lcd panel no backlight free sample

Newhaven 160x100 graphic Chip-On-Glass (COG) Liquid Crystal Display shows dark pixels on a gray background. This reflective LCD Display is visible with high ambient light while offering a wide operating temperature range from -20 to 70 degrees Celsius. This NHD-C160100CZ-RN-FBW display has an optimal view of 6:00 and has no backlight. This display operates at 3V supply voltage and is RoHS compliant.

Adjust the length, position, and pinout of your cables or add additional connectors. Get a cable solution that’s precisely designed to make your connections streamlined and secure.

Choose from a wide selection of changes including shape, size, pinout, and component layout of your PCB to make it a perfect fit for your application.

This graphic LCD module acts as a shield for Arduino Uno-style microcontrollers. The pins on the carrier board match up to the Arduino Uno"s ports, so the module simply presses on and is fully and correctly connected. Plus, this carrier board is able to be connected to either a 3.3v logic level or a 5v logic level device. (Read our blog post if you have questions about logic level.)

This module is also available with a white-on-blue graphic display, or as a fully built kit with an included Seeeduino (Arduino Uno clone) loaded with code to demonstrate the graphic display.

The hardware design of this carrier board is open source. Under the Datasheets & Files tab is a downloadable zip file that contains everything you need to manufacture your own boards: Gerber files, PADs source schematic and layout, and full BOM. If you have any questions, please contact our knowledgeable and friendly support staff by email, phone, or chat.

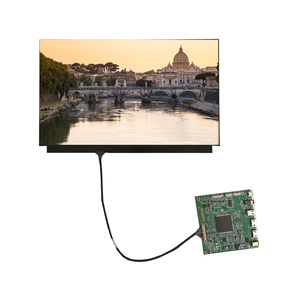

Compared with lcd displays in bulk available, Alibaba.com offers both options of them. For lcd displays and bulk functions, Lcd displays provide more functions and are aesthetically pleasing.

Both lcd displays and Lcd enable similar functions and arefabricated from the source. Lcd displays, on the other hand, are more conventional and can be used for a variety of purposes.

Find wholesale lcd displays in bulk, Alibaba.com offers a wide variety of options. For the buyers who are looking for a more portable LCD display in bulk, that are the for.imum brightness in the future. Many lcd displays in bulk will have a better brightness future than.

Unlike conventional displays, lcd displays offer more buttons and interfaces for other information, as well as a mechanism. Find a variety of lcd displays available on Alibaba.com to stock and stock lcd displays with different features, such as touch sensitive, light-emitting diodesal, or LED signals.

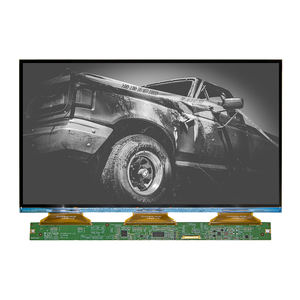

We manufacture and stock backlight assemblies for many Innolux LCD panels. We produce premium quality replacements to extend the life of your flat panel screen devices. If you do not see your panel model listed here, please contact us to learn about our cost effective design and manufacturing process. Simply mail us a sample of the backlight you are looking to replace, and we can recreate and supply you with what you need to meet you needs.

We manufacture and stock backlight assemblies for many AUO LCD panels. We produce premium quality replacements to extend the life of your flat panel screen devices. If you do not see your panel model listed here, please contact us to learn about our cost effective design and manufacturing process. Simply mail us a sample of the backlight you are looking to replace, and we can recreate and supply you with what you need to meet you needs.

DASUNG"s 3rd Generation E-ink Monitor-Paperlike 3 (Paperlike HD), 13.3” E-ink Screen (Carta & Flexible), 2200*1650 Retina Display. Just Like a Real Paper. Fast nearly as LCD. No Back Light. No Blue Light. No Screen Flash. You can Type, Code, Browse the Web, etc. Work well with any Equipment (HDMI). Support PC/ Mac/ iPhone/ iPad and so on.It is the best monitor to protect your eyes.

This DASUNG"s Paperlike HD monitor uses electronic paper. For those not familiar with this technology it is also sometimes called "electronic ink or electrophoretic display, are display devices that mimic the appearance of ordinary ink on paper. Unlike conventional flat panel displays that emit light, electronic paper displays reflect light like paper. This may make them more comfortable to read, and provide a wider viewing angle than most light-emitting displays. The contrast ratio in electronic displays available as of 2008 approaches newspaper, and newly (2008) developed displays are slightly better. An ideal e-paper display can be read in direct sunlight without the image appearing to fade."

I"ve been working on an iPad 2 that was dropped. It worked fine, despite the digitizer glass being shattered. I carefully disassembled the unit and installed a new Digitizer. Before sealing the digitizer in place, I tested the iPad. I discovered that the LCD backlight was not working. I reseated all cables. No change. I inspected the unit for any visible damage and found none. I replaced the LCD with a known working unit—and there"s still no backlight on the iPad. What else could be wrong?

As I reflect on my disassembly procedure, I have considered that I did something differently the second time around. The first time, I used a plastic scribe to release the LCD cable from the logic board. The second time around, I used the mini screwdriver from the kit to pop up the retainer. Reflecting on my actions, and knowing better, using the screwdriver probably created a short across contacts and damaged the logic board, despite my working carefully. Of course, I am just guessing—but that was a difference between the two repairs I did. The first iPad repair being successful—the second, not so successful.

Note: If your MacBook Pro has any damage which impairs the service, that issue will need to be repaired first. In some cases, there may be a cost associated with the repair.

LCD (Liquid Crystal Displays) have two options or display modes.Positive mode (dark characters on a light colored background) and negative mode (lighter colored characters on a darker background).

Positive mode displays have the advantage of their lighter background and no backlights are needed. They normally use transflective or reflective polarizers and have lower power consumption. They can be seen with ambient light.

Negative mode displays need backlit in order to be seen. They normally use transmissive polarizers. They have better contrast and wider viewing angles in the indoor dim environment. The readability is much better than positive displays.

But under bright ambient light or even under direct sunlight, the displays will be easily washed out. In order to be seen under the bright surrounding light, the backlight brightness has to be increased to over 800 nits. The sunlight readable displays consume much power.

Of course, we can always use LED backlight in the LCD module with fewer LED chips and turn off LED backlight when not use to save power. When can also add transflective polarizer to some negative LCDs to make it sunlight readable, but the contrast will be compromised.

Positive and negative mode concept is not only limited to monochrome LCD displays (LCD panels, character LCDs, graphic LCDs etc.), it also uses for color displays, or even other display technologies. We will categorize the displays as below,

Character LCD modules (Alphanumeric LCD display modules) with character sets: 8×1 LCD display, 8×2 LCD display, 16×1 LCD display, 16×2 LCD display, 16×4 LCD display, 20×2 LCD display, 20×4 LCD display, 24×2 LCD display, 40×2 LCD display, 40×4 LCD display. COB (Chip on Board) bonded, 4 or 8 bits parallel, SPI, I2C interface

Graphic LCD modules with dot matrix sets 122×32, graphic LCD display, 128×64 graphic LCD display, 192×48 graphic LCD display,192×64 graphic LCD display,240×64 graphic LCD display,240×128 graphic LCD display,240×160 graphic LCD display with different color LED backlights, with COB and COG (Chip on Glass) assembling technologies

Monochrome and Color Graphic OLED modules with dot matrix sets 128×32 graphic OLED display,128×64 graphic OLED display, 128×96 graphic OLED display, 160×128 graphic OLED display, 128×128 graphic OLED display, 256×65 graphic OLED display

Full Color TN and IPS displays with panel sizes: 1.3”IPS display, 1.44” TN display, 1.5” IPS display, 1.77”TN and IPS displays, 2.0” TN and IPS displays, 2.2” IPS display, 2.35” IPS display, 2.4” TN and IPS displays, 2.8” TN and IPS displays, 3.5” TN and IPS displays, 4.3” TN display, 5.0” TN and IPS display, 7.0” TN and IPS display, 10.1” IPS display with medium and high brightness (sunlight readable), with parallel, SPI, RGB, LVDS, MIPI interfaces.

LCD displays don’t emit light by themselves. They need a light source, and LED backlights are now dominating the market. In this article, Orient Display’s Bill Cheung provides a complete overview of LED backlight technology, discussing different types, driver technologies, color deviation, brightness options and more.

LCD (liquid crystal display) has long been the dominant technology in the display world. Certainly, there are some emerging competing display technologies—such as OLED (Organic Light Emitting Diode) [1] and micro-LED—that have the potential to threaten LCD’s position in the market. But both are currently only used for niche and high-end markets.

An LCD display can’t emit light by itself. In order to have an LCD display [2] used in a dim environment, a backlight has to be used as the light source. There are a few different technologies that are able to produce backlight ranging from EL (electroluminescent), CCFL (cold cathode fluorescent lamps) and LED (light emitting diode). However, a breakthrough in blue LED technology by Shuji Nakamura [3] led to LED backlights dominating the market.

One of the greatest benefits of LED backlighting is its long lifetime. Normally, LED lifetime can be measured with half-life when the original brightness decreases by 50%. With different LED chip manufacturing materials, technologies and environment used, the LED life can vary from 20,000 hours to well over 100,000 hours.

LED backlights have low power consumption and produce much less heat than other backlight technologies, which extends the durability and performance of the other display components. Furthermore, this reduces the risk of fire and explosion. LED backlights are also driven with DC (direct current) and low voltage (can be as low as 1.5V), which are good for battery drive and emit no interference to the circuitry. With the development of LED technology, the LED chips become small. So, it is possible to produce very thin backlight (0.5mm thick or thinner).

Although white LED is the most popular color, LED backlight can be made into different single colors, bi-colors and tri-colors [4] (Figure 1) (Figure 2). With RGB LED backlight color mixing, normal 8 color LED backlight can be produced (Figure 3).

LED backlight can be classified as bottom (array) lit and side (edge) lit backlights, and each have their plusses and minuses. The advantages of the bottom lit (array) backlight are that it is uniform and bright. Its disadvantage is high current draw, thickness, heat dissipation and cost. Meanwhile, the advantages of the side lit backlight are its thinness, flexibility in design, low current and lower cost. The main disadvantage of the side lit backlight is its non-uniformity—hot spots can be seen from most of the side lit backlight from certain angle. Figure 4 compares the bottom lit and side (edge) lit backlight LCD types.

Now let’s look at LED backlight structures. An LED backlight can be simplified into layers starting with a LED chip, light guide, diffusor and reflector (Figure 5). This is the lowest cost structure. Except for some very low current efficiency LCD displays—such as utility meters, battery-powered clock, watch, GPS and so on—most LCD displays need backlights to be visible in the dim lighting. Most often the backlight is actually at the back of the LCD. In rare cases, this light can be done as front light. The traditional LCD structure with LED backlight shown in Figure 6.

Direct current driving: This is the simple and low-cost way to drive a LED backlight, however, be mindful of the current limit otherwise the LED life can deteriorate quickly. The solution is simply to add a current limiting resistor in the circuit. Current limitation resistors value calculation formula: R = (V0– Vf)/If.Also be mindful of reverse drive, otherwise, the LED chip can break down easily.

LED driver with constant current: The advantage of constant current LED driver is that it will be the best option to use when building your own fixture or working with high powered LED because they avoid violating the maximum current specified for the LEDs, therefore avoiding burnout/thermal runaway. They are easier for designers to control applications, and help create a more consistent bright light.

LED driver with constant voltage: Using a constant voltage LED driver makes sense when using an LED or array that has been specified to take a certain voltage. This is helpful because constant voltage is a much more familiar technology for design and installation engineers. Moreover, the cost of these systems can be lower, especially in larger scale applications.

There are a variety of ways to connect a backlight and LCD module electrically. It can be done with wires that are soldered on the LCD or LCD module. It can be connected using pins, which can be soldered onto the LCD or LCD module. A third way is to use a FPC (flexible printed circuit), which can be soldered or plugged in a ZIF (zero insertion force) connector. And finally, there is the connector method. With this method you use connectors which can be plugged into mating connectors.

As the LED is manufactured via the semiconductor process, there are some color deviations that can be a quality control issue. One way to solve the issue is through a process of selection and sorting after manufacturing the LEDs. The LEDs are sorted into different categories or bins. How this sorting is done and what each bin actually contains is defined differently by each LED manufacturer. The backlight manufacturer can choose from which bin they take the LEDs for backlight color hue.

Some customers might request very fine binning by the LED manufacturer, which can be very expensive since only a very small percentage of the LEDs manufactured would meet the requirements for a specific bin. Figure 7 shows an example of the bin selection from Nichia, the most renowned LED manufacturer in the world. Figure 8 shows the 1931 CIE chromaticity diagram. And Figure 9 shows the color deviations (bin definition) by Cree for a qualified production lot.

In actual LED backlight production, most customers will accept the LED color for two big categories: white with yellowish (warm) and white with bluish (cold). Of course, the LED brightness will also need to be defined. For general application, most customers will accept a brightness tolerance of 70 percent.

It is extremely hard to estimate the LED backlight lifetime or MTBF (mean time between failures) because there are so many variable factors. However, the most important is the temperature on the LED chip. The factors that can affect the LED chip temperature include: surrounding temperature, humidity, driving current, voltage, backlight design (how many LED chips to be used, how close to each other, heatsink design), backlight manufacturing process (type and thickness of adhesive), quality of the LED chip and so forth.

To test the LED life is also very time consuming, requiring at least 1,000 hours. That’s the reason why no LED manufacturers can guarantee LED backlight life and most backlight manufacturers also are reluctant to provide lifespan data. As for LCD manufacturers, they need to discuss it with the customer to understand the applications and provide suggestions. It is normal that the LCD datasheet lists the typical life time and avoids providing a minimum lifetime. From Figure 10, we can see that over room temperature, the current needs to decrease as the temperature increases. At over 85°C, the LED is not usable.

To estimate LED backlight lifetime, you can use ballpark estimation or theoretical calculation. Let’s first examine the ballpark method. To take white LED as example, the nominal biasing current is 20mA. If we use a safe lifetime estimation, we can estimate using Table 1.

Now let’s use the theoretical calculation approach. As we previously mentioned, LED life is affected by a lot of factors: surrounding temperature, humidity, driving current, voltage, backlight design (how many LED chips to be used, how close to each other, heatsink designed), backlight manufacturing process (type and thickness of adhesive), quality of the LED chip and so on. LED chip manufacturers are not willing to give absolute values of LED chip lifetimes, but there is a theoretical calculation that we can use.

Finally, let’s look at ways to increase LED backlight brightness. There are many ways to increase LED backlight brightness, but all these measures are balanced with performance and cost. Here are some of the methods:

For the LCD module side, using better aperture opening ratio, anti-reflection coating on surface, optical bonding. This results in higher cost. Actually, this measure is not to increase LED backlight brightness directly but to increase to the visibility to users.

Note: We’ve made the May 2020 issue of Circuit Cellaravailable as a free sample issue. In it, you’ll find a rich variety of the kinds of articles and information that exemplify a typical issue of the current magazine.

Bill Cheung is an engineering lead and marketing manager at Orient Display, an LCD and display technology provider with over two decades of industry experience in delivering cutting edge display solutions. You can browse Orient Display"s knowledge base [7] to learn more about LCDs.

Transmissive LCD is the most common LCD screen, which requires a backlight as the light source and there is no reflective film at the back of the LCD screen.

Advantage: we can see the graphic and character on the screen very clearly if there is only little light. It is such a mature and cheap technology that 90% of LCD screens in the market are transmissive LCD display.

Reflective LCD is the cheapest LCD screen because there is no backlight, which uses light from outside as the light source, such as sunshine or lamplight and there is a reflective film at the back of the LCD screen.

Transflective LCD is the best and most expensive LCD screen, which has a semi-reflective film at the back of the LCD screen. The front light can’t go through the semi-reflective film, but the backlight can go through it. Like sunglasses.

Advantage: it has the advantages of both transmissive LCD and reflective LCD. We not only can see it very clearly in the outdoor like the reflective LCD, but also can see it vividly when we are in a dark place like a transmissive LCD. We see the transflective LCD in the front as the reflective LCD because it can reflect the sunshine, but the LED backlight panel can also supply the light which can penetrate the semi-reflective film at the back of LCD screen.

Accidental Damage is any damage due to an unintentional act that is not the direct result of a manufacturing defect or failure. Accidental damage is not covered under the standard warranty of the product. Such damage is often the result of a drop or an impact on the LCD screen or any other part of the product which may render the device non-functional. Such types of damage are only covered under an Accidental Damage service offering which is an optional add-on to the basic warranty of the product. Accidental Damage must not be confused with an occasional dead or stuck pixel on the LCD panel. For more information about dead or stuck pixels, see the Dell Display Pixel Guidelines.

No, accidental damage is covered for Dell computers or monitors which are covered under the Accidental Damage Service offering for that specific product.

NOTE: Other damages may be considered customer induced if determined by Dell Technical Support, an on-site field engineer, or at the mail-in repair center.

The LCD glass on the display is manufactured to rigorous specifications and standards and will not typically crack or break on its own under normal use. In general, cracked, or broken glass is considered accidental damage and is not covered under the standard warranty.

Spots typically occur due to an external force hitting the screen causing damage to the LCD panel"s backlight assembly. While the top layer did not crack or break, the underlying area was compressed and damaged causing this effect.

If your Dell laptop LCD panel has any accidental damage but the laptop is not covered by the Accidental Damage service offering, contact Dell Technical Support for repair options.

Dell monitors cannot be repaired by an on-site field engineer or at the mail-in repair center. If you notice any damage to the monitor, you must purchase a new monitor.

Laptop users can strive to make the most of their laptops to maximize stability, longevity, and usability. Understanding and implementing a few best practices for the safe handling of their laptop will enable them to enjoy their laptop for many years to come. For more information, see the Dell knowledge base article Dell Laptop Best Practices for Care, Use, and Handling.

The V-LCD651STX-3GSDI offers a durable and lightweight design, weighing in at only 1.3 pounds. It also features our completely digital TFT-MegaPixel high resolution LCD screen with 2.4 million pixels, 4-pin XLR power jack, and optical-grade polycarbonate screen protection. Analog signals are digitized using advanced 10-bit processing with 4x oversampling and adaptive 5-line comb filter.

Marshall Electronics offers a full line of Super Transflective Outdoor Monitors, designed specifically for outdoor applications with high ambient light. Our technology minimizes surface reflection of both outdoor and indoor light, while featuring a much wider color reproduction range than typical transflective/reflective LCDs or even those with increased backlight performance.

These outdoor super-transmissive LCDs provide improved visibility by producing high-contrast images and a wider viewing angle, even under diverse and challenging lighting environments! This innovative technology dramatically boosts the efficiency of the LCD backlight"s light utilization, while maintaining extended temperature ratings and low power consumption for outdoor operation.

To best utilize this feature, you must understand the color chart and have a basic understanding of camera exposure. Normally, when shooting subjects like people, it is common practice to set exposure of faces to the equivalent of approximately 56 IRE. The False Color filter will show this area as the color PINK on the monitor. Therefore, as you increase exposure (open the IRIS), your subject will change color as indicated on the chart: PINK, then GREY, then a few shades of YELLOW. Overexposed subjects (above 101 IRE) on the monitor will be shown as RED. In addition, underexposed subjects will show as DEEP-BLUE to DARK-BLUE, with clipped-blacks indicated with a FUCHSIA-like color. Lastly, the color GREEN is used to indicate elements of the image that are approximately 45 IRE. This represents a "neutral" or "mid-level" exposure commonly used for objects (not people).

The Peaking Filter is used to aid the camera operator in obtaining the sharpest possible picture. When activated, all color will be removed from the display and a black-and-white image will remain. The internal processor will display RED color on the screen where sharp edges appear. When the camera operator adjusts (or "racks") the focus control (on the camera lens), different parts of the image will have RED colored edges. This indicates that this portion of the image is sharp or in focus. Final focus is achieved by racking the camera lens focus control back and forth until the desired portion of the image has RED colored edges. Please note that this feature is most effective when the subject is properly exposed and contains enough contrast to be processed.

Ms.Josey

Ms.Josey

Ms.Josey

Ms.Josey