3d printer tft lcd setup quotation

Next, we"ll need to configure the Raspberry Pi to launch a browser and load the OctoPrint/OctoPi interface on boot using the TouchUI boot to browser setup scripts.

4K MONO (6.6 inch) LCD masking screen. 4098x2560(4K)HD masking LCD allows for amazing print detail and much faster printing speed. It typically only needs 2.5 to 3 seconds for normal exposure time, compared to color screen which needs 8 to 10 seconds. Pixel size is 35 microns.

For customized, full-scale printing capabilities that accelerate time from ideation to application at an affordable price, the WorkSeries 400 (Workbench Xtreme) is the only large scale 3D printer that has been engineered from the ground-up. Most importantly, the unique, parametric design can be easily adjusted to match the needs of our customers.

Our 300 Series WorkbenchPro is a Fused Filament Fabrication (FFF) additive manufacturing system with a large 1 m x 1 m x 0.7 m build area. Therefore, its industrial strength mechatronics deliver superior performance and reliability. Further, with SIMO Series actuators and Constant Force™ anti-backlash lead screws and nuts, the WorkbenchPro provides a rugged, industrial framework that won’t let you down. Additionally, the 3DP WorkbenchPro large scale 3D printer delivers 40% more build volume and up to 16x faster print rates with its unique features.

Print larger parts at faster rates with the 200 Series Workbench Classic large scale 3D printer. Overall, this classic printer features auto-mesh bed leveling, SurePrint Step-Servo hybrid motors, and duel electronics with remote operating and monitoring capabilities.

The 100 Series WorkTable large scale 3D printer features the same build area size and mechanical features as the Workbench Classic. It is designed for smaller businesses, schools, and entry-level designers looking to implement large-format, industrial strength 3D printing into their projects.

The Sigma D25 from BCN3D is a new generation of our best-known 3D printer, engineered to grant maximum productivity through a hassle-free experience thanks to features like its massive print volume and full connectivity. Powered by our Independent Dual Extruder (IDEX) system, the Sigma D25 delivers quickly functional prototypes with quality and precision.

The Epsilon W27 from BCN3D is a powerful professional 3D printing solution, designed to deliver large-scale parts with industrial-grade materials. It features a passive heated chamber, full enclosure, and humidity-controlled environment. Powered by our Independent Dual Extruder (IDEX) system, the Epsilon Series delivers exceptionally strong functional parts with quality and precision.

For an all-in-one 3D printing solution, customers can opt for a Smart Cabinet Bundle. The Epsilon W27, together with the Smart Cabinet (SC) filament storage system, work seamlessly together to help boost your printer"s performance and keep your materials in optimal condition for a superior 3D printing experience.

Save $500 when you bundle an Epsilon W27 3D printer with a Smart Cabinet Filament Management System from BCN3D. The Smart Cabinet (SC) completes the Epsilon ecosystem, offering seamless integration with Epsilon W27 while maximizing its uptime. Its filament humidity control boosts your printers’ performance, keeping your materials in optimal condition. In addition, its uninterruptible power supply protects your work at all times, avoiding the risk of losing your print job due to power outages.

The BCN3D Smart Cabinet is equipped with sturdy caster wheels that allow the 3D printing workstation to be moved smoothly within any environment including manufacturing, universities, or even a garage. The Smart Cabinet is also stocked with a sliding drawer to keep all the necessary 3D printing tools in one convenient location. This is the complete solution for professional 3D printing production.

The W50 3D printer from BCN3D is the larger of the two Epsilon Series. It offers a powerful professional 3D printing solution, delivering large-scale parts with industrial-grade materials. It includes features such as a passive heated chamber, full enclosure, and humidity-controlled environment. The Epsilon Series is powered by an Independent Dual Extruder (IDEX) system, delivering exceptionally strong functional parts with quality and precision.

For an all-in-one 3D printing solution, customers can opt for a Smart Cabinet Bundle. The Epsilon W50, together with the Smart Cabinet (SC) filament storage system, work seamlessly together to help boost your printer"s performance and keep your materials in optimal condition for a superior 3D printing experience.

The Smart Cabinet (SC) completes the Epsilon ecosystem, offering seamless integration with your BCN3D Epsilon printers and maximizing their uptime. Its filament humidity control boosts your printers’ performance, keeping your materials in optimal condition, and its uninterruptible power supply protects your work at all times, avoiding the risk of losing your print job due to power outages.

Save $500 when you bundle an Epsilon W50 3D printer with a Smart Cabinet Filament Management System from BCN3D. The Smart Cabinet (SC) completes the Epsilon ecosystem, offering seamless integration with Epsilon W50 while maximizing its uptime. Its filament humidity control boosts your printers’ performance, keeping your materials in optimal condition. In addition, its uninterruptible power supply protects your work at all times, avoiding the risk of losing your print job due to power outages.

The BCN3D Smart Cabinet is equipped with sturdy caster wheels that allow the 3D printing workstation to be moved smoothly within any environment including manufacturing, universities, or even a garage. The Smart Cabinet is also stocked with a sliding drawer to keep all the necessary 3D printing tools in one convenient location. This is the complete solution for professional 3D printing production.

Now Available! – Starting at $250k USD, we have designed this extra large-scale 3D printer to provide affordability – without sacrificing quality or throughput. It uses a Fused Filament Fabrication (FFF) system and is currently the only machine in the large format category to provide the option of pellet or filament extruder(s) – or both!

Resin 3D printers are more affordable than ever – you can now pick up a great quality resin printer with a 4K LCD screen for just a few hundred dollars. So if you’re a home maker who wants to make detailed miniatures for your next game, or have more professional ambitions, it’s never been easier.

With 2K, 4K, and even up to 8K LCD screen quality available under $1,000, and sub-35-micron resolution becoming increasingly common, with the right settings you can create incredible-looking miniature models, as well as key uses in jewelry molds and in the dental industry.

We’ve split our recommendations into the best cheap resin 3D printers with recommendations for $200, $300, $500, and $700, as well as recommending a couple of clear winners for professional resin 3D printers if you’re looking to start a business or scale things up.

Whereas the Mars 2 Pro has a 6.08-inch 2K LCD, the Mars 3 and Mars 3 Pro both have 6.6-inch 4K screens, improving XY resolution from 50 microns to 35 microns – a 30% accuracy improvement.

The latest entry-level Photon 3D printer, the Anycubic Photon M3 takes everything we loved about the series – fast print times, excellent resolution, and a user-friendly printing experience – and levels it up with a few choice enhancements.

The Anycubic Mono X 6K allows makers to craft exceptionally detailed 6K prints at 34 microns XY resolution without sacrificing build volume (or vice versa), which inches close to standard FDM printer sizes at 197 x 122 x 245mm. A max print speed of 80 mm/h also prints the most complex minis and models at a blistering pace.

If you’re not constrained by a tight budget and want some of the best quality offered by any consumer-grade printer, there’s no question the Anycubic Mono X 6K is a sensible buy. The same goes for those piecing together the kit needed to take a budding minis business to the next level.

Featuring an 8.9-inch 4K monochrome LCD screen for fast layer curing, the Elegoo Saturn comes much upgraded on standard models, printing 60% faster than the Elegoo Mars Pro, printing a layer every 2-3 seconds.

For your money, you get a number of other key upgrades, most notably the larger build area, turning the Elegoo Saturn into a solid resin 3D printer for larger resin models or terrain for miniatures, as well as for printing more minis in one batch and taking advantage of resin printers’ abilities to print entire layers at once.

If this isn’t enough, you have two upgrade options:Elegoo Saturn S: a slight improvement across the board, with an 9.1” 4K LCD, and a slight build volume increase to 196 x 122 x 210 mm

Elegoo Saturn 2: upgrades to a 10” 8K LCD, 28.5nm XY resolution, and a larger 219 x 123 x 250 mm build area.Elegoo SaturnElegoo Saturn SElegoo Saturn 2LCD Quality8.9″ 4K LCD9.1″ 4K LCD10″ 8K LCD

Phrozen’s flagship resin printer capitalizes on a sleek 7.1″ LCD screen and 22-micron resolution to deliver frankly outstanding print detail and surface quality that more budget-priced printers simply can’t provide.

As consumer printers go, the Phrozen Sonic Mini 8K has the potential to produce the most intricate, detail-rich models of any printers currently on the market.

One thing we really want to drive home is how important it is not to get tunnel vision when looking at the specs of printers when choosing which to buy. As we explain in the buyer’s guide portion below, a well-made printer made from high-quality parts that can handle precise movements and stability will outperform a printer with a higher-spec LCD screen but worse build quality.

The 5.96” monochrome LCD is smaller than some lower-priced printers like the Elegoo Saturn 2, but it is capable of fantastic accuracy, even for tiny miniature models smaller than a penny. It’s made from high-quality parts to minimize vibrations, with a rigid aluminum body, and features a quick release mechanism to maintain z-axis calibration.

You can buy the printer on its own, or as a bundle with the CW1S 4-in-1 wash and cure machine. It pre-heats your resin before use, washes resin prints, dries them off, and cures them, all in one add-on. The bundle is available here.

Formlabs make professional resin 3D printers, but at desktop resin printer prices. The US manufacturer sells the Form 3 SLA 3D printer for $3,499, with its quality making it key for super accurate prototypes, as well as being adopted in the dental and jewelry industries.

The Form 3 comes with a huge variety of new features as compared with the previous Form 2. It comes with new LFS technology advantages as well as a new Light Processing Unit (LPU) to improve resin part surface finishes, as well as better layer registrations. The Form 2 was already fantastic, and these added features elevate the Form 3 to a whole new dimension within desktop SLA printers.

In addition, it has a scanning system for the resin tray after each layer, and automatically adjusts based on the type of resin used. Furthermore, its got a fantastic touch screen and can be operated remotely via a WiFi connection, as well as operable as part of a factory with Formlabs’ industrial multi-printer ‘Form Cell’ solutions.

This UV 3D resin 3D printer has a print volume of 145 x 145 x 185 mm, and is extremely precise with 25-micron XY resolution. The Formlabs Form 3 is compatible with a large number of resins, from ceramic, to flexible resins, to castable resins, though Formlabs also sell their own high-quality resin materials.Formlabs resins are availablehere.

With washing and curing an unavoidable part of resin 3D printing, we’ve rounded up a few choice washing and curing stations well worth weaving into your printing setup to take some of the sting and mess out of post-processing.

The Anycubic Wash & Cure is an all-in-one station compatible with the overwhelming majority of resin printers. Thanks to a nifty recent price cut from Anycubic, the Wash & Cure sets you back under $100.

Anycubic has simplified the whole wash and cure process thanks to a set-and-forget design – choose either wash or cure on the touch button interface, and off it goes. The station blocks 99.95% of UV light and comes with an auto-pause function if the cover inadvertently comes off. The station has an adjustable bracket that can latch onto an Anycubic build platform if you’re working with a Photon Mono series printer.

The accepted max print size is 125 x 85 x 160 mm for washing and 140 x 165 mm for curing. You can either use the provided cleaning basket or mount an Elegoo build plate with models still attached, making it compatible with most if not all resin 3D printers, not just with Elegoo machines.

A 385 nm and 405 nm UV light set and 360-degree rotating curing turntable do all the curing work with the option to key in and monitor curing time up to 30 minutes on the TFT touchscreen. Safety’s covered with an anti-UV lid that blocks 99.95% of UV rays and a suspend operation function should the cover come off during curing.

However, while a higher resolution makes a clear difference to print results, even the highest resolution 3D printer will not perform as well as a lower-res 2K screen if it is built from low-quality parts.

As a general rule, resin printers feature smaller build volumes than more common FDM machines, hence why makers and professionals use them to create small intricate parts with high precision.

If you do need extra printing space for duplicate part printing or larger figurines and models, consider larger format resin printers such as the Peopoly Phenom and Phrozen Sonic Mighty 4K.

Resin 3D printing is a messy business, and post-processing is a core part of the printing process. Post-processing breaks down into two parts, washing and curing.

Your resin printer’s LCD screen uses the same UV light as the sun but in a more stable indoor environment, flashing light at certain parts of the resin to selectively cure parts, based on your model’s features.

The screen sits under the resin vat, and projects light upwards into the build platform. An FEP screen (fluorinated ethylene propylene) protects the screen from damage – though these FEP films themselves need to be replaced more often than any other parts of the printer.

As each layer is cured, the resin printer’s z-axis platform, lifts up one layer, for the next resin layer to be cured. The cured model sticks to the build platform as it moves up out of the resin (if it sticks to the resin, the print fails), with the layer on the edge cured and moved up each time.

Good cheap resin 3D printers start at around $200, with either a 2K or 4K screen that can still print precise features on miniature models. 6K and 8K screen resin printers cost from $600 to $1000+, and professional resin 3D printers from companies like Formlabs cost $3500 and up.

Budget resin 3D printers are typically used by hobbyists to make accurate figures and miniatures at details FDM printers just cannot reach. They’re commonly used for 28mm miniatures, D&D figures, and other similar projects for tabletop models.

However, these low cost options can sometimes be used for creating wax molds for jewelry casting. For better quality casting with precious metals however it is recommended to use a more professional resin 3D printer capable of better resolutions and precision.

Resin printers are commonly used in the dental, audiology, jewelry, and medical industries. For example, within dentistry resin 3D printers can print orthodontic models and implants, and within audiology, almost 100% of custom hearing aids are now 3D printed.

For the home resin 3D printing $200-600 range, the best resin 3D printer brands are Anycubic, Elegoo and Phrozen, who make high-quality printers capable of accurate details. In the professional resin printer range, Prusa, Formlabs and Peopoly are well-reputed, as well as industrial brands like 3D Systems, Carbon 3D and EnvisionTEC.

Resin 3D printers can print incredible-looking details for miniatures that FDM simply can’t compete with, so for anything precise and detailed, resin printers can’t be beaten. However, if you want a simpler printing experience without washing or curing prints, or want to print large-scale models, go for an FDM 3D printer instead.

Curing is an equally important part of the process. When a printer completes a part, the resin is in a transitory state: hard enough to retain the desired shape and detail but lacking overall rigidity, making it prone to scratches, scarring, and blemishes. By curing the print with UV, or even sunlight if you’ve got time on your side, the resin reaches its optimal, finished state.

WASP 3MT HDP is the big 3D printerdesigned to print objects up to 1 meter in diameter and 1 meter in height,using thermoplastic, technical and recycled plastic granules.

The user experience has been further simplified with the adoption of a new 7-inch TFT touch display and an LED bar located at the top of the printer, which allows you to recognize the working status remotely.

WASP 3MT HDP can be connected to the network and then be managed directly via mobile phone, tablet or computer. A camera has been included inside the printer to monitor printing even from afar.

HDP XL pellet 3d printer extruder, reduces the cost of the material up to 1/10 compared to the corresponding filament. It allows you to use a greater variety of materials, and decreases printing times.

Prints directly from granules, reduces the cost of the material up to 1/10 compared to the corresponding filament. It allows you to use a greater variety of materials, and decreases printing times. A capacitive sensor placed on the extruder body detects the presence of material and independently requests it from the main 20-liter tank located on the side of the printer, interrupting the process in case the material runs out.

Simplify3D® provides complete control over your print settings, making it easier than ever to create high-quality 3D prints. Pre-configured settings optimized for WASP printers.

With AiSync software it is about multi-axis 3D printing which unlike traditional 3D printing software produces multi-axis toolpaths that are not constrained by slicing layers.

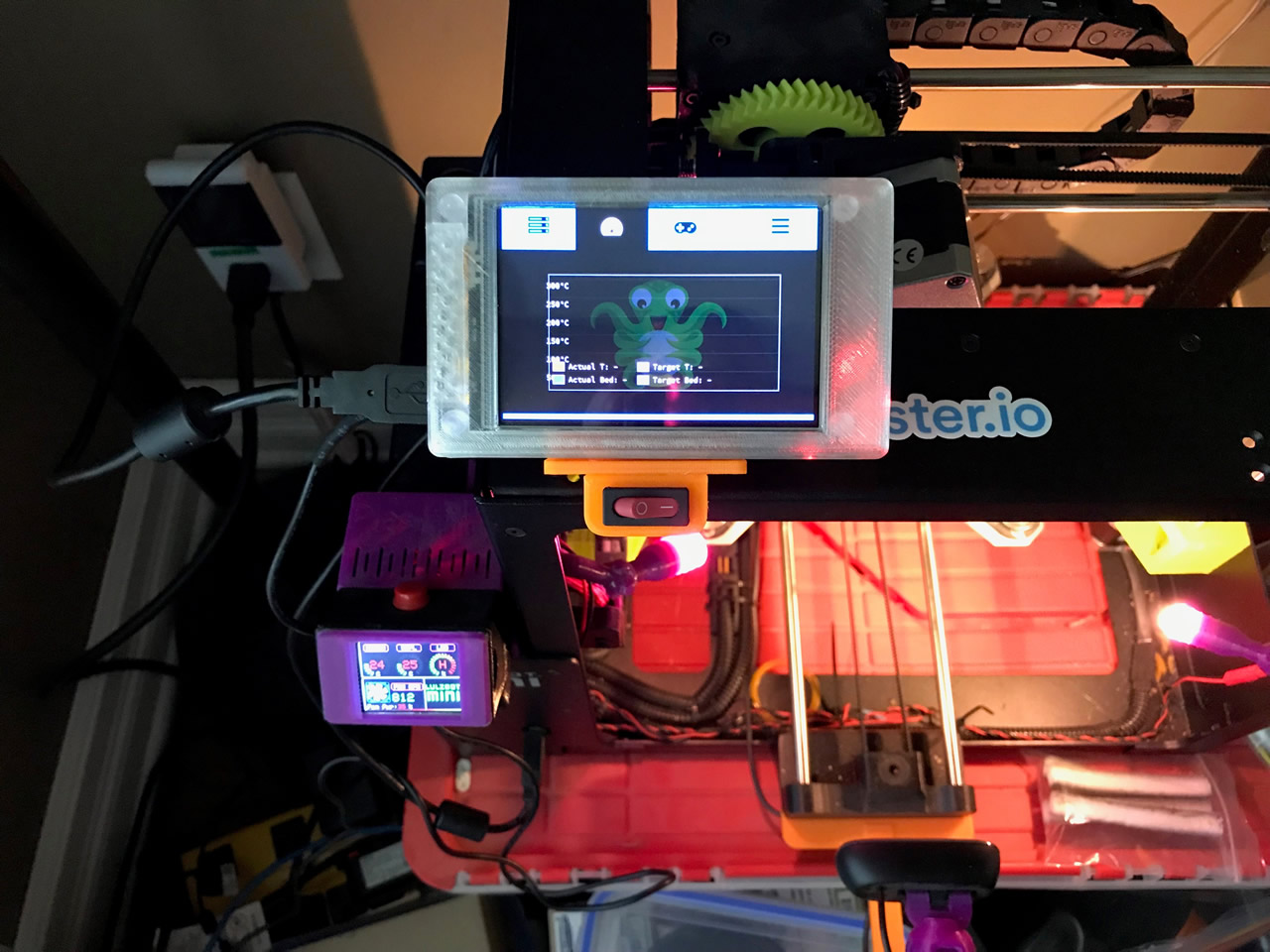

I recently ventured into adding a 3.5″ TFT to my LulzBot Mini. I already have OctoPrint running, but there are times (usually during filament failure events) I need to directly control the printer (heat the filament, move axis motors etc). After 3 painful days of messing around with different tutorials, I finally figured it out and it works dammit! I haven’t found a single source that has all steps in one place, so I decided to do a mashup of instructions based on my experience. There are others that deserve credit here – I simply brought together the steps for this specific TFT.

As most would have done, I started with the easy route trying to get it working. In this case, I attempted the Adafruit tutorial – no go. I also tried other methods using the LCD-show driver and others. After hours of tinkering, it was still a fail. I almost got there, except the X/Y axis were flipped and it had calibration issues. One of other problems was the amount of software updates these other approaches called for. I wanted a vanilla OctoPrint setup that started with a clean install and added the TFT from there with limited extra fluff. So, here’s hoping I’ve saved you days worth of work. if this works for you, consider supporting this blog by dropping me a few coins below. You can also check out the 3D printed parts. Find out more about the LED / fan controller (shown in pic above in purple)

The purpose here is to to demonstrate an end-to-end setup for an OctoPi rig with TouchUI on a TFT for a 3D printer (in this case a LulzBot Mini). It may work for other TFTs too.

Log into OctoPrint via your browser. http://octopi.localshould work.Else, use your router to find the IP address. Follow the wizard to configure the setup of your printer and settings.

3.5 TFT driver: Install the 3.5 TFT driver, follow steps here: https://www.elecrow.com/wiki/index.php?title=3.5_Inch_480x320_TFT_Display_with_Touch_Screen_for_Raspberry_Pi

You should see the below details already in there: If not reboot the device and try again. If it still fails, something went wrong in a prior step and the TFT did not get configured correctly.

14. Reboot the Pi. You should see the CLI scrolling text on the TFT by now? If it doesn’t work, edit the file above and change fb1 to fb0. See if that works. Else change it back to fb0.

The default setup has TouchUI oriented in such a way that the USB power cable is on the bottom and all USB/LAN ports on the right. In my case this is an issue as I want to mount the unit on the top left of my printer. In order to flip the screen, it’s a pretty straight forward mod with 2 key steps required.

Credit goes to the folks that put together the various instruction sets. My role was to bring them together to work for an OctoPi setup and this specific TFT with Touch UI.

Tiny Machines 3D is a Houston, TX based company aiming to provide great working 3D printers, upgrades and filament to new and old printing enthusiasts. All 3D printers, excluding DIY versions, are tested before shipping.

342 x 460 x 580 mm (13.5 x 18.1 x 22.8 in)This is the process of depositing layers of filament, one on top of the other, to build up shapes and models. It is a form of additive manufacturing technology and the process used by all Ultimaker 3D printers.Print technology

100 - 240 VAC, 50 - 60 HzThe peak power output that the printer can reach – usually when the heated bed and hot ends are heating up.Maximum power output

A micron is the measurement used to define the thickness of a 3D printed layer. 20 micron is 0.02 mm thick. Thinner layers are used for high-detail prints, thicker layers are great for fast prototypes.Layer resolution

0.8 mm nozzle: 600 - 20 micronThe more accurate the stepper motors within the printer, the greater degree of accuracy and finer resolution can be achieved with each print.XYZ resolution

2.4-inch (6 cm) TFT color touchscreenThanks to the swappable nozzle, you can easily switch between different nozzle diameters. This results in higher uptime and easier maintenance of your 3D printer.Print head

The build speed relates to how fast the filament can be extruded through the hot end of the 3D printer. The higher the value the greater the achievable print speed.Build speed

< 2 minutesThanks to their quiet operation, Ultimaker 3D printers are suitable for use in the office, studio, or classroom environment.Operating sound

< 50 dBAAssisted leveling is easy with the Ultimaker 2+ Connect. The setup wizard guides you through the process, using the included calibration card and build plate knobs to ensure the build plate is perfectly level.Build plate leveling

0 - 32 °C (32 - 90 °F)The printer will notify you when the filter needs replacing (every 1,500 print hours – about once per year). Ultimaker 2+ Connect Air Manager sold separately.Air Manager filter technology

Ultimaker Cura is our industry-leading slicing software that turns your 3D model into a file your printer can use. Use Ultimaker Digital Factory to manage printers and print jobs via your local network or the cloudSupplied free software

SolidWorks, Siemens NX, Autodesk InventorAn STL file is the most used file type for 3D printing. Nearly any 3D modeling software program is able to create these files.Supported file types

"Last year, we produced around 1,000 different 3D printed parts. The benefits of these are improved ergonomics, productivity, and operator satisfaction. In the end, we get very good feedback from the operators working on the line."

"If you compare our 3D printed tools to conventionally manufactured tools, we can easily save approximately €1,000 per tool, which is of course a lot when you consider all the tools which are needed to produce a vehicle."

Ms.Josey

Ms.Josey

Ms.Josey

Ms.Josey