types of touch screen monitors quotation

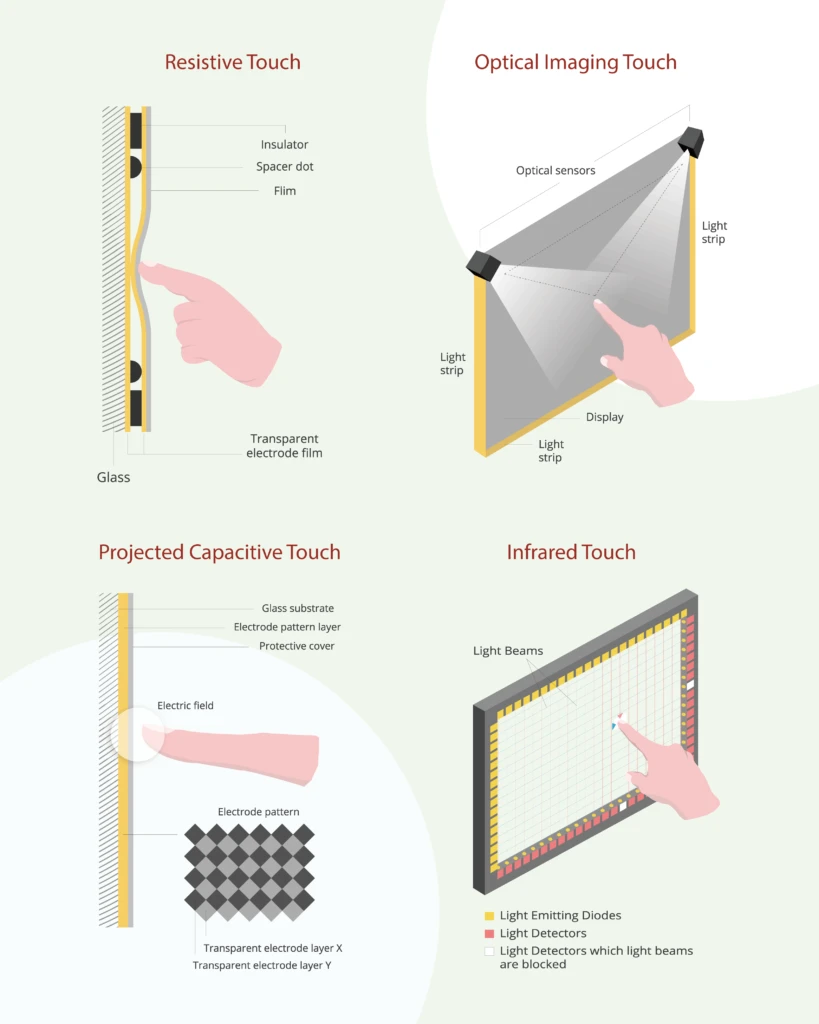

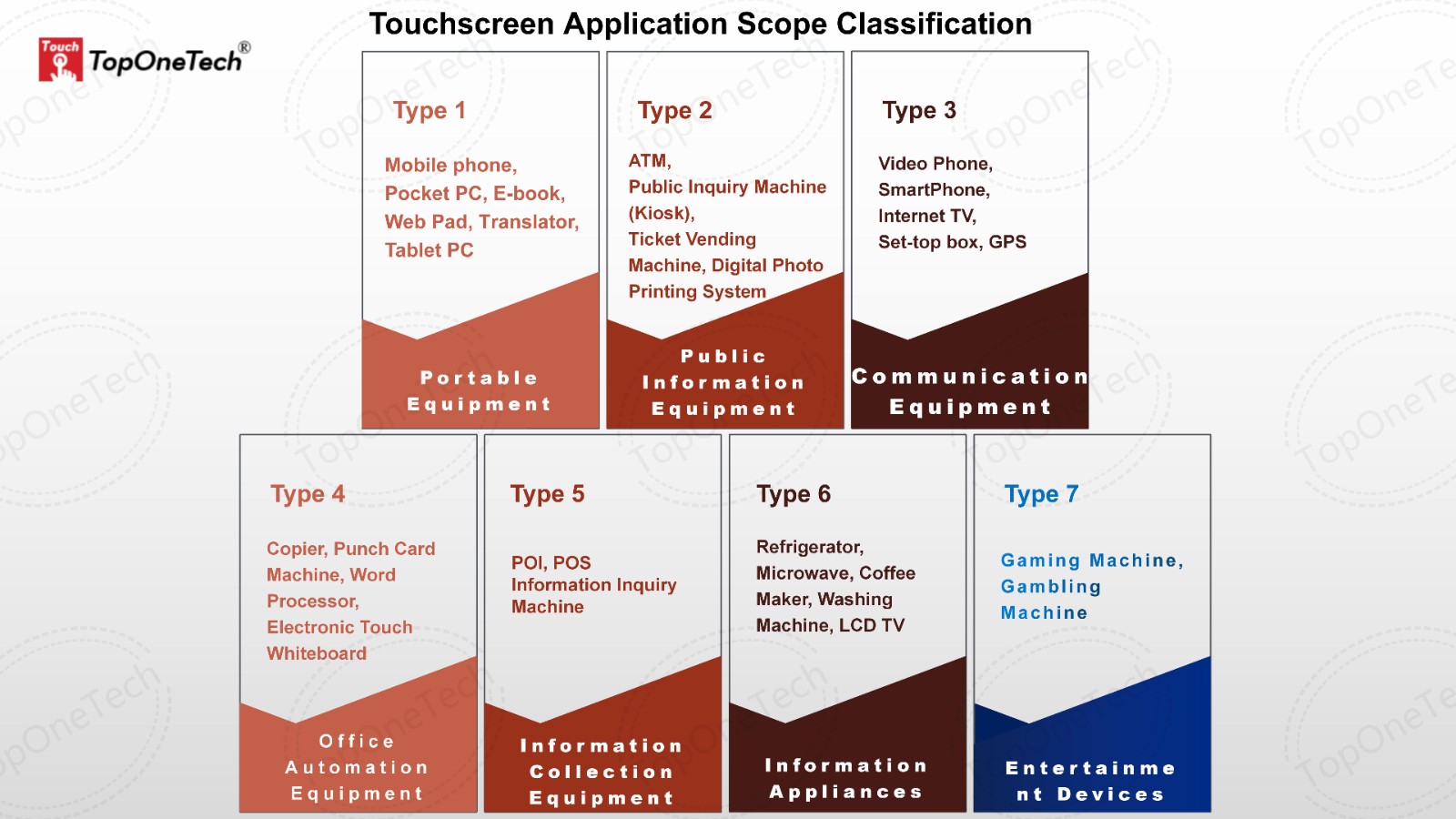

You interact with a touch screen monitor constantly throughout your daily life. You will see them in cell phones, ATM’s, kiosks, ticket vending machines, manufacturing plants and more. All of these use touch panels to enable the user to interact with a computer or device without the use of a keyboard or mouse. But did you know there are several uniquely different types of Touch Screens? The five most common types of touch screen are: 5-Wire Resistive, Surface Capacitive touch, Projected Capacitive (P-Cap), SAW (Surface Acoustic Wave), and IR (Infrared).

We are often asked “How does a touch screen monitor work?” A touch screen basically replaces the functionality of a keyboard and mouse. Below is a basic description of 5 types of touch screen monitor technology. The advantages and disadvantages of type of touch screen will help you decide which type touchscreen is most appropriate for your needs:

5-Wire Resistive Touch is the most widely touch technology in use today. A resistive touch screen monitor is composed of a glass panel and a film screen, each covered with a thin metallic layer, separated by a narrow gap. When a user touches the screen, the two metallic layers make contact, resulting in electrical flow. The point of contact is detected by this change in voltage.

Surface Capacitive touch screen is the second most popular type of touch screens on the market. In a surface capacitive touch screen monitor, a transparent electrode layer is placed on top of a glass panel. This is then covered by a protective cover. When an exposed finger touches the monitor screen, it reacts to the static electrical capacity of the human body. Some of the electrical charge transfers from the screen to the user. This decrease in capacitance is detected by sensors located at the four corners of the screen, allowing the controller to determine the touch point. Surface capacitive touch screens can only be activated by the touch of human skin or a stylus holding an electrical charge.

Projected Capacitive (P-Cap) is similar to Surface Capacitive, but it offers two primary advantages. First, in addition to a bare finger, it can also be activated with surgical gloves or thin cotton gloves. Secondly, P-Cap enables multi-touch activation (simultaneous input from two or more fingers). A projected capacitive touch screen is composed of a sheet of glass with embedded transparent electrode films and an IC chip. This creates a three dimensional electrostatic field. When a finger comes into contact with the screen, the ratios of the electrical currents change and the computer is able to detect the touch points. All our P-Cap touch screens feature a Zero-Bezel enclosure.

SAW (Surface Acoustic Wave) touch screen monitors utilize a series of piezoelectric transducers and receivers. These are positioned along the sides of the monitor’s glass plate to create an invisible grid of ultrasonic waves on the surface. When the panel is touched, a portion of the wave is absorbed. This allows the receiving transducer to locate the touch point and send this data to the computer. SAW monitors can be activated by a finger, gloved hand, or soft-tip stylus. SAW monitors offer easy use and high visibility.

IR (Infrared) type touch screen monitors do not overlay the display with an additional screen or screen sandwich. Instead, infrared monitors use IR emitters and receivers to create an invisible grid of light beams across the screen. This ensures the best possible image quality. When an object interrupts the invisible infrared light beam, the sensors are able to locate the touch point. The X and Y coordinates are then sent to the controller.

We hope you found these touch screen basics useful. TRU-Vu provides industrial touch screen monitors in a wide range of sizes and configurations. This includes UL60601-1 Medical touch screens, Sunlight Readable touch screens,Open Frame touch screens, Waterproof touch screens and many custom touch screen designs. You can learn more by viewing TRU-Vu Touchscreens or call us at 847-259-2344. To address safety and hygiene concerns, see our article on “Touch Screen Cleaning and Disinfecting“.

A surface capacitive touchscreen uses a transparent layer of conductive film overlaid onto a glass sublayer. A protective layer is then applied to the conductive film. Voltage is applied to the electrodes on the four corners of the glass sublayer to generate a uniform electric field. When a conductor touches the screen, current flows from the electrodes to the conductor. The location of the conductor is then calculated based on the activity of the currents. Surface capacitive touchscreens are often used for large screen panels.

Projected capacitive touchscreens are extremely precise and quick to respond and are typically found on smaller devices such as iPhones, iPod touches, or iPads. Unlike the surface capacitive touchscreens, which use four electrodes and a transparent conductive film, the projected capacitive touchscreens use a vast amount of transparent electrodes arranged in a specific pattern and on two separate layers. When a conductor moves near the screen, the electrical field between the electrodes changes, and sensors can instantly identify the location on the screen. Projected capacitive touchscreens can accurately register multi-touch events.

Touch screens have become a very common part of our daily lives. Smartphones, handheld video games, car navigation systems, ticket vending machines, kiosks, bank ATMs, and more all use touch panels to enable users to interact with a computer or device without the use of a keyboard or mouse. Even though they are all touch screens, there are several uniquely different types of touch panels. The term touch panel incorporates varied technologies for sensing the touch of a finger or stylus. The most common types are resistive, surface capacitive, projected capacitive, surface acoustic wave, infrared optical imaging, and electromagnetic induction. This article will mainly focus on resistive, surface capacitive, and projected capacitive as these are the touch panels Acnodes Corporation primarily uses for the products.

A major factor influencing the widespread of touch panels is the benefit offered in the way of intuitive operation. They are easy to understand and easy to use even by people who are inexperienced with computers since they can be used for input through direct icons and buttons. Touch panels also contribute to miniaturizing and simplifying the devices by fusing display and input into a single piece of equipment. Since touch panels are software, not hardware, their interfaces can be easily changed through software. A touch panel requires a wide range of characteristics like precision in position sensing, rapid response to input, durability, installation costs, and most importantly display visibility, their characteristics vary significantly depending on the methods used to sense touch input. Below are the three common types of touch screens integrated into Acnodes" industrial monitors and displays.

The resistive film is the most widely used sensing method in the touch screen panel market. A resistive touch screen monitor is composed of a glass panel and a film screen, each covered with a thin metallic layer, separated by a narrow gap. When a user touches the screen, the two metallic layers come into contact, resulting in electrical flow. The point of contact is detected by this change in voltage. The front surface is scratch-resistant with a coating of a conductive material.

The surface capacitive is the second most popular type of touch screen on the market. It is often used in relatively large panels. In a surface capacitive touch screen monitor, a transparent electrode layer is placed on top of a glass panel and covered by a protective cover. When an exposed finger touches the monitor screen, it reacts to the static electrical capacity of the human body; some of the electrical charges transfer from the screen to the user. This decrease in capacitance is detected by sensors located at the four corners of the screen, allowing the controller to determine the touchpoint. Capacitive touch screens can only be activated by the touch of human skin or stylus holding an electrical charge.

Projected capacitive touch panels are often used for smaller screen sizes than capacitive touch panels. Smartphones and handheld devices use this method to accomplish high-precision multi-touch functionality and high response speed. Projected capacitive is similar to surface capacitive, but it offers two primary advantages: in addition to bare fingers, it can also be activated with surgical gloves or thin cotton gloves and it enables multi-touch activation. A project capacitive is composed of a sheet of glass with embedded transparent electrode films and an IC chip, which creates a three-dimensional electrostatic field. When a finger comes into contact with the screen, the ratios of the electrical currents change and the computer is able to detect the touchpoints.

- Surface Capacitive touch screens have a protective barrier to defend the screen from scratches and weakening. Even with the problems of spills, dents and abrasions, it sustains its maximum capabilities and maintains its functionality by remaining unaffected by demanding external environments.

- Secure Touch Surface Wave touch screens use exceptionally reliable and dependable glass for imitable picture and resolution quality. Made with all glass, this scratch resistant technology is suitable for environments with harsh conditions.

- AccuTouch technology qualifies as the most contaminant-resistant touch screen due to its ability to withstand and protect itself against moisture. Even under the toughest conditions such as including liquid spills, sprays, sprinkles, and splashes, this touch screen maintains its durability.

- CarrollTouch Infrared touchscreen uses a choice of glass or acrylic overlay for protection, making it the optimal option for environments with critical surroundings. Because this is the only technology that does not depend on a substrate, the touchscreen works flawlessly even when used with a gloved hand.

- Put together with pure glass, the IntelliTouch surface wave is state-of-the-art touchscreen technology making it the most scratch-resistant obtainable equipment out there. With its durable glass surface, it provides the utmost quality for image clarity, resolution, and light transmission.

Capacitive touch screens depend on our electric impulses for it to work. Depending on when and where touched, the human body sends signals to the screen. Capacitive touch screens cannot function if used with a stylus or a gloved hand, because of their reliance on the light touch of a finger. Surface Capacitive touch screens have a protective barrier to defend the screen from scratches and weakening. Even with the problems of spills, dents, and abrasions, it sustains its maximum capabilities and maintains its functionality by remaining unaffected by demanding external environments. Although this type of screen cannot function when using with a gloved hand, special application gloves with an embroidered patch of conductive threads are now available for more functionality. Most hand-held technologies use a capacitive touch screen because of its thin and more accurate sensor.

The Accutouch Five-Wire Resistive touchscreen is composed of a glass panel with a resistive overlay plus a cover sheet with a conductive layer. This technology is essential due to its proficiency in stability and long product life. These are primarily used on voting machines, office retail mechanization, and medical industrialization. This type of screen is made from three different sheets: conductive, resistive, & a protective layer which is why it is so durable. Resistive touch screens are very common because it is affordable and generally has a longer life. The most important layers include two electrically resistive layers, which form a gap between each other. The part we touch, the outermost part of the screen, is called the protection layer which protects the screen from scratches, water spills, and other types of damage.

The Secure Touch Surface Wave touch screen is made out of pure glass and has a scratch-resistant surface that can tolerate extreme physical wear and tear damage over time. This type of touch screen is used primarily in ATMs, amusement parks, kiosks, and banking applications. This screen has what’s called “X & Y axes” to convey and pick up piezoelectric transducers. This transducer device receives five-megahertz electrical signals which are modified into ultrasonic waves amidst the glass. When the screen is touched, a coordinate is calculated depending on how much of the signal is absorbed.

What is it and how does it work?The CorrollTouch is ideal for brutal industrial applications and used predominantly in the hospital setting. Because of its vandal resistance capabilities, it is physically impossible to weaken the touch screen, making it the top-notch touch screen technology thus far. The touch screen technology allows the display to become viewable under the brightest luminance, including direct sunlight. This high-tech technology uses photoreceptors and LEDs to create IR light beams touched and is able to perform flawlessly even under extreme temperatures from -20ºC to 70ºC (operating temperature) to -40ºC to 85ºC (storage temperature).

What is it and how does it work?The IntelliTouch Surface Wave touchscreen technology has a sensitive touch response that determines the location and amount of pressure applied and can be used with a gloved hand, stylus, or even a fingernail. It has a scratch-resistant surface, making it durable enough to withstand vandal environments while maintaining its functionality. This screen has what’s called “X & Y axes” to convey and pick up piezoelectric transducers. This transducer device receives five-megahertz electrical signals which are modified into ultrasonic waves amidst the glass. When the screen is touched, a coordinate is calculated depending on how much of the signal is absorbed.

Whether you want to interact with an application, browse the internet, scroll through galleries, utilise wayfinding maps, or access general information about a business – a touch screen monitor makes a convenient tool.

A touch screen monitor looks like a normal monitor, but responds to the touch of a finger or stylus. They provide faster response to the touch to perform a particular action. So, it is essentially a screen where users need to perform direct touch on the surface to enter data and send orders to the devices. Usually touch screen monitors have a really solid base so that the screen doesn’t wobble when touched. Well designed touch screen monitors intended for public use have a similar look and feel to a mobile phone screen so that the user understands that they are a touch screen and know that they can interact with them.

Resistive touch screens work on the basis of pressure being applied to the screen. A resistive touch screen has a glass panel, film screen, and a metallic layer. Once the user touches the screen, it results in an electrical flow.

Capacitive touchscreens work by sensing the conductive properties of an object, usually the skin on your fingertip, but also a stylus or other item. This is the leading technology today, used in most smart phones and is the technology that InTouch uses.

Surface capacitive touchscreens have a conductive coating on the front surface.Wires are attached to each corner, and a small voltage is applied to each of the corners. When the screen is touched, a small current flows to the touch point, causing a voltage drop.When a finger touches the monitor screen, the electrical charge transfers inside. They are only activated through the touch of human skin or stylus.

Touch screens that use surface capacitive technology are mostly obsolete now as they have been superseded by the far superior Projected Capacitive technology.

Surface Acoustic Wave (SAW)touch screen monitorswere popular some years ago, but have also largely been superseded by touch screens using Projected Capacitive technology. When you touch a touch screen that uses Surface Acoustic Wave (SAW) technology your finger interrupts the acoustic waves across a clear glass panel with a series of transducers and reflectors.

The panel is all glass, so there are no layers that can be worn, or damaged over time. This makes SAW touch screen technology highly durable and suitable for applications where high clarity is desired.

Infrared (IR) touchscreen devices support touch-based input just like any other touchscreen device, but these monitors identify touch by looking for interruptions in a uniform beam of light. They have a grid-like array of LED lights and photodetectors (sensors) around the edges of the screen. While invisible to the naked eye, these LEDs are constantly emitting and projecting light. When you touch the surface, it creates a disturbance in this light, and this is how the touch point is identified.

Extremely cheap to produce, especially in large sizes. (They are very scalable for larger sizes, as the light beam just goes further, and so are cost effective solutions for screens 65” and larger)

They must have a bezel for the LED lights, and these are relatively deep. See all the disadvantages of screens requiring bezels above. In our COVID new normal many customers are insisting on screens that are easy to clean and do not have bezels to attract dust and germs.

In most situations Projected Capacitive touch screens are the preferred technology. However, if you require a touch screen that is 65” or larger you may like to consider infrared technology.

With plenty of options on the market for touch screens and kiosks, working with a dedicated touch screen team will ensure you have the best outcome – talk to our Sales Team today for more information on our entire range 1300 557 219 oremail

Touch screens offer ease of use, speed, accuracy, and negate the need to become proficient with a handheld device. General Digital offers the option of equipping your LCD monitor with a variety of touch technologies, such as:

In 1977, we created the world’s first touch responsive industrial terminal, the VuePoint™. It didn’t have a true touch screen; rather, the VuePoint was equipped with a circuit board onto which infrared LEDs were mounted. The LEDs were arranged to form a 12 x 40 grid and when the screen was touched, the infrared beams were broken, indicating the touch location to the terminal. Thus, an operator could control a system right at the terminal.

As touch screen technology evolved (along with monitor technology), we incorporated various touch panels into our LCD monitors, starting with our SlimLine™ series of flip-up LCD monitors. Over time and based on demand, our Saber RackMount, PanelMount and Standalone Series became the next logical candidates for touch integration. This was due to increased use of flat panel technology in human-machine interface applications.

Featuring pure glass construction, Surface Acoustic Wave (SAW) touch screens will almost never physically “wear out” due to a superior scratch-resistant coating. Excellent light transmission ensures that the image clarity of the display remains sharp and vibrant. The stable, “drift-free” operation means that the touch response is always accurate. They work well with a finger, gloved hand or a soft stylus. And SAW touch screens have a sensitive touch response—they recognize the touch location and the amount of pressure applied.

Being an all-glass design, light transmission of surface capacitive touch screens is improved, when compared to resistive touch screens. This improves display viewability and reduces eye fatigue. Featuring a scratch-resistant top coat, durability in heavy-use environments is easily maintained. This type of touch screen is ideally suited for rugged, industrial or military applications.

Infrared touch technology doesn’t rely on an overlay or a substrate to register a touch, so it cannot physically “wear out,” thus ensuring a long product life cycle. Possessing superior optical performance and excellent gasket-sealing properties, an infrared touch screen is ideal for harsh industrial environments and outdoor kiosks. They work with a finger, gloved hand, stylus, and most any object wider than 1/10". They adjust to changing light conditions, even direct sunlight. And they benefit from stable, no-drift calibration performance.

Working in tandem, two optical sensors track the movement of an object close to the surface by detecting the interruption of the touch screen’s infrared light source, which is emitted in a plane across the display surface and can be either active (infrared LED) or passive (special reflective surfaces).

Optical touch screens use a controller board that receives signals from the optical sensors, then compensates for optical distortions and triangulates the position of the touching object with extreme accuracy.

The infrared light source and optical sensors of the touch screen are synchronized using a sophisticated algorithm that also reduces the effect of ambient light, thus creating a very clear, accurate touch selection.

Developed specifically for interactive digital signage applications, Dispersive Signal Technology determines a touch point by measuring the mechanical energy (bending waves) within a substrate created by the pressure of a finger or stylus. As these bending waves radiate away from the touch location, the signal spreads out over time due to the phenomena of dispersion. The “smeared” signals are then interpreted by a complex set of algorithms to precisely pinpoint the exact touch location on the screen.

DST is a passive technology, waiting for a signal created by a touch impact. Therefore, contaminants such as dirt, grease, and other solids can accumulate on the surface and edges of the display screen without significantly affecting touch responsiveness. In addition, surface damage, such as scratches, has no significant impact on touch performance.

The sophisticated and optimized controller that continuously monitors for a touch impact is the fastest and most responsive technology available for large format displays, offering greater than 99% touch location accuracy.

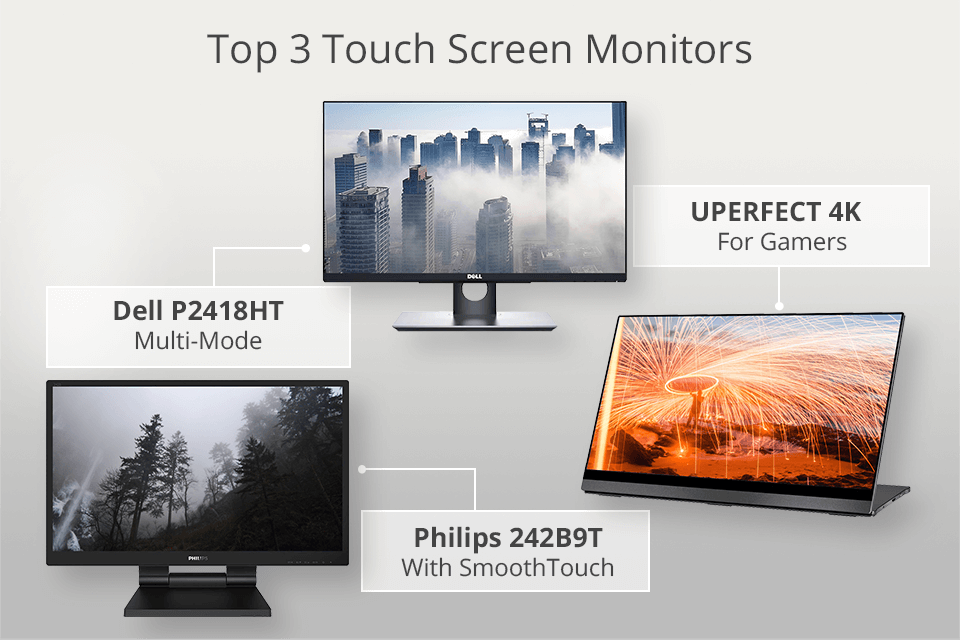

As with shopping for a conventional monitor, some core considerations include: resolution, price, size, and panel type. The resolution of a monitor will determine the how much detail it is able to display, and you should aim for a 1920 × 1080 monitor if your budget allows. You should also consider what type of panel technology a touch screen monitor uses, as it can affect color accuracy, response time, and viewing angles.

The most common panel technologies for touchscreen monitors are: twisted nematic (TN), vertical alignment (VA), and in-plane-switching (IPS). Twisted nematic (TN) is the most common LCD monitor panel technology due to its low cost but has narrower viewing angles and less color accuracy than other panel technologies. VA and IPS panels offer superior viewing angles and color accuracy, but are more expensive. If you expect that the touch screen monitor will be used by a single user looking at it straight on, then a TN panel will be just fine. However, if it is going to be constantly viewed from the sides then you will need to look for a VA or IPS display.

When shopping for a non-touchscreen monitor, the importance of the stand is often downplayed and the focus is more on the display. For touch screen monitors though, the stand plays a central role. Because users will be touching the monitor with varying amounts of force, the stand will need to be sturdy enough to hold the monitor in place. Also, it needs to offer a large amount of adjustability for customizable ergonomics.

Touch panel tech puts the power controlling your display at your fingertips, resulting in faster display operations. In business settings, this reduction in time can give way to a multitude of benefits including shorter queue times and faster service for your customers. Moreover, these benefits can create a domino effect of positive outcomes, including higher customer satisfaction, better customer experiences, and greater brand loyalty from your customers.

Since the introduction of touchscreen smartphones, the use of touch technology has become nearly universal. As such, everyone has become a master. In this case, this technology’s benefit is two-fold; it’s easy to implement and it’s faster for employees to operate. Easy implementation will enable employees to begin using the technology immediately without a learning curve, thus enabling faster operations.

Because touch panels are so versatile in the ways they can be implemented, they possess the ability to positively affect the user experience. Displaying engaging content for consumer interaction, for instance, is a good way to elevate your business above the competition.

Beyond employee interactions, touch panels can be beneficial to customers. Therein, touch panel technology allows users to serve themselves. This functionality can be useful for mall or hotel information services and restaurant meal selection, to name just a few applications. This allows employees more time to focus on higher priority tasks and allows customers to take ownership of their own experience.

Inherently, touchscreens must be able to withstand constant physical interaction. With durability and limited replacement in mind, touch panel producers aim for the greatest possible lifespans and accidental damage prevention.

Non-touch panels often require additional peripherals for operation. Implementation of touch technology eliminates the need for these accessories and, through its faster operation, results in a more streamlined workspace.

Touch panel technology can increase efficiency in the workplace by, for example by reducing queue times. This efficiency increase translates into bottom line benefits by allowing employees to service more customers, thereby enhancing the customer experience.

Digitizing your workflow with touch panel technology can reduce costs by eliminating office supply expenditures. Touch displays also can reduce storage costs by eliminating the need for physical document storage.

Select from a wide selection of industrial touch and non-touch LCD displays. We offer many different types of Industrial LCDs, including VESA-capable, panel-mountable, and rackmountable displays with a wide variety of touch interface options.

Select from a wide selection of industrial touch and non-touch 12" LCD monitors. We offer many different types of Industrial LCDs, including VESA-capable, panel-mountable, and rackmountable displays with a wide variety of touch interface options.

Responsible for performing installations and repairs (motors, starters, fuses, electrical power to machine etc.) for industrial equipment and machines in order to support the achievement of Nelson-Miller’s business goals and objectives:

• Perform highly diversified duties to install and maintain electrical apparatus on production machines and any other facility equipment (Screen Print, Punch Press, Steel Rule Die, Automated Machines, Turret, Laser Cutting Machines, etc.).

• Provide electrical emergency/unscheduled diagnostics, repairs of production equipment during production and performs scheduled electrical maintenance repairs of production equipment during machine service.

Science fiction has always served as a window into a potential future, namely in the way of technology. But what was once regulated to episodes of Star Trek is quickly becoming the stuff of reality. Many fixtures of these kinds of shows and books have begun to inspire real-life counterparts, including - but not limited to - touchscreen technology.

One only has to look at how far cell phones have come since their inception. Physical keyboards, like those from BlackBerry, gave people about as much of a solution as is possible for those who found themselves doing more on the devices as they became more advanced. Where tactile options came up short, touchscreens graciously stepped up to bat, providing a much fuller experience. This kind of functionality then spread to tablets, which are considered by many to be rivals of laptops and even standard PCs.

While there are still some things that are best done on a desktop computer, that does not change the fact that many users find themselves longing for the same abilities on their PCs afforded by many of their mobile devices. This is what helped breed the touchscreen monitor market, which has many viable options for people seeking the best of both worlds. With stronger computing power and a finer ability to control actions occurring in the screen, users can get more work done in new and exciting ways.

Traditionally, computer mice are what have allowed us to "touch" in a virtual context, but touchscreen monitors are changing all that. It might be said that the reason that mice were used in the first place was because the technology had not evolved to a responsive enough level to enable that natural solution. Now that people have the touchscreen technology, they want it everywhere.

If one thing is for certain, it is that the burgeoning adoption of touchscreen technology is no fad. Proliferation has already come too far to turn back now, and computer manufacturers are taking notice. Everyone is trying to get a piece of the action, including ELO Touch Solutions, Laiputuo Electronics, Planar, HP, 3M, Touch Systems, ViewSonic, Dell and ACER as well. Getting into the touchscreen monitor game is a no-brainer for the companies involved in this generation of computing. With so many different applications made for touchscreen monitors, options exist for all sorts of interested parties.

Touchscreen monitors are becoming the new standard in both private and enterprise settings. Here are some of the ways they can be leveraged effectively for business: touchscreen monitors for workstations, touchscreen monitors for hospitals, and touchscreen monitors for POS systems.

Newegg offers a large selection of touchscreen monitors which vary according to the type from 5-wire Resistive touchscreen monitors, and Accu Touch touchscreen monitors, to Capacitive touchscreen monitors, and more. Newegg’s wide selections will definitely meet your needs.

This TSD-45-17 is a fully waterproof touchscreen display, ideal for food and beverage manufacturing facilities, clean rooms, and even outdoor applications. This unit is IP66/IP69K rated and NEMA 4x compliant. The grade 304 stainless steel housing ensures that the monitor will not rust, even if exposed to water and moisture daily. You can also upgrade to grade 316L stainless steel, for settings exposed to salt water. The on-screen display (OSD) controls placed on the rear of the monitor allow for quick adjustments of display settings and the IOs are protected by M12 metal connectors, included with the unit. The TSD-45 series comes in screen sizes from 10” up to 24” and in various screen ratios, so you can choose the best configuration for your application.

Touch Screen monitors come in many shapes and sizes. For the most part, a 15-inch screen will be plenty for retail and restaurant POS software. For other applications, such as informational kiosks, you may need a larger or smaller screen. The main concern when purchasing a touch screen monitor is what type of touch technology you will need: Resistive, Capacitive, or Infrared.

One of the more common and affordable touch technologies, resistive touch screens use two thin screens separated by a thin gap to identify cursor position. When you tap the screen, the screens identify the position of the tap and adjust accordingly. Resistive touch screens are great for restaurants and factories because the technology can be activated using anything- finger, credit card, pen cap, stylus, as long as it creates the connection it will activate the screen.

Most consumer smartphones use a capacitive touch screen. This touch technology uses an overlay of capacitive wires on top of the screen. Your body conducts electricity, and so when you touch a portion of the screen, the touch screen can identify a change in capacitance and know where you touched the screen. Capacitive touch screens tend to be brighter than resistive monitors, but you are limited in the ways to interact with the device. They"re often seen in gaming, customer service kiosks, and outdoor applications.

Infrared touch technology uses a grid of infrared light beams. When your finger, or a pen, or anything else breaks the plane of beams, the software identifies the location by which beams were broken. This technology provides some of the brightest colors, as there is no overlay whatsoever. It can also be sealed, making it more durable than capacitive or resistive touch screens. These monitors are great in harsh environments, such as automotive, food processing, hospital operating rooms, and ATMs.

There are other models available if you have specific needs, such as acoustic pulse touch screens or open-frame monitors. If you are having trouble finding the touch screen monitor right for your business, please call our sales team at 1-800-903-6571 and we will help you out.

SAW – (Surface Acoustic Wave) Touch Screens utilize a series of transducers and reflectors along the sides of the monitor’s glass plate to create an invisible grid of ultrasonic waves on the surface. When the panel is touched, a portion of the wave is absorbed. The receiving transducer locates the touch point, and sends this data to the controller.

Resistive – A Resistive Touch Screen is composed of a glass panel covered with thin conductive and resistive metallic layers, separated by a thin space. When a user touches the screen, the 2 layers connect at that point. The computer detects the change in the electrical field and calculates the touch point.

Capacitive – In a Capacitive Touch Screen, an indium tin oxide sheet that stores a continuous electrical current is placed on top of the monitor’s glass panel. When an exposed finger touches the monitor screen, some of the electrical charge transfers to the user. This decrease in capacitance is detected and located by circuits located at each corner. The computer then determines the touch point.

★ Infrared Touch Screen ★ – Infrared touch screen monitors use vertical and horizontal infrared sensors around the perimeter of the touch screen. Creating a grid, the Touch Screen is able to pinpoint the exact location of where the screen is touched and send that information to the computer for processing. Infrared Touch Screen Monitors are very durable and commonly used for industrial and military applications.

In simple terms, a Resistive Touch Screen is a touch-sensitive computer display that responds by applying pressure. It’s made from two resistive-coated transparent sheets that are separated by a small air gap. When contact is made to the surface of the touchscreen, these two sheets are pressed together. Each sheet has horizontal and vertical lines that register the precise location of the touch. Because the touchscreen senses input from contact with nearly any object (finger, stylus/pen, palm, etc.) resistive touchscreens are a type of passive technology. All this means is that the Resistive Touch Screens do have an internal power source, and so rely on electromagnetic energy transmitted from an RFID reader.

If you are looking for touch screen manufacturing services, RSP is here to help. Head over to our Touch Screen Capabilites page or contact us directly to get a quote for your new touch screen manufacturing services.

A Digital Resistive touch screen works by applying pressure to the screen, and can be operated by pressing a finger, a stylus or even a fingernail onto the surface. This type of touch screen works on an X-Y matrix.

Capacitive Touch Screen panels look similar to digital panels to the user, but they do not require pressure to operate. A simple touch of the finger draws a small amount of current creating a voltage drop, therefore, it does not need as much physical pressure on the screen. This can help ensure the touch screen’s longevity. Since both layers of a Capacitive Touch Screen are glass, it allows for higher resolution and can detect multi-touch. Generally, Capacitive Touch Screens are more expensive due to their complex structure.

The differences between the three types of touch screens can be subtle, but they are important in determining which touchscreen is best for you. Whether you need a Digital Resistive, Analog Resistive, or Capacitive touch screen, RSP has the versatility to provide the best option for your company.

We design and produce every touch screen panel to meet our customer’s needs and offer custom solutions for integration with membrane switches, silicone rubber keypads, displays, as well as plastic and metal enclosures.

To find out more about RSP’s high-quality custom touch screens and how they can help your business, contact us at 1-866-329-1804 or send us a message.

Ms.Josey

Ms.Josey

Ms.Josey

Ms.Josey