full active lcd displays manufacturer

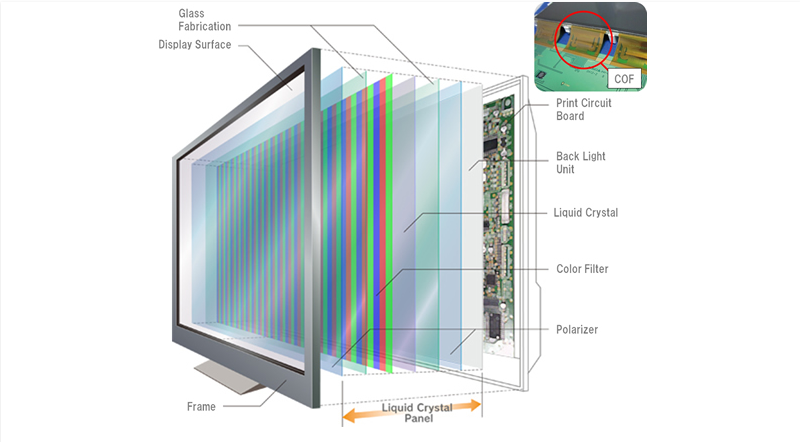

TFT is an LCD Technology which adds a thin-film transistor at each pixel to supply common voltages to all elements. This voltage improves video content frame rates. Displays are predominantly utilizing color filter layers and white LED backlighting.

OLED Displays are emissive displays and do not utilize liquid crystal. Each pixel is emissive with light. Passive OLED displays multiplex power and logic through the IC. Active OLED displays add a transistor at each pixel to supply power directly to the pixels and the IC only performs logical functions.

As your Kyocera Display distributor and solution provider, Edge can help you choose the appropriate LCD display for your project and supply you with compatible accessories or enhancements such as a controller board or inverter. We supply Kyocera Display"s full line of LCD displays including active TFT LCDs, passive displays, and OLEDs.

Kyocera is a leading manufacturer of LCD products, focused on total solutions for the industrial and automotive markets. Kyocera offers high performance TFT display products, applied LTPS TFT array technology, and high performance passive displays.

Kyocera Display products feature superior optical performance, such as high transmittance, high contrast, high brightness, and high reliability in both standard TFT-LCDs and full custom products.

Our company specializes in developing solutions that arerenowned across the globe and meet expectations of the most demanding customers. Orient Display can boast incredibly fast order processing - usually it takes us only 4-5 weeks to produce LCD panels and we do our best to deliver your custom display modules, touch screens or TFT and IPS LCD displays within 5-8 weeks. Thanks to being in the business for such a noteworthy period of time, experts working at our display store have gained valuable experience in the automotive, appliances, industrial, marine, medical and consumer electronics industries. We’ve been able to create top-notch, specialized factories that allow us to manufacture quality custom display solutions at attractive prices. Our products comply with standards such as ISO 9001, ISO 14001, QC 080000, ISO/TS 16949 and PPM Process Control. All of this makes us the finest display manufacturer in the market.

Without a shadow of a doubt, Orient Display stands out from other custom display manufacturers. Why? Because we employ 3600 specialists, includingmore than 720 engineers that constantly research available solutions in order to refine strategies that allow us to keep up with the latest technologiesand manufacture the finest displays showing our innovative and creative approach. We continuously strive to improve our skills and stay up to date with the changing world of displays so that we can provide our customers with supreme, cutting-edge solutions that make their lives easier and more enjoyable.

In a nutshell, Orient Display means 18% of global market share for automotive touch screen displays, emphasis on innovation, flexibility and customer satisfaction.Don"t wait and see for yourself that the game is worth the candle!

Japan Display Inc. (JDI) has announced its development of a new display technology known as a “Full Active” panel. The new design boasts that it can reduce the width of the bottom bezel down to as narrow as the other three sides, potentially reducing the size of smartphones using this display type. To coincide with the announcement, the company also introduced a 5.5-inch 1080p LCD display for smartphones built on this technology.

The “Full Active” name seems to be a bit of misnomer though. The display technology still appears to operate using the traditional LCD active-matrix method of controlling individual pixels using capacitors and transistors.

Instead, JDI says that it has managed to decrease the bezel requirements for its new display by adopting a new high-density wiring layout, along with new processing and module assembly technologies. Essentially, the company has managed to pack extra wiring into the display itself, which reduces the extra space usually required at the bottom of the LCD.

Raystar is a professional TFT (Thin Film Transistor) module manufacturer. There are different models of our TFT active matrix display with various features. Whether you need TFT display with control board, high brightness, wide viewing angle, monochrome, bar type, we have some options for you to choose from. We also offer customization service of backlight and FPC. The available diagonal sizes of our standard TFT display modules are 0.96", 1.77" 2.4", 2.8", 2.84", 3.5", 3.9", 3.97", 4.3", 4.6", 5", 5.2", 5.6", 5.7", 6.2", 7", 8", 8.88", 9",10.1", 10.2", 12.1" and 12.3.

Mercury"s military-grade LCD modules improve operational safety, enhance end-user efficiency, and reduce complete lifecycle costs by customizing active matrix LCD characteristics to your unique application. Whether it is in the air, on the ground, under the sea, day or night, hot or cold, displays built with Mercury"s LCD modules illuminate mission-critical data, regardless of where you work.

Safety-certifiable up to DAL-A, rugged, and NVIS compatible, Mercury"s LCD modules operate in demanding environments and enhance user situational awareness.

Liquid crystal displays (LCD) are the most widespread display technology. The application of electric voltage to LCDs changes the alignment of the liquid crystals within the two layers of glass. This affects the amount of polarized light transmitted, which is generated either by a backlight system or polarizing filter films.

Microtips Technology is a leading custom lcd module manufacturer and we offer a full array of products and services. We have the most advances display technologies available to use in your design and if there is anything you want to change about one of our displays, we can make it happen. All of our displays are fully customizable to your specification and can include extra features like a capacitive touchscreen, an anti-reflective or anti-glare coating, or custom cover glass. Our sales and engineering staff will be with you through the entire process and will ensure our custom lcd display and your end product look their very best.

Planar® CarbonLight™ VX Series is comprised of carbon fiber-framed indoor LED video wall and floor displays with exceptional on-camera visual properties and deployment versatility, available in 1.9 and 2.6mm pixel pitch (wall) and 2.6mm (floor).

From cinema content to motion-based digital art, Planar® Luxe MicroLED Displays offer a way to enrich distinctive spaces. HDR support and superior dynamic range create vibrant, high-resolution canvases for creative expression and entertainment. Leading-edge MicroLED technology, design adaptability and the slimmest profiles ensure they seamlessly integrate with architectural elements and complement interior décor.

From cinema content to motion-based digital art, Planar® Luxe Displays offer a way to enrich distinctive spaces. These professional-grade displays provide vibrant, high-resolution canvases for creative expression and entertainment. Leading-edge technology, design adaptability and the slimmest profiles ensure they seamlessly integrate with architectural elements and complement interior decor.

From cinema content to motion-based digital art, Planar® Luxe MicroLED Displays offer a way to enrich distinctive spaces. HDR support and superior dynamic range create vibrant, high-resolution canvases for creative expression and entertainment. Leading-edge MicroLED technology, design adaptability and the slimmest profiles ensure they seamlessly integrate with architectural elements and complement interior décor.

Planar® CarbonLight™ VX Series is comprised of carbon fiber-framed indoor LED video wall and floor displays with exceptional on-camera visual properties and deployment versatility, available in 1.9 and 2.6mm pixel pitch (wall) and 2.6mm (floor).

Carbon fiber-framed indoor LED video wall and floor displays with exceptional on-camera visual properties and deployment versatility for various installations including virtual production and extended reality.

a line of extreme and ultra-narrow bezel LCD displays that provides a video wall solution for demanding requirements of 24x7 mission-critical applications and high ambient light environments

Since 1983, Planar display solutions have benefitted countless organizations in every application. Planar displays are usually front and center, dutifully delivering the visual experiences and critical information customers need, with proven technology that is built to withstand the rigors of constant use.

This is another story just like those, except this one involves the very screen you’re probably looking at, especially if it’s based on LCD technology.

In the 1970s, a pair of engineers that worked for Westinghouse, T. Peter Brody and Fang-Chen Luo, came to develop the first active-matrix LCD screen. Brody, born in Hungary, had gained an interest in the fledgling technology of thin film transistors, an experimental technology that had come to be seen as a potential avenue for visually displaying content in a more compact form than a cathode-ray tube.

“It has been apparent for some time that a solid-state flat panel display is conceptually achievable,” the patent filing stated. “Efforts to utilize silicon technology to this end are limited by the size limitation problems of the silicon wafer, which negates achievement of large area displays.”

But it was the starting point of the technology that stuck. By the mid-1990s, active-matrix displays that relied on color became the norm in laptops, thanks to their combination of vivid color and thinness. But despite the concept coming from an American company’s R&D department and improved by other American R&D departments, nearly all panels were developed by Japanese manufacturers even at the beginning of their mainstream use cases.

In fact, Westinghouse’s efforts with the flat-panel LCD display ended way back in the 1970s, as did similar efforts at other large U.S. companies. “Both large corporations and venture capital-backed start-ups have quit the field, usually after hitting production difficulties,” authors Richard Florida and David Browdy wrote.

From their discovery in 1888 to their first application within displays in the 1960s, liquid crystals have become a mainstream material choice with many impactful applications in the world of electronics.

As the key component behind liquid crystal displays (LCD), these materials change light polarization to create vibrant, high-resolution images on digital screens. The growth of LCD technology has helped propel the larger display panel market enormously, with industry valuation projected to reach $178.20 billion by 2026.

A prolific variety of LCD types has been developed to best meet their exact use-cases and end-environments. Displays may be optimized for power consumption, contrast ratio, color reproduction, optimal viewing angle, temperature range, cost, and more.

Passive Matrix LCDs are addressed with common and segment electrodes. A pixel or an icon is formed at the intersection where a common and a segment electrode overlap. Common electrodes are addressed one-at-a-time in a sequence. Segment electrodes are addressed simultaneously with the information corresponding to all pixels or icons connected to the current common electrode. This method is referred to as multiplexing.

Passive Matrix LCDs offer a cost advantage (both parts and tooling) and are highly customizable. The counterpart to Passive Matrix displays are Active Matrix displays.

Active-Matrix LCDs were developed to overcome some of the limitations of Passive Matrix LCDs – namely resolution, color, and size. Within an Active-Matrix LCD, an “active element” is added to each pixel location (the intersection between a horizontal row and vertical column electrode). These active elements, which can be diodes or transistors, create a threshold and allow control of the optical response of the liquid crystal structure to the applied voltage. Transistors are used as switches to charge a capacitor, which then provides the voltage to the pixel. Whenever a row is turned on, one at a time, all transistor switches in that row are closed and all pixel capacitors are charged with the appropriate voltage. The capacitor then keeps the voltage applied to the pixel after the row is switched off until the next refresh cycle.

Furthermore, the processes used for manufacturing Active-Matrix LCDs can create much finer details on the electrode structure. This allows splitting each pixel in three sub-pixels with different color. This together with the better voltage control allows full color displays.

The transistor switches used in Active Matrix Displays must not protrude significantly above the surface of the display substrates lest they might interfere with a uniform liquid crystal layer thickness. They must be implemented in thin films of suitable materials. Hence, the name Thin Film Transistors (TFT). While AM and TFT have a different meaning, they are often used interchangeably to indicate a higher performance display.

Currently the most common Electronics Display Technology on the market is LCD technology and among LCD technologies, TFT display technology is the most widely used across consumer applications (laptops, tablets, TVs, Mobile phones, etc.) as well as many industrial, automotive, and medical applications.

As the first commercially successful LCD technology, Passive Matrix Twisted Nematic (TN) LCDs use a 90° twist of the nematic LC fluid between two polarizers to display information. The twist of the LC fluid either blocks light from passing through the LCD cell or allows light to pass, depending on the applied voltage. The applied voltage changes the twisted nematic orientation into an orientation that does not change the polarization of tight. This is called the TN effect.

TN displays can be normally white (NW) when they use two orthogonal liner polarizers or normally black (NB) when parallel linear polarizers are used. ‘Normally’ refers to what happens when no voltage is applied.

Initially, Passive TN LCDs were used in segmented, icon, or character displays where an image element was turned “on” and “off” depending on how the fluid was driven. Improvements were made along the way to address the limited viewing angle of TN technology, which can suffer from contrast loss or even inversion at shallow angles.

It can be advantageous to twist the director of the nematic phase a bit more than 90 degrees, but less than 180 degrees. Displays like this are a subset of TN displays and are sometimes caller Hyper Twisted Nematic Displays.

The numbers of rows or icons that can be addressed in a TN display without Active Matrix addressing is very limited. This is related to how strongly the liquid crystal responds to the applied voltage. Twisting the LC nematic fluid more than 180 degrees (typically between 210 and 270 degrees) causes the display to require a much smaller voltage difference between on and off pixels. This in turn allows addressing of many more rows without an active matrix. Displays with a twist between 210 and 270 degrees are called Super Twisted Nematic displays.

The higher display resolution of STN displays comes at a price. The optical effect is no longer neutrally black and white as in a TN display. Rather these displays are naturally yellow and black or blue and white. The color can be somewhat compensated with colored polarizers, but that comes at the expense of brightness and contrast.

The color in STN displays is caused by birefringence. Adding the same birefringence in the opposite direction can compensate for the effect. Initially this was done by stacking two STN displays on top of each other. This is referred to as Double STN or DSTN, but this is of course thicker and more expensive.

The birefringence of an STN display can be approximated with a stretched transparent plastic film. Adding such a film to an STN display instead of the 2nd STN display is a lot more attractive and has almost the same performance. This is referred to as a Film Compensated STN display (FSTN, or sometimes if two films are used as FFSTN).

FSTN displays are used commonly in consumer, medical and industrial display applications that require low cost and do not need high resolution images or full color.

Another development to the TN display was to use the same concept as in FSTN displays on TN displays. However, the film cannot just be a stretched polymer. Instead, a twisted liquid crystal structure is made and polymerized into a film that is used as a compensation film for TN displays. As this method mostly improves the display characteristics at shallow viewing angles while preserving the excellent performance in straight on viewing, this technology is called Wide View Twisted Nematic (WVTN).

The above display technologies have liquid crystal molecules that are aligned nearly parallel to the display surface with more or less twisting when going from one substrate to the other. In VA (also called VAN) displays, the liquid crystal molecules are aligned vertically with respect to the display surface. Applying a voltage causes the molecules to lay flat, with or without twist.

The advantage of this arrangement is a very dark black state with very little light leakage. This allows making displays with a black mask and colored icons or symbols. These displays look like color displays with brilliant colors, however each image element or icon can only have its assigned color or black.

Due to the ability in AM displays to address one row while the other rows are isolated, the demands on the electro-optical performance of the Liquid Crystal Configuration are less stringent. In principle, all the above mentioned configurations can be used in AM displays. In practice, TN, and WVTN are frequently used as well as some versions of VA technology described below. (MVA, AIFF-MVA, PVA, ASV).

The advantage of these technologies is a much wider and more symmetrical viewing angle along with the elimination of the contrast inversion (or color shift) seen in TN TFT LCDs when viewed from various angles. IPS and FFS displays also are less sensitive to pressure, which is a big advantage in touchscreen displays.

Here, each color sub-pixel is further divided into zones (called domains) having a different direction of the molecular movement when voltage is applied. Again, the purpose is a much wider and more symmetric viewing performance and the elimination of color shifts and contrast inversion at shallow angles. MVA technology achieves that with carefully designed protrusions on the inside surfaces of the display, while PVA uses fine patterning of the electrodes on both substrates.

The integrated circuit is a patterned piece of silicon or other type of semiconducting material. A modern IC contains millions or even billions of tiny transistors. Their tiny size allows for the fabrication of smaller, faster, more efficient, and less expensive electronic circuits. The driver chips addressing electronics displays are ICs.

Legacy LCDs normally have the driver ICs (integrated circuit) mounted on a printed circuit board (PCBA) which consists of a flat sheet of insulating material used to mount and connect the driver IC and electronic periphery to the LCD. PCBs can be a single-sided, double-sided or multi-layer.

Low Voltage Differential Signaling (LVDS) is an interface to the display, not a display technology itself. This technology is not specific to displays, as it’s used in many other applications as well. It’s a high-speed signal that provides some noise immunity for the display. It also allows for longer distances compared to parallel interfaces.

US Micro Products manufactures a wide selection of TFT LCD (Active Matrix LCDs) displays to accommodate the needs of OEMs across many different industries, including medical, industrial, gaming, military and many more.

An array of available interfaces, brightness levels, and temperature ranges ensure that our TFT LCDs work well with your design and in the environment of your choice

320 x 240 5.70” Graphic Display The G-320240-5.7 is a 5.70” 320 x 240 Monochrome LCD Display with a module size of 167.0 x 109.0 x 12.1 and an active area of 115.18 x 86.38. The G-320240-5.7 320 x 240 display uses Super Twisted Nematic or Film Compensated Super Twisted Nematic glass with LED backlighting and a reflective, transflective, or transmissive display. View Additional Details Generic Part G-320240-5.7 Display Format 320 x 240 Graphic Display Module Size 167.0 x 109.0 x 12.1 Diagonal 5.70 Active Area 115.18 x 86.38 Pixel Pitch 0.360 x 0.360 Backlight…

320 x 240 5.70” Graphic LCD Display The PDI320240B0-TFH-VZ# is a 5.70” 320 x 240 Monochrome LCD Display with a module size of 160.0 x 109.0 x 13.0 and an active area of 115.2 x 86.4. The PDI320240B0-TFH-VZ# 320 x 240 display uses Super Twisted Nematic or Film Compensated Super Twisted Nematic glass with LED backlighting and a reflective, transflective, or transmissive display. View Additional Details Generic Part PDI320240B0-TFH-VZ# Display Format 320 x 240 Graphic Display Module Size 160.0 x 109.0 x 13.0 Diagonal 5.70 Active Area 115.2 x 86.4 Pixel Pitch 0.360 x 0.360 Backlight LED…

320 x 240 5.70” Graphic LCD Display The PDI320240BX-TFH-VZ# is a 5.70” 320 x 240 Monochrome LCD Display with a module size of 160.0 x 109.0 x 13.0 and an active area of 115.2 x 86.45. The PDI320240BX-TFH-VZ# 320 x 240 display uses Super Twisted Nematic or Film Compensated Super Twisted Nematic glass with LED backlighting and a reflective, transflective, or transmissive display. View Additional Details Generic Part PDI320240BX-TFH-VZ# Display Format 320 x 240 Graphic Display Module Size 160.0 x 109.0 x 13.0 Diagonal 5.70 Active Area 115.2 x 86.4 Pixel Pitch 0.360 x 0.360…

5.70” 320 x 240 Graphic Display LCD The PDI320240C0-TFH-VZ# is a 5.70” 320 x 240 Monochrome LCD Display with a module size of 148.0 x 120.2 x 15.6 and an active area of 115.2 x 86.4. The PDI320240C0-TFH-VZ# 320 x 240 display uses Super Twisted Nematic or Film Compensated Super Twisted Nematic glass with LED backlighting and a reflective, transflective, or transmissive display. View Additional Details Generic Part PDI320240C0-TFH-VZ# Display Format 320 x 240 Graphic Display Module Size 148.0 x 120.2 x 15.6 Diagonal 5.70 Active Area 115.2 x 86.4 Pixel Pitch 0.360 x 0.360…

5.70” LCD 320 x 240 Graphic Display The PDI320240CX-TFH-VZ# is a 5.70” 320 x 240 Monochrome LCD Display with a module size of 140.0 x 120.2 x 15.6 and an active area of 115.2 x 86.4. The PDI320240CX-TFH-VZ# 320 x 240 display uses Super Twisted Nematic or Film Compensated Super Twisted Nematic glass with LED backlighting and a reflective, transflective, or transmissive display. View Additional Details Generic Part PDI320240CX-TFH-VZ# Display Format 320 x 240 Graphic Display Module Size 140.0 x 120.2 x 15.6 Diagonal 5.70 Active Area 115.2 x 86.4 Pixel Pitch 0.360 x 0.360…

320 x 240 LCD 5.70″ Graphic Display The PDI320240H-TFH-VZ# is a 5.70” 320 x 240 Monochrome LCD Display with a module size of 148.0 x 120.2 x 15.6 and an active area of 115.2 x 86.4. The PDI320240H-TFH-VZ# 320 x 240 display uses Super Twisted Nematic or Film Compensated Super Twisted Nematic glass with LED backlighting and a reflective, transflective, or transmissive display. View Additional Details Generic Part PDI320240H-TFH-VZ# Display Format 320 x 240 Graphic Display Module Size 148.0 x 120.2 x 15.6 Diagonal 5.70 Active Area 115.2 x 86.4 Pixel Pitch 0.360 x 0.360…

5.70” 320 x 240 Graphic Display The PDI320240L-TFH-VZ# is a 5.70” 320 x 240 Monochrome LCD Display with a module size of 160.0 x 109.0 x 13.0 and an active area of 115.2 x 86.4. The PDI320240L-TFH-VZ# 320 x 240 display uses Super Twisted Nematic or Film Compensated Super Twisted Nematic glass with LED backlighting and a reflective, transflective, or transmissive display. View Additional Details Generic Part PDI320240L-TFH-VZ# Display Format 320 x 240 Graphic Display Module Size 160.0 x 109.0 x 13.0 Diagonal 5.70 Active Area 115.2 x 86.4 Pixel Pitch 0.360 x 0.360 Backlight…

5.70” 320 x 240 Graphic Display The PDI320240A-TFH-VZ# is a 5.70” 320 x 240 Monochrome LCD Display with a module size of 120.0 x 109.0 x 13.0 and an active area of 115.2 x 86.4. The PDI320240A-TFH-VZ# 320 x 240 display uses Super Twisted Nematic or Film Compensated Super Twisted Nematic glass with LED backlighting and a reflective, transflective, or transmissive display. View Additional Details Generic Part PDI320240A-TFH-VZ# Display Format 320 x 240 Graphic Display Module Size 120.0 x 109.0 x 13.0 Diagonal 5.70 Active Area 115.2 x 86.4 Pixel Pitch 0.360 x 0.360 Backlight LED Display…

5.70” 320 x 240 LCD Graphic Display The G-32024007S-VA is a 5.70” 320 x 240 Monochrome LCD Display with a module size of 172.0 x 129.0 x 36.0 and an active area of 115.2 x 86.4. The G-32024007S-VA 320 x 240 display uses Super Twisted Nematic or Film Compensated Super Twisted Nematic glass with LED backlighting and a reflective, transflective, or transmissive display. View Additional Details Generic Part G-32024007S-VA Display Format 320 x 240 Graphic Display Module Size 172.0 x 129.0 x 36.0 Diagonal 5.70 Active Area 115.2 x 86.4 Pixel Pitch 0.360 x 0.360…

320 x 240 5.70” LCD Graphic Display The G-32024012T-VA is a 5.70” 320 x 240 Monochrome LCD Display with a module size of 165.5 x 112.3 x 11.0 and an active area of 115.17 x 86.37. The G-32024012T-VA 320 x 240 display uses Super Twisted Nematic or Film Compensated Super Twisted Nematic glass with LED backlighting and a reflective, transflective, or transmissive display View Additional Details Generic Part G-32024012T-VA Display Format 320 x 240 Graphic Display Module Size 165.5 x 112.3 x 11.0 Diagonal 5.70 Active Area 115.17 x 86.37 Pixel Pitch 0.360 x 0.360 Backlight…

5.90” 240 x 128 Graphic Display The G-24012816C-VA is a 5.90” 240 x 128 Monochrome LCD Display with a module size of 180.0 x 120.0 x 10.5 and an active area of 131.98 x 70.38. The G-24012816C-VA 240 x 128 display uses Super Twisted Nematic or Film Compensated Super Twisted Nematic glass with no backlighting and a reflective, transflective, or transmissive display. View Additional Details Generic Part G-24012816C-VA Display Format 240 x 128 Graphic Display Module Size 180.0 x 120.0 x 10.5 Diagonal 5.90 Active Area 131.98 x 70.38 Pixel Pitch 0.550 x 0.550 Backlight…

To create an LCD, you take two pieces ofpolarized glass. A special polymer that creates microscopic grooves in the surface is rubbed on the side of the glass that does not have the polarizing film on it. The grooves must be in the same direction as the polarizing film. You then add a coating of nematic liquid crystals to one of the filters. The grooves will cause the first layer of molecules to align with the filter"s orientation. Then add the second piece of glass with the polarizing film at a right angle to the first piece. Each successive layer of TN molecules will gradually twist until the uppermost layer is at a 90-degree angle to the bottom, matching the polarized glass filters.

If we apply an electric charge to liquid crystal molecules, they untwist. When they straighten out, they change the angle of the light passing through them so that it no longer matches the angle of the top polarizing filter. Consequently, no light can pass through that area of the LCD, which makes that area darker than the surrounding areas.

Building a simple LCD is easier than you think. Your start with the sandwich of glass and liquid crystals described above and add two transparent electrodes to it. For example, imagine that you want to create the simplest possible LCD with just a single rectangular electrode on it. The layers would look like this:

The LCD needed to do this job is very basic. It has a mirror (A) in back, which makes it reflective. Then, we add a piece of glass (B) with a polarizing film on the bottom side, and a common electrode plane (C) made of indium-tin oxide on top. A common electrode plane covers the entire area of the LCD. Above that is the layer of liquid crystal substance (D). Next comes another piece of glass (E) with an electrode in the shape of the rectangle on the bottom and, on top, another polarizing film (F), at a right angle to the first one.

The electrode is hooked up to a power source like a battery. When there is no current, light entering through the front of the LCD will simply hit the mirror and bounce right back out. But when the battery supplies current to the electrodes, the liquid crystals between the common-plane electrode and the electrode shaped like a rectangle untwist and block the light in that region from passing through. That makes the LCD show the rectangle as a black area.

There are, however, a number of European companies with the technical capabilities to produce LCDs and to compete worldwide, provided that production investments are made on an appropriate scale for a well-defined technology.

The approach, which is now widely recognised as the most promising, is to deposit a matrix of switching transistors on an inner wall of the LCD (AMLCD). Three of the partners have demonstrated their technical know-how in the field of active matrix panels by the realisation, at the laboratory level, of displays with viewing areas of approximately 10 x 10 cm{2} and resolution up to 256 x 256 pixels (see project 833).

Although applications for such displays are expected in small portable equipment and video projectors, it seems necessary to develop larger (A4) high-resolution panels to meet the key requirements of office terminals. The main goal of the project is therefore to validate technologies for the production of active matrix LCDs up to A4 in size.

There are a number of European companies with the technical capabilities to produce liquid crystal displays (LCD) and to compete worldwide, provided that production investments are made on an appropriate scale for a well defined technology. Such a display, compact and operating at low voltage, must be able to show colour and grey scale with high resolution and should be less bulky than current cathode ray tube (CRT) devices in orderto fulfil office systems requirements in the near future.

The main goal of the project is therefore to validate technologies for the production of active matrix LCD up to A4 in size. The work involves the preparation of direct view flat panel displays using amorphous silicon wilth external integrated circuit (IC) drivers in the short term, or using polycrystalline silicon with integrated drivers as an alternative in the longer term. During the first 3 years of the project the realization of an A4 amorphous silicon matrix will be carried out, and, in parallel, a polycrystalline silicon process with integrated drivers and A4 glass compatibility, including A4 specific equipment, will be developed (6 inch diagonal demonstrator).

A complete new facility dedicated to the realization of 14 inch x 14 inch substrate displays has been built near Grenoble, and is already experiencing problems arising form amorphous silicon display production in a pilot line. A5 8-colour displays have been demonstrated as a first step towards the final goal. The processing of the panels is on course. The consortium recently demonstrated a 2.8 inch diagonal active matrix LCD display with fully integrated polysilicon row and column drivers. The device contains a 200 x 200 pixel array, and can be driven through a 28-pin connector.

The work involved the preparation of direct-view flat-panel displays using amorphous silicon with external IC drivers in the short term, or using polycrystalline silicon with integrated drivers as an alternative in the longer term.

Sharp NEC Display Solutions incorporates both Sharp and NEC brands of display products. Including desktop, 4K and 8K UHD large format, video wall, dvLED, collaboration and interactive products, Sharp/NEC offers the widest portfolio of displays available. Understanding that every market and environment has unique requirements, Sharp/NEC prides itself on being your partner, delivering customized solutions to match your needs.

Ms.Josey

Ms.Josey

Ms.Josey

Ms.Josey