lcd display assembly code free sample

Text: as global variables in the C program as well as in the called assembly function. In order to refer , following message appears on the LCD display : S2 = ASM S3 = C 3. To select the mode for assembly , Assembly Function When returning values from an assembler function to a C language program , registers can , program and also their corresponding global variables in assembly function, the arguments are passed via , with Assembly Language 4.0 Passing Arguments By Global Variables In this method, a prototype for the

Text: program in assembly language , one must first use a text editor to edit the program source file with the , assembly language program to machine code and set mask options. For more information on the instructions , for preparing a program in assembly language includes editing, assembly , setting mask options , 1011011B 2. Code Area A typical program in the W741xxxx microcontroller assembly language includes the , LCD RAM addresses. In the program , users may not write a number as LCD RAM directly. Instead, they

Abstract: lcd cross reference 40 pin TEXTOOL mini project using microcontrollers HOPE3000 holtek trace code on box label dipswitch dot matrix printer circuit diagram datasheet HT48C10-1 IDE3000

Text: included in the application program by using the Project command in the Options menu. (Refer to the Cross , used to display certain actions when in the debug mode, such as displaying variable values , appearing in this User"s Guide is believed to be accurate at the time of publication. However, Holtek , . 44 To Assemble or Compile a Program . 44 , . 49 To Emulate the Application Program . 50

Abstract: PIC16F877 Free Projects 16F877 sample programs with lcd PIC16F877 SAMPLE C PROJECTS PIC16F877 Free Projects i2c PIC16F877 assembly language codes picdem 2 plus demo board examples 16F877 sample programs PIC16F877 Free Projects keypad PIC16F877 mplab programmer circuit

Text: has an LCD display for error messages, keys to enter commands and a modular detachable socket assembly to support various package types. In stand-alone mode, the PRO MATE II can read, verify, or program , MPLAB ® Software Language Support To make the PICmicro device operate as desired in the application, a software program needs to be written for the microcontroller. This software program needs to be written in , . This demo board also includes peripherals that allow users to display data on an LCD panel, read from

Abstract: MPLAB-C18 keypad PIC16F877 Projects with assembly language PIC16F877 mplab programmer circuit projects microcontroller 16f877 16F877 sample programs PIC16F877 Free Projects PIC16F877 Free Projects with assembly language PICmicro Reference Manual PIC16F877 SAMPLE C PROJECTS

Text: allows you to : · Edit your source files. This includes: - MPASM assembly language - MPLAB-CXX `C" , ® Software Language Support To make the PICmicro device operate as desired in the application, a software program needs to be written for the microcontroller. This software program needs to be written in one of , display for error messages, keys to enter commands and a modular detachable socket assembly to support , . This demo board also includes peripherals that allow users to display data on an LCD panel, read from

Text: 4.4.8 Switching to subclock operation and watch display program , . 48 2-7 Connection to 8-Bit Bus Width Unit Arranged in Space Required for Program Space/16, To our customers, Old Company Name in Catalogs and Other Documents On April 1st, 2010, NEC , circuits, software and other related information in this document are provided only to illustrate the , described in this document for any purpose relating to military applications or use by the military

Abstract: mpasm assembly fuzzy logic library pic c code Temperature control pic16 project PIC16C74 Free Projects i2c handbook fuzzy logic PICMASTER fuzzy logic control microchip write program in assembly language to display LCD PIC16C54 rom based project

Text: operate as desired in the application, a software program needs to be written for the microcontroller. This software program needs to be written in one of the programming languages for the device. Currently , a rich directive language to support programming of the PICmicro. Directives are helpful in making , memory at VDD min and VDD max for maximum reliability. It has an LCD display for error messages, keys to enter commands and a modular detachable socket assembly to support various package types. In

Abstract: assembly language program for speed control of dc lcd interface with cy8c27443 CY8C27443 write program in assembly language to display LCD CY7C64013 LT1587 PSOC lcd user module led display board using psoc P10 led module

Text: Assembly language , may be main program or subroutine that create by developers or the software tools. . IN Assembly source program of each module that created by Device Editor in PSoC Designer. P2[4] P2[6 , program and all fiel in project Write and edit the developed soirce program Display the status of build , Even if you have never worked in the C language before, the product quickly allows you to create , commands allow the designer to read and write program and data memory, read and write IO registers, read

Abstract: microcontroller ST7 datasheet datasheet keypad 4x4 assembly code i2c software program st7 4x4 keyboard AN1041 keyboard 4X4 datasheet for 4x4 keyboard microcontroller ST7 AN1018

Text: device such as E²PROM. With the aid of flowcharts and an example source in assembly language , this , examples how using the indirect addressing mode allows the programmer to write more compact code in both , purpose is to execute, from the ST7 through the on-chip I²C interface, a write and a read in the external , peripheral hardware. The program is written in C language . It implements the I2C master transmitter and , corrupted or not. An example interrupt service routine written in assembly language is provided at the end

Text: program . 1.3 AN986: USING THE ST7 INDIRECT ADDRESSING MODE The ST7 assembly language instruction set , code in both Assembly and C language programs. 1.4 AN987: ST7 IN-CIRCUIT PROGRAMMING This , ST7 device without specific I2C on-chip peripheral hardware. The program is written in C language . It , assembly language is provided at the end of the document. 2.16 AN1048: ST7 SOFTWARE LCD DRIVER This , and program in EPROM have been corrupted and if so not to run the user"s program . The program

Text: become a necessity to simulate a program written in a high-level language . Some simulators â the , sent to the LCD at various points of the program in order to trace the execution path of the program , simulators enabling the user to set breakpoints and display and modify registers and program variables , PICFlash 2 from the mikroElektronika language compilers to watch and modify program variables, to set breakpoints and to single-step the program . Example Use of PICFlash 2 A simple 7-segment display example

Abstract: burglar alarm based pic diagram MIAC-01 stepper motor based projects labview projects 18F4455 flowcode CAN sample flowcode schematic diagram motor controller 24v Industrial controller

Text: to program with flowcharts, C or Assembly code · Physically and electrically rugged Features · , program will automatically download and start. The MIAC can also be programmed in C and assembly code , that students can program MIAC in their own language . PICmicro and PIC are registered trademarks of , or altering sensor or input values, and see how your program reacts to the changes in the , surface How to connect the unit using screw terminals How to write your first simple program How to

Abstract: sprint plus 48 ST62t30 gang programmer schematic ALL07 UNIVERSAL PROGRAMMER AND TESTER PAC DIP 40 RS232 STAG 200 interface ibm t30 laptop schematic diagram leaper-10 CABLE LEAPER-10 driver ibm t40 lcd needham family emp30

Text: display allowing you to perform all program , read and verify functions without a PC. ChipWriter Portable , s s s s s s Universal Device Support Built in 40 by 2 LCD display with BackLight , in the same packaging. Only one 40 pin PAC is required to program virtually all DIP devices with 8 , reasonably expected to result in significant injury to the user. 2 2. A critical component is any , . Software development tools include a Windows Assembly Language development suite, as well as a graphical

Text: flowchart · Listings of code in Assembly language and C language Program Examples In the following , . . . . . . . . . . . . . . . . Assembly Language Program : Example of D/A Conversion . . . . . . . , . . . . . . . . . . . . . . . . . . . 14-1 Assembly Language Program : DEMO_CLK.ASM . . . . . . . . . . . . . . . . . . . . . . . . . . . 14-3 Assembly Language Program : DEMO_LCD.ASM . . . . . . . . . . . . . . . . . . . . . . . . . . 14-10 Assembly Language Program : DEM_TOD.ASM . . . . . . . . .

Abstract: write program in assembly language to display LCD Toshiba T6963C LCD 240x128 LCD 240x128 interfacing WITH 8051 240x64 toshiba t6963c 240x128 toshiba LCD 240*128 T6963C T6963c toshiba 240*128 240x64 lcd commands 240x64 T6963C

Text: sample program here is written in 8051 assembly language and is designed to work with the hardware shown , the byte in R1 to the ; graphics module as data. ; Start of regular program ; Display graphic , Hantronix LCD modules from 128x128 to 240x128 pixels. This class of module is most commonly used to display , 20h from the ASCII code before sending it to the display . In the bit-mapped mode each byte of data , of a 128x128 display Schematic: The 80C51 microprocessor is connected to the LCD controller chip

Abstract: pic16f877a code asm pwm PIC18F usart init example PIC16f877a example uart codes Project Report of smoke detector using pic PIC18 usart example codes PIC18f458 example C codes mmc card DS51519B 18f452 driving lcd PIC18 C18 codes usart

Text: MPLAB IDE to aid in device setup, code debugging and general support. · Chapter 7: Integrated Language , PC to help write , edit, debug and program code the intelligence of embedded systems applications , language for creating programs, should be used to write and edit code. Assemblers and compilers help make , various points in the program , and to do "what if" checks, changing variable values and stepping through , likely, the person doing so is engaged in theft of intellectual property. · Microchip is willing to

Text: The program uses IIC write operations to send commands and strings of data to an LCD module through , Modules in V850ES Microcontrollers When you use Applilet to generate a C language program for the microcontroller, the program automatically generates the crte.s startup file in assembly language . The crte.s , , the program calls LCD_ClearDisplay() to clear the display . The program then formats a string in the , . 9 3.4.4 Main( ): Main Program for IIC Communication to the LCD Module . 10

Text: symbols used for labels and 1 1. Introduction segments in assembly language programs developed , the format specifications to allow users to include user symbol information in program code files in , simulation. The LCD window refresh period can be set to a value in the range 55 to 550 ms. T Wait · , , which requires connection to an in-circuit emulator, executes the user application program in a , program code one instruction at a time. You are therefore able to trace program execution in detail

Abstract: 24LC32B command words lcd display 16x2 simple 12C508 programmer schematic PIC16F84A Free Projects of LED PICBASIC PRO MANUAL tw523 PICBASIC application note 16F877 sample programs with lcd DS1820 ASM example

Text: next-generation programming language that makes it even quicker and easier for you to program Microchip , write than the quirky Microchip assembly language . The PicBasic Pro Compiler is ABASIC Stamp II like , . This is your program in PICmicro code. At the right of the screen there is a display of the , minimize their use as much as possible. Try to write your code in logical sections and not jump around too , temporary variables, they will do two different things. The program in Listing 2 will write the byte store

Text: tools. · Chapter 6: Mixing C with Assembly Language Modules provides guidelines to using C with MPASM assembly language modules. © 1998 Microchip Technology Inc. DS51112C-page 1 MPLABTM-C17 User , . Mixing Assembly Language and C Modules 6.1 6.2 6.3 6.4 Introduction , Assembly Language and C Variables and Functions .88 Chapter 7. ANSI Implementation Issues 7.1 , PICmicro MCU Programming describes how to use MPLAB-C17 in conjunction with device programming. · Chapter

Text: C with Assembly Language Modules - provides guidelines to using C with MPASM assembly language , Source files, setting language tool to MPLAB-C17 or MPASM · Set Processor in Node Properties of , anywhere in a program where white space can occur. Comments can be many lines long and may also be used to , Chapter 6. Mixing Assembly Language and C Modules Introduction , Mixing assembly language and C variables and functions .78 Chapter 7. ANSI Implementation

Abstract: P16F877A ds33014 pic16f877a projects pic16f877a full instruction set PIC16F877A Free Projects OF FUNCTION GENERATOR P18F452 pic 16f877a programming tutorial free projects for PIC 18f452 free projects for PIC 16f877A using assembly language

Text: before the code is assembled. Unlike the while in the C language , the Macro while is used to expand , , section names are then used to switch between allocating variables and positioning code in program memory , function register. · Click on the PC in the status bar to bring up the "Change Program Counter" dialog , window. · When working with PIC16C9XX parts, select View> LCD Pixel to bring up an LCD pixel display that can be used for simulating the LCD . · When using multiple projects in a workspace, go to the

Text: Peripheral functions Program size efficiency M16C/60 EMI & EMS performance Processing capacity to , Teletext radio GPS Digital pagers Wireless terminals with large LCD Middle to high-quality , 144PFB-A(0.4mm pitch) 6 Introduction to Products in Development M32C/80 Series (Under development , operating at 20 MHz. Outline of the M32C/80 series CPU core In addition to the 32-bit transfer, add , processors prefetch instructions equivalent to the number of pipeline stages. Therefore, when a change in

Text: : Mixing C with Assembly Language Modules - provides guidelines to using C with MPASM assembly language , Add Source files, setting language tool to MPLAB-C17 or MPASM Set Processor in Node Properties of each , Chapter 6. Mixing Assembly Language and C Modules Introduction , Mixing assembly language and C variables and functions .78 Chapter 7. ANSI Implementation , .187 Access to pre-loaded code in ROM 187 Header Files and Libraries

As previously mentioned, it takes a certain amount of time for each instruction to be executed by the LCD. The delay varies depending on the frequency of the crystal attached to the oscillator input of the 44780 as well as the instruction which is being executed.

While it is possible to write code that waits for a specific amount of time to allow the LCD to execute instructions, this method of "waiting" is not very flexible. If the crystal frequency is changed, the software will need to be modified. Additionally, if the LCD itself is changed for another LCD which, although 44780 compatible, requires more time to perform its operations, the program will not work until it is properly modified.

A more robust method of programming is to use the "Get LCD Status" command to determine whether the LCD is still busy executing the last instruction received.

The "Get LCD Status" command will return to us two tidbits of information; the information that is useful to us right now is found in DB7. In summary, when we issue the "Get LCD Status" command the LCD will immediately raise DB7 if it"s still busy executing a command or lower DB7 to indicate that the LCD is no longer occupied. Thus our program can query the LCD until DB7 goes low, indicating the LCD is no longer busy. At that point we are free to continue and send the next command.

Thus, our standard practice will be to send an instruction to the LCD and then call our WAIT_LCD routine to wait until the instruction is completely executed by the LCD. This will assure that our program gives the LCD the time it needs to execute instructions and also makes our program compatible with any LCD, regardless of how fast or slow it is.

Programming Tips: The above routines does the job of waiting for the LCD, but were it to be used in a real application a very definite improvement would need to be made: as written, if the LCD never becomes "not busy" the program will effectively "hang," waiting for DB7 to go low. If this never happens, the program will freeze. Of course, this should never happen and won"t happen when the hardware is working properly. But in a real application it would be wise to put some kind of time limit on the delay--for example, a maximum of 256 attempts to wait for the busy signal to go low. This would guarantee that even if the LCD hardware fails, the program would not lock up.

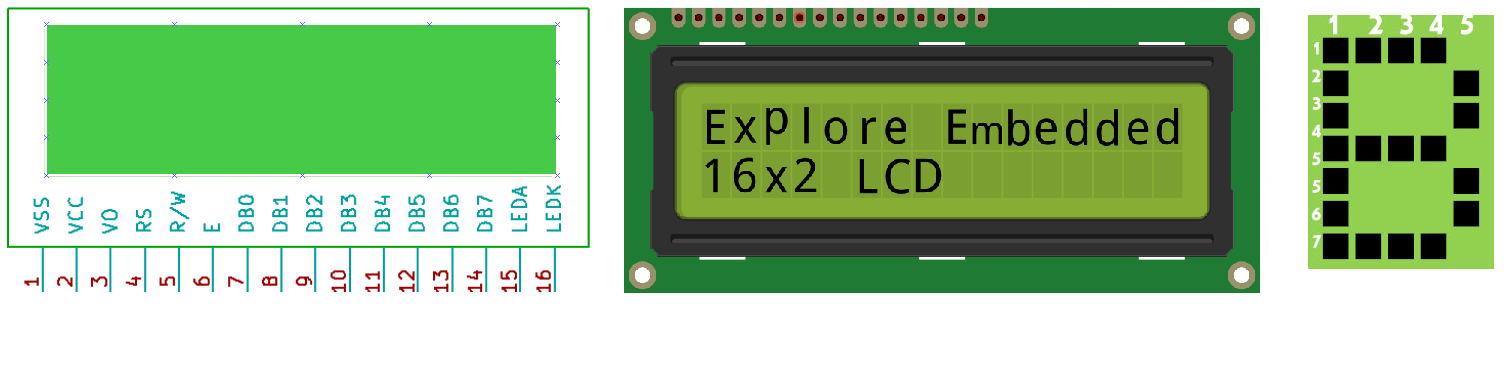

LCD connected to this controller will adjust itself to the memory map of this DDRAM controller; each location on the LCD will take 1 DDRAM address on the controller. Because we use 2 × 16 type LCD, the first line of the LCD will take the location of the 00H-0FH addresses and the second line will take the 40H-4FH addresses of the controller DDRAM; so neither the addresses of the 10H-27H on the first line or the addresses of the 50H-67H on the second line on DDRAM is used.

To be able to display a character on the first line of the LCD, we must provide written instructions (80h + DDRAM address where our character is to be displayed on the first line) in the Instruction Register-IR and then followed by writing the ASCII code of the character or address of the character stored on the CGROM or CGRAM on the LCD controller data register, as well as to display characters in the second row we must provide written instructions (C0H + DDRAM address where our character to be displayed on the second line) in the Instructions Register-IR and then followed by writing the ASCII code or address of the character on CGROM or CGRAM on the LCD controller data register.

As mentioned above, to display a character (ASCII) you want to show on the LCD, you need to send the ASCII code to the LCD controller data register-DR. For characters from CGROM and CGRAM we only need to send the address of the character where the character is stored; unlike the character of the ASCII code, we must write the ASCII code of the character we want to display on the LCD controller data register to display it. For special characters stored on CGRAM, one must first save the special character at the CGRAM address (prepared 64 addresses, namely addresses 0–63); A special character with a size of 5 × 8 (5 columns × 8 lines) requires eight consecutive addresses to store it, so the total special characters that can be saved or stored on the CGRAM addresses are only eight (8) characters. To be able to save a special character at the first CGRAM address we must send or write 40H instruction to the Instruction Register-IR followed by writing eight consecutive bytes of the data in the Data Register-DR to save the pattern/image of a special character that you want to display on the LCD [9, 10].

We can easily connect this LCD module (LCD + controller) with MCS51, and we do not need any additional electronic equipment as the interface between MCS51 and it; This is because this LCD works with the TTL logic level voltage—Transistor-Transistor Logic.

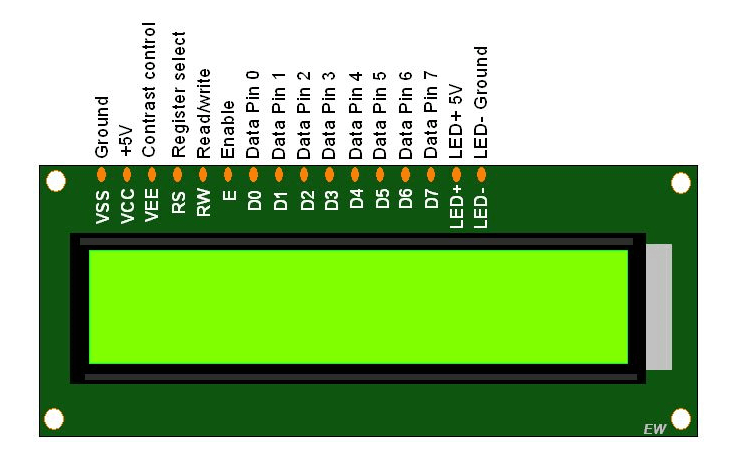

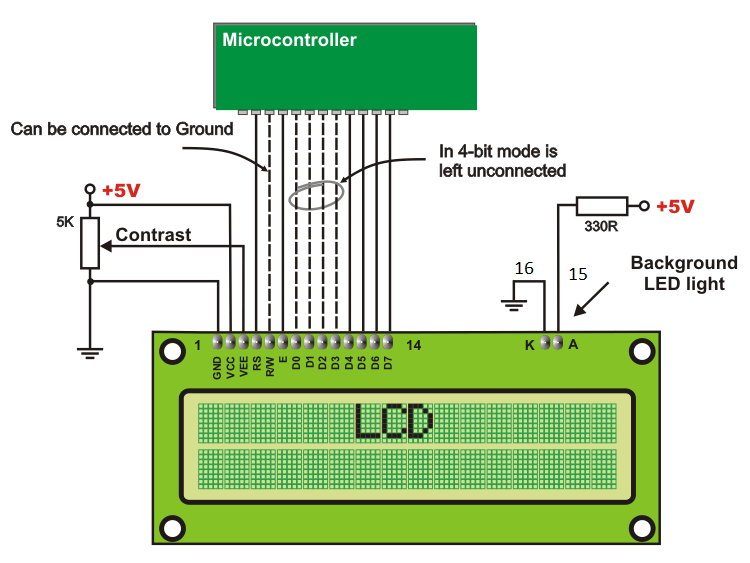

The voltage source of this display is +5 V connected to Pin 2 (VCC) and GND power supply connected to Pin 1 (VSS) and Pin 16 (GND); Pin 1 (VSS) and Pin 16 (GND) are combined together and connected to the GND of the power supply.

Pins 7–14 (8 Pins) of the display function as a channel to transmit either data or instruction with a channel width of 1 byte (D0-D7) between the display and MCS51. In Figure 6, it can be seen that each Pin connected to the data bus (D0-D7) of MCS51 in this case P0 (80h); P0.0-P0.7 MCS-51 connected to D0-D7 of the LCD.

Pins 4–6 are used to control the performance of the display. Pin 4 (Register Select-RS) is in charge of selecting one of the 2 display registers. If RS is given logic 0 then the selected register is the Instruction Register-IR, otherwise, if RS is given logic 1 then the selected register is the Data Register-DR. The implication of this selection is the meaning of the signal sent down through the data bus (D0-D7), if RS = 0, then the signal sent from the MCS-51 to the LCD is an instruction; usually used to configure the LCD, otherwise if RS = 1 then the data sent from the MCS-51 to the LCD (D0-D7) is the data (object or character) you want to display on the LCD. From Figure 6 Pin 4 (RS) is connected to Pin 16 (P3.6/W¯) of MCS-51 with the address (B6H).

Pin 5 (R/W¯)) of the LCD does not appear in Figure 6 is used for read/write operations. If Pin 5 is given logic 1, the operation is a read operation; reading the data from the LCD. Data will be copied from the LCD data register to MCS-51 via the data bus (D0-D7), namely Pins 7–14 of the LCD. Conversely, if Pin 5 is given a voltage with logical 0 then the operation is a write operation; the signal will be sent from the MCS51 to LCD through the LCD Pins (Pins 7–14); The signal sent can be in the form of data or instructions depending on the logic level input to the Register Select-RS Pin, as described above before if RS = 0 then the signal sent is an instruction, vice versa if the RS = 1 then the signal sent/written is the data you want to display. Usually, Pin 5 of the LCD is connected with the power supply GND, because we will never read data from the LCD data register, but only send instructions for the LCD work configuration or the data you want to display on the LCD.

Pin 6 of the LCD (EN¯) is a Pin used to enable the LCD. The LCD will be enabled with the entry of changes in the signal level from high (1) to low (0) on Pin 6. If Pin 6 gets the voltage of logic level either 1 or 0 then the LCD will be disabled; it will only be enabled when there is a change of the voltage level in Pin 6 from high logic level to low logic level for more than 1000 microseconds (1 millisecond), and we can send either instruction or data to processed during that enable time of Pin 6.

Pin 3 and Pin 15 are used to regulate the brightness of the BPL (Back Plane Light). As mentioned above before the LCD operates on the principle of continuing or inhibiting the light passing through it; instead of producing light by itself. The light source comes from LED behind this LCD called BPL. Light brightness from BPL can be set by using a potentiometer or a trimpot. From Figure 6 Pin 3 (VEE) is used to regulate the brightness of BPL (by changing the current that enters BPL by using a potentiometers/a trimpot). While Pin 15 (BPL) is a Pin used for the sink of BPL LED.

4RSRegister selector on the LCD, if RS = 0 then the selected register is an instruction register (the operation to be performed is a write operation/LCD configuration if Pin 5 (R/W¯) is given a logic 0), if RS = 1 then the selected register is a data register; if (R/W¯) = 0 then the operation performed is a data write operation to the LCD, otherwise if (R/W¯) = 1 then the operation performed is a read operation (data will be sent from the LCD to μC (microcontroller); it is usually used to read the busy bit/Busy Flag- BF of the LCD (bit 7/D7).

5(R/W¯)Sets the operating mode, logic 1 for reading operations and logic 0 for write operations, the information read from the LCD to μC is data, while information written to the LCD from μC can be data to be displayed or instructions used to configure the LCD. Usually, this Pin is connected to the GND of the power supply because we will never read data from the LCD but only write instructions to configure it or write data to the LCD register to be displayed.

6Enable¯The LCD is not active when Enable Pin is either 1 or 0 logic. The LCD will be active if there is a change from logic 1 to logic 0; information can be read or written at the time the change occurs.

As per the name the 2x16 has 2 lines with 16 chars on each line. It supports all the ASCII chars and is basically used for displaying the alphanumeric characters. Here each character is displayed in a matrix of 5x7 pixels.

As it is an 8-bit data bus, we can send the data/cmd to LCD in bytes. It also provides the provision to send the data/cmd in chunks of 4-bit, which is used when there are limited number of GPIO lines on the microcontroller.

Register Select(RS): The LCD has two register namely a Data register and Command register. Any data that needs to be displayed on the LCD has to be written to the data register of LCD. Command can be issued to LCD by writing it to Command register of LCD.

If the RS signal is HIGH then the LCD interprets the 8-bit info as data and copies it to data register. After that the LCD decodes the data for generating the 5x7 pattern and finally displays on the LCD.

After sending the data/cmd, Selecting the data/cmd register, Selecting the Write operation. An HIGH-to-LOW pulse has to be sent on this enable pin which will latch the info into the LCD register and triggers the LCD to act accordingly.

The below configuration is as per the above schematic. You can connect the LCD to any of the PORT pins available on your boards and update this section accordingly

This iPhone screen replacement is only have two cables (display + touch) ;NOT have home button, earpiece and front camera cables, You need transfer them from your OEM iPhone screen to this new screen

An import function allows additionally to use Windows fonts. With the FontEditor it is easy to generate for example Cyrillic, Greek and Arabic fonts. The preview function shows immediately the size and style in simulation window. When the testboard EA 9780-2USB is connected to the USB port, you can see the character (or any predefined text) live on the display which is plugged-in!

We come across Liquid Crystal Display (LCD) displays everywhere around us. Computers, calculators, television sets, mobile phones, and digital watches use some kind of display to display the time.

An LCD screen is an electronic display module that uses liquid crystal to produce a visible image. The 16×2 LCD display is a very basic module commonly used in DIYs and circuits. The 16×2 translates a display of 16 characters per line in 2 such lines. In this LCD, each character is displayed in a 5×7 pixel matrix.

Contrast adjustment; the best way is to use a variable resistor such as a potentiometer. The output of the potentiometer is connected to this pin. Rotate the potentiometer knob forward and backward to adjust the LCD contrast.

A 16X2 LCD has two registers, namely, command and data. The register select is used to switch from one register to other. RS=0 for the command register, whereas RS=1 for the data register.

Command Register: The command register stores the command instructions given to the LCD. A command is an instruction given to an LCD to do a predefined task. Examples like:

Data Register: The data register stores the data to be displayed on the LCD. The data is the ASCII value of the character to be displayed on the LCD. When we send data to LCD, it goes to the data register and is processed there. When RS=1, the data register is selected.

Generating custom characters on LCD is not very hard. It requires knowledge about the custom-generated random access memory (CG-RAM) of the LCD and the LCD chip controller. Most LCDs contain a Hitachi HD4478 controller.

CG-RAM is the main component in making custom characters. It stores the custom characters once declared in the code. CG-RAM size is 64 bytes providing the option of creating eight characters at a time. Each character is eight bytes in size.

CG-RAM address starts from 0x40 (Hexadecimal) or 64 in decimal. We can generate custom characters at these addresses. Once we generate our characters at these addresses, we can print them by just sending commands to the LCD. Character addresses and printing commands are below.

LCD modules are very important in many Arduino-based embedded system designs to improve the user interface of the system. Interfacing with Arduino gives the programmer more freedom to customize the code easily. Any cost-effective Arduino board, a 16X2 character LCD display, jumper wires, and a breadboard are sufficient enough to build the circuit. The interfacing of Arduino to LCD display is below.

The combination of an LCD and Arduino yields several projects, the most simple one being LCD to display the LED brightness. All we need for this circuit is an LCD, Arduino, breadboard, a resistor, potentiometer, LED, and some jumper cables. The circuit connections are below.

Do you want your Arduino projects to display status messages or sensor readings? Then these LCD displays can be a perfect fit. They are extremely common and fast way to add a readable interface to your project.

This tutorial will help you get up and running with not only 16×2 Character LCD, but any Character LCD (16×4, 16×1, 20×4 etc.) that is based on Hitachi’s LCD Controller Chip – HD44780.

When current is applied to these crystals, they become opaque, blocking the backlight that resides behind the screen. As a result that particular area will be dark compared to the others. And this is how the characters are displayed on the screen.

True to their name, these LCDs are ideal for displaying only text/characters. A 16×2 character LCD, for example, has an LED backlight and can display 32 ASCII characters in two rows of 16 characters each.

If you look closely you can see tiny rectangles for each character on the display and the pixels that make up a character. Each of these rectangles is a grid of 5×8 pixels.

The good news is that all of these displays are ‘swappable’, which means if you build your project with one you can just unplug it and use another size/color LCD of your choice. Your code will have to change a bit but at least the wiring remains the same!

Vo (LCD Contrast) controls the contrast and brightness of the LCD. Using a simple voltage divider with a potentiometer, we can make fine adjustments to the contrast.

RS (Register Select) pin is set to LOW when sending commands to the LCD (such as setting the cursor to a specific location, clearing the display, etc.) and HIGH when sending data to the LCD. Basically this pin is used to separate the command from the data.

R/W (Read/Write) pin allows you to read data from the LCD or write data to the LCD. Since we are only using this LCD as an output device, we are going to set this pin LOW. This forces it into WRITE mode.

E (Enable) pin is used to enable the display. When this pin is set to LOW, the LCD does not care what is happening on the R/W, RS, and data bus lines. When this pin is set to HIGH, the LCD processes the incoming data.

D0-D7 (Data Bus) pins carry the 8 bit data we send to the display. For example, if we want to see an uppercase ‘A’ character on the display, we set these pins to 0100 0001 (as per the ASCII table).

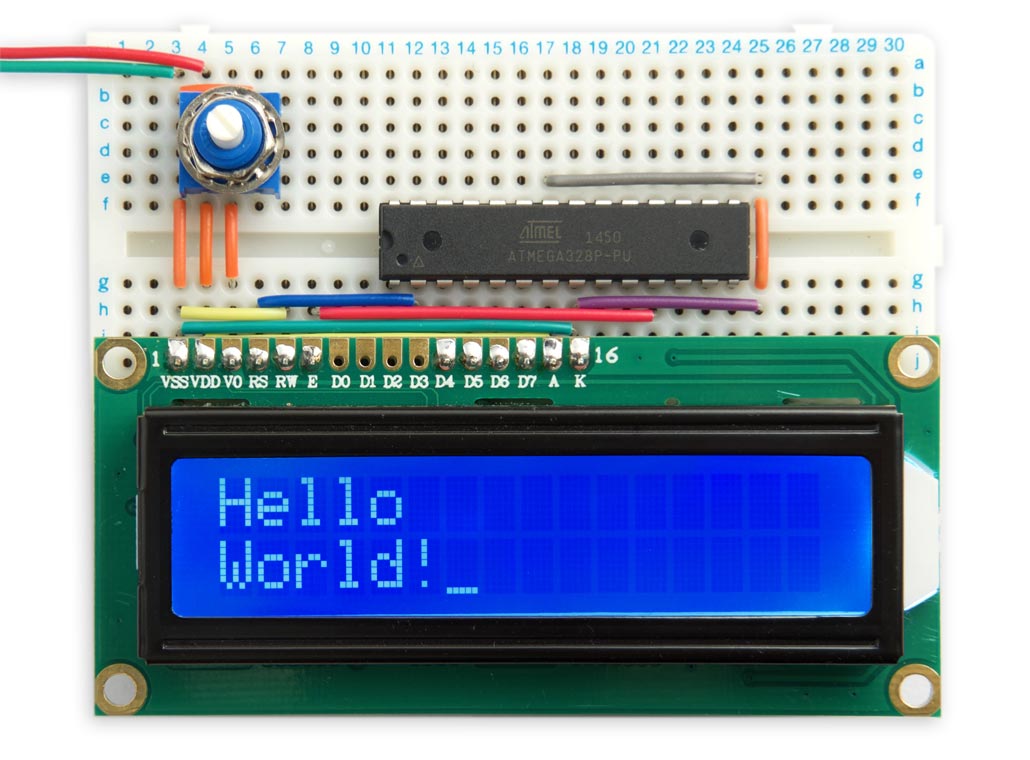

Now we will power the LCD. The LCD has two separate power connections; One for the LCD (pin 1 and pin 2) and the other for the LCD backlight (pin 15 and pin 16). Connect pins 1 and 16 of the LCD to GND and 2 and 15 to 5V.

Most LCDs have a built-in series resistor for the LED backlight. You’ll find this near pin 15 on the back of the LCD. If your LCD does not include such a resistor or you are not sure if your LCD has one, you will need to add one between 5V and pin 15. It is safe to use a 220 ohm resistor, although a value this high may make the backlight a bit dim. For better results you can check the datasheet for maximum backlight current and select a suitable resistor value.

Next we will make the connection for pin 3 on the LCD which controls the contrast and brightness of the display. To adjust the contrast we will connect a 10K potentiometer between 5V and GND and connect the potentiometer’s center pin (wiper) to pin 3 on the LCD.

That’s it. Now turn on the Arduino. You will see the backlight lit up. Now as you turn the knob on the potentiometer, you will start to see the first row of rectangles. If that happens, Congratulations! Your LCD is working fine.

Let’s finish connecting the LCD to the Arduino. We have already made the connections to power the LCD, now all we have to do is make the necessary connections for communication.

We know that there are 8 data pins that carry data to the display. However, HD44780 based LCDs are designed in such a way that we can communicate with the LCD using only 4 data pins (4-bit mode) instead of 8 (8-bit mode). This saves us 4 pins!

The sketch begins by including the LiquidCrystal library. The Arduino community has a library called LiquidCrystal which makes programming of LCD modules less difficult. You can find more information about the library on Arduino’s official website.

First we create a LiquidCrystal object. This object uses 6 parameters and specifies which Arduino pins are connected to the LCD’s RS, EN, and four data pins.

In the ‘setup’ we call two functions. The first function is begin(). It is used to specify the dimensions (number of columns and rows) of the display. If you are using a 16×2 character LCD, pass the 16 and 2; If you’re using a 20×4 LCD, pass 20 and 4. You got the point!

After that we set the cursor position to the second row by calling the function setCursor(). The cursor position specifies the location where you want the new text to be displayed on the LCD. The upper left corner is assumed to be col=0, row=0.

There are some useful functions you can use with LiquidCrystal objects. Some of them are listed below:lcd.home() function is used to position the cursor in the upper-left of the LCD without clearing the display.

lcd.scrollDisplayRight() function scrolls the contents of the display one space to the right. If you want the text to scroll continuously, you have to use this function inside a for loop.

lcd.scrollDisplayLeft() function scrolls the contents of the display one space to the left. Similar to above function, use this inside a for loop for continuous scrolling.

If you find the characters on the display dull and boring, you can create your own custom characters (glyphs) and symbols for your LCD. They are extremely useful when you want to display a character that is not part of the standard ASCII character set.

CGROM is used to store all permanent fonts that are displayed using their ASCII codes. For example, if we send 0x41 to the LCD, the letter ‘A’ will be printed on the display.

CGRAM is another memory used to store user defined characters. This RAM is limited to 64 bytes. For a 5×8 pixel based LCD, only 8 user-defined characters can be stored in CGRAM. And for 5×10 pixel based LCD only 4 user-defined characters can be stored.

Creating custom characters has never been easier! We have created a small application called Custom Character Generator. Can you see the blue grid below? You can click on any 5×8 pixel to set/clear that particular pixel. And as you click, the code for the character is generated next to the grid. This code can be used directly in your Arduino sketch.

Download our Crystalfontz LCD Software. We provide software for you to test many types of LCDs including character displays and graphic displays. Our character and graphic USB display modules can use CrystalControl2 to quickly set up the display. Bitmap to ePaper and Image2Code provide a simple interface to add an image to your display. We also USB LCD drivers and demonstration code for Linux.

In this tutorial, I’ll explain how to set up an LCD on an Arduino and show you all the different ways you can program it. I’ll show you how to print text, scroll text, make custom characters, blink text, and position text. They’re great for any project that outputs data, and they can make your project a lot more interesting and interactive.

The display I’m using is a 16×2 LCD display that I bought for about $5. You may be wondering why it’s called a 16×2 LCD. The part 16×2 means that the LCD has 2 lines, and can display 16 characters per line. Therefore, a 16×2 LCD screen can display up to 32 characters at once. It is possible to display more than 32 characters with scrolling though.

The code in this article is written for LCD’s that use the standard Hitachi HD44780 driver. If your LCD has 16 pins, then it probably has the Hitachi HD44780 driver. These displays can be wired in either 4 bit mode or 8 bit mode. Wiring the LCD in 4 bit mode is usually preferred since it uses four less wires than 8 bit mode. In practice, there isn’t a noticeable difference in performance between the two modes. In this tutorial, I’ll connect the LCD in 4 bit mode.

BONUS: I made a quick start guide for this tutorial that you can download and go back to later if you can’t set this up right now. It covers all of the steps, diagrams, and code you need to get started.

Here’s a diagram of the pins on the LCD I’m using. The connections from each pin to the Arduino will be the same, but your pins might be arranged differently on the LCD. Be sure to check the datasheet or look for labels on your particular LCD:

Also, you might need to solder a 16 pin header to your LCD before connecting it to a breadboard. Follow the diagram below to wire the LCD to your Arduino:

All of the code below uses the LiquidCrystal library that comes pre-installed with the Arduino IDE. A library is a set of functions that can be easily added to a program in an abbreviated format.

In order to use a library, it needs be included in the program. Line 1 in the code below does this with the command #include

Now we’re ready to get into the programming! I’ll go over more interesting things you can do in a moment, but for now lets just run a simple test program. This program will print “hello, world!” to the screen. Enter this code into the Arduino IDE and upload it to the board:

There are 19 different functions in the LiquidCrystal library available for us to use. These functions do things like change the position of the text, move text across the screen, or make the display turn on or off. What follows is a short description of each function, and how to use it in a program.

TheLiquidCrystal() function sets the pins the Arduino uses to connect to the LCD. You can use any of the Arduino’s digital pins to control the LCD. Just put the Arduino pin numbers inside the parentheses in this order:

This function sets the dimensions of the LCD. It needs to be placed before any other LiquidCrystal function in the void setup() section of the program. The number of rows and columns are specified as lcd.begin(columns, rows). For a 16×2 LCD, you would use lcd.begin(16, 2), and for a 20×4 LCD you would use lcd.begin(20, 4).

This function clears any text or data already displayed on the LCD. If you use lcd.clear() with lcd.print() and the delay() function in the void loop() section, you can make a simple blinking text program:

This function places the cursor in the upper left hand corner of the screen, and prints any subsequent text from that position. For example, this code replaces the first three letters of “hello world!” with X’s:

Similar, but more useful than lcd.home() is lcd.setCursor(). This function places the cursor (and any printed text) at any position on the screen. It can be used in the void setup() or void loop() section of your program.

The cursor position is defined with lcd.setCursor(column, row). The column and row coordinates start from zero (0-15 and 0-1 respectively). For example, using lcd.setCursor(2, 1) in the void setup() section of the “hello, world!” program above prints “hello, world!” to the lower line and shifts it to the right two spaces:

You can use this function to write different types of data to the LCD, for example the reading from a temperature sensor, or the coordinates from a GPS module. You can also use it to print custom characters that you create yourself (more on this below). Use lcd.write() in the void setup() or void loop() section of your program.

The function lcd.noCursor() turns the cursor off. lcd.cursor() and lcd.noCursor() can be used together in the void loop() section to make a blinking cursor similar to what you see in many text input fields:

Cursors can be placed anywhere on the screen with the lcd.setCursor() function. This code places a blinking cursor directly below the exclamation point in “hello, world!”:

This function creates a block style cursor that blinks on and off at approximately 500 milliseconds per cycle. Use it in the void loop() section. The function lcd.noBlink() disables the blinking block cursor.

This function turns on any text or cursors that have been printed to the LCD screen. The function lcd.noDisplay() turns off any text or cursors printed to the LCD, without clearing it from the LCD’s memory.

These two functions can be used together in the void loop() section to create a blinking text effect. This code will make the “hello, world!” text blink on and off:

This function takes anything printed to the LCD and moves it to the left. It should be used in the void loop() section with a delay command following it. The function will move the text 40 spaces to the left before it loops back to the first character. This code moves the “hello, world!” text to the left, at a rate of one second per character:

Like the lcd.scrollDisplay() functions, the text can be up to 40 characters in length before repeating. At first glance, this function seems less useful than the lcd.scrollDisplay() functions, but it can be very useful for creating animations with custom characters.

lcd.noAutoscroll() turns the lcd.autoscroll() function off. Use this function before or after lcd.autoscroll() in the void loop() section to create sequences of scrolling text or animations.

This function sets the direction that text is printed to the screen. The default mode is from left to right using the command lcd.leftToRight(), but you may find some cases where it’s useful to output text in the reverse direction:

This code prints the “hello, world!” text as “!dlrow ,olleh”. Unless you specify the placement of the cursor with lcd.setCursor(), the text will print from the (0, 1) position and only the first character of the string will be visible.

This command allows you to create your own custom characters. Each character of a 16×2 LCD has a 5 pixel width and an 8 pixel height. Up to 8 different custom characters can be defined in a single program. To design your own characters, you’ll need to make a binary matrix of your custom character from an LCD character generator or map it yourself. This code creates a degree symbol (°):

Ms.Josey

Ms.Josey

Ms.Josey

Ms.Josey