lcd panel ribbon latch quotation

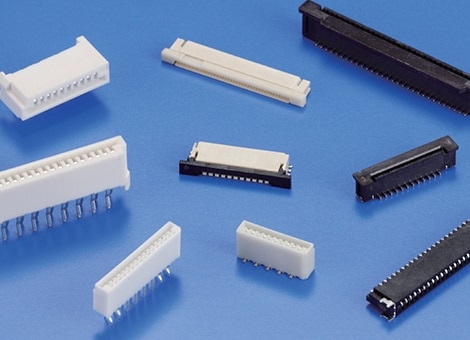

As @DaveTweed mentioned, your picture is not of ribbon cable, but of FFC (Flat Flexible Cable; while not completely equivalent, the term is sometimes used interchangeably with Flexible Printed Circuit, or FPC). If you"re brave enough to try to replace the connector, you"ll want to use FFC as your search term on your favorite distributor"s website.

Another name for ribbon cable is multi-wire planar cable or hippie cable. It is a cable type with many conducting wires running parallel on the same flat plane.

The ribbon cable is flat and rectangular. The flexibility of the ribbon cable makes it easy to hold many connectors simultaneously and transmit a large amount of data through signals. Furthermore, ribbon cables help to manage conductors effectively, even where space is limited.

A typical instance that proves the usefulness of ribbon cable is its function in computer hardware. The ribbon cable connects the disk drive to the disk drive controller.

The essence of ribbon cable color coding is to prevent the occurrence of reverse connections. One rule for ribbon cable color coding is that the edge of the cable, which bears a red stripe, connects to pin 1 of the connector. The cable color-coding makes it easy to identify the different sets of connectors.

A pertinent question that engulfs individuals’ minds is the exact size of the ribbon cable that suits their needs. There are two ways of identifying ribbon cable sizes. The two factors considered are:

For the conductors’ pitch or spacing, a spacing of 0.05 inch (1.27 mm) is the most common form of ribbon cable spacing. This spacing type allows for a two-row connector with a pin spacing of 0.1 inches (2.54mm). Most personal computers favor this exact spacing ribbon cable size. It is a common type of ribbon cable size in floppy disk drive cables and custom parallel ATA cables.

Additionally, ribbon cables are essential in building many electrical products. A good number of electrical products make use of ribbon cables. It is because of the miniature nature of ribbon cables, which makes them easy to use for designing electrical products.

There are a host of names for the ribbon connectors. These names are a telco, 25 pair, miniature delta ribbon, mini D ribbon, MDR, Amphenol, or even miniature ribbon connector.

Microribbon connector possesses a shape similar to D- Subminiature connector with two parallel rows of contact. Its contacts are not pins. Rather, they are small bands of metal in the form of ribbons.

Flexible flat cables are a type of ribbon cable that is flat and flexible. These are direct connections without any additional components. It is a thin flat cable commonly found in high-density electronics applications. Its material is very flexible.

Flexible flat cables are a smaller form of ribbon cables. These cables possess a special sort of makeup. Its makeup is a flat and flexible plastic film base and multiple conductors on a surface.

Both cable types are important in diverse ways. While one assist in a particular field, the other remains relevant in a field that suits it. However, flat cables existed long before the ribbon cables came into existence.

Ribbon cables are efficient in various areas like computing, aerospace, military, and robotics. These cables possess good superior quality, flexibility, and packaging efficiency and reduce the presence of electronic noise.

Therefore, it is necessary to understand the capabilities of both the ribbon cable and flexible flat cables to ensure proper usage. In all, flexible flat cables possess better features than ribbon cables.

Asides from recognizing ribbon cables, the confusion lies in choosing them. In choosing ribbon cables, there are quite a several factors to put into consideration. These cables are:

Pitch is spacing. It refers to the spacing of conductors within the ribbon cable. The pitch depends on the cable requirements and specifications. Some examples of pitches include 0.5mm, 1mm, 1.25mm, and 2mm.

Another way of determining the pitch of the ribbon cable is by measuring the outside edge of the cable and then dividing the figure by the total number of connectors.

Ribbon cables tolerate all sorts of temperatures, be they harsh or friendly. But, if ribbon cables operate perfectly in unfavorable temperatures, a silicon jacket is the best bet.

In choosing ribbon cables, flexibility is a necessary factor. Since ribbon cables are flexible, there is still a need to purchase a more flexible type. If the design is limited or requires a more flexible type, purchase a custom ribbon cable with greater flexibility that suits the job.

Consider the life span of the ribbon cable you intend to purchase. Like every other electrical component, choosing a ribbon cable that can survive the test of time is necessary.

Fire resistance is another factor to consider when choosing a ribbon cable. The importance is not only for the benefits of the electrical equipment but also for safety.

Make it a duty to settle for a ribbon cable type in line with the EU’s Restriction of Hazardous Substances Directives and fit according to fire safety standards.

Cloom Tech is not just a body of professional teams specialized in different areas of expertise. With us, you are guaranteed a superb custom ribbon cable service, as it is a part of what we are known to do well.; we are a team of seasoned professionals who take a keen interest in delivering effective results.

Ribbon cables are indeed important for various connections of sorts. They play important roles in connecting various applications like mobile phones, laptops, and electronic devices.

These colored-looking cables are very efficient in producing second-to-none output results. They appear in various sizes and pitches. It is important to derive all its information to fully use the ribbon cable.

Another name for ribbon cable is multi-wire planar cable or hippie cable. It is a cable type with many conducting wires running parallel on the same flat plane.

The ribbon cable is flat and rectangular. The flexibility of the ribbon cable makes it easy to hold many connectors simultaneously and transmit a large amount of data through signals. Furthermore, ribbon cables help to manage conductors effectively, even where space is limited.

A typical instance that proves the usefulness of ribbon cable is its function in computer hardware. The ribbon cable connects the disk drive to the disk drive controller.

The essence of ribbon cable color coding is to prevent the occurrence of reverse connections. One rule for ribbon cable color coding is that the edge of the cable, which bears a red stripe, connects to pin 1 of the connector. The cable color-coding makes it easy to identify the different sets of connectors.

A pertinent question that engulfs individuals’ minds is the exact size of the ribbon cable that suits their needs. There are two ways of identifying ribbon cable sizes. The two factors considered are:

For the conductors’ pitch or spacing, a spacing of 0.05 inch (1.27 mm) is the most common form of ribbon cable spacing. This spacing type allows for a two-row connector with a pin spacing of 0.1 inches (2.54mm). Most personal computers favor this exact spacing ribbon cable size. It is a common type of ribbon cable size in floppy disk drive cables and custom parallel ATA cables.

Additionally, ribbon cables are essential in building many electrical products. A good number of electrical products make use of ribbon cables. It is because of the miniature nature of ribbon cables, which makes them easy to use for designing electrical products.

There are a host of names for the ribbon connectors. These names are a telco, 25 pair, miniature delta ribbon, mini D ribbon, MDR, Amphenol, or even miniature ribbon connector.

Microribbon connector possesses a shape similar to D- Subminiature connector with two parallel rows of contact. Its contacts are not pins. Rather, they are small bands of metal in the form of ribbons.

Flexible flat cables are a type of ribbon cable that is flat and flexible. These are direct connections without any additional components. It is a thin flat cable commonly found in high-density electronics applications. Its material is very flexible.

Flexible flat cables are a smaller form of ribbon cables. These cables possess a special sort of makeup. Its makeup is a flat and flexible plastic film base and multiple conductors on a surface.

Both cable types are important in diverse ways. While one assist in a particular field, the other remains relevant in a field that suits it. However, flat cables existed long before the ribbon cables came into existence.

Ribbon cables are efficient in various areas like computing, aerospace, military, and robotics. These cables possess good superior quality, flexibility, and packaging efficiency and reduce the presence of electronic noise.

Therefore, it is necessary to understand the capabilities of both the ribbon cable and flexible flat cables to ensure proper usage. In all, flexible flat cables possess better features than ribbon cables.

Asides from recognizing ribbon cables, the confusion lies in choosing them. In choosing ribbon cables, there are quite a several factors to put into consideration. These cables are:

Pitch is spacing. It refers to the spacing of conductors within the ribbon cable. The pitch depends on the cable requirements and specifications. Some examples of pitches include 0.5mm, 1mm, 1.25mm, and 2mm.

Another way of determining the pitch of the ribbon cable is by measuring the outside edge of the cable and then dividing the figure by the total number of connectors.

Ribbon cables tolerate all sorts of temperatures, be they harsh or friendly. But, if ribbon cables operate perfectly in unfavorable temperatures, a silicon jacket is the best bet.

In choosing ribbon cables, flexibility is a necessary factor. Since ribbon cables are flexible, there is still a need to purchase a more flexible type. If the design is limited or requires a more flexible type, purchase a custom ribbon cable with greater flexibility that suits the job.

Consider the life span of the ribbon cable you intend to purchase. Like every other electrical component, choosing a ribbon cable that can survive the test of time is necessary.

Fire resistance is another factor to consider when choosing a ribbon cable. The importance is not only for the benefits of the electrical equipment but also for safety.

Make it a duty to settle for a ribbon cable type in line with the EU’s Restriction of Hazardous Substances Directives and fit according to fire safety standards.

Cloom Tech is not just a body of professional teams specialized in different areas of expertise. With us, you are guaranteed a superb custom ribbon cable service, as it is a part of what we are known to do well.; we are a team of seasoned professionals who take a keen interest in delivering effective results.

Ribbon cables are indeed important for various connections of sorts. They play important roles in connecting various applications like mobile phones, laptops, and electronic devices.

These colored-looking cables are very efficient in producing second-to-none output results. They appear in various sizes and pitches. It is important to derive all its information to fully use the ribbon cable.

This Gymnast Medal Display and Ribbons Holder is new design for 2018. We offer a full line of Medal displays with hundreds of design combinations for all our medal holders, pict...

If you need help replacing the top screen on an original DS, refer to this set of instructions. If you are trying to repair the bottom LCD or touch screen on an original DS, those instructions won"t help much, but I"m not too sure how much the DS lite instructions coincide with the original DS"s.

Let me just begin by saying: these cables are the primary cause of errors, failed repairs and general headaches. You need to be very careful, and if there"s a problem with any of your screens, it"s probably due to a cable misaligned, improperly latched down, or simply broken by mishandling (most likely due to the repairer"s efforts).

Carefully open the console up, and push gently on the bottom screen to free the PCB. "Flip" the PCB over, so that you can see both the bottom LCD, as well as the top LCD.

Now, there will be two ribbon cables readily visible, and one more little one slightly hidden. One broad cable, and the little cable are for the bottom LCD, but the remaining broad cable is the one linked to the top screen.

If you are replacing the top LCD and/or shell: you will need to unlatch one of the big ribbon cables (the one nearest to the hinge), but leave the other two alone.

If you are replacing the bottom LCD and/or touch screen: you will probably want to detach the bottom LCD + touch screen cables, but do not touch the big ribbon cable that"s connected closest to the hinge.

For unlatching the two larger cables: there are two beige plastic connectors linking the cables to the PCB. See the narrow black plastic bar lying across the ribbon cable? Carefully wedge your fingernail in, under the black latch, from the cable side and then gently pry up. If you use a screwdriver to do the prying, be extremely cautious not to damage the plastic, as any misalignment of any of these cables will render the console rather useless.

For unlatching the small cable: Flip the PCB over so that you cannot see the screen, and turn the console so that Slot 1 (the hinge edge) is towards you. Slightly to the right of Slot 1 is a tiny cable connection (the cable is about 2mm wide). See the tiny black latch? You will need to carefully flip it towards you. You will probably need to use a flat-head screwdriver or tweezers.

This step is applicable only if you are replacing the top screen, and/or the shell. (If you are replacing just the bottom LCD and/or touch screen, you should have already finished your repairs by now. Go back to step 2 and step 3.)

You need to be looking at the plastic shell, under the bottom PCB. See two screws on one side of the hinge? Remove these. Now separate the two halves of the DS, but be careful not to damage the two wires and ribbon cable still connecting both sections!

With both halves disconnected at the hinge, feed the ribbon cable from the bottom PCB side, through the slot in the hinge, and gently pull the ribbon all the way through.

If you are replacing the top LCD, you can "cheat" and simply cut the ribbon cable to bypass threading the end through the hinge. This, however, would be a terrible idea if you intend to continue using that screen.

It"s somewhat tricky to get the screen up. If you are only replacing the LCD, you should attempt to leave the plastic cover in place, attached to the shell, and be very careful not to scratch it. A replacement LCD will not include a new plastic cover, but a shell replacement probably will.

If you are not replacing the top LCD, proceed to the next step for shell replacement information. (If you are only replacing the bottom LCD and/or touch screen, you are totally in the wrong place. Go back to step 2 and step 3.)

Take your new LCD and solder the speakers on to the appropriate pads on the cable. There should be tiny "+" and "-" signs at each of the four contact points. Just figure out which speakers should be soldered to which pair, and then match the red wires to the "+" pads, and the black wires to the "-" pads.

-Take the ribbon cable, coil it and then feed it through the small section of hinge. You will want to coil it such that the loop is towards the front of the LCD (refer to photos), and have it wrapped around the white & black wires that connect to the bottom half of the DS.

-Take the ribbon cable on the LCD, coil it and then feed it through the small section of hinge that is part of the top half of the DS. You will want to coil it such that the loop is towards the front of the LCD (refer to photos).

I also broke the black plastic clamp that holds the touch screen ribbon cable in place on my old dslite and was told by people here and official places that my ds was done for, well as far as the touch screen was concerned as there is no place to buy those particular spare parts!

What i did was to place a large bit of bluetac on the ribbon and close the ds very gently whilst holding the bluetac in place, a little trial and error but once the case has been pushed together you can test to see if it works without screwing it all back together.

The other idea would be to buy a broken ds of ebay or somewhere so you can get that black clip off it and also a new top screen though i think you probably just need to remove the ribbon cable and re seat it for the screen to work as its probably just not pushed in properly!

Ms.Josey

Ms.Josey

Ms.Josey

Ms.Josey