2 4 tft lcd shield library price

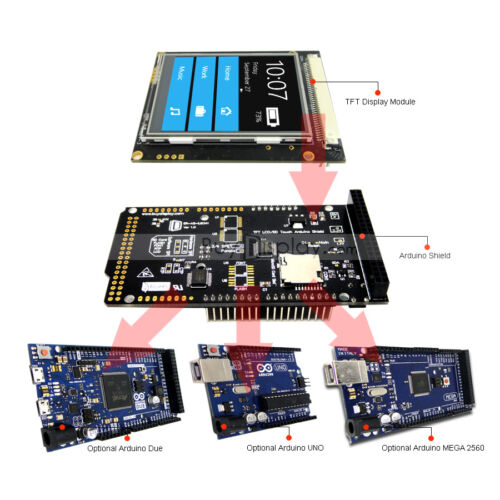

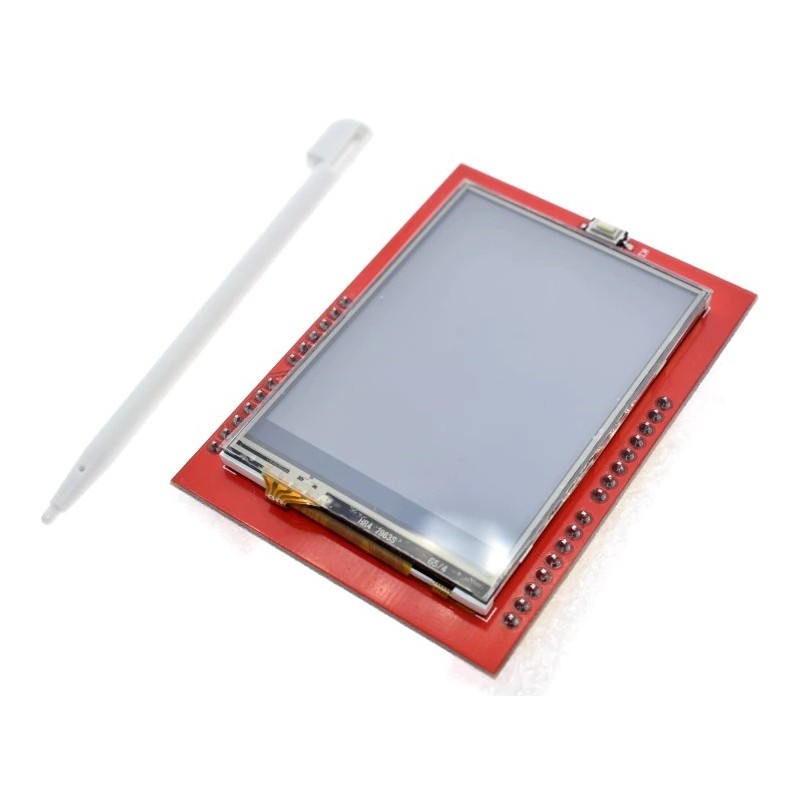

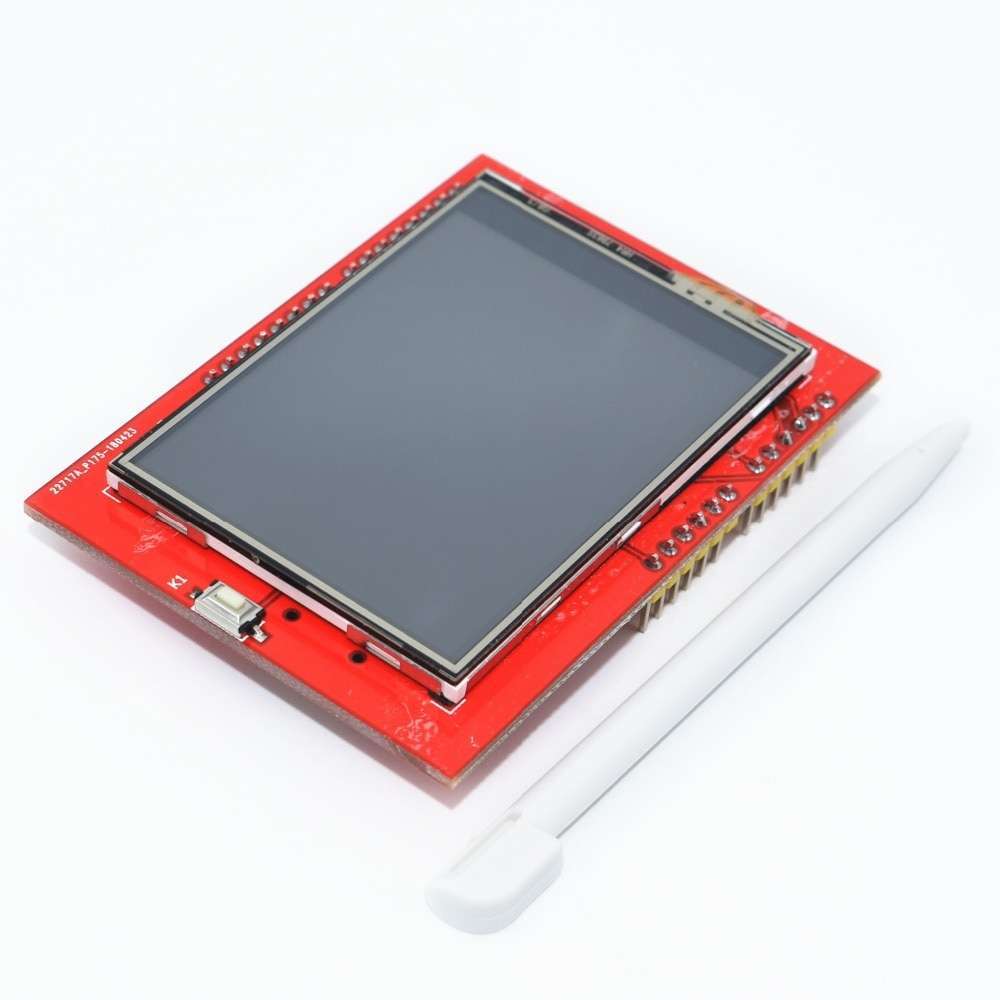

Spice up your Arduino project with a beautiful touchscreen display shield with built in microSD card connection. This TFT display is 2.4" diagonal and colorful (18-bit 262,000 different shades)! 240x320 pixels with individual pixel control. As a bonus, this display has a optional capacitive touch panel and resistive touch panel with controller XPT2046 attached by default.

The shield is fully assembled, tested and ready to go. No wiring, no soldering! Simply plug it in and load up our library - you"ll have it running in under 10 minutes! Works best with any classic Arduino (UNO/Due/Mega 2560).

This display shield has a controller built into it with RAM buffering, so that almost no work is done by the microcontroller. You can connect more sensors, buttons and LEDs.

Of course, we wouldn"t just leave you with a datasheet and a "good luck!" - we"ve written a full open source graphics library at the bottom of this page that can draw pixels, lines, rectangles, circles and text. We also have a touch screen library that detects x,y and z (pressure) and example code to demonstrate all of it. The code is written for Arduino but can be easily ported to your favorite microcontroller!

Spice up your Arduino project with a beautiful touchscreen display shield with built in microSD card connection. This IPS TFT display is 2.4" diagonal and colorful (18-bit 262,000 different shades)! 240x320 pixels with individual pixel control. As a bonus, this display has a optional capacitive touch panel and resistive touch panel with controller XPT2046 attached by default.

The shield is fully assembled, tested and ready to go. No wiring, no soldering! Simply plug it in and load up our library - you"ll have it running in under 10 minutes! Works best with any classic Arduino (UNO/Due/Mega 2560).

This display shield has a controller built into it with RAM buffering, so that almost no work is done by the microcontroller. You can connect more sensors, buttons and LEDs.

Of course, we wouldn"t just leave you with a datasheet and a "good luck!" - we"ve written a full open source graphics library at the bottom of this page that can draw pixels, lines, rectangles, circles and text. We also have a touch screen library that detects x,y and z (pressure) and example code to demonstrate all of it. The code is written for Arduino but can be easily ported to your favorite microcontroller!

1.2.4 inch arduino shield with resistive touch panel could only support Due board. It can support DUE,UNO,MEGA2560 boad if matched with capacitive touch panel.

2.If you"ve had a lot of Arduino DUEs go through your hands (or if you are just unlucky), chances are you’ve come across at least one that does not start-up properly.The symptom is simple: you power up the Arduino but it doesn’t appear to “boot”. Your code simply doesn"t start running.You might have noticed that resetting the board (by pressing the reset button) causes the board to start-up normally.The fix is simple,here is the solution.

Received one motor without encoder magnet. All 4 motors are running with differnr speeds, there by robot is not maintaing straightness for even 1 meter travel distance. Mobile app is connecting with robot 1 time out of 5 times trying.

Ground clearence is very less , so I placed order for 80mm wheel dia. Speaker is supplied but no place to fix. Specified DC motors are not available in India presently. No operating guide for 1st time use of robot. There is a switch on USB expansion board... Usage not clear. Rarly 2 beeps are coming while start up... then only mobile app is connecting other wise no beep most of the time.

This Simple No library test sketch for Arduino Uno and the2.4" 320x240 TFT LCD Shield from Banggood.com, is based on a version 2 release sketch from Banggoo...

I"ll show you how to get started with a very popular variant of the TFT touch screen, including how to make a "button" (spoiler alert: it"s not a button just an area of screen that looks like one, that you can then receive touches from).

To download. click the DOWNLOADS button in the top right corner, rename the uncompressed folder Adafruit_ILI9341. Check that the Adafruit_ILI9341 folder contains Adafruit_ILI9341.cpp and Adafruit_ILI9341.

Place the Adafruit_ILI9341 library folder your arduinosketchfolder/libraries/ folder. You may need to create the libraries subfolder if its your first library. Restart the IDE

There are many tutorials on Arduino shields for 2.4 inch TFT LCD displays. In this road test I apply different tutorials to check the performance and issues of this specific shield: AZ-Delivery 2.4 inch TFT LCD display with resistive 4-wire touchscreen and an integrated SD card reader.AZ-Delivery 2.4 inch TFT LCD display.

TFT LCD is a variant of a liquid-crystal display (LCD) that uses thin-film-transistor (TFT) technology. That improves image quality, better contrast and addressability.

Depends on the needs of your project. Arduino UNO processor frequency is low. With the Arduino UNO full-color TFT LCDs are suitable to display simple data and commands. The TFT controller used cannot switch internal display RAM, so you can"t use the double buffer technique for animations but still you can only re-draw small sections of screen.

This module consumes most of the resources available in Arduino UNO. This is not a limitation of the module itself. In return, using a parallel interface allows you to quickly update the image. If you want to take advantage of all its functionality (LCD + touch screen + SD card), only pins 0 and 1 (RX and TX, respectively) and pin 19 (A5) remain unused. If the SD card is not used, pins 10, 11, 12 and 13 are additionally available. With a suitable layout, some SPI devices could be connected even if the SD card is used.

The module arrived well packed and in perfect condition. The board comes in a sealed antistatic bag, with protective foams to prevent the terminals from bending, and all this wrapped with a bubble bag and inside an individual cardboard box. The label on the antistatic bag indicates the controller is an ILI9341.

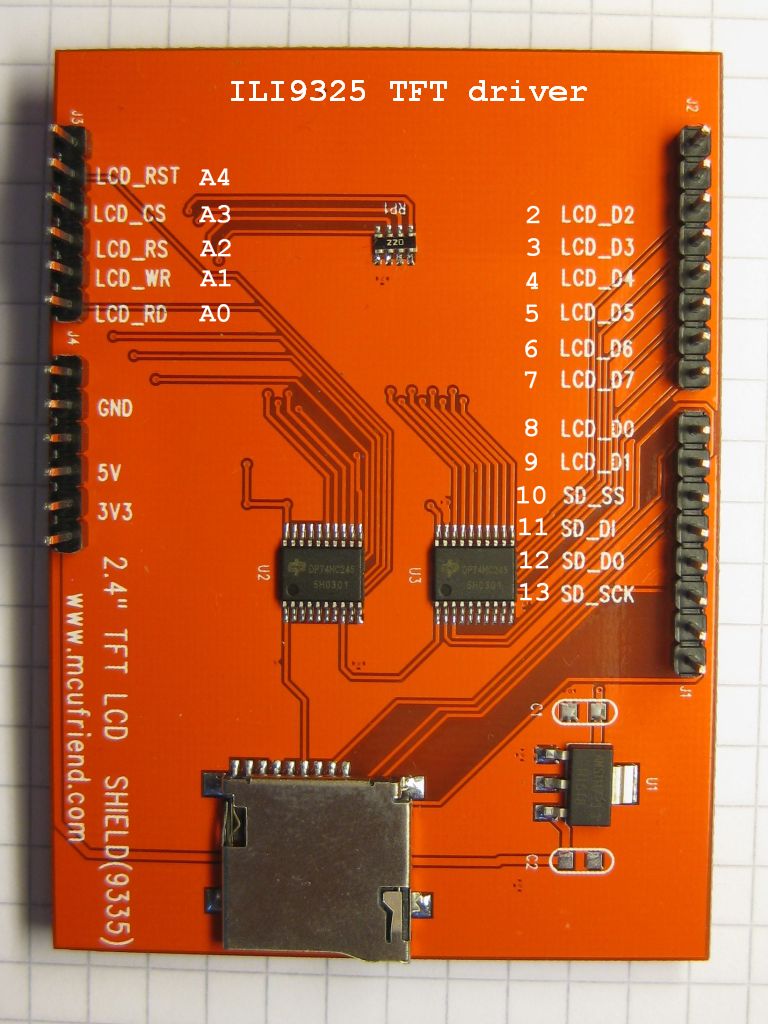

The PCB silkscreen indicates the main function of each pin, the labels are easy to read, although it does not show labels for the touch screen pins:Pin 9 - Touch X+ / LCD_D1

The SD card reader is very well located between the USB connector and the power connector, it does not touch either of them as it happens in other lcd tft shield modules and it is easily accessible to insert and remove the SD cards.

You can directly use the shield with any arduino uno. In this case we are using an Arduino UNO that exposes all the pins both on the header and on the board. In such a way that you do not need another shield to access the pins not used by the screen

ShieldCompatible with Arduino. 5V compatible, can be used with 3.3V or 5V logic. On-board 3.3 V (300mA LDO controller). The design is very well thought out and fits Arduino UNO perfectly.

2x74LVC245A Octal Bus Transceiver With 3-State outputs. This octal bus transceiver is designed for 1.65-V to 3.6-V VCC operation. The LVC245A is designed for asynchronous communication between data buses. The device transmits data from the A bus to the B bus or from the B bus to the A bus, depending on the logic level at the direction-control (DIR) input. The output-enable (OE) input can be used to disable the device so the buses effectively are isolated. Inputs can be driven from either 3.3-V or 5-V devices. This feature allows the use of this device as a translator in a mixed 3.3-V/5-V system environment. This chip solves the problem of how to interface 3.3V logic devices to a 5.0V logic chip such as the Arduino. Most 3.3V devices do not like being run with 5V signals and can be damaged or flaky. The 74LVC245 is designed so that even when it runs at 1.8V, it still happily accepts 5V signals in one pin and converts it to a lower logic level on the opposite pin. It has 8 pipes it can convert but it won"t work with bi-directional/pull-up based devices such as I2C or 1-Wire. It does work great for SPI, Serial, Parallel bus, and other logic interfaces.

If you want to take advantage of all its functionality (LCD + touch screen + SD card), only pins 0 and 1 (RX and TX, respectively) and pin 19 (A5) remain unused. If the SD card is not used, pins 10, 11, 12 and 13 are additionally available. With a suitable layout, some SPI devices could be connected even if the SD card is used.

The ILI9341 which can control each pixel with a small number of pins. The shield connects ILI9341"s data pins 0-7 to Arduino digital pins 2-8 (allowing parallel communication, not SPI). ILI"s RESET goes to pin to Arduino analog pin A4.CS (chip select) to A3. RS (CD command/data) to A2. WR and RD to A1 and A0.

Includes a resistive 4-wire touchscreen (touchpad). The touch screen is attached on the surface of the display. Touch screen needs two analog inputs and two digital outputs. It connects through 4 wires, which share arduino pins 8, 9, A2, A3 with the ILI9341 driver. So you can"t write to LCD display and read the touch screen in the same time. I. Driver chip is XPT2046.

The resistive touch screen does not appear to appreciably affect the optical characteristics. Works properly, It takes a little pressure with the stylus for it to respond like in old mobile phones. You notice how it sinks into the screen when you press with the stylus. The stylus that comes with the module makes it easy to use if your interface design uses small controls. Some touch screen libraries offer better accuracy by specifying the resistance of the touch screen in the X direction. Resistance can be easily measured with a multimeter by connecting the test leads to the LCD_D1 - X + and LCD_DS X- terminals. Touch is sensitive to pressure.

The SD card reader works well. Accessing the SD card with the functions available in the SD library included in the IDE version used does not present any problem. SD cards are recognized and can be written or deleted.

In this Arduino touch screen tutorial we will learn how to use TFT LCD Touch Screen with Arduino. You can watch the following video or read the written tutorial below.

The next example is controlling an RGB LED using these three RGB sliders. For example if we start to slide the blue slider, the LED will light up in blue and increase the light as we would go to the maximum value. So the sliders can move from 0 to 255 and with their combination we can set any color to the RGB LED, but just keep in mind that the LED cannot represent the colors that much accurate.

As an example I am using a 3.2” TFT Touch Screen in a combination with a TFT LCD Arduino Mega Shield. We need a shield because the TFT Touch screen works at 3.3V and the Arduino Mega outputs are 5 V. For the first example I have the HC-SR04 ultrasonic sensor, then for the second example an RGB LED with three resistors and a push button for the game example. Also I had to make a custom made pin header like this, by soldering pin headers and bend on of them so I could insert them in between the Arduino Board and the TFT Shield.

Here’s the circuit schematic. We will use the GND pin, the digital pins from 8 to 13, as well as the pin number 14. As the 5V pins are already used by the TFT Screen I will use the pin number 13 as VCC, by setting it right away high in the setup section of code.

I will use the UTFT and URTouch libraries made by Henning Karlsen. Here I would like to say thanks to him for the incredible work he has done. The libraries enable really easy use of the TFT Screens, and they work with many different TFT screens sizes, shields and controllers. You can download these libraries from his website, RinkyDinkElectronics.com and also find a lot of demo examples and detailed documentation of how to use them.

After we include the libraries we need to create UTFT and URTouch objects. The parameters of these objects depends on the model of the TFT Screen and Shield and these details can be also found in the documentation of the libraries.

So now I will explain how we can make the home screen of the program. With the setBackColor() function we need to set the background color of the text, black one in our case. Then we need to set the color to white, set the big font and using the print() function, we will print the string “Arduino TFT Tutorial” at the center of the screen and 10 pixels down the Y – Axis of the screen. Next we will set the color to red and draw the red line below the text. After that we need to set the color back to white, and print the two other strings, “by HowToMechatronics.com” using the small font and “Select Example” using the big font.

Ok next is the RGB LED Control example. If we press the second button, the drawLedControl() custom function will be called only once for drawing the graphic of that example and the setLedColor() custom function will be repeatedly called. In this function we use the touch screen to set the values of the 3 sliders from 0 to 255. With the if statements we confine the area of each slider and get the X value of the slider. So the values of the X coordinate of each slider are from 38 to 310 pixels and we need to map these values into values from 0 to 255 which will be used as a PWM signal for lighting up the LED. If you need more details how the RGB LED works you can check my particular tutorialfor that. The rest of the code in this custom function is for drawing the sliders. Back in the loop section we only have the back button which also turns off the LED when pressed.

Since inception in 2009, company has expanded to become a national provider of hands-on science and technology education in India. KitsGuru is an online retail store that sells electronics projects, Kits and components to make your hardware possible. Whether it"s a robot that can fight robot or an accident avoiding systems, mechanical project or software project we have everything in store.

A while ago I bought this 2.4"" Inch TFT LCD Touch Display Shield for Arduino UNO, but only recently I came up with a project where I could make use of this piece of hardware.

It turned out that indeed the RGB packing function from the Adafruit library did not play well with that display, but shifting and OR"ing the bits only slightly different would do the trick.

Then, instead of calling the method tft.clor565, a call to the newly created function fixed_color565 made sure that images got displayed correctly from now on..

PIO_Set(PIOC, (((d) & 0x01)<<(22-0)) | (((d) & 0x02)<<(21-1))| (((d) & 0x04)<<(29-2))| (((d) & 0x10)<<(26-4))| (((d) & 0x40)<<(24-6))| (((d) & 0x80)<<(23-7))); \

PIO_Clear(PIOC, (((~d) & 0x01)<<(22-0)) | (((~d) & 0x02)<<(21-1))| (((~d) & 0x04)<<(29-2))| (((~d) & 0x10)<<(26-4))| (((~d) & 0x40)<<(24-6))| (((~d) & 0x80)<<(23-7))); \

The above shield can be easily topped over an Arduino UNO. Hence, there is no need to bother about pin arrangements or circuit setup. Just be gentle when connecting the LCD Display to Arduino to avoid breaking the pins of the LCD.

Figure below shows the pinout of the LCD module when connected to an Arduino UNO. The numbered pin boxes located outside of the figure shows the respective Arduino Pins when the shield connected is stacked on top of Arduino Uno.

D/CX pin in table above is equivalent to RS pin from the LCD. D[17:0]refers to the Data Pin. DataPins from LCD Module refers to pin LCD_D0to LCD_D7which are 8 pins in total. These pins are connected to Arduino Digital Pin 2 – 9. For this tutorial, we are not utilizing the SD Card pins.

Understand that when we are communicating a certain instruction to LCD Display from the microcontroller or Arduino UNO in our case, there will generally be two components to it; which are command and data. Command part will instruct the LCD on what instruction we’re working on, at a given time. For instance, setting colours and address, sleep, max and min voltage, LCD awake and sleep, write to memory and many more. Subsequently, we will send Data command which contains relevant or supporting information for the Command part that we sent earlier. It is also important to note, that some LCD instructions works using Command part alone in which we shall discuss the examples later.

#defineBLACK0x0000#defineBLUE0x001F#defineRED0xF800#defineRED20x4000#defineGREEN0x07E0#defineCYAN0x07FF#defineMAGENTA0xF81F#defineYELLOW0xFFE0#defineWHITE0xFFFF#defineGREEN20x2FA4#defineCYAN20x07FF

#defineLCD_RDA0//Serves as read signal/MCU read data at the rising edge. Pg11 Datasheet#defineLCD_WRA1//Serves as write signal/command at the rising edge#defineLCD_RSA2//D/CX (0=Command/1=Data)#defineLCD_CSA3//Chip Select Pin : Active Low#defineLCD_RSTA4//Shield Reset

At this stage, we are defining our RD, WRX, D/CX, CS and Reset PIN from LCD to Arduino Analog Pins. This configuration is very crucial as assigning wrong PIN will result in almost guaranteed failure, hence be sure to double check. If you are using different type of shield or manually wiring the connections, then you can change analog PINS accordingly.

voidLCD_write(uint8_t d){// Serves as write signal/command at the rising edgedigitalWrite(LCD_WR,LOW);// WR 0// LCD Pins |7|6|5|4|3|2|1|0|// Uno Pins |7|6|5|4|3|2|9|8|//Arduino Port D : Pin 0 - 7, but Pin 0,1 not used in the LCD Shield//Arduino Port B : Pin 8 - 13,but Pin, 10,11,12,13 not used in the LCD Shield//Arduino Port C : Analog PinsPORTD=(PORTD&B00000011)|((d)&B11111100);PORTB=(PORTB&B11111100)|((d)&B00000011);digitalWrite(LCD_WR,HIGH);// WR 1}

In our void LCD Write, we are writing values to our Data Pins. Data written into this void or function are written to LCD Data Pins from microcontroller thru Port Command after converted to binary format. Port command can set multiple pins to HIGH or LOW seamlessly. LCD_WR pin are changed accordingly to create a rising edge signal as per the Write Cycle Sequence discussed earlier.

This void is used to write the Command Instructions into the LCD Display. As discussed earlier from the Write Cycle Sequence, LCD_RS or DC/X pin will be set to LOW state when sending command instructions. Example of Command Instructions will be 0x2C, 0x0F,0x20 and many more.

This void is used to write data information. Contrarily, when communication data information that comes after command instruction, we will set the LCD_RS or DC/X pin to High state.

voidLcd_Init(void){//Reset Signal is Active LOWdigitalWrite(LCD_RST,HIGH);delay(5);digitalWrite(LCD_RST,LOW);//Actual Reset Done Heredelay(15);digitalWrite(LCD_RST,HIGH);delay(15);

//The below is just preparation for Write Cycle SeqdigitalWrite(LCD_CS,HIGH);//Chip-Select Active Low SignaldigitalWrite(LCD_WR,HIGH);digitalWrite(LCD_RD,HIGH);digitalWrite(LCD_CS,LOW);//Chip-Select Active Low Signal

LCD_command_write(0xC5);//Test this Out | VCOM Control 1 : ColourContrast MaybeLCD_data_write(0x7F);//VCOM H 1111111LCD_data_write(0x00);//VCOM L 0000000

The above command is used in setting VCOM High and Low Voltage. The calibration set here kind of functions similar to contrast adjustment. Try varying these values as per the datasheet to get the best display on your LCD.

LCD_command_write(0x36);//Memory Access Control | DataSheet Page 127LCD_data_write(0x48);//Adjust this value to get right color andstarting pointofx and y//LCD_data_write(B00001000); //Example

The above command (0x36) defines read/write scanning direction of frame memory based on ILI9341 datasheet. Try varying the values to understand the function of this command. Based on my analysis, any changes in this command can alter your starting X and Y position and RGB or BGR color orientations. Hence, it is important to do some experimentation to understand how your LCD behaves to each changes in this command.

LCD_command_write(0x11);//Sleep Out | DataSheet Page 245delay(10);//Necessary to wait 5msec before sending next commandLCD_command_write(0x29);//Display on.LCD_command_write(0x2c);//Memory Write | DataSheet Page 245

The above command (0x11) command causes the LCD module to enter the minimum power consumption mode. Command (0x29) is used to recover from DISPLAY OFF mode while command (0x2c) transfers data from MCU to frame memory.

voidAddress_set(int16_t y1, int16_t y2, int16_t x1, int16_t x2){LCD_command_write(0x2a);//Column Address Set | DataSheet Page 110LCD_data_write(y1>>8);//8 Bit Shift Right of x1LCD_data_write(y1);//Value of x1LCD_data_write(y2>>8);//8 Bit Shift Right of x2LCD_data_write(y2);//Value of x2LCD_command_write(0x2b);//Page Address Set | DataSheet Page 110LCD_data_write(x1>>8);//8 Bit Shift Right of y1LCD_data_write(x1);//Value of y1LCD_data_write(x2>>8);//8 Bit Shift Right of y2LCD_data_write(x2);//Value of y2LCD_command_write(0x2c);// REG 2Ch = Memory Write}

Command (0x2A) writes the Column Address or Y-Coordinates of your LCD Display whereas command (0x2B) writes the Page Address or X-Coordinates of your LCD Display. When combined together, it helps the LCD Processor understand the area that we are working on, in a LCD Display. This instruction is necessary before drawing pixels or any combination of shapes. As the Column and Page address are 16 bit information, we are using 8bit shift (>>8). Once Column and Page address are set, we will then communicate these information from MCU to frame memory by using 0x2C command.

voiddrawPixel(int16_t x, int16_t y, uint16_t color){digitalWrite(LCD_CS,LOW);// Chip Select activeAddress_set(y,y+1,x,x+1);LCD_command_write(0x2C);LCD_data_write(color>>8);LCD_data_write(color);}

The above is a simple function that draws a pixel in LCD Display. A pixel will always be a constituent for all other designs such as a lines, rectangles, circles and even images. Hence, it is good to start from here to gain proper understanding on writing programs that will help to create shapes, images and design. The coordinates and color for the pixel are 16 bit information and therefore we are using data types int16_t. Color is a 16 bit information and therefore we are using bit 8-bit shift to right again. We will learn more about color in the next tutorial.

voidsetup(){// Setting Pin 2-7 as Output, DDR is PinMode Commnand, Pin0,1 UntouchedDDRD=DDRD|B11111100;// Setting Pin 8-9 as OutputDDRB=DDRB|B00000011;//Setting Analog Pins A4-A0 as OutputDDRC=DDRC|B00011111;Lcd_Init();Serial.begin(9600);}

Now, let’s look into void setup. DDR command is a pinMode command. It sets whether a certain pin should be input or output pin. Using DDR command allows us to easily change pinMode of multiple pins. From PortD, we are setting Pin 2-7 as Output Pins. Next, we are setting Pin 8-9 as Output from Port B. Once the necessary PINS are set as Output, we run our LCD_Init void so that the initialization can begin.

voidloop(){for(int i=50;i<90;i++){drawPixel(i,60,RED);drawPixel(i,70,RED);drawPixel(i,80,RED);drawPixel(i,90,RED);drawPixel(i,100,RED);drawPixel(i,110,RED);drawPixel(i,120,RED);drawPixel(i,130,RED);drawPixel(i,140,RED);drawPixel(i,150,RED);}}

With this, we have come to the end our code. I hope this tutorial has given you a fair amount of understanding in using LCD that uses ILI9341. By controlling the LCD without a library gives you more flexibility and the joy of learning. I hope you enjoyed reading this blog. Feel free to post your comment and questions.

Ms.Josey

Ms.Josey

Ms.Josey

Ms.Josey