity, pressure, sound, light, voltages, or combinations of recorded data in a weather station. With the addition of fast and capable ESP32 microcontroller boards to my personal ‘fleet’ my collection of good old Arduino Unos with their TFT display shields seemed prone to gather dust. The ESP32 combines well with TFT displays through a 4-pin SPI interface* while the Uno shields have parallel interfaces that feature 28 pins of which a minimum of 13 is necessary for the daily display business (see figure 2). A parallel interface is generally faster than a SPI interface. The prospect of a bunch of shield displays with fast parallel interface parked forever in a deep drawer was a stimulus for me to start a project to connect these shields to an ESP32. Fortunately there are several solutions available of which I selected the one proposed by Alberto Iriberri Andrés at https://www.pangodream.es/ili9341-esp32-parallel. However, the nightmarish prospect of connecting shield after shield with an ESP with unwieldy Dupont jumper wires inspired me to create a Uno-shield compatible parallel ESP32 TFTdisplay workbench for the purpose of checking all my Uno TFT shields, one by one. Here follows the design, wiring, and the results with a collection of parallel Uno shield type displays.

The market is swamped with TFT shields that can be placed directly on the pin sockets of an Arduino Uno. These shields feature parallel interfaces. They have in common that there are four pin header blocks through which one can stick such a shield very handy right onto a Uno (fig. 2). The displays mounted on these shields have different pixel dimensions and, more important, different controller chips. Most commonly used are ILI9341, ILI9481 and ILI 9486 chips. The best performing TFT shields are equipped with 3V-5V voltage converters (e.g. the shield shown in fig 2) but there are plenty of cheap shields available that lack a voltage regulator and therefore accept only 3V.

Controllers need their own specific driver to make the display work correctly. A major effort to supply the Arduino world with adequate drivers for ESP8266 and ESP32 microprocessors running smoothly with the above ILI controllers has been undertaken in recent years by the electronics engineer known as Bodmer: the TFT_e_SPI.h library.

So what I needed is a board that accomodates an ESP32 and that has enough space to accommodate a variety of small (2.4 inch) and large (3.95 inch) Uno TFT shields.

The base board consists of a doule-sided soldering board fastened with four nylon spacers on a piece of cardboard. Mounted on this base are two 15-pin parallel socket headers to accommodate an ESP32 microcontroller board and the four socket headers to accommodate the Arduino Uno TFT shields to be tested. As screen diagonals of TFT shields in my ‘arsenal’ vary between 2.4 inch and 3.95 inch, a 12080 mm double-sided soldering board with 4230 holes was selected for this purpose. The positioning of the socket headers is shown in figure 3. There are also two 2-pin pin headers to allow to select the proper voltage to power the display being tested (with jumpers).

The positioning of pins on the original Arduino Uno does not follow the uniform 2.54 mm (0.1 inch) pitch rule. Any Uno parallel TFT shield therefore will not immediately fit a standard soldering board. On the back of each shield are jumper blocks labeled J1 through 4 (figure 2). We call J1 here the ‘SD jumper block’, J2 the ‘parallel jumper block’, J3 the ‘control jumper block’ and J4 the ‘power block’. Part of the SD jumper block is occupied by the parallel data interface. Some manoevering makes it clear trhat the J2-J3-J4 blocks fit the holes of the soldering board while the parallel jumper block (J1) is the outlier. Fortunately, the pins in all blocks follow the 2.54 mm pitch rule. It is J1 as a whole that is half a unit positioned ‘out of pitch’. Through this unorthodoxy, say asymmetry, a TFT shield fits an Arduino in only one way. Very clever. The present soldering board was adapted to this configuration by cutting a narrow sleeve where the pins of the J1 parallel jumper block should be, just wide enough to let the pins of the corresponding socket header through. Then an extra piece of soldering board was prepared and fastened with wire and solder under the sleeve, taking care that the J1 accepting socket header would exactly match jumper block J1.

The design is quite simple: two parallel rows of 15-pin socket headers serve as a mounting point for the ESP32 (figures 2,3). These sockets are positioned in the upper left corner of the board to leave as much area as possible to position the TFT shields. Here, TFT shields are oriented landscape. The bench is designed only for displaying data and graphs only, with no SD card reader support.

All Uno TFT shields have three pins that deal with power (3V3, 5V, GND), five pins that are necessary for display control and eight pins connected with the parallel data transfer interface, i.e., there is a total of 16 pins that need to be wired (figure 2). In addition I planned three ‘free’ pins of the ESP32 available via pin sockets for input-output puposes: pins D2, D5 and D15 (figure 4).

With so many wires it is necessary to bring order in the assembly of the bench. One can distinguish (1) power wires, (2) TFT control wires, (3) parallel interface wires, (4) additional wiring. One by one the groups of wires were mounted on the soldering board.

The group of control wires originates from pins D26, D27, D14, D12 and D13 and connect to the socket header that accomodates TFT shield jumper J1 (figure 5).

There are eight data pins on the TFT shields, marked LCD_D0 through LCD_D07. LCD-00 and LCD_01 are pins on jumper block J3 while the remaining LCD_nn pins can be found on jumper block J2. These pins must be connected to, respectively, pins RX2, D4, D23, D22, D21, D19, D18 and TX2 (figure 6).

Bodmer’s TFT_eSPI library is different than other libraries, e.g. Adafruit_GFX and U8G2 in the sense that there is no ‘constructor’. Pin definitions for each type of controller are in TFT_eSPI systematics stored in a separate Setup_nn.h file that is placed in a folder with the name ‘User_Setups’. In turn, the specific Setup_nn.h is called in another stetup file named User_Setup_Select.h. Consider the systematics as a kind of two-stage rocket. Both stages need to be edited befor launch. The first stage is User_Setup_Select.h and the second stage is Setup_nn.h.

An example of the specific Setup_nn.h file for one of my ILI9341 shields (the one shown in figure 1) is named ‘Setup_FW_WROOM32_ILI9341_parallel_TFT_016.h’. This is a file editable with any ASCII editor.

Figure 1 shows one of my Uno TFT shields mounted on the bench, running the example ‘TFT_graphicstest_one_lib,’ that can be found in the Arduino IDE under File, Examples, TFT_eSPI, 320×240, of course after correct installation of Bodmer’s TFT_eSPI library. With an ESP32. My own ‘ESP32_parallel_Uno_shield_TFT_radar_scope.ino’ runs fine: the downloadable demo sketch which mimics an aviation traffic controller’s radar scope with a sweeping beam. I created this sketch in 2017 as a demo for one of my first Arduino Uno TFT shields**. The body of that demo was used for the present demo sketch.

Testing my complete collection showed marked differences between shields. I tested shields with ILI341, ILI9481, ILI8486 and ILI9488 controllers, with mixed results. Best performance was achieved with ILI9341 controller equipped shields. Shields that lack a voltage regulator appeared to be dedicated 3V3 shields as they would not perform, or produce an upload error, if the 5V jumper was closed. One 3V3 shield needed the 3V3 jumper closed during upload while after upload it needed 5V to lighten up the screen. Some but not all shields accepted closed 3V3 and 5V jumpers during uploading and running sketches. One ILI9481-powered shield behaved very peculiar: only if both 3V3 and 5V jumpers were open during upload the sketch would be accepted and then be visible on screen only with the 5V jumper closed.

The experiences with the TFT shields lead to the following rule of thumb: first try to figure out the correct controller (this on an Arduino Uno with David Prentices’ ‘MCUFRIEND_kbv.h’), then checking the User_Setup_nn.h file icreated for this shield n the TFT_eSPI library system, and then try to upload first with the 3V3 jumper closed, then again (if necessary) with the 5V jumper closed, and finally with both jumpers closed.

Ms.Josey

Ms.Josey

Ms.Josey

Ms.Josey