multiplexing lcd displays manufacturer

Segmented LCDs and graphic displays are a popular choice among products such as thermostats, kitchen appliances, medical devices, industrial meters, and more. A segmented LCD is an ideal solution for products that require a customizable cost-effective, low-power display option. Displaytech offers custom 7 segment displays in static or multiplex drive.

Segmented LCDs are monochrome liquid crystal displays where the elements on the panel are divided into segments which can either be visible (on) or hidden (off).

A 7-segment LCD is a cost-effective, low-power display option to use within your product design. At Displaytech, we are here to help you choose the best LCD solution for your product.

Multiplex addressing is an addressing scheme used in various types of LCDs where one (or a few) rows of an image at a time are being addressed sequentially until the entire screen is painted. Then the addressing repeats. The picture elements (pixels, icons, segments) are arranged in a matrix. The matrix arrangement is either physical or electrical. In a physical arrangement, pixels are arranged in rows and columns within a graphic array. In an electrical arrangement, COM (commons) electrodes are the equivalent of rows, and SEG electrodes are the equivalent of columns. The cross-overs of rows and columns form capacitors with the liquid crystal as the dielectric.

Multiplex addressing works for liquid crystal displays because nematic liquid crystals respond to the RMS value of the applied signal and not to the instant applied field. The ratio between the resulting RMS voltage for an on and off pixel (Von/Voff) is a function of the number of rows (N) that are being addressed in multiplex addressing. This function is named after its first authors as the Alt-Pleshko limit:

The more rows to be addressed, the smaller the ratio between the on and off voltage. Higher row count also requires the liquid crystal display to have a steeper transition within the transmission-voltage characteristic. STN displays have a steeper transition than TN displays, so STN displays can have a higher number of rows than TN displays.

The ratio of the amplitudes of the column and row signals is called the Bias Ratio B. The square root of the number of rows (N) is an ideal bias ratio as it results in the largest possible Von:Voff ratio. N is often expressed as the multiplex ratio 1/N. Multiplex and bias ratio are parameters that must be specified and programmed into the LCD driver/controller.

TFT is an LCD Technology which adds a thin-film transistor at each pixel to supply common voltages to all elements. This voltage improves video content frame rates. Displays are predominantly utilizing color filter layers and white LED backlighting.

OLED Displays are emissive displays and do not utilize liquid crystal. Each pixel is emissive with light. Passive OLED displays multiplex power and logic through the IC. Active OLED displays add a transistor at each pixel to supply power directly to the pixels and the IC only performs logical functions.

The basic LCD cell has no readily discernible optical characteristics and looks transparent under any condition. But if a piece of properly oriented linear polarizer (such as those found in polarized sunglasses) is placed on each glass surface, the basis of the cell"s display properties is provided.

Users often backlight such "transmissive" displays with any convenient source - incandescent, fluorescent, or neon, for example - or with ambient light.

TN liquid crystals work very well in multiplex applications, however, it is important to understand the restraints that multiplexing applies to the display so that they can be properly implemented.

The most important thing to remember in multiplexing displays is that the elements are all interconnected, and there is a cross-talk problem which must be addressed.

In effect, this makes the effective drive voltage on the display a function of "n," or the number of lines it is multiplexing. So the higher the multiplex ration, the poorer the viewing angle and contrast ratio.

If the LCD panel breaks, do not get the liquid crystal in your mouth. In case of contact with your skin or clothes, wash it off immediately with soap and water.

When soldering displays with pins, avoid excessive heat. Keep the soldering temperature between 260°C and 300°C and apply heat for no more than 5 seconds. Never use wave or reflow soldering. Cover the surface of the LCD to avoid flux spatter. Remove flux residues afterward.

Do not use DC voltage to drive the LCD and keep the voltage within the specified limit. Excess voltage will shorten the display"s life. Within limit, the viewing angle can be fine tuned by varying the voltage (especially for STN). Response time will increase as the temperature decreases.

We receive many calls regarding direct drives and multiplex drives for custom segment LCD displays. The Segment LCD is a common type of custom display module; in fact, it is the lowest cost custom LCD glass option available. One reason for the low cost is that it does not contain a controller/driver chip. Therefore, instead of having a parallel / IC2 / SPI interface options, you now have two options: Direct (or static) drives and multiplex drives.

There are two drive types available for a custom segmented LCD module. Direct drives or static and multiplex drives. There is no difference in tooling cost between the two. Before we explain the difference between direct and multiplex drives, let’s talk about segments.

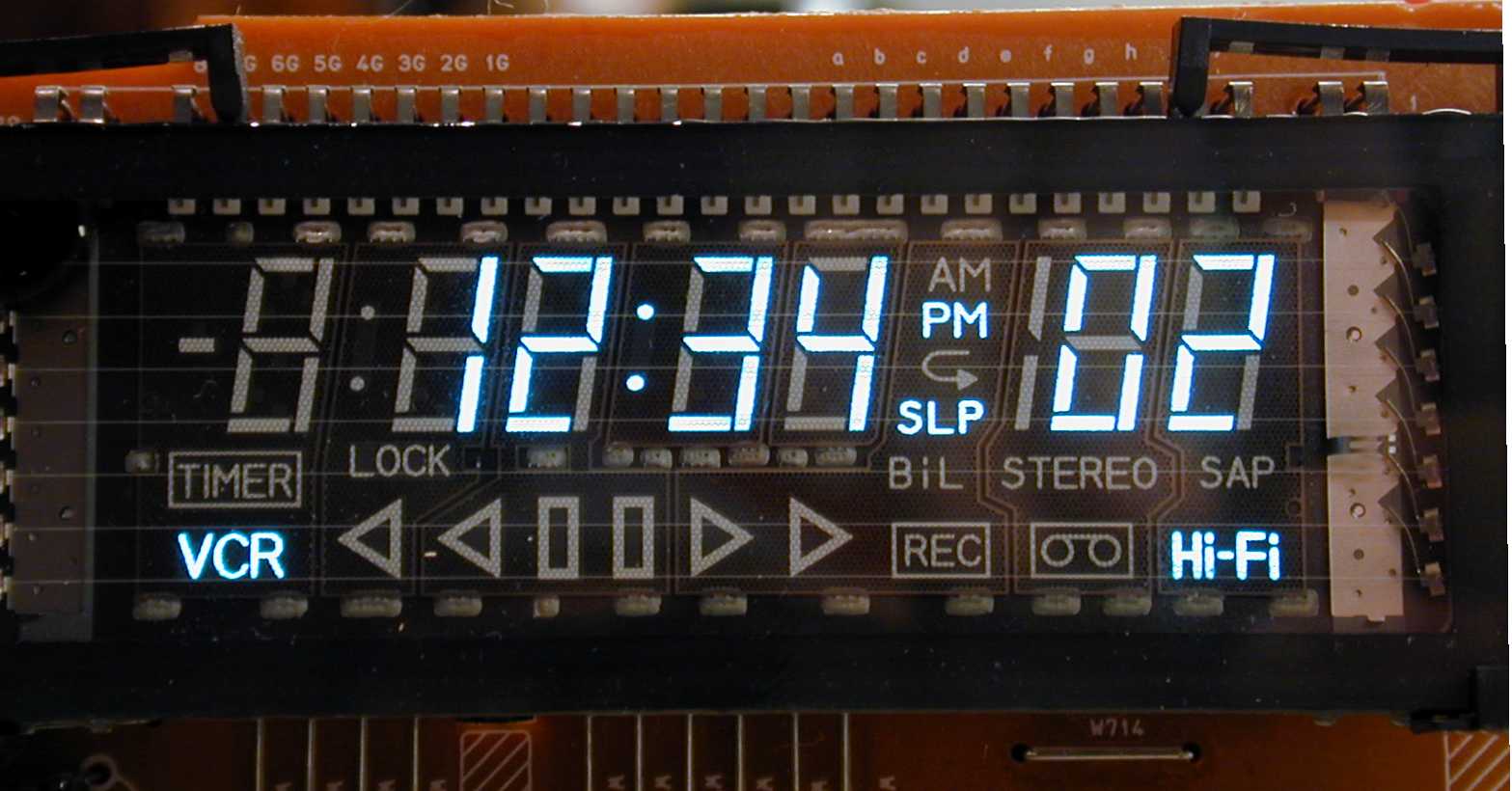

Figure one below is a custom segmented LCD module. The number ‘8’ is made up of seven (7) independent segments and a decimal point. Each one of these segments can be turned on and off individually. This allows the user to create any number and many letters such as ‘E’, ‘F’, ‘L’ and others.

Direct drive custom segmented LCDs contain one pin for every segment plus supporting pins such as power, ground and COM’s. Figure one shows eight segments, this would require a total of eight pins for the segments, plus supporting pins.

Figure two shows an LCD with eight number ‘8’s. This equates to 8 numbers multiplied by 7 segments per number, which equals 56 segments. If you were to use direct drive on this display, you would need 56 pins plus supporting pins. The higher quantity of pins not only increases the size of the display , since you will need a larger display to hold all the leads, but it also increases the unit cost and the amount of time to install the LCD on a printed circuit board (PCB)

The most common type of multiplex LCD display used on a custom segment LCD is called a 4:1 mux. The means that there is one pin for every four segments. The advantage of this configuration is that it reduces the number of pins by 75%. Add up all the segments and divide by four and you arrive at the number of pins necessary, plus supporting pins.

One down side to a multiplex custom segmented LCD is the reduced LCD contrast. On a direct drive each segment is on 100% of the time, in a 4:1 mux configuration, each segment is on 25% of the time. The reduced sharpness is not very noticeable and difficult for the human eye to notice.

![]()

This article is a continuation in the Focus Display’s LCD Design Guide for Engineers series and will cover segment LCD Displays with the 4:1 multiplex bus.

Segmented display technology is the most popular custom LCD technology that Focus Display Solutions designs; customized solutions allow the design engineer to choose the size of glass, placement of the icons, and type of interface or bus.

This article covers all segment types of LCDs including 7-segment, 14-segment structures and all fluid types including UWVD (Ultra-Wide Viewing Display Technology) FSTN, STN and TN.

The 4:1 mux interface (or multiplex bus) is the most popular option for custom segment LCDs and is preferred for a display containing multiple segments and when low cost is important.

The formula to calculate the exact number of pins necessary for a 4:1 mux is listed below and can be located at the Focus Displays custom LCD design guide.

The display does not contain a segment LCD driver instead there are four commons (aka backplanes or coms). The absence of the chip lowers the unit cost and the tooling cost.

Liquid Crystal Displays or more commonly known as LCDs are one of the most common electronic components which help us interact with an equipment or a device. Most personal portable equipment and even gigantic industrial equipment utilize a custom segment display to display data. For many portable consumer electronics, a segment LCD display is one of the biggest contributors to the overall cost of the device, hence designing a custom segment display can drive the cost down while also utilizing the display area in the most optimum manner. These displays have the lowest cost per piece, low power requirements, and a low tooling fee too.

At first thought, designing a custom segment LCD might look like a Herculean task, but trust me that it is easier than it seems. In this article, we have summarised and compared the display types and available technologies which are required to construct a custom segment LCD. We have also provided a flowchart that can act as a step-by-step guide while you design your own custom LCD. We have also provided the process we followed, a require gathering sheet we used for communicating our needs to the manufacturer, and a few other data and the quotation we received from the manufacturer.

LCD Bias– It denotes the number of different voltage levels used in driving the segments, static drives (explained later in this article) only have 2 voltage levels or 2 bias voltage while multiplex drives have multiple voltage levels. For example, 1/3 will have 4 bias voltages.

LCDs utilizes the light modulating properties of liquid crystals which can be observed by using polarizing filters. Polarizing filters are special materials that have their molecules aligned in the same direction. If the light waves passing through polarisers have the same orientation as the filter, then the molecules of lights are absorbed by the filter, hence reducing the intensity of light passing through it, making it visible.

A custom LCD is important for maximizing the efficiency of the display area by adding custom symbols and characters. It also helps in reducing the cost and improving energy efficiency of the product. A higher number of custom symbols and specified placement of numerical and alphanumerical characters make the display more informative and readable for the user. This makes it look better than the plain old boring displays we get in the market. Furthermore, we can specify the viewing angle, contrast, and other specifications which can increase durability or give a better value for money for our intended usage. A typical Custom Segment display is shown below, we will also show you how to design and fabricate the same further in the article.

The LCD display doesn’t emit any light of its own, therefore it requires an external source of illumination or reflector to be readable in dark environments.

While designing a custom segment LCD display, we have the leverage of choosing a lot of parameters that affect the final product. From the color of the display to the illumination technique and color of illumination as well as the type of input pins. Some important considerations we need to take while designing a custom 7 segment display are - the type of display, i.e. positive or negative, illumination method, driving technique, polarising type, and connection method. All these design criteria are explained below:

Positive and negative displays can be easily distinguished by the colour of the background and characters. Some common differences between the positive and negative displays are:

So, which one should you choose? When the displays are to be used in areas with higher ambient light, we should select positive segment LCD display as it has better visibility than negative segment LCD displays without using a backlight.

As we know that LED displays don’t emit any light, hence to illuminate it and make it visible in a dark environment, we can use different methods of illumination. The most common LCD Illumination methods are compared below:

For displays that need to be used for budget-friendly devices that should be small and rugged, LED lights are preferred for the displays due to the high durability and low cost of operations. For high brightness, CCFL and Incandescent lights can be used.

A polarizer film is the most important component of an LCD display, which makes it possible to display characters by controlling the light. There are 3 types of polarizers that can be used in the LCD display, the properties and difference are given below:

Displays can be categorized into two types, passive displays, and active display, passive displays are simpler to construct as they have 2 connections at each segment, the conductors comprise of an Indium Tin Oxide to create an image, whereas the active displays use thin-film transistors (TFT) arranged in a grid. The name is due to its ability to control each pixel individually.

If your displays have fewer segments, then static LCD drive is preferred as it is easier to control and cheaper to construct, and has a better contrast ratio. But let’s say that if the number of segments in the display are more than 30-40 then a multiplex LCD drive should be preferred as it has multiple common pins, hence reducing the total number of pins required to drive the display.

Choosing a connector type!!! For the prototyping phase or if you need to connect your LCD display on a Microcontroller directly, a pin type connector is the best and most economical option you have. If you need to connect your LCD display in a final product with a high volume of production which also requires to be extremely durable, but at the same time should not take up a lot of space, a Flex type LCD Connector will work best for you

LCDs have limited viewing angles and when seen from an angle they lose contrast and are difficult to be observed. The viewing angle is defined by the angles perpendicular to the center of the display towards its right, left, up, and down which are denoted by the notations 3:00, 9:00, 12:00, and 6:00 respectively. The viewing angle of LCD can be defined as the angle w.r.t. to the bias angle at which the contrast of segments is legible.

To improve the viewing angle in an LCD, a Bias is incorporated in the design which shifts the nominal viewing angle with an offset. Another technique is to increase the Voltage, it affects the bias angle, making the display crisper when viewed from a direction.

For example, the viewing angle of a TN type TFT LCD is 45-65 degrees. Extra-wide polarising film (EWP) can increase the viewing angle by 10 degrees, using an O film polariser can make the viewing angles 75 degrees but these come at a cost of reduced contrast.

LCD Control chip or LCD driver chips can be mounted on the flex cable, display, or externally on a PCB. The placement of LCD control chip can affect the cost and size of the display. The 2 most common methods of chip placement are-Chip of Board (COB)and Chip on Glass(COG) which are described below:

We planned to design an air quality monitoring system for which we needed a custom segment LCD panel for an air quality monitoring device. Our product needs to display the following data: 2.5-micron and 10-micron particulate matter (PM) suspended in the air; the units should be in parts per million (PPM). CO2 in the air in PPM along with total volatile organic compounds present in the air in parts per billion (PPB). To make the product more usable, we included time in 24-hour format, Temperature in ºC, Battery status, loudspeaker status, Bluetooth status, and Wi-Fi status. And for some personal touch, we also added how good the air quality in the room is by using 3 different smileys.

We realized that it was impossible to provide all these data in a generic LCD available in the market, thus decided to build a custom LCD for our project.

A step-by-step flowchart is shown below to walk you through each and every step of selecting components and getting your custom segment LCD manufactured.

Usually, the displays are mounted at a height of 4.5 feet from the ground, thus the viewing direction was selected to be 12"O clock with an operating frequency of 64Hz. We selected a Transmissive polarizer for the front glass and a reflective polarizer for the rear glass so that the natural light can pass through the front panel and the display can achieve the maximum contrast without the need for backlighting and we opted for the pin type connectors as they are easy for prototyping and are suitable for harsh environment with a lot of vibrations and shocks which best suited our purpose.

We mailed our requirements to multiple LCD manufacturers, (you will find a lot of LCD manufacturers on the Internet). Most LCD manufacturers have competitive pricing, and reply within a week. A sample requirement sheet is shown above which a customer needs to fill to specify all the details to the manufacturer.

This is a sample Custom Segment LCD quotation we got from one of the manufacturers. As you can see, the cost is based on the quantity. Higher the quantity, lower the cost. Apart from the cost per quantity, there is one more component called tooling fees. Tooling fee is a one-time fee charged by the manufacturer. It is for the technical design, support, and customization of the product. Customization of PCB or tooling of LCD can drive the tooling price higher or lower.

A custom segment LCD can help you personalize your product while also saving the overall cost of your product. The whole process will take you around 2-3 months, which will include the designing phase, prototyping phase, and getting your custom segment LCDs delivered to your doorstep. Higher ordering quantity will reduce the cost per piece of each unit, thus driving down the cost of your final product.

Many electronic consumer products today utilize some type of electronic display. This display may offer almost any type of numerical or graphical information to the user relating to status and/or mode of operation of the electronic device. Depending on the type of display that is to be used, there are many types of technologies available for driving the display in order to display the required information. As seen in prior art FIG. 1, a microprocessor is used with a display driver and resister network to drive i.e. supply information to the LCD display.

One such LCD display is a twisted nematic (TN) display. The TN display is commonly used because it is capable of displaying a moderate amount of information to the user while still maintaining low cost with minimal implementation effort. In order to optimize display functionality, a number of low cost liquid crystal display solutions have been developed for use with the TN display using Pulse Width Modulation (PWM). These techniques utilize a driving scheme that enables a multiple character TN display to be incorporated into an electronic device using a limited number of control lines from an associated microprocessor. This type of scheme eliminates the need for all external components and thus can greatly reduce the manufacturing cost of the display.

For example, a standard liquid crystal display multiplex (LCD MUX) drive operates by addressing/selecting a single row of the LCD at a time. After this selection, the desired ON/OFF states are applied to that selected Row through the LCD columns which are common to all ROWs. Rows are selected in a continuing round-robin fashion. Only when a row is addressed/selected, do the states on the columns affect a row, otherwise on unselected rows, the column states are seen as low level noise. Therefore, Table 1 shows each row supplied with the following type of waveform:

As is evident to those skilled in the art, time division is being used to select one row at a time. The method of selecting the row is by supplying the row selected with voltage amplitude several times the level of unselected rows. The method of selecting the row is therefore voltage division multiplexing.

Voltage division multiplexing is a technique requiring more than two driven voltage levels. This technique is not possible with digital circuitry since digital circuitry by definition is limited to two voltage levels. Thus, in modern day electronic equipment that includes an multiplexed LCD display, some type of analog circuitry is required to interface the multiplexed LCD to the equipment"s control circuits. In general, digital circuits are smaller and less costly than analog circuits for similar functions, and therefore an all digital multiplexed LCD drive scheme would be of smaller size and less costly to implement than an analog multiplexed LCD drive scheme.

Accordingly, the need exists for a digital drive scheme for an LCD multiplexed display that can be used with electronic devices and circuits having easy implementation and low cost.

Referring now to FIGS. 2 and 3, a block diagram 200 shows the preferred architecture of the preferred embodiment of the invention. A microprocessor 201 is used to drive a multiplexed liquid crystal display (LCD) 203. As is evident from the operation of the invention, the display driver and resistor biasing network as used in the prior art have been eliminated.

For an LCD display to be designed into a product in typical fashion requires that an LCD driver integrated circuit (IC) be provided to control the LCD FIG. 1. Several costs are associated with the use of an LCD driver which include the cost of the LCD driver IC 103, the cost of a resistor divider network 105 to provide multiple drive voltage levels, a power supply booster to generate drive voltages needed for medium multiplex rates, and power supply control to implement temperature compensation for the LCD, all part of the LCD driver 103. The LCD driver IC 103 along with its support circuitry 105 also add cost in that the printed circuit board (PCB) area of the product increases to hold the extra circuitry. This increase in area may also increase the overall size and weight of the product. Substantial cost savings are achieved using the invention described herein because the need for the driver boosted power supply, power supply resistor divider network 103, and power supply adjustment circuits for temperature compensation are eliminated.

In the preferred embodiment, the product LCD driver or microprocessor with imbedded LCD driver 201 is used to drive the LCD 203 in the electronic device. As compared with typical LCD driver IC parts, the PWM driver does not need the boosted power supply voltage, the resistor dividers, nor a power supply adjustment for temperature compensation. Additionally, the PWM LCD drive provides comparable display contrast quality when refreshing the display at half the speed of standard drive techniques. This reduction in speed translates into lower power dissipation and improved product battery life.

One problem of PWM LCD MUX drive method as compared to standard LCD MUX drive schemes is that as the PWM multiplex rate increases, the select and non-select voltages, as seen by the liquid crystal material, move closer together. This has the effect of placing more stringent performance criteria on the liquid crystal requiring the transition between select and non-select states to become more and more steep for higher multiplex rates. This phenomenon of the select/non-select voltages moving closer together will limit the use of PWM to substantially low or medium multiplex rates that are less than approximately thirty (30) multiplex ROWS with current state of the art liquid crystal materials.

In FIG. 3, a wiring diagram 300 of a multiplexed LCD illustrates the configuration of a typical LCD. Each circle 301 to 309 represents an LCD segment. An LCD segment is conceptually formed as a layered structure with the ROW conductor 311, 313, or 315 on top, a COLUMN conductor 317, 319, or 321 on bottom, and liquid crystal (not shown) in between these conductors. Assuming the display memory has one bit per display segment, eg. intersection of ROW y and COLUMN x designated Sxy where y=1 to N for ROWs and x=1 to M for COLUMNs. If the bit Sxy=1 then the corresponding LCD segment will be in an ON state, else if the bit Sxy=0 then the corresponding LCD segment will be in the OFF state.

A block diagram of a general bi-level LCD multiplex driver 400 is shown in FIG. 4 and includes a display memory 411 and a timing generator 413 that supply a synchronization signal to both a column mulitplexer 415 and row multiplexer 417. The column 215 and row multiplexer 417 are both used to provide bi-level data waveforms to the ROW and COLUMN intersections in the display panel 419.

The hardware produces bi-level waveforms on the ROW/common lines and COLUMN/segment lines of a multiplexed LCD that drive the display using the binary data from display memory locations. At periodic intervals a cycle counter is incremented. The counter value is then used to 1) generate ROW/common waveforms through ROM table look-up or through combinational logic computations, and 2) look-up memory locations associated with the active COLUMN/segments using digital multiplexer circuit blocks, 3) to invert or not invert the COLUMN/segments data before sending the bi-level data to the COLUMN/segment lines of the LCD. The cycle counter increments from zero to four times the number of ROW/commons minus one before being reset to zero and the waveforms repeated. Thus, the bi-level waveforms for the COLUMNS are formed to produce the desired ON or OFF state by either copying a binary equivalent directly to a COLUMN output port of the LCD or copying and inverting the ON or OFF state to a COLUMN output port.

A ROM table can also be used to generate the row waves by using the cycle counters as address inputs to the ROM, and the ROM output driving the row pins. The COLUMN wave generators consist of three types of circuitry: 1) the display memory, 2) digital multiplexers to pick off display memory contents at particular sub-intervals of each refresh cycle, and 3) combinational logic the inverts the multiplexer output depending on which refresh cycle quarter is currently being executed. The display memory holds the LCD segment on/off information. Each segment is mapped to one unique bit of display memory. A memory location with a logic one turns the corresponding segment ON and with a logic zero turns the segment OFF. The multiplexer for a particular COLUMN selects the memory bits for the segments associated with that particular COLUMN. Each bit is selected once per refresh cycle quarter for a total of four times for the entire refresh cycle. The exclusive-OR logic gates on the multiplexer outputs selectively invert the sense of the display memory bits such that the second and third quarters output inverted data and the first and fourth quarters output non-inverted data.

For example, those skilled in the art will recognize that because the ROW and COLUMN are being driven with bi-level waveforms, that are of equivalent amplitude, a voltage potential will either be applied to a particular segment or zero voltage potential will be applied to that particular segment during each and every display update time period. The sum of the display update time periods form a display refresh waveform. This PWM technique operates at the most basic level since a non-zero voltage potential is applied to an LCD segment for greater than 50% of the refresh waveform duty cycle to turn the segment ON and for less than 50% of the refresh waveform duty cycle to turn the segment OFF. To preserve the integrity of the liquid crystal material, the bi-level LCD multiplex driver hardware produces the same number of non-zero positive voltage potential time periods and non-zero negative voltage potential time periods or pulses during a complete display refresh waveform cycle or period.

The multiplexing is accomplished by manipulating the waveform on the COLUMN lines such that in relation to a fixed repeating pattern on the ROW lines each individual segment is controlled to the proper ON or OFF state. The ROW lines are stimulated with a fixed repeating pattern that applies binary waveforms that are mathematically orthogonal to each other. This is accomplished by supplying or `marching a logic zero` through the first quarter of the ROW wave and `marching a logic 1` through the third quarter of the ROW wave. The second quarter and fourth quarter of the ROW wave is needed to assure that only one select and one non-select voltage is produced.

The manipulation of COLUMN data follows a simple rule with respect to the repeating ROW waves of the preceding paragraph. In the first quarter of the LCD refresh cycle, the position of the marching 0 logically marks that ROW as active. The ON/OFF LCD segment data for the active ROW is placed on the COLUMN lines during the cycle first quarter. In the third quarter of the LCD refresh cycle, the position of the marching logical 1 marks that ROW as active. During the time periods of the second quarter, the COLUMN data waveform that was output during the cycle first quarter is repeated but in logically inverse form. The inverse of the ON/OFF LCD segment data for the active ROW is placed on the COLUMN lines during the cycle third quarter. During the time periods of the fourth quarter, the COLUMN data waveform that was output during the cycle first quarter is repeated.

A check of all possible ON/OFF segment combinations when applying the PWM algorithm will show that only one select and one non-select voltage is produced at each LCD segment and that the voltage produced is select when the segment data is set to be ON and non-select when the segment data is to be OFF. LCD MUX rates for three, four, and five multiplex ROWs were exhaustively checked and verified. By mathematical induction, the PWM LCD MUX drive scheme can be extended to any desired MUX rate. A display with 29 multiplexed ROWs has been constructed and operates well using the PWM MUX LCD drive technique.

As will be evident to those skilled in the art, the voltage difference seen by each LCD segment 301 to 309 formed by the segment"s corresponding ROW and COLUMN values determines the segment waveform shape. The standard LCD MUX method applies all of the select voltage in a single time period of the display refresh cycle. In contrast, the PWM LCD MUX drive method of the invention does not operate in this fashion. Instead PWM LCD MUX spreads the select voltage over the entire display refresh cycle. In the present invention, there is no difference between the ROW select and non-select voltage amplitude. In operation, each ROW is addressed while a portion of a root mean squared (RMS) voltage may be added to each LCD segment. The sum total of all the RMS voltage portions cause the PWM LCD segment to be either in an ON or OFF state In Tables 2a through 2d and Tables 3a through 3d below, waveform data for each ROW of the liquid crystal display is used for the state transition diagram illustrated in FIGS. 7A and 7B. Note that N equal the n display multiplex rate and the number of ROW lines on the display.

To summarize, the method of the present invention produces bi-level waveforms on the ROW/common lines and COLUMN/segment lines of a multiplexed LCD that drive the display using the binary data from display memory locations. At periodic intervals the driver steps through a set of states. Depending on the present state, a bi-level data pattern is output on the ROW/commons, and data values or their inverse from display memory locations associated with the active ROW are output on the COLUMN/segment lines of the LCD. There are four times the number of ROW/commons SUBSTATE states and each is entered once before the driver is reset and the waveforms repeated.

Thus, the ON/select and OFF/non-select voltages formulas above follow from a graphical analysis of the pulses seen by a LCD segment stimulated by the PWM algorithm. The segment will be ON when it is pulsed greater than 50% of the time and the segment will be OFF when it is pulsed less than 50% of the time during a LCD refresh cycle. Because the LCD refresh cycle is four (4) times the desired MUX rate, the refresh cycle will have an even number of time slots. Also, because the second half of the refresh cycle is identical but inverted from the cycle first half, an ON segment will see pulses greater than half the time of the half cycle time and an OFF segment will see pulses less than half the time of the half cycle. This constrains the ON calculation to be the first number above 50% that can be achieved with integer multiples of the MUX rate which is the same as the number of ROW lines/common lines. Similarly, this constrains the OFF calculation to be the first number below 50% that can be achieved with integer multiples of the MUX rate which is the same as the number of ROW lines/common lines.

Distributor of electronic, flooring, solar and plumbing supplies. Products include LCDs, Bluray players, sound receivers, speakers, multiplex systems, solar chargers, cooktops, microwaves, dishwashers and refrigerators. Hardwood, vinyl sheets, vinyl tile, laminate, ceramic and linoleum flooring, showers, tubs, sinks and putty products are also offered.

System integrator of telecommunication systems. Products include structured cabling systems, network systems, multiplexing systems, interactive white boards, power systems, audio and video projection systems, amplified speaker systems, and security cameras.

Manufacturer of media transportation systems for production and transportation of content. Products include flash link broadcast products, audio and video processing systems, data routing systems, transport and management over IP, optical fibers, legacy systems, processing and multiplexing systems, controls and broadcast routers.

ISO 9001:2008 certified manufacturer of standard & custom fiber optic multiplexing systems. Types of multiplexers include RS-232 to fiber multiplexers, RS-422 to fiber multiplexers, RS-485 to fiber multiplexers, twin-axial to fiber multiplexers, 3270 coaxial to fiber multiplexers & wave division multiplexers. Wave division multiplexers are available in single mode fiber optic & multimode fiber optic types. UL® & CE listed. Made in the USA.

Manufacturer of multiplexing systems including multiplexing controllers & snow & ice controls for mobile applications. Features of multiplexing systems include in-cab LCD display for system information & diagnostics, Controller Area Network (CAN) wire communications, localized troubleshooting, reporting broken wires on outputs & inputs to operator, 10 position auger & spinner dials, optional LED backlighting, Palm Pilot™ interface including diagnostics display, logical parameter calibration, program transfer to control systems, histogram, & password protection for calibration parameters.

Distributor of multiplexing systems for industrial & commercial applications. Capabilities include bar coding, engraving, enclosure cutting & punching, enclosure modification, labeling, meter configuration, prototyping, rail assembling, rail cutting & notching, terminal block marking & wire cutting.

Manufacturer of electronic equipment and control system integrator for OEM manufacturers. Products include harnesses and connection kits, CAN bus I/O controllers. CAN bus HMI data terminal displays, software, and connectors and pins.

ISO 9001:2000 certified manufacturer of multiplexing systems. Multiplexing system features include high density, up to 256 analog inputs & up to 128 digital inputs in the same system, expansion to 7936 inputs, Zone 0, 1 & 2 inputs, robust isolation of plus/minus 200 V from channel to channel & high immunity against interference & ground loops, programmable via PC & modbus, 18 bit A/D converter, redundant communication lines & AISI 316 stainless steel enclosure for field units.

Custom manufacturer of re-configurable multiplexing systems. Features of multiplexing systems include real-time onboard diagnosis, programmable switch panels, multiple power distribution modules & wireless PDS or ES-Key® professional software.

Worldwide manufacturer of multiplexing systems including multiplexing power distribution systems. Designed to monitoring and control AC and DC components and marine devices. Multiplexing power distribution system includes DC power distribution boxes, AC power distribution boxes, AC power monitors, system monitors, battery monitors, touchscreen displays and network power supply devices. Available in standard and custom configurations and can be used in telecommunication, server, marine, generator, alternative power and medical industry applications.

Manufacturer of wireless remote controlled multiplexing systems. Also a custom manufacturer of wire harnesses. Industries served include military, security, mining, construction, and aerospace. Documentation, integration, product design, project management, and reverse engineering services are provided.

All modern high-resolution LCDs are "active matrix", which means that there"s a thin-film transistor (TFT) located at each subpixel that is used to store its state for the current frame. The state of the subpixel is stored as a voltage on a capacitor, which is either a separate element or the capacitance of the liquid crystal cell itself.

This means that refreshing the display does not inherently introduce any significant flicker. However, there is a certain amount of leakage associated with the capacitor, and an LCD designer needs to make a tradeoff between minimizing this "droop" by making the liquid crystal respond more slowly, or minimizing the "smear" introduced in fast-moving images by making it respond faster.

The normal VTN LCD has a dead spot viewing angle. Full Viewing Angle VTN LCD is designed to have good contrast for all the viewing angles. The typical parameters are exampled as below.

FS LCD is not a full color LCD, it can realize maximum 8 colors at one segment. It is better to be designed to be less than ½ duty otherwise the color saturation will be low. The typical parameters are exampled as below.

Ms.Josey

Ms.Josey

Ms.Josey

Ms.Josey