esp32 lcd screen quotation

This tutorial shows how to use the I2C LCD (Liquid Crystal Display) with the ESP32 using Arduino IDE. We’ll show you how to wire the display, install the library and try sample code to write text on the LCD: static text, and scroll long messages. You can also use this guide with the ESP8266.

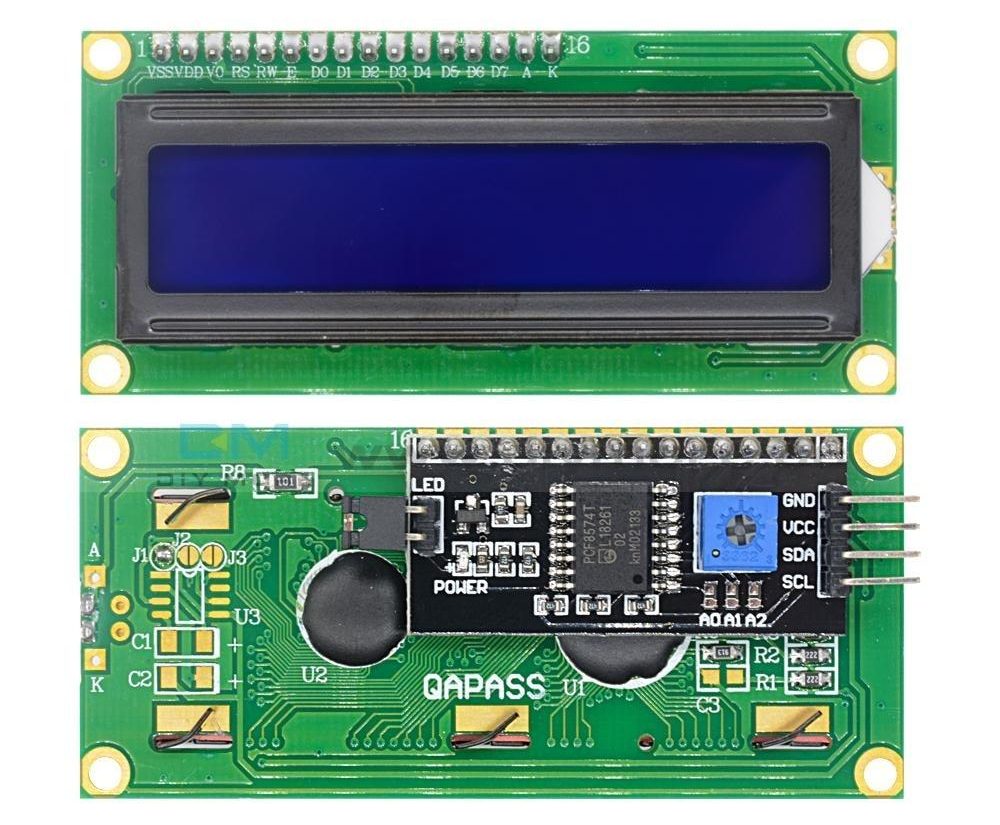

Additionally, it comes with a built-in potentiometer you can use to adjust the contrast between the background and the characters on the LCD. On a “regular” LCD you need to add a potentiometer to the circuit to adjust the contrast.

Before displaying text on the LCD, you need to find the LCD I2C address. With the LCD properly wired to the ESP32, upload the following I2C Scanner sketch.

After uploading the code, open the Serial Monitor at a baud rate of 115200. Press the ESP32 EN button. The I2C address should be displayed in the Serial Monitor.

Displaying static text on the LCD is very simple. All you have to do is select where you want the characters to be displayed on the screen, and then send the message to the display.

The next two lines set the number of columns and rows of your LCD display. If you’re using a display with another size, you should modify those variables.

To display a message on the screen, first you need to set the cursor to where you want your message to be written. The following line sets the cursor to the first column, first row.

Scrolling text on the LCD is specially useful when you want to display messages longer than 16 characters. The library comes with built-in functions that allows you to scroll text. However, many people experience problems with those functions because:

In a 16×2 LCD there are 32 blocks where you can display characters. Each block is made out of 5×8 tiny pixels. You can display custom characters by defining the state of each tiny pixel. For that, you can create a byte variable to hold the state of each pixel.

In summary, in this tutorial we’ve shown you how to use an I2C LCD display with the ESP32/ESP8266 with Arduino IDE: how to display static text, scrolling text and custom characters. This tutorial also works with the Arduino board, you just need to change the pin assignment to use the Arduino I2C pins.

We hope you’ve found this tutorial useful. If you like ESP32 and you want to learn more, we recommend enrolling in Learn ESP32 with Arduino IDE course.

My previous instructables, ESP32 Photo Clock is am example, it download a current minute photo from the Internet, decode the JPEG photo and display it.

Many Arduino projects use monochrome display, one of the reason is the limited resources of a MCU. 320 pixels width, 240 pixels height and 8 bits color for each RGB color channel means 230 KB for each full screen picture. But normal Arduino (ATmega328) only have 32 KB flash and it is time consuming (over a second) to read data from SD card and draw it to the color display.

ESP32 have changed the game! It have much faster processing power (16 MHz vs 240 MHz dual core), much more RAM (2 KB vs over 200 KB) and much more flash (32 KB vs 4 MB), so it is capable to utilize more color and higher resolution image for displaying. At the same time it is capable to do some RAM hungry process such as Animated GIF, JPEG or PNG file decoding, it is a very important feature for displaying information gathered from the internet.

There are various color display for hobby electronics: LCD, IPS LCD, OLED with different resolutions and different driver chips. LCD can have higher image density but OLED have better viewable angle, IPS LCD can have both. OLED have more power efficient for each light up pixel but may have burn-in problems. Color OLED operate in 14 V, it means you need a dedicate step-up circuit, but it is not a problem if you simply use with a break-out board. LCD in most case can direct operate in 3.3 V, the same operating voltage as ESP32, so you can consider not use break out board to make a slimmer product.

Software support on the other side also influence your selection. You can develop ESP32 program with Arduino IDE or direct use ESP-IDF. But since ESP-IDF did not have too much display library and not much display hardware supported, so I will concentrate on Arduino display libraries only.

OLED have a big advantage, the pixel only draw power if it lights up. On the other hand, LCD back light always draw full power even you are displaying a black screen. So OLED can help save some power for the project powered by a battery.

This is a 1.5" 128 x 128 color OLED, this form factor is very fit for smart-watch-like wearable project. The most barrier of select this should be the price tag is around 4 times of a normal LCD.

ST7735 is a very popular LCD driver model for the resolution 128x128 and 128x160. It may cause by its popularity, there are many manufacturer produce compatible product. However, they are not fully compatible.

Thanks for the popularity of wearable gadget, I can find more small size IPS LCD in the market this year(2018). The above picture is an 0.96" 80x160 IPS color LCD using ST7735 driver chip. As you can see in the 3rd picture, you can treat it as a 128x160 color display in code but only the middle part is actually displaying. The 4th picture is the display without breakout board, it is thin, tiny and very fit for a wearable project!

SSD1283A is 1.6" 130x130 display, it claim only consume 0.1 in sleep mode and backlight turned off. In sleep mode the last drawn screen still readable under sufficient lighting.

It is a 2.2" 176x220 color LCD. It is relatively fewer projects using this chips and resolution. It may caused by the success of its chip family brother, ILI9341 (0.2" larger in size but have near double resolution).

Lower resolution still have its advantages, e.g. it can save half of the processing power on decoding the full screen size JPEG image and double the FPS ;>

I think ILI9341 is the most popular LCD driver chip in the hobby electronics market. In most case it is 240x320 resolution and have many screen size from 1.7" to 3.5". Some breakout board also built-in touch screen feature.

ST7789 also a common driver chip in ESP32 community. One of the reason is ESP32 official development kit using it. As same as ILI9341, ST7789 also can drive 240x320 resolution.

This also the highest pixel density color display in my drawer. As same as normal LCD, it can direct operate in 3.3 V, so it is very good for making slim wearable device.

The display speed is one of the most important thing we consider to select which library. I have chosen TFT_eSPI PDQ test for this comparison. I have made some effort to rewrite the PDQ test that can run in 4 libraries. All test will run with the same 2.8" ILI9341 LCD.

As I found TFT_eSPI is the most potential display library for ESP32 in this instructables, I have paid some effort to add support for all my display in hand. The newly added display support marked letter M in red at the above picture, here is my enhanced version:

Adafruit sell various display module in hobby electronics market and they also have very good support in software level. Their display libraries all built on a parent class called Adafruit_GFX, so I call it Adafruit GFX Family. This library generally support most Arduino hardware (also ESP32).

This library method signature is very similar to Adafruit GFX, but it is tailor-made for ESP8266 or ESP32. I think the source code is optimised for ESP32, so the PDQ result is much faster than other libraries.

#define LOAD_GLCD // Font 1. Original Adafruit 8 pixel font needs ~1820 bytes in FLASH

#define LOAD_FONT2 // Font 2. Small 16 pixel high font, needs ~3534 bytes in FLASH, 96 characters

ESP32 + ILI9341 can run at SPI speed 40 MHz, it require some code change at library folder. The above pictures are the fine tuned result. Here are the code change summary:

ST7735 and ILI9341 are the most popular display, this 2 are better option for the beginner. You may notice LCD have a big weakness, the viewable angle, some color lost outside the viewable angle and the screen become unreadable. If you have enough budget, OLED or IPS LCD have much better viewable angle.

OLED require 14 V to light up the pixel so it is not easy to decouple the breakout board. On the other hand, LCD (also IPS LCD) usually operate in 3.3 V, as same as the ESP32. In most case, there are only the LED control circuit required between LCD and ESP32, i.e. a transistor and few resistors. So it relatively easy to make it.

It is very important to read the data sheet first before you decide not using breakout board. The pins layout, pin pitch size, the sample circuit connection and maximum rating all you can find in data sheet. The maximum voltage is especially important, you should sticky follow the rating or you will blow your LCD. The chip can operate in 3.3 V but LED may be 2.8 - 3.0 V so it require some electronics in the middle, most data sheet have the sample circuit. You may ask your seller send a soft copy of data sheet to you or simply Google it by the model number.

My special hint: I like to soldering a FPC cable with the same pin pitch size as the LCD to help the connection with the MCU. I have used this technique in these instructables:

Hello! Yes, I purchased this display from keyestudio, connected it to esp32 using this library from dfrobot. It is only necessary to consider that the pinout of the display connectors differs from dfrobot and keyestudio.

I"m wanting to connect a VGA camera, the sort you find as a little module on eBay with OVPxxxx chip, to a screen such as ILxxxx family, which appears to have direct VGA input. I think it will work if I connect the camera directly with no MCU, but I"d also like to add a cross-hair to the display (for a drill targetting system). I wonder is it possible to intercept the serial video data and change individual pixels in a streaming fashion, instead of loading a whole screen into memory, changing it and passing it on? I ask because it seems to me it would need a much less powerful MCU.0

So, basically I make a reset in the beggining (read datasheet) then next I use only SPI_DAT and SPLI_CLK. If I destroy the sequence touching with an oscilloscope, the LCD stops to understand the sequence DAT/CLK and I have to make another reset.

Those 2 pins must be dedicated to the display, otherwise the display will get confused without the CS pin. One DAT/CLK to LCD and another DAT/CLK to I2C.

Hello! Thank"s for your instruction. I want to use your 8pin ili9486 320x480 spi display with one of your presented libraries and esp32. 1.) Could you please tell me the connections between the display and the esp32 and 2.) which numbers do I have to write into the line utft myglcd (ili9486,?,?,?,?)?

A few weeks ago, we examined the features of ESP32 module and built a simple hello world program to get ourselves familiar with the board. Today, we will continue our exploration of the ESP32 on a higher level as we will look at how to interface a 16×2 LCD with it.

Displays provide a fantastic way of providing feedback to users of any project and with the 16×2 LCD being one of the most popular displays among makers, and engineers, its probably the right way to start our exploration. For today’s tutorial, we will use an I2C based 16×2 LCD display because of the easy wiring it requires. It uses only four pins unlike the other versions of the display that requires at least 7 pins connected to the microcontroller board.

ESP32 comes in a module form, just like its predecessor, the ESP-12e, as a breakout board is usually needed to use the module. Thus when it’s going to be used in applications without a custom PCB, it is easier to use one of the development boards based on it. For today’s tutorial, we will use the DOIT ESP32 DevKit V1 which is one of the most popular ESP32 development boards.

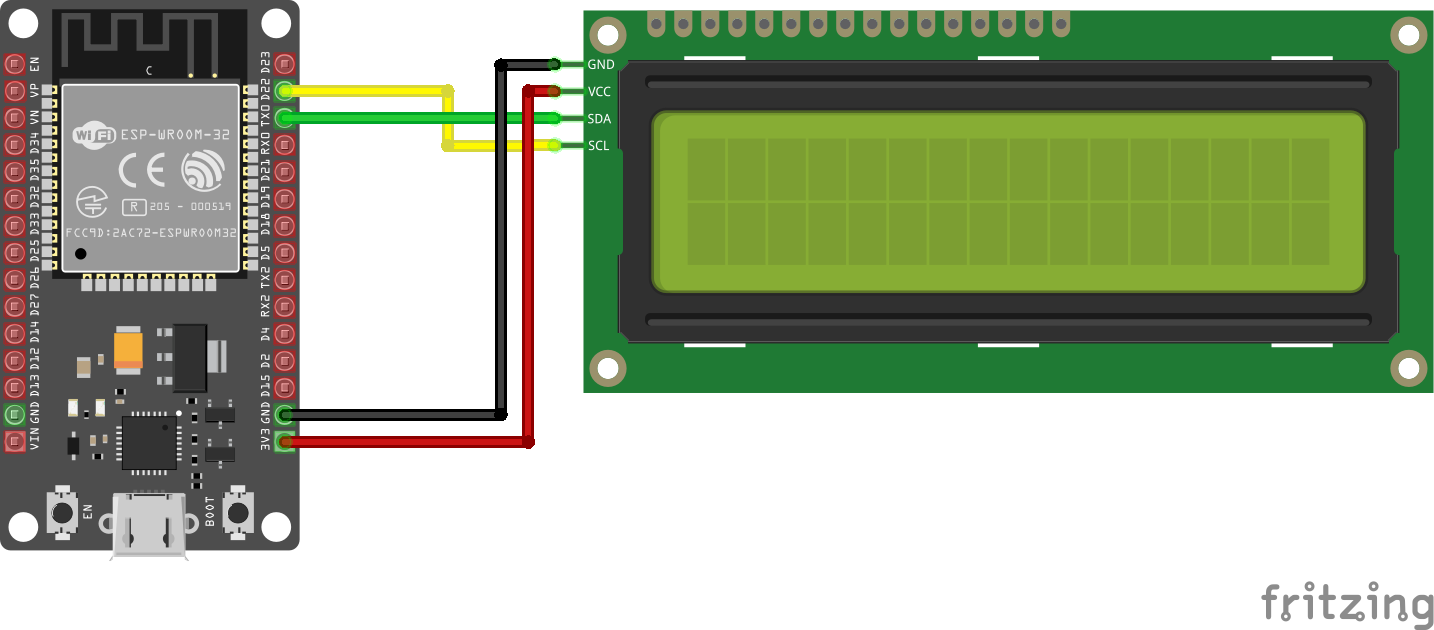

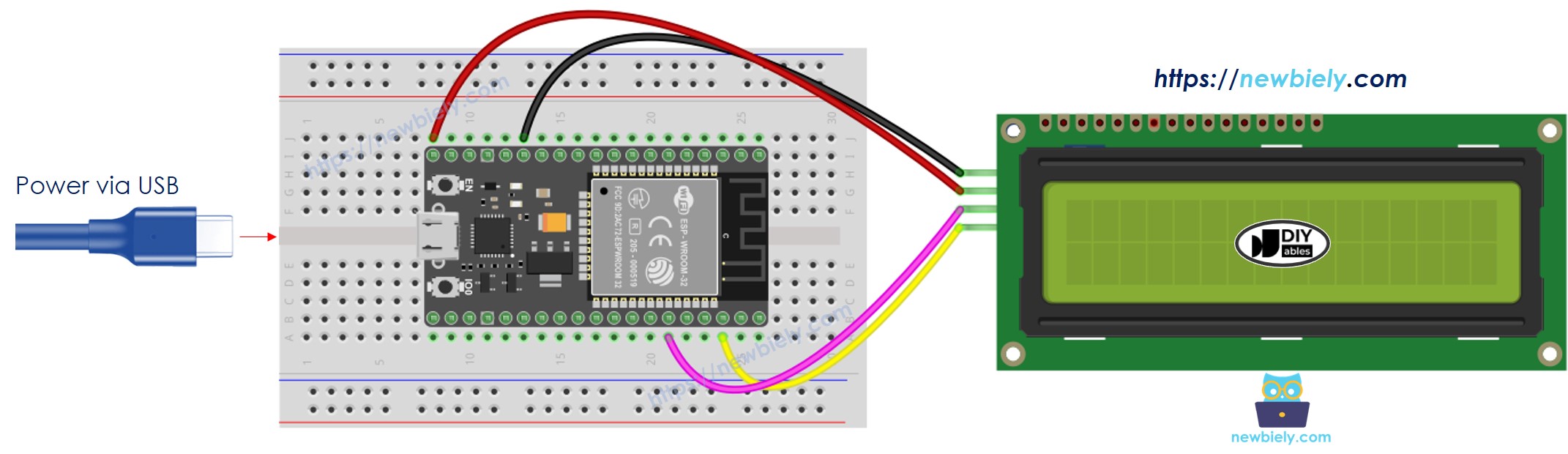

The schematics for this project is relatively simple since we are connecting just the LCD to the DOIT Devkit v1. Since we are using I2C for communication, we will connect the pins of the LCD to the I2C pins of the DevKit. Connect the components as shown below.

Due to the power requirements of the LCD, it may not be bright enough when connected to the 3.3v pin of the ESP32. If that is the case, connect the VCC pin of the LCD to the Vin Pin of the ESP32 so it can draw power directly from the connected power source.

At this point, it is important to note that a special setup is required to enable you to use the Arduino IDE to program ESP32 based boards. We covered this in the introduction to ESP32 tutorial published a few weeks go. So, be sure to check it out.

To be able to easily write the code to interact with the I2C LCD display, we will use the I2C LCD library. The Library possesses functions and commands that make addressing the LCD easy. Download the I2C LCD library from the link attached and install on the Arduino IDE by simply extracting it into the Arduino’s library folder.

Before writing the code for the project, it’s important for us to know the I2C address of the LCD as we will be unable to talk to the display without it.

While some of the LCDs come with the address indicated on it or provided by the seller, in cases where this is not available, you can determine the address by using a simple sketch that sniffs the I2C line to detect what devices are connected alongside their address. This sketch is also a good way to test the correctness of your wiring or to determine if the LCD is working properly.

If you keep getting “no devices found”, it might help to take a look at the connections to be sure you didn’t mix things up and you could also go ahead and try 0x27 as the I2C address. This is a common address for most I2C LCD modules from China.

Our task for today’s tutorial is to display both static and scrolling text on the LCD, and to achieve that, we will use the I2C LCD library to reduce the amount of code we need to write. We will write two separate sketches; one to displaystatic textsand the other to display both static and scrolling text.

To start with the sketch for static text display, we start the code by including the library to be used for it, which in this case, is the I2C LCD library.

Next, we create an instance of the I2C LCD library class with the address of the display, the number of columns the display has (16 in this case), and the number of rows (2 in this case) as arguments.

With that done, we proceed to the void setup() function. Here we initialize the display and issue the command to turn the backlight on as it might be off by default depending on the LCD.

Next is the void loop() function. The idea behind the code for the loop is simple, we start by setting the cursor to the column and row of the display where we want the text to start from, and we proceed to display the text using the lcd.print() function. To allow the text to stay on the screen for a while (so its visible) before the loop is reloaded, we delay the code execution for 1000ms.

Next, we create an instance of the I2C LCD library class with the address of the display, the number of columns the display has (16 in this case), and the number of rows (2 in this case) as arguments.

Next, we create the function to display scrolling text. The function accepts four arguments; the row on which to display the scrolling text, the text to be displayed, the delay time between the shifting of characters, and the number of columns of the LCD.

That’s it for today’s tutorial guys. Thanks for following this tutorial. This cheap LCD display provides a nice way of providing visual feedback for your project and even though the size of the screen and the quality of the display is limited, with the scrolling function you can increase the amount of text/characters that can be displayed.

Than displays are the way to go. There are different kinds of displays like 7 Segment LED display, 4 Digit 7 Segment display, 8×8 Dot Matrix display, OLED display or the easiest and cheapest version the liquid crystal display (LCD).

Most LCD displays have either 2 rows with 16 characters per row or 4 rows with 20 characters per row. There are LCD screen with and without I2C module. I highly suggest the modules with I2C because the connection to the board is very easy and there are only 2 instead of 6 pins used. But we will cover the LCD screen with and without I2C module in this article.

The LCD display has an operating voltage between 4.7V and 5.3V with a current consumption of 1mA without backlight and 120mA with full backlight. There are version with a green and also with a blue backlight color. Each character of the display is build by a 5×8 pixel box and is therefore able to display custom generated characters. Because each character is build by (5×8=40) 40 pixels a 16×2 LCD display will have 16x2x40= 1280 pixels in total. The LCD module is able to operate in 8-bit and 4-bit mode. The difference between the 4-bit and 8-bit mode are the following:

If we use the LCD display version without I2C connection we have to add the potentiometer manually to control the contrast of the screen. The following picture shows the pinout of the LCD screen.

Also I added a table how to connect the LCD display with the Arduino Uno and the NodeMCU with a description of the LCD pin. To make it as easy as possible for you to connect your microcontroller to the display, you find the corresponding fritzing connection picture for the Arduino Uno and the NodeMCU in this chapter.

4RSD12D2Select command register to low when we are sending commands to the LCD like set the cursor to a specific location, clear the display or turn off the display.

8Data Pin 1 (d1)Data pins 0 to 7 forms an 8-bit data line. The Data Pins are connection to the Digital I/O pins of the microcontroller to send 8-bit data. These LCD’s can also operate on 4-bit mode in such case Data pin 4,5,6 and 7 will be left free.

Of cause we want to try the connection between the microcontroller and the LCD display. Therefore you find an example sketch in the Arduino IDE. The following section shows the code for the sketch and a picture of the running example, more or less because it is hard to make a picture of the screen ;-). The example prints “hello, world!” in the first line of the display and counts every second in the second row. We use the connection we described before for this example.

Looks very complicated to print data onto the LCD screen. But don’t worry like in most cases if it starts to get complicated, there is a library to make the word for us. This is also the case for the LCD display without I2C connection.

Like I told you, I would suggest the LCD modules with I2C because you only need 2 instead of 6 pins for the connection between display and microcontroller board. In the case you use the I2C communication between LCD and microcontroller, you need to know the I2C HEX address of the LCD. In this article I give you a step by step instruction how to find out the I2C HEX address of a device. There is also an article about the I2C communication protocol in detail.

On the backside is a 10 kΩ potentiometer build in to control the screen contrast. You do not have to add the potentiometer manually like in the version without I2C connection.

The following picture shows how to connect an I2C LCD display with an Arduino Uno. We will use exact this connection for all of the examples in this article.

To use the I2C LCD display we have to install the required library “LiquidCrystal_I2C” by Frank de Brabander. You find here an article how to install an external library via the Arduino IDE. After you installed the library successful you can include the library via: #include < LiquidCrystal_I2C.h>.

The LiquidCrystal library has 20 build in functions which are very handy when you want to work with the LCD display. In the following part of this article we go over all functions with a description as well as an example sketch and a short video that you can see what the function is doing.

LiquidCrystal_I2C()This function creates a variable of the type LiquidCrystal. The parameters of the function define the connection between the LCD display and the Arduino. You can use any of the Arduino digital pins to control the display. The order of the parameters is the following: LiquidCrystal(RS, R/W, Enable, d0, d1, d2, d3, d4, d5, d6, d7)

If you are using an LCD display with the I2C connection you do not define the connected pins because you do not connected to single pins but you define the HEX address and the display size: LiquidCrystal_I2C lcd(0x27, 20, 4);

xlcd.begin()The lcd.begin(cols, rows) function has to be called to define the kind of LCD display with the number of columns and rows. The function has to be called in the void setup() part of your sketch. For the 16x2 display you write lcd.begin(16,2) and for the 20x4 lcd.begin(20,4).

xxlcd.clear()The clear function clears any data on the LCD screen and positions the cursor in the upper-left corner. You can place this function in the setup function of your sketch to make sure that nothing is displayed on the display when you start your program.

xxlcd.setCursor()If you want to write text to your LCD display, you have to define the starting position of the character you want to print onto the LCD with function lcd.setCursor(col, row). Although you have to define the row the character should be displayed.

xxlcd.print()This function displays different data types: char, byte, int, long, or string. A string has to be in between quotation marks („“). Numbers can be printed without the quotation marks. Numbers can also be printed in different number systems lcd.print(data, BASE) with BIN for binary (base 2), DEC for decimal (base 10), OCT for octal (base 8), HEX for hexadecimal (base 16).

xlcd.println()This function displays also different data types: char, byte, int, long, or string like the function lcd.print() but lcd.println() prints always a newline to output stream.

xxlcd.display() / lcd.noDisplay()This function turn on and off any text or cursor on the display but does not delete the information from the memory. Therefore it is possible to turn the display on and off with this function.

xxlcd.scrollDisplayLeft() / lcd.scrollDisplayRight()This function scrolls the contents of the display (text and cursor) a one position to the left or to the right. After 40 spaces the function will loops back to the first character. With this function in the loop part of your sketch you can build a scrolling text function.

Scrolling text if you want to print more than 16 or 20 characters in one line, than the scrolling text function is very handy. First the substring with the maximum of characters per line is printed, moving the start column from the right to the left on the LCD screen. Than the first character is dropped and the next character is printed to the substring. This process repeats until the full string is displayed onto the screen.

xxlcd.autoscroll() / lcd.noAutoscroll()The autoscroll function turn on or off the functionality that each character is shifted by one position. The function can be used like the scrollDisplayLeft / scrollDisplayRight function.

xxlcd. leftToRight() / lcd.rightToLeft()The leftToRight and rightToLeft functions changes the direction for text written to the LCD. The default mode is from left to right which you do not have to define at the start of the sketch.

xxlcd.createChar()There is the possibility to create custom characters with the createChar function. How to create the custom characters is described in the following chapter of this article as well as an example.

xlcd.backlight()The backlight function is useful if you do not want to turn off the whole display (see lcd.display()) and therefore only switch on and off the backlight. But before you can use this function you have to define the backlight pin with the function setBacklightPin(pin, polarity).

xlcd.moveCursorLeft() / lcd.moveCursorRight()This function let you move the curser to the left and to the right. To use this function useful you have to combine it with lcd.setCursor() because otherwise there is not cursor to move left or right. For our example we also use the function lcd.cursor() to make the cursor visible.

xlcd.on() / lcd.off()This function switches the LCD display on and off. It will switch on/off the LCD controller and the backlight. This method has the same effect of calling display/noDisplay and backlight/noBacklight.

The following code shows you the Arduino program to use all three LCD display functions of the library divided into three separate functions. Also the video after the program shows the functions in action.

The creation of custom characters is very easy if you use the previous mentioned libraries. The LiquidCrystal and also the LiquidCrystal_I2C library have the function “lcd.createChar()” to create a custom character out of the 5×8 pixels of one character. To design your own characters, you need to make a binary matrix of your custom character from an LCD character generator or map it yourself. This code creates a wiggling man.

In the section of the LCD display pinout without I2C we saw that if we set the RS pin to how, that we are able to send commands to the LCD. These commands are send by the data pins and represented by the following table as HEX code.

Connecting a colour screen over SPI to ESP32 based MCU’s is a straight forward process and is extremely similar to using one with the Arduino or ESP8266. Firstly though you need to ensure that you have set up your ESP32 to work with the Arduino IDE, see this articleif you have not already done so and then come back here.

The ScreenThe screen I chose is shown below, finding one very similar will probably make your build easier, but as long as your screen is an SPI screen using the ST7735 driver chip then you should be good to go.

As can be seen from the connections it accepts both 5V and 3.3V with the 5V side having a pre-soldered pin header. This particular one was ordered from Ali-Express and had a picture of a cartoon boy on the screen. I suspect buying any with the same pin connections will give you the same screen as the one above.

For my new Froggerproject (after the Space Invaders one), I wanted a screen where I could directly port the Arcade graphics and screen layout without too much messing about re-designing graphics. But for the price point I wanted this proved impossible. Most arcade games of the early 80’s did not go above 256 pixels in any give direction so porting the graphics should be easy I thought. At half the resolution (128×128) I hope that transferring the graphics will not be too tedious and that in most cases I can simply reduce the number of pixels in each image by half.

Due to the planned game being more advanced than Space Invaders I needed a processor with more memory and speed than the Arduino could offer. Enter the ESP32 was the obvious choice, it has more power than the ESP8266 (not that that was an issue) and more importantly it has loads of input pins, cool! Wifi is also available but will not be required for this project unless we implemented a World High Score Table perhaps! I’m using a NodeMCU development board which brings out all the ESP32’s pins to headers and enables the board to be plugged into a 5V USB power source. It also adds a USB controller chip to handle program transfers with the host computer.

Connections – very careful now!Looking at the back we can see +3v3 (this screen can be powered from 5v as well), several grounds (Gnd) and SCL/SDA. This shouldmean that this device is an I²C device and can be easily connected to our Arduino. Err… Think again. This screen gave me no end of problems as connecting it to the I²C connections and running any demo I could find on the internet did not get anything on the display. I went back and looked at the listing for this device, it stated SPI Bus not I²C ! So it began to become apparent that this screen had an SPI interface. SCL and SDA would logically seem to be SPI clock and data (MOSI) respectively but other pin labels didn’t match normal SPI protocol labels. Reading several resources for other different screens and looking at the source code for the examples in the Arduino IDE Examples library lead me to find the correct connections to power and use this screen.

Power is self explanatory. LED adds a little extra brightness to the screen but it does still work if not connected. I’ve seen resistors added in series here and even variable ones to vary the brightness but I’ve ran it directly connected on this screen with no issues and wouldn’t want it dimmer as its not ultra bright. Connect it to the 5V pin of the NodeMCU to get 5V from the USB connection, this will make the screen nice and bright and clear. SCL is the SPI clock and goes to the NodeMCU’s hardware SPI pin (pin GPIO18). SDA is actually the SPI MOSI connection and goes to the NodeMCU’s SPI MOSI pin (GPIO23). RS is a Regsiter Select pin for ST7735 driver chips, this maps to a variable called TFT_DC in the Adafruitcode (explained later) that I was using for testing. This controls whether we are sending a command to the ST7735 chip or actual data. I think that Adafruit call it DC meaning Data Control, but I’m not sure. On some boards it may even be referred to as A0. For our purposed we connect it to GPIO2. RST is the screen reset and and is connected to pin GPIO4. These last two can connect to any NodeMCU pins that are not used for other functions. CS is Chip Select (usually referred to as Slave Select in the SPI protocol) and again can connect to any pin but I use the official SPI SS for the ESP32, GPIO5. If this is pulled low then this device can receive or send data on the SPI bus. If only one device in your design you could pull this low permanently and not use GPIO5.

Driver CodeWhen presented with this board (as mentioned above) it was difficult to work out where wires should go and what driver software I needed for the display. Looking at the solitary chip on the board and Googling revealed nothing. So I went back to the sellers listing and found buried deep in a sub-page description the phrase “7735 drive”. Googling this revealed Adafruit had written some drivers for this chip for a board they had created (which also had an SD card slot on it as well). It was not surprising I didn’t find the 7735 chip on the board as this chip is designed to by embedded onto the back of the screen. It was being armed with this source code and other web pages dealing with different chip sets but similar displays that I managed to work out (with a little trial and error) the connections talked about previously above. Initially I used the Adafruit driver code but gave issues with this screen (as it was designed to work with the one they sell). Look below.

Also when the screen orientation is rotated (in software) so you can write to the display any way up then more things either correct themselves or mess up again.

Fixing the ST7735 driver to work with this screen.So we have some work to do still to make this work well with our display. The driver we have used to get this up and running was not designed for this display exactly. Things appear clipped and off screen. There were other issues with colour (i.e. red was blue and blue was red amongst other colour problems) and other graphics routines were not correct. I won’t bore you with all the tiny re-writes I did but just supply you with the new driver for this particular display. This driver is very specific, i.e. only targeting this display and resolution but it may well work with many other similar displays. At the time of writing I have no other displays to test with but will be expanding the driver code as and when required. The full driver code is available from the link below, add it into your Arduino in the usual manner (Adding libraries to the Arduino IDE.)

Load up the example code that should now be available at “Files->Examples->XTronical ST7735 Library->GraphicsTestESP32”. This is basically the Adafruit example with just some tiny changes (It goes through all the tests for each rotational position of the screen) so that it uses the new driver file and slightly altered initialisation routine.

M5Paper is M5Stacks latest core device with a touch enabled E-ink display. Powered by the ESP32-D0WDQ6-V3 this is our first device to integrate a super sized 540*960 @4.7" E-ink display,which supports 16 gray scale levels. The display is a GT911 capacitive touch screen,which supports two point touch and a variety of gesture controls . Compared to a regular LCD,E-ink displays are easier on the eyes, which makes them a great choice for reading or viewing for longer periods. Other benefits are the low power consumption and the ability to retain the image even if power to the display is terminated. Integrated in the CoreInk are an multi-function button for operation, SHT30 temperature and moisture sensor, physical buttons and an TF-card(microSD) port for data storage.

WT32-SC01 is an ESP32 Development board with a 3.5-inch color touch screen. The touch screen enables a new way of interacting with the ESP32. The board is equipped with a graphical user interface (GUI) firmware, which supports graphical drag-and-drop programming and helps users develop a customized control platform.

A beautiful 3.5” touchscreen display, based on ESP32-WROVER, with a built-in 2M pixel OV2640 camera, makes it an ever perfect platform for your ESP32 projects.

Makerfabs ESP32 3.5” Touch with camera is absolutely open for makers, and besides, Makerfabs provide plenty of Demos to help the users on the usage. Have a try at this fantastic display in your next ESP32 project!~

ESP-LCD is a multimedia smart-control solution built around ESP32-S2-HMI-DevKit-1 and an LCD capacitive touch screen. With ESP-LCD, users can easily realize a hardware network, and achieve remote or smart-touch control, data visualization, music playback, recording, etc. ESP-LCD is suitable for several smart-control scenarios involving smart clocks, air-quality detectors, smart audio control, and various other applications based on touch screens.

ESP32-S2-HMI-DevKit-1 is a development board based on the ESP32-S2-WROVER module. It has a 4.3-inch TFT-LCD, and a capacitive touch panel with a resolution of up to 480×800 and an initial start-up time that is less than 200 ms. ESP32-S2-HMI-DevKit-1 has various components, including a light sensor, a temperature and humidity sensor, a MEMS sensor, a micro-SD card connector, a TWAI® interface (compatible with CAN 2.0) etc. On top of that, it also supports functions, such as LVGL GUI development, music playback, and recording.

Ms.Josey

Ms.Josey

Ms.Josey

Ms.Josey