lcd display brightness control in stock

For the video display developer LCD panels are available in many sizes and resolutions, they are also available with many choices of maximum brightness. The following considers the topic of LCD panel brightness, the choices, the methods for adjusting brightness and some brightness adjustment scenarios.

LCD panels are generally rated as to their maximum brightness level which is expressed in Nits, it is equal to Candela/sqm (cd/m2), and this will be at a particular color temperature as noted in the specification, usually 10,000 K. In terms of a practical understanding, the following is a rough guide:

Outdoor displays range from a low end of 700 nits to typically 1,000 or 1,500nits and up with 2,000~2,500nits and even up to 5,000nits seen with some models. This may include standard LCD panels, custom LCD panels as well as custom cut LCD panels.

Virtually all LCD panels have a LED backlight these days, these are powered by an LED driver board. Brightness control via the driver board will be by one of two methods:

PWM (Pulse Width Modulation): This varies the duty cycle of the backlight “on time” – it is predominant in modern LCD panel LED backlight designs to enable support for digital brightness controls.

Analog: Uses a simple variable voltage to adjust brightness, for example this might be a dial or slider type potentiometer / variable resistor. To see how to enable analog backlight adjustment visit: https://www.digitalview.com/blog/brightness-adjustment/

One of the advantages of LED for the backlight is the range of adjustment that is possible, however it is important to note that the range varies significantly from model to model. Some industrial panels can be turned to very low light levels making them suitable for use in special environments such as at night. Lower cost panels limit the range of brightness to what might be required for typical usage, whereas panels with full range dimming from full off to full on require more complex backlight drivers.

Backlight lifetime: Many LCD panels have a backlight lifetime rating of 50,000 hours (typically measured to half brightness), this can be extended by running the LED backlight at a lower brightness level. Some panels may only offer 30,000 hours as a lower cost solution while other panels may offer up to 100,000 hours for high end applications.

An LCD panel backlight may be constructed so the LED’s are mounted directly behind a light guide diffuser, or they may be mounted along one or more edges of the light guide.

Active backlight: This is a function of some LCD panel backlights to automatically adjust the backlight brightness in response to the image. For more advanced systems there is an LED array making up the LED backlight, this adjusts the brightness in areas localized to the image being shown. This can greatly enhance the brightness across the display and is being used primarily with video, for example on consumer TV sets. It is not useful to all image types, for example a spreadsheet or content like maps or data is not likely to benefit.

Local dimming: Some LCD panels with direct LED may support local dimming so the LED’s are dimmed in response to the image close to them. This will not be at the same resolution as the LCD panel itself but will help greater contrast over the display by enhancing the brightness in bright areas of the image and darkening the image in dark parts of the image.

For the LCD monitor manufacturer it is important to consider that any covering over the LCD panel will reduce the brightness. For example the protective glass over a digital signage display, or a touch screen, or a semi-silvered mirror. So if a specific brightness is required the measurement should be taken with these in place.

There are various relatively low cost brightness meters available, typically in the couple of hundred dollars range. It is difficult to comment on the accuracy of these but we have found them to be within 5% of each other, though more importantly they do appear to be quite consistent in measurement so good for measurement comparisons. For more accurate measurement there are light meters from companies such as Minolta that can be calibrated, the cost may run into several thousand dollars.

Examples of light meters costing a few hundred dollars include SpyderX by Datacolor (needs a PC), a handheld meter is the SM208 by Sanpometer (search SM208 meter). Note: Many light meters, including smartphone apps, will be meters used for photography and not give readings in nits (or candelas). LCD panel specifications are typically measured using nits.

PWM and Analog: Most Digital View LCD controllers support PWM and Analog as a method for adjusting the backlight brightness level (this is noted in the column headed “Other” on the controller board summary table: https://www.digitalview.com/controllers/lcd-controllers-home.html. Also see https://www.digitalview.com/blog/brightness-adjustment/ for a guide to using a dial or slider type variable resistor to adjust the backlight.

DPMS (Display Power Management System): The backlight will be automatically turned off after a period if there is no valid video signal being received.

Ambient light sensor: The backlight is adjusted for brightness or powered off depending on ambient light conditions. This uses a light sensor attached to the LCD controller board, see https://www.digitalview.com/blog/light-sensor-app-note/ for more details.

The specifics of the backlight control are documented separately for each LCD controller model (product summary here) in the product manual available for download on the product page.

Note: There are two ways to adjust the perceived brightness of a LCD panel or LCD monitor, the backlight and the black-level. Very often, particularly in the past, the monitor brightness setting adjusted the black-level, this adjusts the LCD but not the backlight.

Color, color temperature etc: In addition to adjusting the brightness other settings may be adjusted as well. For example the color temperature or for example a switch to green monochrome for night vision.

Night-safe lighting (update) : Dual-rail backlights can also be supported. These special backlight enable normal brightness and extreme low level brightness with custom night-safe lighting. Contact us for details.

Note: We have a blog on methods for implementing an ambient light sensor with Digital View LCD controller boards to automatically adjust the backlight or system power, see: Ambient Light Sensor

Update March 2019: Most of the above remains unchanged except for the increased availability of high bright LCD panels of around the 1,000 nit to 2,500 nit range. AUO for example has a number of large size LCD panels with 1,500 nit brightness for the digital signage market. Tianma has panels under 20″ with 1,000 nit to 1,500 nit brightness for various outdoor applications.

The other change is that high bright panels are now increasing edge-lit, this makes the panels thinner and these panels tend to use less power than the previous models. One of the benefits for monitor designers is easier heat management and reduced overall display system costs.

Brightness level in LCD panels is controlled by pulse-width modulation (PWM). PWM is a simple turning the switch between supply and load on and off at a fast rate. The longer the switch is on compared to the off periods, the higher the power supplied to the load is. The PWM switching frequency has to be much faster than what would affect the load, which is to say the device that uses the power. Typically, switching frequency is set to about 200 Hz in most LCD backlight control units.

The term duty cycle describes the proportion of time when switch is on to the regular period of time. A low duty cycle corresponds to low power (low brightness in our case), because the power is off for most of the time. Duty cycle is expressed in percent, 100% being fully on (max. backlight brightness).

PWM waveform is generated by PIC12 microcontroller (U3) on our PCB. The duty cycles of PWM depends on voltage measured on its pin 7 (AN0) that is used as an input to internal analog to digital converter (ADC). We supply our LCD bundle with ambient light sensor connected to this pin. PIC12 measures voltage 10 times every second, and smoothly changes PWM duty cycle. Full cycle of brightness change takes 2 seconds to avoid screen flickers. Here is short video that shows how this works.

Now you can turn knob to control brightness of screen. Please, be aware that it has the same delay of 2 seconds to change brightness to new level. And finally, short video of manual brightness control in action.

Also, you can increase default brightness level by adding resistor in parallel with light sensor. The lower value of resistor will provide higher default brightness level.

Intel Display Power Saving Technology (DSPT) is a power-saving feature in Intel’s latest version of mobile graphics chips. These graphics chips reducing power consumption on the computer by altering the brightness and contrast of the display.

Intel DPST controls the LCD backlight, by reducing the backlight as needed they can save power. This can be important on mobile computers running off the battery. The aim is to automatically reduce the backlight brightness while maintaining good visuals on-screen. It analyzes the image to be shown, and it uses equations to change the chroma value and reduce the brightness of the backlight simultaneously. This means you should not see any distortion to the image on-screen. Intel says that 70% of the power that the backlight uses when watching media is saved.

I bought a cheap ($12) 3.5 inch LCD screen from ebay and it worked fine with the waveshare35a and the builtin piscreen overlays - including touch events. But one thing I could not do was control brightness.

The fix was easy and required only 2 components - 2N4401 (or any other comparable NPN transistor) and a 10k resistor. But the tricky part was removing the connection from 3.3v to common anode of backlight. I used a hobby knife to remove the trace which is under the board - right where C1 meets 3.3V. Will add a picture next time I open up the LCD module.

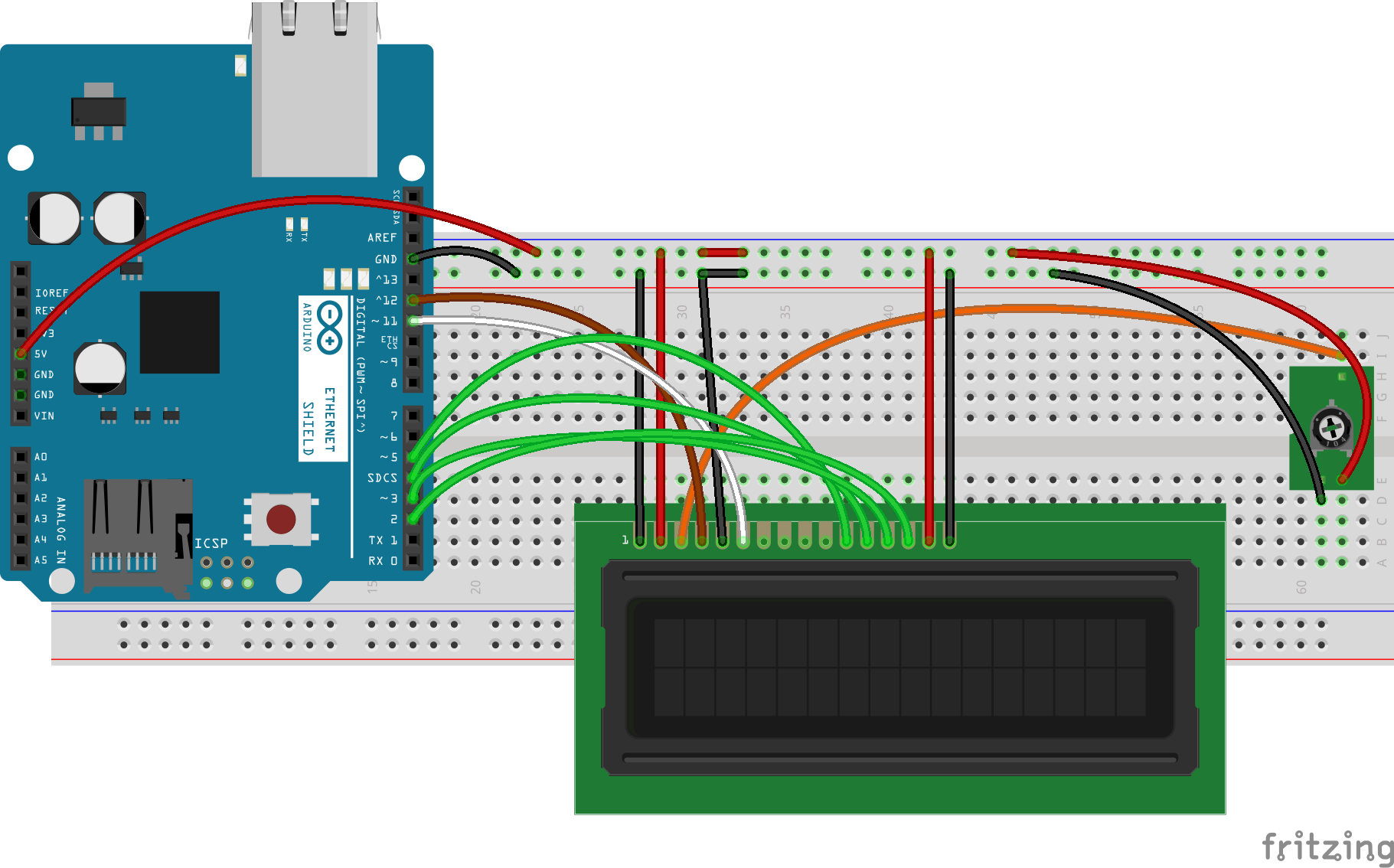

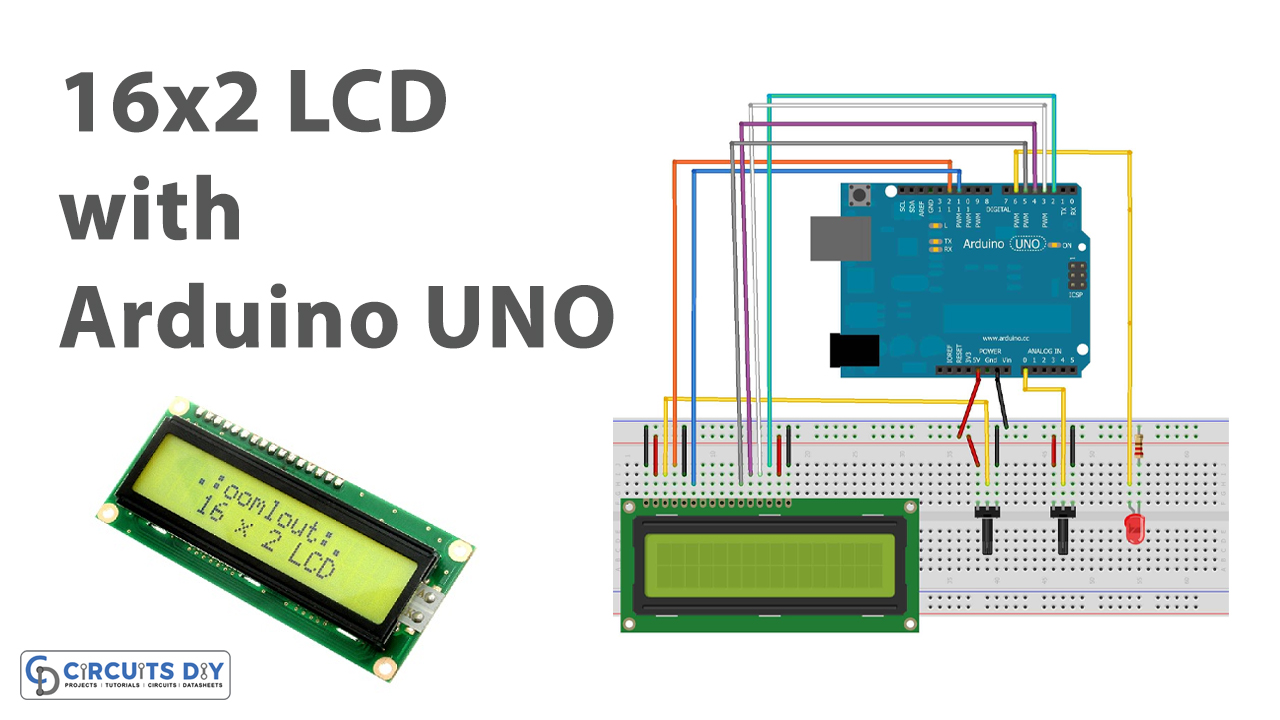

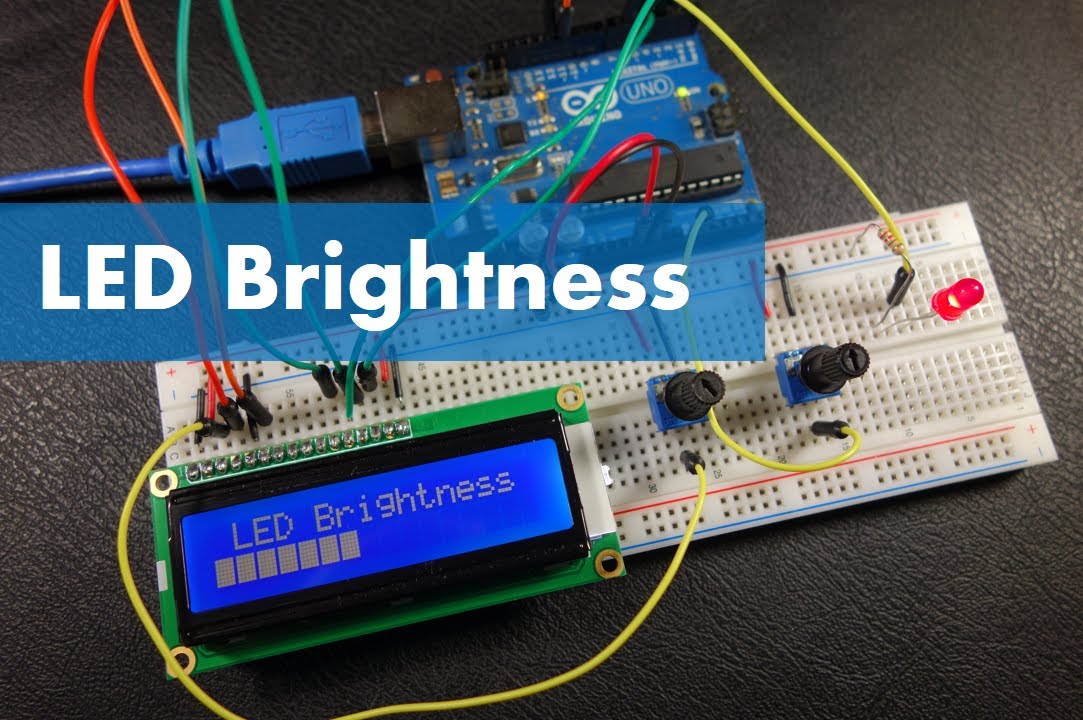

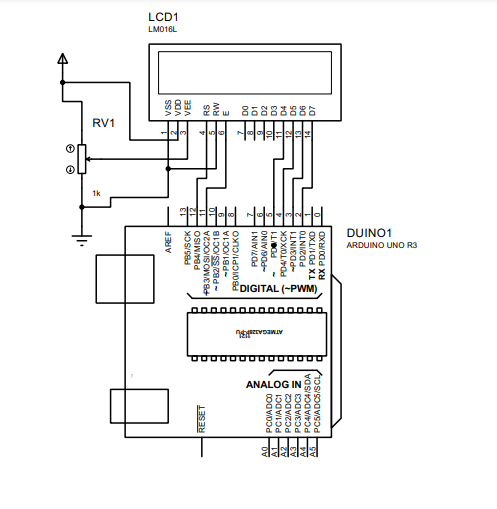

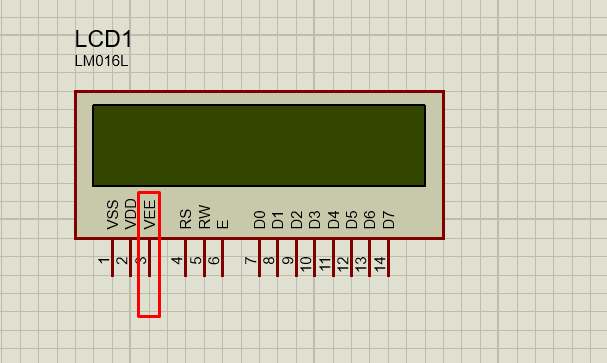

In this project we’re going to display the LED brightness on a LCD 16×2 with a progress bar. This is a good Arduino beginner project for getting started with the LCD display. We provide a list of the parts required, schematic diagram, and code.

The simplest and inexpensive way to display information is with an LCD (liquid crystal display). These are found in everyday electronics devices such as vending machines, calculators, parking meters, printers, and so on, and are ideal for displaying text or small icons. The figure below shows a 16×2 LCD front and the back view.

This LCD has 2 rows, and each row can display 16 characters. It also has LED backlight to adjust the contrast between the characters and the background.

This post showed you a basic example on how to use the LCD display with the Arduino. Now, the idea is to modify the sketch and use the display in other projects.

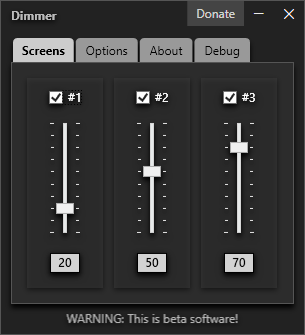

Select the Networkicon on the right side of the taskbar, and then move the Brightnessslider to adjust the brightness. (If the slider isn"t there, see the Notes section below.)

Some PCs can let Windows automatically adjust screen brightness based on the current lighting conditions. To find out if your PC supports this, select Settings >System>Display. Select Brightness, look for theChange brightness automatically when lighting changes check box, and then select it to use this feature. This automatic setting helps make sure your screen is readable wherever you go. Even if you use it, you can still move theBrightness slider to fine-tune the brightness level for a built-in display.

You might also see another check box displayed: Help improve battery by optimizing the content shown and brightness. Some Windows PCs can automatically adjust the screen brightness and contrast based on content that’s displayed on your built-in screen. For more info, see Adaptive brightness and contrast in Windows.

You might not see the Brightness slider on desktop PCs that have an external monitor. To change the brightness on an external monitor, use the buttons on it.

If you don"t have a desktop PC and the slider doesn"t appear or work, try updating the display driver. Select Search on the taskbar, type Device Manager, and then select Device Manager from the list of results. In Device Manager, select Display adapters, then select the display adapter. Press and hold (or right-click) the display adapter name, then select Update driver and follow the instructions.

Some Windows 11 PCs can automatically adjust the screen brightness and contrast based on content that’s displayed on your built-in screen. For example, if you’re watching a video that has a dark scene, followed by a brighter scene (for example, one that shows a bright sunny day), the brightness and contrast may change. This is normal.

Content adaptive brightness control provides ideal brightness and contrast levels, while saving power and providing longer battery life at the same time. If these sudden brightness changes are distracting, or if you work in photo and video apps where color accuracy is important to you, you can turn this off any time. When you turn it off, it can result in shorter battery life.

In Display settings, select Brightness, then clear the Help improve battery by optimizing the content shown and brightness check box. You can select the check box to turn this back on any time.

Some Windows PCs can also adjust the screen brightness automatically based on the light around you. For more info, see Change screen brightness in Windows.

Lux isn"t your stock brightness app. It wisely adjusts the brightness of your display based on environment light. Lux will automatically lower the brightness of your display to make it not only comfortable to read, but to also preserve battery power.

Lux is also able to adjust the screen temperature of your display automatically to make it appropriate for night usage. Lux is completly automatic. Just teach it how to behave and it will dim or light your screen for you!

Starting firmware version 3.9.0, for the Original Prusa MK3S manufactured after June 2019, it is possible to adjust the brightness of the screen directly from the LCD menu and also have the option of dynamic lighting, triggered by navigating the LCD menu.

Printers received before June 2019 including the MK3 model may not have the compatible components for this feature. EinsyRambo rev. 1.1a, and an LCD panel supplied after June 2019 is required. These can be purchased in our eshop (note that you have to be logged in).

If this setting does not appear, we recommend contacting Microsoft Support or your system manufacturer for information on how to disable the Adaptive Brightness. Adaptive Brightness is a setting provided by Windows that uses an ambient light sensor in the system to automatically adjust a display"s brightness to the surroundings.

Do you have a Scriptel LCD tablet and need to adjust the brightness or contrast? Perhaps your work environment is dark (movie theater or warehouse), or has a lot of light (dental clinic, reception desk) and you need to adjust the brightness or contrast for better clarity?

You can alter the brightness or contrast on your Scriptel LCD tablet screen (ST1525, ST1526, ST1550, ST1551, ST1570, ST1571) using the ScripTouch Toolbox (except on the Desktop LCD models – ST1500/1B. On these models only, the backlight may be turned on or off, but cannot be dimmed). This is how you do it.

Great! Now, using the arrows on the Brightness and Contrast sliders, move them to the right or left to adjust your LCD tablet screen to your own requirements. You will see the result on your LCD tablet screen instantly.

The present invention relates to an apparatus and method for controlling the brightness level of a display, and more particularly, to an apparatus and method for controlling the brightness level of a liquid crystal display in an electronic device such as a notebook computer.

Generally, a notebook computer providing a portable convenience is provided with a liquid crystal display (LCD) integrally constructed with a main body. The LCDs can be fabricated or produced in various kinds and sizes according to manufacturers.

As shown in FIG. 1, an inverter power is supplied to the LCD through an inverter cable under the control of a microprocessor. The brightness of the LCD is controlled regardless of manufacturer or the LCD"s characteristics.

LCDs manufactured by different suppliers have different sizes and have different inherent optical characteristics. In a conventional LCD a cold cathode fluorescent lamp (CCFL) device is provided at an upper side or a lower side as a light emitting device. The CCFL device emits light in response to a high voltage applied through the inverter, which controls the brightness of the LCD.

The CCFL devices also have different inherent optical characteristics according to the manufacturers. However, the manufacturers producing notebook computers use the same inverter to operate all CCFL devices equipped in various LCDs, regardless of the particular characteristics of the CCFL devices.

Because the LCDs and the CCFL devices have different inherent optical characteristics, although an equal level of power is applied to the CCFL devices by the use of the same inverter, the brightness levels are different depending on the individual device characteristics.

Even when the LCDs and the CCFL devices are manufactured by a single manufacturer, and even though they employ the same inverter, the brightness levels of the LCDs may be different because of small differences between individual devices.

In order to solve the aforementioned problems and maintain the brightness of the LCDs at a constant level, the power applied to the CCFL device through the inverter is set based on the assumption that the LCD has relatively bad optical characteristics. In this case, an LCD having relatively good optical characteristics will operate at an unnecessarily high brightness level. This wastes battery power, and can dazzle a user"s eye.

For instance, when it is assumed that in notebook computers using the same inverter, the appropriate brightness level is 30 nit (Cd/m2), an LCD #A having relatively bad optical characteristics needs 2 Watts of power to maintain the brightness level at 30 nit. However, an LCD #B having a relatively good optical characteristics needs only 1.5 Watts of power. In spite of the above fact, the manufacturers set the consumption power applied to both LCD #A and LCD #B at 2 Watts to ensure that all computers will output 30 nit. Because of this, the LCD #B wastes the power of 0.5 Watts ineffectively, and too bright a picture is outputted on the screen of computer #B.

Accordingly, the present invention is directed to an apparatus and method for controlling a brightness of a display that substantially obviates one or more problems due to limitations and disadvantages of the related art.

An object of the present invention is to provide an apparatus and method for controlling a brightness of a display. A device embodying the invention includes a sensor for detecting the brightness of an LCD. The device may be a portable electronic device such as a notebook computer, a PDA, and a cellular phone. A device embodying the invention variably controls the brightness of the LCD at an optimum level with reference to the brightness detected by the sensor.

An apparatus embodying the invention utilizes a sensor for measuring the brightness of the display. A memory is provided in the display for storing brightness level information therein. A control part outputs a corresponding brightness level control signal by using the brightness level information. An adjusting part adjusts the brightness of the display according to the control signal.

A method embodying the invention includes the steps of reading out a brightness level control information stored in a memory unit, measuring the brightness of the liquid crystal display using a sensor, and variably setting the brightness level control information which is stored in the memory with reference to the brightness measured by the sensor.

In devices and methods embodying the invention it is possible to control the brightness of the LCD at an appropriate level, and thereby prevent the unnecessary consumption of power.

FIG. 2 is a block diagram schematically showing a construction of a notebook computer to which a brightness level control method embodying the invention is applied;

FIG. 3 is a table showing brightness level control information so as to illustrate a brightness level control method of an LCD embodying the invention;

FIG. 4 shows a format of EDID (Extended Display Identification Data) configured in VESA regulation and including brightness level control information of an LCD;

FIG. 8 is a table showing brightness controlled by the method shown in FIG. 7 in each level, and control codes corresponding the controlled brightness.

FIG. 2 is a block diagram schematically showing a construction of a notebook computer to which a brightness level control method of an LCD according to the invention is applied. The notebook computer 100 includes an LCD 10, a sensor 20, an inverter 30 and a microcomputer 40. The LCD 10 also includes a CCFL device arranged at an upper side or lower side thereof.

The sensor 20 is fixedly or movably installed at a center or one side of the LCD 10 to detect the brightness of the LCD 10. The sensor would then output an electrical signal indicative of the brightness. As the sensor 20, a passive device such as a small-sized photodiode can be used.

When the brightness control procedure has been finally completed by using the detected brightness, the movable sensor 20 can be configured to be equipped in an outer case invisibly and/or to be again used for detecting the brightness level around a PDA or the like, for instance.

In addition, the sensor 20 may be configured in the form of a jig in the production line. In this instance, the sensor 20 may be provided with a connector configured to connect with the microcomputer 40 so as to output a brightness value measured by the sensor 20. Alternatively, the sensor 20 may be configured in a movable structure.

The inverter 30 variably controls a high voltage of power applied to the CCFL device serving as a back light lamp of the LCD 10 according to the control of the microcomputer 40. The microcomputer 40 reads out brightness level information stored in an inner memory to control the operation of the inverter 30.

In other words, whenever a user presses a brightness control button, for instance, the increase or decrease key on a keyboard, a SMI (System management interrupt) or SCI (system configuration interrupt) is generated. If a SMI or SCI is generated, an SMI handler of a corresponding system bios or a corresponding routine of the operating system can control the brightness level control information of the inverter 30.

The microcomputer 40 variably sets the brightness level control information that is stored in advance with reference to electrical signals detected by the sensor 20. For instance, the brightness level control information of the LCD includes an LCD brightness level, an LCD brightness specification, control codes and inverter power. This information can be stored in a combined structure. The control codes are variably set as arbitrary values by the microcomputer 40, system BIOS or operating system.

If the control codes of the brightness level control information of an LCD #A and an LCD #B having different optical characteristics were set to be the same values, LCD #B, which has good optical characteristics relative to LCD #A, would attempt to perform the same brightness control operation as LCD #A. However, the brightness level of LCD #B would exceed an appropriate brightness, so that power would be wasted and a user"s eye may be influenced badly.

The brightness level control information of an LCD includes an LCD brightness level, an LCD brightness specification, control codes and inverter power. This information can be defined in an EDID (Extended display identification data) format under the regulation of VESA. Such EDID information can be stored in an inner memory of the LCD.

For instance, when the manufacturers set the brightness control information to correspond to the vendor/product ID of each LCD, the system bios, operating system or microcomputer can read out the brightness control information through the LCD interface and store the read brightness control information in the system memory. It is possible to control a corresponding brightness from the stored information.

In other embodiments, when the LCD as a host writes the brightness control information in the system memory, the system can use the recorded information to control a corresponding brightness.

In addition, brightness level information corresponding to when the LCD is in a high temperature state can be provided within the EDID specification. This information is provided because as the temperature of the LCD rises, the brightness level rises too.

In order to provide the LCD with brightness level information related to high temperature in the EDID specification, a temperature sensor is also installed. The LCD temperature information sensed by the temperature sensor is provided to the system through the interface.

When a user continues to use the system, the system bios, operating system or microcomputer can periodically check the temperature and use the brightness level information related with the high temperature characteristic, and the sensed temperature, to control the brightness of the LCD. By doing so, when the temperature of the LCD rises to a high temperature, unnecessary power consumption is saved to thereby extend the battery life.

Accordingly, as shown in FIG. 5, the microcomputer 40 reads out and confirms a control code selected and designated by a user from the brightness level control information of the LCD which is stored in advance. The microcomputer then outputs a control signal corresponding to the read control code to the inverter, controls the power applied to the LCD, for instance, LCD #B to an appropriate level, and confirms the brightness of the LCD measured by the sensor 20.

Then, with reference to the confirmed brightness, it performs a series of control code reset operations to variably set the values of the control codes. For instance, in case of LCD #B of FIG. 3, if the value of the sensed brightness of the LCD at current level L1 (control code: 10, Spec: 10 nit) is 15 nit (e.g., 1.1 watt), the microcomputer controls the code value until the sensed brightness value decreases to 10 nit gradually and finely. In an example of FIG. 6, it is shown that the code value is adjusted to 0.9 watt.

At this time, the set code values are newly added to the code table and the respective brightness levels 1 to 8 are optimized in this manner so that a new code table suitable for the current LCD is made.

Accordingly, as shown in FIG. 6, the reset control codes become a new code controlling the inverter variably. The new codes optimize a power supplied to the LCD, so that the brightness of the LCD is adjustable to an appropriate level. Additionally, inefficient power consumption can be prevented. The system can also adjust a corresponding brightness of the LCD by using the brightness information that is set in the EDID specification in advance.

Meanwhile, the micom 40 resets the brightness level control information of the LCD and selectively carries out the operation of variably controlling the inverter by a user"s key input, thereby preventing a continuous consumption of the power required for the brightness adjustment operation.

Referring to FIG. 7, a control code value is read out and a level L1 is set as a variable value (S71). In other words, among the variables having one or more brightness levels, a value of a predefined level or an arbitrary level is set as a variable value.

A pulse width modulation (PWM) type control code corresponding to the read information is outputted (S72). The control code is converted into a binary code and used as information.

The adjusted LCD brightness is then sensed by a sensor (S73). The brightness value previously stored at the step S71 is compared with the actual brightness value sensed at the step S73 (S74). If both values are equal to each other, the control code is set and the process is performed with respect to next levels until the level 8 (S75, S76, S77, S78).

If the sensed value is greater than the previously stored value, the control code value is decreased by a predefined value (e.g., unity). Then, a PWM code value corresponding to the decreased control code value is outputted (S79, S80) and the process is repeatedly performed until the level=8.

However, if the sensed value is not greater than the previously stored value, the control code value is increased by a predefined value (e.g., unity). Then, a PWM code value corresponding to the increased control code value is outputted (S79, S81) and the process is repeatedly performed until the level=8.

In addition to a notebook computer, the present invention is also applicable to various electronic equipments with an LCD, such as a personal digital assistant (PDA) and mobile communications equipment such as a cellular telephone.

In some embodiments of the invention, the brightness sensor can be incorporated into the device having the LCD screen. In these embodiments, the method shown in FIG. 7 can be periodically performed to periodically optimize the PWM Control Code values used to control the inverter. This allows the device to adjust the power applied to the inverter over time to always maintain the appropriate screen brightness.

In other embodiments of the invention, the sensor may be incorporated into a jig or fixture used during manufacture of the LCD screen. In these embodiments, the screen would be checked after it is manufactured to determine the appropriate settings that will result in optimal screen brightness. These brightness settings would then be stored in a memory of the LCD itself. The brightness settings will be then be accessed by a microprocessor that is later coupled to both the LCD screen and a power inverter to ensure that the power inverter supplies the optimal power to the LCD screen for each selected brightness setting.

Ms.Josey

Ms.Josey

Ms.Josey

Ms.Josey