3-wire serial lcd module factory

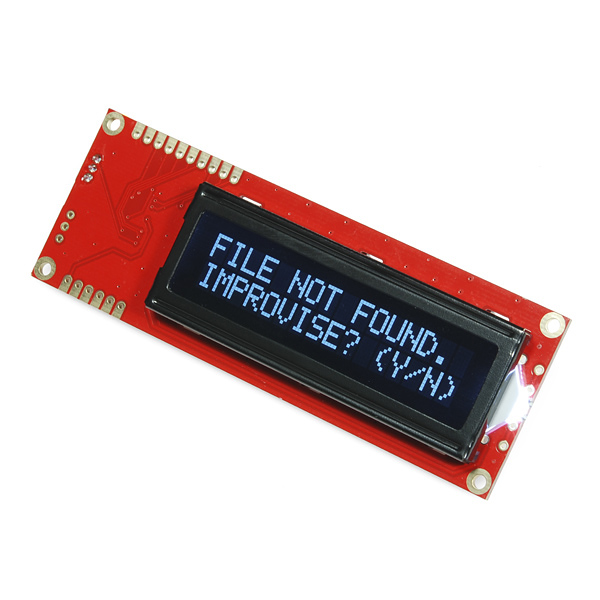

This LCD module uses a 128x64 liquid crystal display that support Chinese character , English characters and even graphics. It can exhibit 4 lines and 12 English characters/6 Chinese characters per line. It is suitable for interactive work with Arduino.

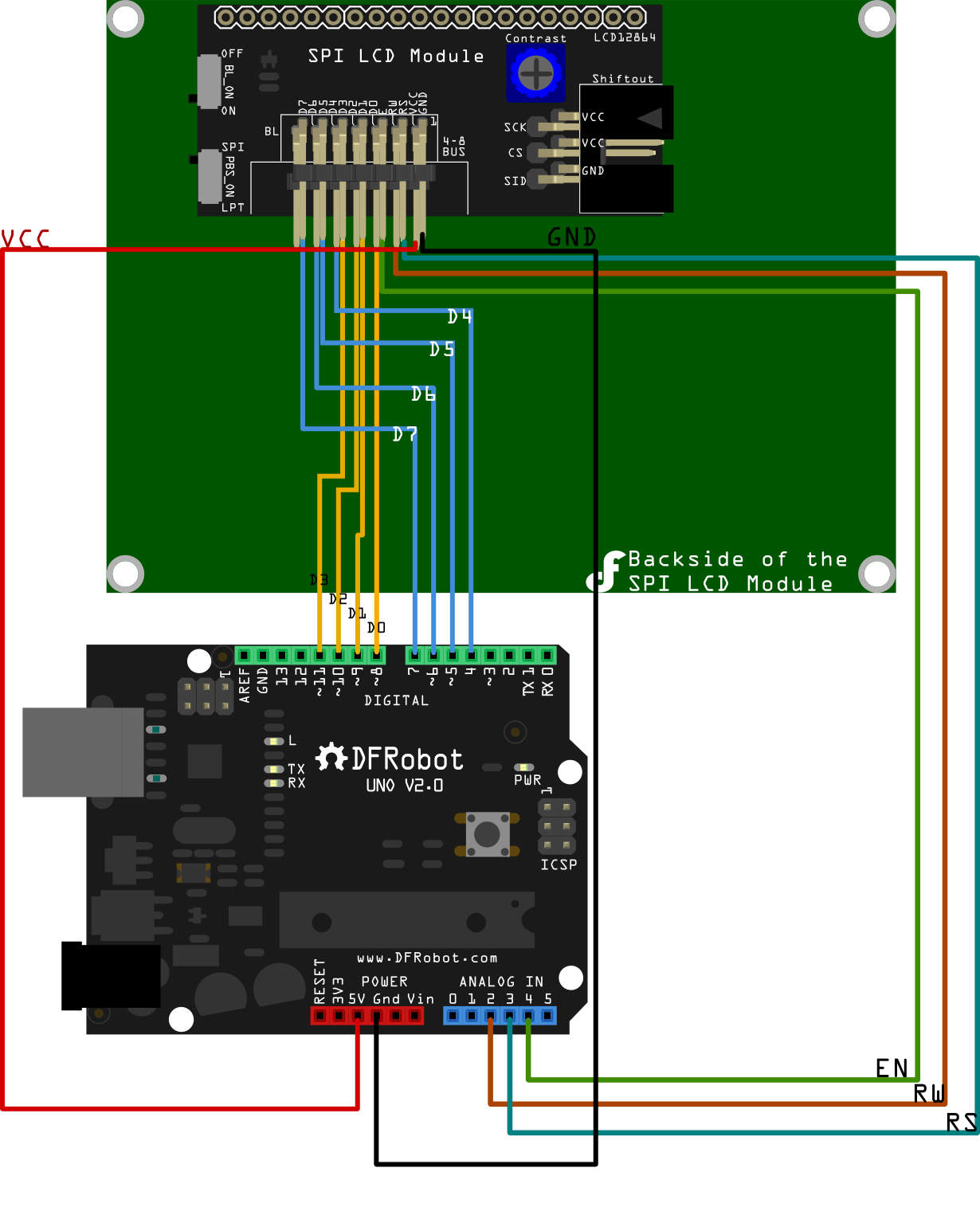

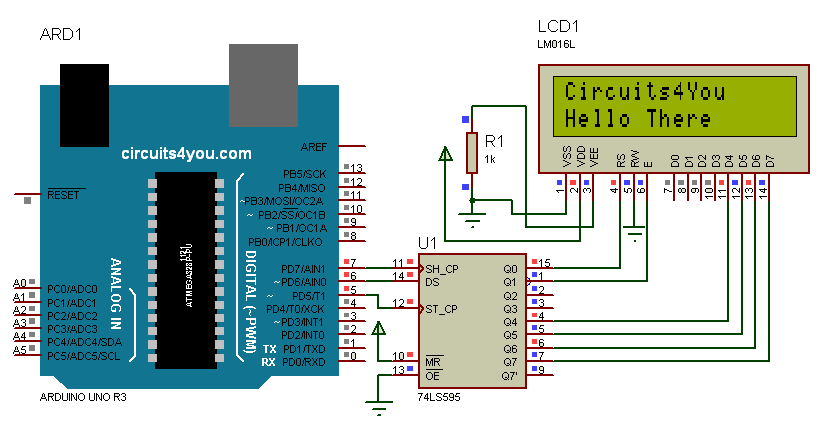

The following sample is working under 3-Wire mode. It demonstrates how to display integers on the LCD screen. You will need the Arduino Library which can be downloaded here.

ER-TFT035-6 is 320x480 dots 3.5" color tft lcd module display with ILI9488 controller,superior display quality,super wide viewing angle.As a bonus, this display has a optional resistive touch panel and a optional capacitive touch panel with controller FT6236, so you can detect finger presses anywhere on the screen and doesn"t require pressing down on the screen with a stylus and has nice glossy glass cover and easily controlled by MCU such as 8051, PIC, AVR, ARDUINO ARM and Raspberry PI.It can be used in any embedded systems,industrial device,security and hand-held equipment which requires display in high quality and colorful image.It supports 8080 8-bit,9-bit,16-bit, parallel,3-wire,4-wire serial spi interface. FPC with zif connector is easily to assemble or remove.Lanscape mode is also available.

This LCD module uses a 128x64 liquid crystal display that support Chinese character, English characters and even graphics. It is suitable for interactive work with Arduino.

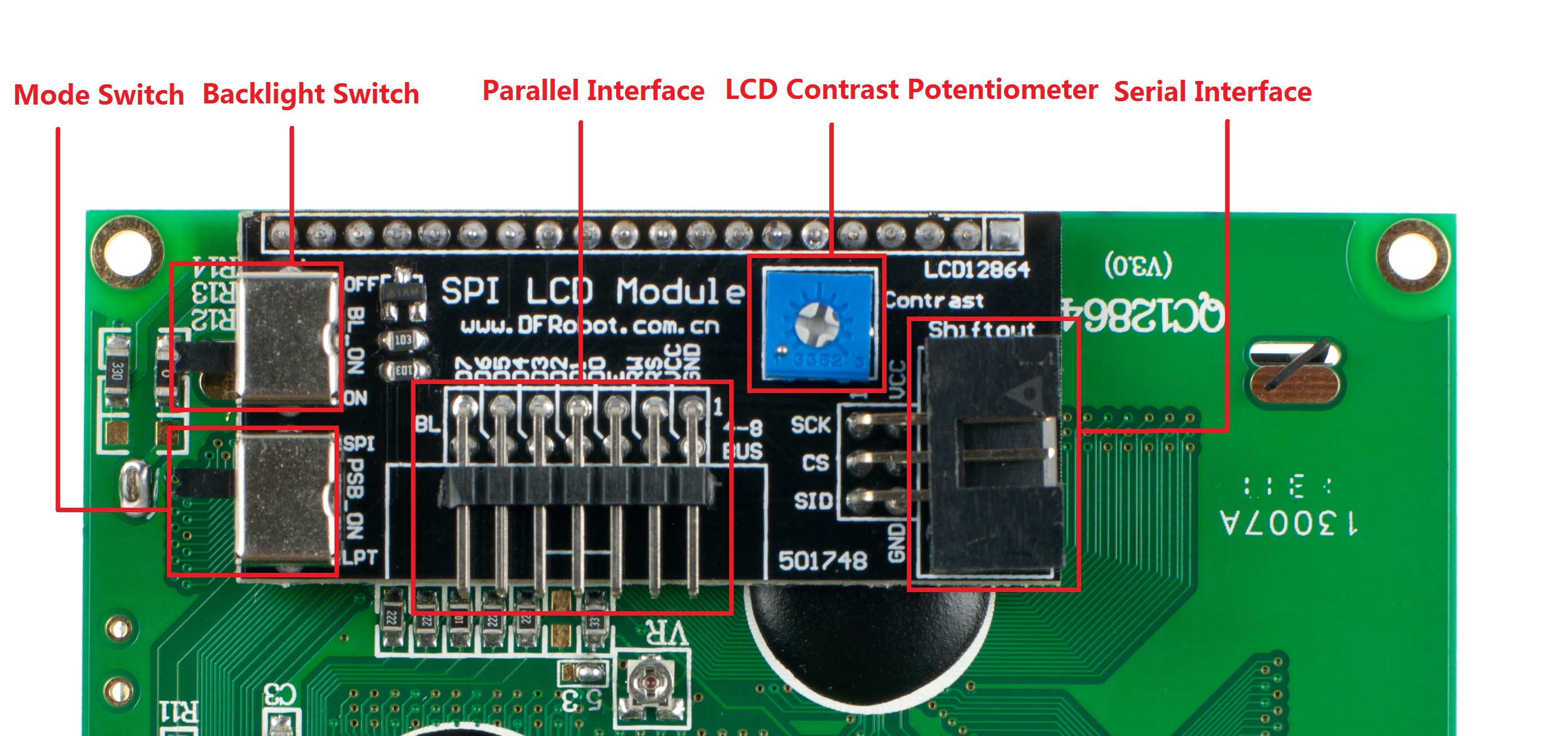

It features a backlit control, pallerlel or serial control, contrast adjust. It can be connect to our interface shield for arduino via IDC6 socket and Cable for Shiftout.

The LCD is shipped in Pallelel mode in default. The R9 is used to set the interface mode. To switch to SPI mode, the R9 resistor need to be moved to R10

Try using lcd parallel to serial found on Alibaba.com to make many types of production jobs faster and easier. Each model can be filled with different types of liquid and quickly dispensed into containers. Use lcd parallel to serial to fill paint cans with speed and precision. Other compatible fluids include resin or glue, making such devices suitable for manufacturing all kinds of helpful products.

All lcd parallel to serial are built to be easy to operate, reducing labor and training times needed. Some versions can pour food-grade liquids such as beer or milk into bottles for future sealing. Most units work automatically so workers can program them and stay back as they work on their own. When installed on a factory floor, they offer greater efficiency to help save time and costs.

Shop for lcd parallel to serial at Alibaba.com to find many helpful suppliers with a wide range of options that can be ordered. Choose just the right size to fit the intended workspace. Pick a wattage level that promises good speed and power without using too much electricity and driving up costs. Certain designs can dispense products in the form of powder or granules into nearby containers. Use these to package particular powdered food and pharmaceutical ingredients.

Search for lcd parallel to serial on Alibaba.com and enjoy lower costs when working with various liquids or powders. Whether for use in food manufacturing or building materials, there are plenty of options to browse. Find a satisfactory brand that will improve efficiency for better overall quality in each final product.

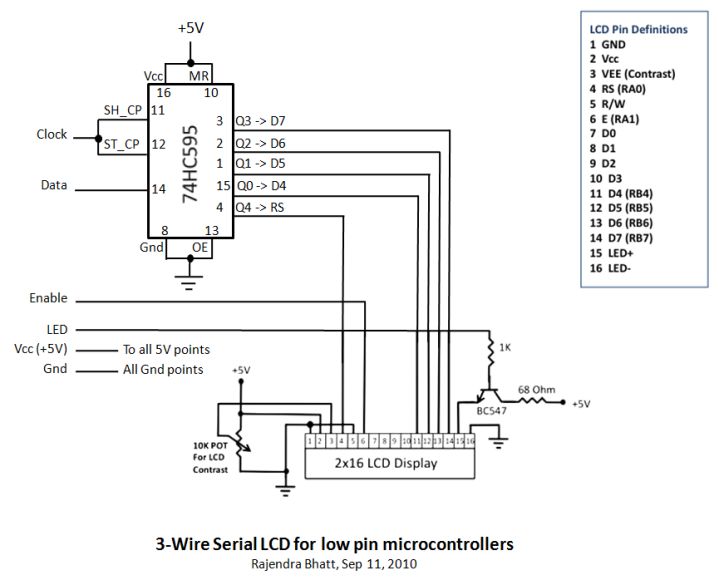

The parallel interface typically controls the LCD via 8 data pins and 3 control lines. The control lines used are Enable (E), Register Select (RS), and Read/Write (R/W). RS tells the LCD module if the information being sent is an Instruction or Data. The Enable tells the LCD module that the data or instruction in the register is ready to be interpreted by the LCD Module. Some controllers may have more than one Enable Control Line. The Read/Write tells the module whether to write data or read data from the register.

Serial LCD controllers typically have one Serial Data Line that writes data and cannot read. Normally, a Register Select Line(Sometimes designated A0) is used to tell the controller whether the incoming data is display information or a controller command

SPI, or Serial Peripheral Interface bus, is a synchronous (data is synchronized to the clock) serial data link standard that operates in full duplex mode, which means that devices that can communicate with one another simultaneously. To do this, two data lines are required. With this standard, devices communicate in a master/slave mode, where the master device (host processor) initiates the data and the clock. The LCD module is the (or one of the) peripheral slave device(s) attached to the data bus. Multiple peripherals (display modules and other devices) are addressed on the same serial data bus. However, the LCD module will only listen to the data it sees when the Chip Select line is active (usually low). If the Chip Select line is inactive (usually High), the LCD module listens to the data on the bus, but ignores it. The SDO line is not active when this state occurs. The SPI bus is comprised of four logic signals, two control lines and two data lines and is commonly referred to as SPI (4 wire).

Occasionally, SDI (serial data in) may be called out as MOSI (Master Out Slave In) from Motorola"s original name for these lines and MISO (Master In Slave Out) for SDO. The chip select line may be alternatively labeled SS (Slave-Select), or STE (Slave Transmit Enable). SPI is sometimes referred to as National Semiconductor"s trademark Microwire, which is essentially a predecessor of SPI, which only supports half duplex.

With CS (Chip-Select) the corresponding peripheral device is selected by the LCD Controller. This pin is mostly active-low. In the unselected state the SDO lines are hi-impedance and therefore inactive. The clock line SCL is brought to the device whether it is selected or not. The clock serves as synchronization of the data communication.

The chip select signal CS is optional for a single device system, because you could tie the CS input at the LCD Module low, if the other lines are dedicated to SPI use. This is sometimes called a 3 Wire SPI Interface.

SPI Data transmissions usually involve two shift registers. Most display module applications normally use 8-bit words. However, different size words, such as 12 bit, are also used. By convention, the most significant bit is shifted out of one shift register while the least significant bit is shifted in. The word is then written into memory if the CS (chip-select) is low (active). If not, the data is ignored.

Since the SPI interface protocol is a de facto standard, many variations of the standard protocol are used. For instance, chip manufacturers may use some of the parallel data lines when configuring the IC driver chip for serial communication. chip manufacturers may use some of the parallel data lines when configuring the IC driver chip for serial communication.

I2C uses only two bi-directional lines, Serial Data Line (SDA) and Serial Clock (SCL), which are both typically pulled up with resistors. Typical voltages used are +5 V or +3.3 V. One of the strengths of the I2C interface is that a micro can control multiple devices with just the two I/O pins and software. Because of the I2C design, it is only half-duplex. The interface generally transmits 8-bit words, sending the most significant bit first.

SPI is a useful communication method if you have more than one device to hook up on a single bus. It requires more wires than basic serial, but it"s more dependable because it"s a synchronous interface.

This example works a lot like the serial version. The s7s.print() functions from the previous example are replaced by SPI transfers. Take note that each time an SPI.transfer() occurs, it"s blanketed by two digitalWrite()s to the SS pin. The SS pin must go LOW, to let the display know that usable data is incoming. Once SS goes back to HIGH, the display will know that data is no longer being sent to it.

In these videos, the SPI (GPIO) bus is referred to being the bottleneck. SPI based displays update over a serial data bus, transmitting one bit per clock cycle on the bus. A 320x240x16bpp display hence requires a SPI bus clock rate of 73.728MHz to achieve a full 60fps refresh frequency. Not many SPI LCD controllers can communicate this fast in practice, but are constrained to e.g. a 16-50MHz SPI bus clock speed, capping the maximum update rate significantly. Can we do anything about this?

-DPIRATE_AUDIO_ST7789_HAT=ON: If specified, targets a Pirate Audio 240x240, 1.3inch IPS LCD display HAT for Raspberry Pi with ST7789 display controller

-DKEDEI_V63_MPI3501=ON: If specified, targets a KeDei 3.5 inch SPI TFTLCD 480*320 16bit/18bit version 6.3 2018/4/9 display with MPI3501 display controller.

-DGPIO_TFT_DATA_CONTROL=number: Specifies/overrides which GPIO pin to use for the Data/Control (DC) line on the 4-wire SPI communication. This pin number is specified in BCM pin numbers. If you have a 3-wire SPI display that does not have a Data/Control line, set this value to -1, i.e. -DGPIO_TFT_DATA_CONTROL=-1 to tell fbcp-ili9341 to target 3-wire ("9-bit") SPI communication.

-DSINGLE_CORE_BOARD=ON: Pass this option if you are running on a Pi that has only one hardware thread (Pi Model A, Pi Model B, Compute Module 1, Pi Zero/Zero W). If not present, autodetected.

I don"t know, I don"t currently have any to test. Perhaps the code does need some model specific configuration, or perhaps it might work out of the box. I only have Pi 3B, Pi 3B+, Pi Zero W and a Pi 3 Compute Module based systems to experiment on. Pi 2 B has been reported to work by users (#17).

Perhaps. This is a more recent experimental feature that may not be as stable, and there are some limitations, but 3-wire ("9-bit") SPI display support is now available. If you have a 3-wire SPI display, i.e. one that does not have a Data/Control (DC) GPIO pin to connect, configure it via CMake with directive -DGPIO_TFT_DATA_CONTROL=-1 to tell fbcp-ili9341 that it should be driving the display with 3-wire protocol.

The performance option ALL_TASKS_SHOULD_DMA is currently not supported, there is an issue with DMA chaining that prevents this from being enabled. As result, CPU usage on 3-wire displays will be slightly higher than on 4-wire displays.

The performance option OFFLOAD_PIXEL_COPY_TO_DMA_CPP is currently not supported. As a result, 3-wire displays may not work that well on single core Pis like Pi Zero.

This has only been tested on my Adafruit SSD1351 128x96 RGB OLED display, which can be soldered to operate in 3-wire SPI mode, so testing has not been particularly extensive.

Displays that have a 16-bit wide command word, such as ILI9486, do not currently work in 3-wire ("17-bit") mode. (But ILI9486L has 8-bit command word, so that does work)

make sure the display is configured to run 4-wire SPI mode, and not in parallel mode or 3-wire SPI mode. You may need to solder or desolder some connections or set a jumper to configure the specific driving mode. Support for 3-wire SPI displays does exist, but it is more limited and a bit experimental.

This suggests that the power line or the backlight line might not be properly connected. Or if the backlight connects to a GPIO pin on the Pi (and not a voltage pin), then it may be that the pin is not in correct state for the backlight to turn on. Most of the LCD TFT displays I have immediately light up their backlight when they receive power. The Tontec one has a backlight GPIO pin that boots up high but must be pulled low to activate the backlight. OLED displays on the other hand seem to stay all black even after they do get power, while waiting for their initialization to be performed, so for OLEDs it may be normal for nothing to show up on the screen immediately after boot.

First, make sure the display is a 4-wire SPI and not a 3-wire one. A display is 4-wire SPI if it has a Data/Control (DC) GPIO line that needs connecting. Sometimes the D/C pin is labeled RS (Register Select). Support for 3-wire SPI displays does exist, but it is experimental and not nearly as well tested as 4-wire displays.

Implement a kernel module that enables userland programs to allocate DMA channels, which fbcp-ili9341 could use to amicably reserve its own DMA channels without danger of conflicting.

Improve support for 3-wire displays, e.g. for 1) "17-bit" 3-wire communication, 2) fix up SPI_3WIRE_PROTOCOL + ALL_TASKS_SHOULD_DMA to work together, or 3) fix up SPI_3WIRE_PROTOCOL + OFFLOAD_PIXEL_COPY_TO_DMA_CPP to work together.

Optimize away unnecessary zero padding that 3-wire communication currently incurs, by keeping a queue of leftover untransmitted partial bits of a byte, and piggybacking them onto the next transfer that comes in.

A normal SPI interface consists of four signals: clock (SCLK), slave select (!SS or !CS), master input/slave output (MISO), and master output/slave input (MOSI). SPI has separate pins for input and output data, making it full-duplex. Some chips use a half-duplex interface similar to true SPI, but with a single data line. Interfaces like this are commonly called "3-wire SPI" and can be used with Total Phase SPI products with some simple circuit modifications.

In this article, we will show how the Aardvark I2C/SPI host adapter and the Beagle I2C/SPI protocol analyzer can work with slaves that use a 3-wire SPI interface. As an example, we have chosen to work with the National LM74 temperature sensor, whose pinout is shown below:

The Aardvark adapter is meant to work with full-duplex SPI, so you will need to carefully setup the bytes to be transmitted. Additionally, you will need to convert the raw temperature data into meaningful Celsius/Fahrenheit values. For a complete example, please see the Python program (lm74.zip in the Reference section below) which was used to interface the Aardvark adapter with the with the National LM74. This program reads and writes data to the LM74 using 3-wire SPI.

Ms.Josey

Ms.Josey

Ms.Josey

Ms.Josey